Trailer Manufacturing Plant Overhead Cranes 5 Ton, 5+5 Ton,10 Ton

Overhead cranes for sale trailer manufacturing plant, customized for different trailer production & workshops. 5 ton, 5 +5 ton, 10 ton, 20 ton bridge crane.

| Overhead Crane | 1 ton -80 ton |

| Crane span | As your request |

| Lifting height | As customer requirement |

| Note | Custom design and configuration are available. |

Category: Factory Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Trailer Manufacturing Plant Overhead Cranes 5 Ton, 5+5 Ton,10 Ton

Overhead cranes for sale trailer manufacturing plant, customized for different trailer production & workshops. 5 ton, 5 +5 ton, 10 ton, 20 ton bridge crane.

Elevating Trailer Manufacturing Efficiency with Overhead Cranes

In the realm of trailer manufacturing, where precision, efficiency, and safety reign supreme, overhead cranes take center stage as the silent architects orchestrating the symphony of production. These mechanical marvels play an irreplaceable role in harmonizing operations, bearing the weight of heavy responsibilities, and raising productivity to unprecedented levels. In this comprehensive guide, we embark on a journey to explore the world of overhead cranes—diving into their diverse types, unique features, versatile applications, and the compelling reasons behind their status as the trusted workhorses of the trailer manufacturing industry.

The Role of Overhead Cranes in Trailer Manufacturing

Picture a bustling trailer manufacturing plant, where raw materials undergo a metamorphosis into robust cargo carriers. In this dynamic setting, the precise placement, lifting, and transportation of materials, components, and trailers themselves are essential processes carried out with utmost efficiency and care. Enter the stage, overhead cranes.

Overhead cranes, often referred to as bridge cranes or Electric Overhead Traveling (EOT) cranes, are ingeniously engineered to perform heavy lifting and material handling tasks with astonishing precision. Whether suspended gracefully from the ceiling or gracefully gliding on runways, these cranes possess the remarkable ability to traverse both horizontally and vertically, covering vast expanses within the manufacturing facility.

In the realm of trailer manufacturing, overhead cranes take on the role of skilled artisans from bygone eras, delicately assembling each piece of the puzzle with meticulous care. They are the robust support behind the finesse, the sturdy foundation facilitating the creation of trailers known for their resilience, reliability, and capacity to withstand the rigors of the open road.

Why Opt for Overhead Cranes?

The question may arise amidst a myriad of material handling options: why choose overhead cranes? The answer lies in the distinctive blend of capabilities and benefits they bring to the table:

- Precision Lifting and Impeccable Positioning: Overhead cranes are the epitome of precision, capable of lifting hefty components and trailers with unparalleled accuracy. This precision is indispensable in trailer manufacturing, where even the slightest deviation can have a significant impact on the final product's quality.

- Space Optimization at Its Finest: Operating above the workshop floor, overhead cranes leave the ground uncluttered. This ingenious design not only optimizes available space but also allows for seamless material and trailer movement, reducing the risk of collisions and workspace congestion.

- A Boost in Efficiency: Overhead cranes are adept at streamlining production processes. They facilitate the swift and efficient flow of materials, reducing trailer assembly times. This efficiency translates into heightened production output and shortened lead times.

- Fortified Safety Measures: Safety takes precedence in any manufacturing environment. Overhead cranes come equipped with an arsenal of safety features, encompassing limit switches, overload protection, and emergency stop mechanisms. These built-in safeguards minimize the likelihood of accidents and injuries.

- Tailored Solutions for Unique Needs: Trailer manufacturing is a diverse landscape with varying demands. Overhead cranes can be meticulously customized to accommodate precise requirements, whether it entails hoisting robust steel frames, positioning delicate components, or navigating through tight and challenging spaces.

- Long-Term Cost Savings: Through the optimization of operations, the reduction of labor requirements, and the minimization of material handling errors, overhead cranes contribute significantly to cost savings over the long haul.

As we venture deeper into the realm of overhead cranes, we'll embark on a voyage of discovery, unveiling the various crane types, exploring their remarkable features, and delving into their multifaceted applications. Join us as we uncover the secrets of these mechanical wonders, which fuel efficiency, champion safety, and propel success within the vibrant world of trailer manufacturing.

