What Makes Rail-Mounted Gantry Cranes So Efficient?

Rmg container crane for sale. Check main parts of rail-mounted gantry cranes & how to ensure smooth, reliable container handling. Ge affordable rmg crane !

Category: Featured

Your Trusted Rail Mounted Gantry Crane Manufacturer & Supplier

What Makes Rail-Mounted Gantry Cranes So Efficient?

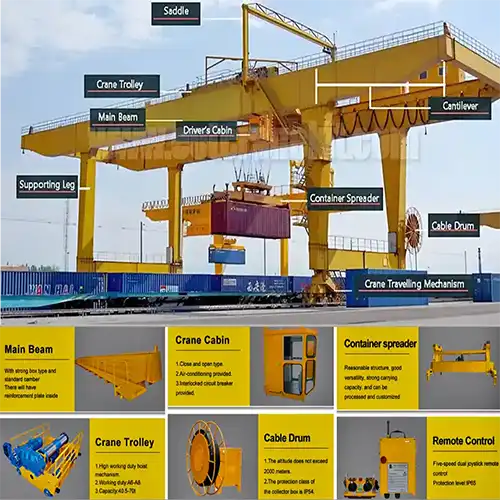

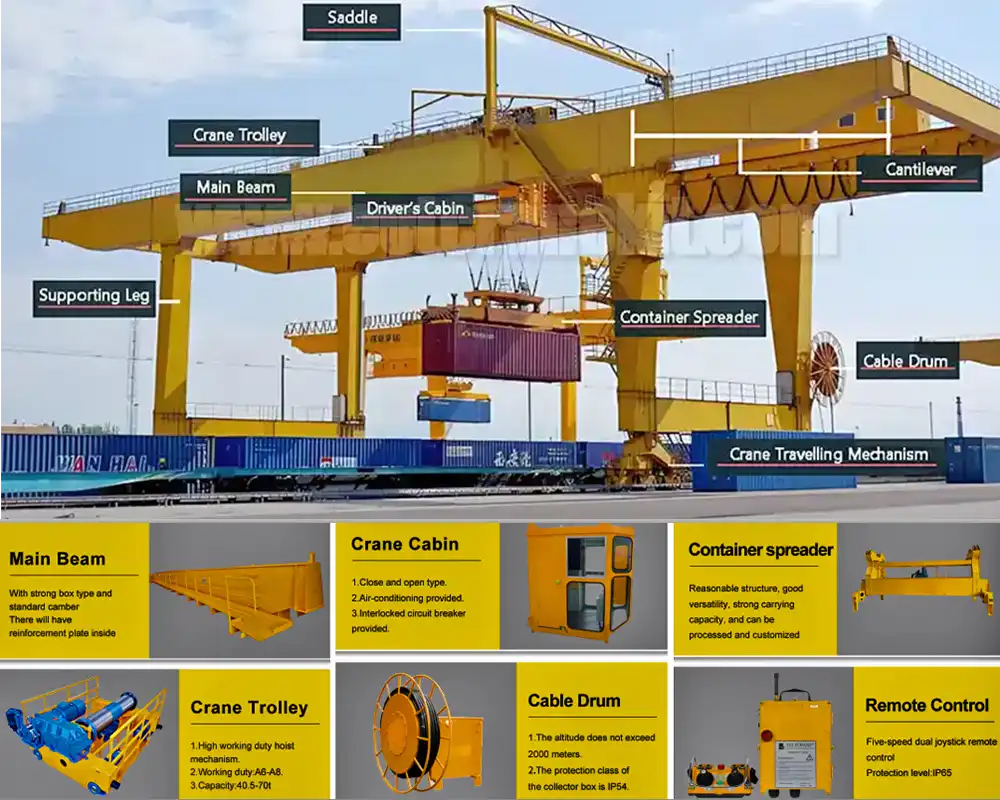

Key Components of a Rail-Mounted Container Gantry Crane

Rmg container crane for sale. Check main parts of rail-mounted gantry cranes & how to ensure smooth, reliable container handling. Ge affordable rmg crane !

Explore the essential structural elements that ensure stability, efficiency, and precision in rail-mounted container gantry crane operations.

The structure of a rail-mounted container gantry crane is an intricate assembly of several high-strength components designed to work together for maximum efficiency and durability.By understanding the structure of RMG cranes, you can better appreciate the technology behind these machines and make informed decisions about your purchase and deployment in container handling facilities.

Rail mounted container gantry crane main parts and components for your reference,

Customized rmg with smart features are available.

Contact us to get your design. WhatsApp: + 86 151 3871 1597

RMG Crane Metal Structure

The metal structure of the rail mounted container gantry crane generally adopts a box structure. It includes:

- Main Beam Structure – The main beam structure consists of two box girders supported on rigid and flexible legs. The connection between the main girder and the rigid leg adopts high-strength bolts or welding, and the connection between the main beam and the flexible leg adopts a hinged connection. For the convenience of installation, the connection between the main beam and the end beam is generally connected by high-strength bolts.

- Gantry Leg Structure – Both rigid and flexible legs adopt box-shaped structure. For rail-mounted container gantry cranes with small and medium spans, the skew force on the legs and main girder caused by the asynchronous operation of the two sides of the crane is borne by the rigid and single-degree-of-freedom hinged connection between the main girder and the rigid and flexible legs. For large-span RMG cranes, the connection between the flexible legs and the main girder adopts a three-degree-of-freedom hinged connection, and a synchronous detection device is provided.

- Trolley Structure – The structure of the running trolley is different depending on whether the hoisting mechanism is a wire rope drum type or a telescopic rigid frame type. Generally, a combined structure of box girder and plate truss is adopted. The driver’s cab, electric control cabinet, festoon cable, etc. are all connected to the trolley structure.

- Auxiliary Structure – Auxiliary structures include electrical room structures, railings, walkways, maintenance platforms, etc.

Lifting And Travelling Mechanisms of RMG

In addition to the special selection of the lifting mechanism of the rail-mounted container gantry crane, the running mechanisms of the trolley and the crane are basically the same as those of other types of overhead cranes and gantry cranes.

- Lifting Mechanism – There are two types of hoisting mechanisms: the wire rope drum type and the the rigid telescopic hoisting mechanism.

- Trolley Running Mechanism – The trolley running mechanism consists of DC or AC motor, gear coupling, block or disc brake, medium-hard tooth surface reducer, low-speed gear coupling, wheels and wheel supports. The arrangement of the driving mechanism is generally divided into two ways: along the direction of the trolley track and perpendicular to the direction of the trolley track.

- Crane Running Mechanism – The structure and form of the RMG crane running mechanism are similar to other types of gantry cranes. Due to the fast running speed of the RMG gantry crane, in order to prevent the wheels from slipping when braking, an electrical control system with good speed regulation performance is generally used, such as thyristor DC voltage regulation, AC frequency conversion speed regulation, AC stator speed regulation, etc.

Electrical and Control Systems

Rail mounted stacking cranes are equipped with sophisticated electrical and control systems that ensure safe and efficient operation. These systems control the movement of the trolley, hoist, and crane itself, as well as manage load handling. Key components of the electrical and control systems include:

- Control Cabin: From where the operator manages crane operations, ensuring precise control of the lifting and moving processes.

- Programmable Logic Controllers (PLC): Automated systems that govern crane functions, optimizing movement patterns and load handling.

- Safety Sensors: Installed throughout the crane to detect potential hazards, such as overloads, misalignments, or obstacles in the crane’s path.

Power Supply System

RMG cranes require a continuous supply of power to operate, which is typically provided through a conductor bar system or cable reel.

- Conductor Bar System: Supplies power via rails positioned along the crane’s track.

- Cable Reel: Supplies power via a retractable cable that moves with the crane.

Devices of the RMG Crane

- Buffer System and Bumpers – At the ends of the rail tracks, rail gantry cranes are fitted with buffer systems and bumpers to absorb any excess energy or shock if the crane reaches the end of its track. These components ensure the safety of the crane and its surroundings by preventing collisions or structural damage.

- Slewing Device – For the wire rope drum type hoisting mechanism, the plane slewing mechanism can be composed of wire rope, pulley block, wire rope connection joint and hinge point, rocker arm and support, push rod, etc. For the rigid telescopic lifting mechanism, the spreader can not only rotate in the plane through power, but also float vertically and horizontally (without power) to adapt to the inclination of the upper plane of the container.

- Anti-swaying Device – If it is necessary to install anti-swaying devices for rail mounted stacking cranes, two forms are generally used: when the lifting mechanism is a wire rope drum type, the anti-sway device is pulled by two diagonal thin steel cables, one end is connected to the corner of the spreader, and the other end is wound to the damping drum. When the trolley or crane starts or brakes, the inertia force of the spreader and the container is transmitted to the damping steel wire rope, its swing energy will be absorbed by damping drum; rigid anti-sway device. It is mainly realized by the rigid lifting frame and guiding device.

Safety System

- Weight Overload Protection Device: Ensures safe operation by preventing the crane from lifting loads beyond its capacity.

- Lifting Limit Switch: Automatically halts the lifting mechanism to avoid over-hoisting.