Main types of overhead cranes used in trailer manufacturing facility

In a trailer manufacturing facility, several types of overhead cranes are used to handle various tasks and materials efficiently. The choice of overhead crane type depends on the specific needs and requirements of the facility. Here are the main types of overhead cranes commonly used in trailer manufacturing facilities:

Bridge Crane (Single Girder and Double Girder):

Overview of Bridge Crane: Bridge cranes are versatile and common in manufacturing facilities. They consist of a horizontal beam (the bridge) that moves along rails mounted on the ceiling. Single girder bridge cranes have one bridge beam, while double girder bridge cranes have two.

- Functions in Trailer Manufacturing: Bridge cranes are used for lifting, transporting, and positioning heavy materials, trailer components, and completed trailers within the manufacturing facility.

- Applications: They are applied in various stages of trailer production, including welding, assembly, painting, quality control, and loading for shipment.

- Loads Handled: Bridge cranes can handle a wide range of loads, from smaller components to entire trailers.

- Workshop Installed: Bridge cranes are commonly found in welding shops, assembly areas, paint booths, and inspection zones within the trailer manufacturing facility.

Overview of Gantry Crane: Gantry cranes are similar to bridge cranes but are supported on legs that run on the floor, making them suitable for both indoor and outdoor use.

- Functions in Trailer Manufacturing: Gantry cranes are used for lifting, moving, and positioning trailers, heavy materials, and components throughout the facility, including outdoor areas and loading docks.

- Applications: They are employed for tasks like loading trailers onto transport vehicles, moving trailers between workstations, and handling materials in outdoor storage areas.

- Loads Handled: Gantry cranes have high load capacity and can handle entire trailers or heavy trailer components.

- Workshop Installed: Gantry cranes can be found in outdoor yards, loading areas, and other spaces where overhead support is limited.

Overview of Jib Crane: Jib cranes have a vertical post or mast with a horizontal boom. They are typically used for localized lifting and positioning tasks within a specific area.

- Functions in Trailer Manufacturing: Jib cranes are employed for precise lifting and positioning of materials, trailer components, and tools within confined spaces or near workstations.

- Applications: They are useful for tasks like moving materials to and from assembly workstations, aiding in component assembly, and assisting in maintenance and repair work.

- Loads Handled: Jib cranes handle lighter loads compared to some other crane types, making them suitable for smaller trailer components.

- Workshop Installed: Jib cranes are commonly installed in assembly areas, maintenance workshops, and locations requiring localized lifting.

- Overview of Monorail Crane: Monorail cranes consist of a single rail system with a hoist and trolley that moves along the rail. They are designed for linear material handling tasks.

- Functions in Trailer Manufacturing: Monorail cranes are used for transporting materials, components, and tools along a defined path, making them suitable for production lines or specific material flow requirements.

- Applications: They are applied in tasks such as moving materials down an assembly line, transporting components through paint booths, or facilitating material flow between workstations.

- Loads Handled: Monorail cranes handle moderate loads and are suitable for transporting smaller trailer components.

- Workshop Installed: Monorail cranes are often installed above production lines or in areas with linear material handling needs.

Overview of Wall-Mounted Crane: Wall-mounted cranes are attached to a wall or vertical support structure, offering a compact lifting solution.

- Functions in Trailer Manufacturing: Wall-mounted cranes are used for localized lifting and material handling tasks within limited spaces.

- Applications: They are employed for moving materials, components, and tools along a specific wall or workstation, optimizing space usage.

- Loads Handled: Wall-mounted cranes handle lighter loads and are suitable for smaller-scale lifting requirements in the facility.

- Workshop Installed: They are commonly installed in areas with limited floor space or specific workstation applications.

Overview of Underhung Crane: Underhung cranes are suspended from the ceiling, similar to bridge cranes, but they have a compact design that makes them ideal for tight spaces.

- Functions in Trailer Manufacturing: Underhung cranes are used for moving materials, components, and tools within confined areas in the facility.

- Applications: They are employed for tasks such as transporting materials between workstations, aiding in component assembly, and optimizing space utilization.

- Loads Handled: Underhung cranes handle lighter to moderate loads, suitable for various trailer manufacturing tasks.

- Workshop Installed: Underhung cranes are installed in areas with limited ceiling height or where a compact crane design is advantageous.

Overview of Wire Rope Hoist Crane: Wire rope hoist cranes use a drum and wire rope to lift and lower loads.

- Functions in Trailer Manufacturing: Wire rope hoist cranes are employed for precise and controlled lifting of heavy trailer components during manufacturing.

- Applications: They are used for positioning large and heavy components, such as trailer chassis or frames, in welding or assembly processes.

- Loads Handled: Wire rope hoist cranes are suitable for handling heavy loads encountered in trailer manufacturing.

- Workshop Installed: They are often found in welding and assembly workshops where precise positioning of heavy components is critical.

Overview of Chain Hoist Crane: Chain hoist cranes use a chain and hoist mechanism for lifting loads.

- Functions in Trailer Manufacturing: Chain hoist cranes are employed for lifting and positioning tasks requiring controlled and precise movements.

- Applications: They are used in various trailer manufacturing processes, including component assembly, maintenance, and repair work.

- Loads Handled: Chain hoist cranes are suitable for handling moderate to heavy loads, depending on their capacity.

- Workshop Installed: Chain hoist cranes can be installed in assembly areas, maintenance workshops, and locations requiring controlled lifting.

These different types of overhead cranes in a trailer manufacturing facility serve specific purposes and are strategically placed to optimize production processes, reduce manual labor, enhance safety, and maintain the quality of the final products.

Key Features and Benefits of Overhead Cranes in Trailer Manufacturing Workshops

In the world of trailer making, where being precise and efficient is a must, overhead cranes are like the trusty superheroes. They quietly work behind the scenes, moving heavy stuff around. These machines come with a bunch of cool features and bring many benefits to the workshop. Let's break down what makes them special and why they're such a big deal.

What's So Cool About Overhead Cranes?

- Strong and Sturdy Frames:Built to Last: Overhead cranes have super strong main frames, kind of like their backbone. This frame can handle heavy loads and keeps the crane steady while it works.

- Wheels on the Edges: They have these special wheel-houses called end carriages. These are like the crane's feet, and they help it move smoothly from side to side. - Lifting Stuff with Precision:Hoist and Trolley Team: These cranes have a hoist, which is like their lifting hand, and it sits on a trolley. The trolley moves along the main frame and helps the crane put stuff exactly where it needs to be.

- Easy to Control:Control Options Galore: You can operate overhead cranes in different ways. There are controls you can hold, ones that work wirelessly, and even ones you can use from a cabin. It's like choosing how you want to drive your crane.

- Safety First:Keeping Things Safe: Safety is super important when working with cranes. Overhead cranes come with safety features like switches to stop them from moving too far, protection from carrying too much weight, and emergency stop buttons. These features keep people and things safe.

- Meeting Standards:Doing Things Right: Overhead crane makers follow strict rules and standards to make sure their cranes are safe and work well. This means you can trust that the crane will do its job properly.

What's in It for You?

- Super Precise Lifting:No Misses Here: Overhead cranes can pick up heavy stuff and put it down exactly where it needs to go. This precision is crucial when you're making trailers because even tiny mistakes can cause big problems.

- More Space to Move:Less Clutter: Overhead cranes work above the ground, so they don't take up space on the floor. This means the workshop stays tidy, and things can move around smoothly without bumping into each other.

- Speedy Work:Quick and Efficient: These cranes are experts at making things move fast. They help materials get where they're needed in no time. This means you can make more trailers in less time to meet customer demands.

- Safety Always:No Accidents Here: Safety is a big deal, and overhead cranes are designed with that in mind. They have special features to prevent accidents and injuries, making sure everyone stays safe.

- Made Just for You:Customized Solutions: Trailer making is unique, and your workshop has its own needs. Overhead cranes can be adjusted to fit those needs perfectly, whether you're lifting heavy metal frames or delicate parts.

- Save Money in the Long Run:Efficiency = Savings: Over time, using overhead cranes can save a lot of money. They make work smoother, reduce the need for extra workers, and cut down on mistakes. All of this adds up to big savings.

In the competitive world of trailer making