- Crane Travelling Limit Switch: Stops the crane’s movement at predefined limits to prevent collisions.

- Trolley Travelling Limit Switch: Controls trolley travel range for added safety.

- Voltage Lower Protection Function: Protects the crane’s electrical system from damage caused by low voltage.

- Emergency Stop System: Allows immediate cessation of operations during emergencies.

- Wind Speed Indicator: Monitors wind conditions to ensure safe outdoor operation.

Design Standards

- Steel Structure: Constructed with Q235B/Q345B carbon structural steel using seamless one-time forming technology for enhanced strength and durability.

- Lifting Mechanism: Features high-quality components such as a reducer, drum, brake, and motors with Class F protection for reliability and efficiency.

- Hook: Equipped with ZPMC brand spreader, known for its precision and robust performance.

- Wheels: Made with vacuum casting technology, ensuring compact structure and superior durability.

- Electrical Components: Includes trusted brands like Chint, Schneider, or Siemens for dependable performance.

This ensures a combination of safety, durability, and performance tailored to your operational needs.

FAQ on Rail Mouned Gantry Cranes

What is a Rail Mounted Gantry (RMG) Crane?

A Rail Mounted Gantry (RMG) crane is a specialized crane that moves on tracks fixed to the ground. It features a large, sturdy structure designed to span across multiple container rows, allowing it to lift and transfer containers between trains, trucks, and storage areas. These cranes are commonly found in intermodal terminals, container ports, and large industrial facilities where efficient container handling is essential.

RMG cranes excel in environments that require handling large volumes of containers with speed and accuracy. Their rail-guided design allows them to carry heavy loads over long distances, and many are equipped with advanced automation systems to enhance operational efficiency.

How is an RMG Crane Different from an RTG Crane?

The main difference lies in their mobility:

- RMG Cranes: Operate on fixed rails, making them ideal for precise, heavy-duty operations in static locations like container terminals or intermodal yards.

- RTG Cranes: Equipped with rubber tires, allowing them to move freely within a container yard, providing more flexibility for dynamic operations.

While RMG cranes are best suited for high-capacity, fixed-path operations, RTG cranes are preferred for mobile and adaptable container handling tasks. Both play critical roles in modern logistics.

How Long Does it Take to Deliver and Install an RMG Crane?

The delivery time for an RMG crane depends on its design and customization needs. Typically, it takes several months from the time of order to delivery. Aicrane ensures smooth installation by offering both on-site and online setup guidance to help customers get their cranes operational quickly and efficiently.

What Are the Power Supply Options for an RMG Crane?

RMG cranes are usually powered electrically, using systems like:

- Cable Reels

- Conductor Bars

- Festoon Systems

These options ensure reliable and energy-efficient operation, supporting the crane's heavy-duty tasks.

How Does Anti-Sway Technology Work in an RMG Crane?

Anti-sway technology reduces the swinging motion of the load during lifting and transportation. Using advanced sensors and control algorithms, the system stabilizes the crane's movements, ensuring precise load placement and enhancing safety. This technology is vital for improving operational accuracy and minimizing risks in container handling.

Customizing Your RMG Gantry Crane for Optimal Lifting Performance

Choosing the right Rail Mounted Gantry (RMG) crane for your operations is essential to ensure efficiency, safety, and cost-effectiveness. To tailor the crane to your needs, consider the following key factors:

1. Load Capacity: How Much Do You Need to Lift?

Determine the maximum weight the crane will need to handle. This is typically measured in tons and ensures the crane is robust enough for your heaviest loads.

2. Crane Span: What Width Do You Require?

The span refers to the distance the crane needs to cover, measured in meters. This depends on the layout of your facility and the rows of containers or materials to be handled.

3. Lifting Height: How High Should the Crane Reach?

Identify the maximum height the crane must lift materials. This is particularly important for stacking containers or reaching elevated platforms.

4. Material Handling: What Will the Crane Lift?

Specify the type of materials or containers to be handled, such as:

- Standard shipping containers

- Bulk materials

- Specialized equipment

Providing this information helps customize lifting mechanisms and attachments.

5. Operational Hours: How Long Will the Crane Work Daily?

Understand the crane's working hours to ensure it is built to handle the required workload. High-usage cranes may need enhanced durability and efficient cooling systems.

6. Project Introduction: What Are Your Unique Needs?

Share details about your project, including:

- Working Site: Indoor or outdoor, terrain conditions, climate, and more.

- Budget: A clear budget range helps customize the crane to meet your financial and operational requirements.

By addressing these aspects, your RMG crane can be customized to deliver maximum performance, reliability, and longevity in your specific application. Reach out to us today to get started on designing the perfect crane for your project!

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch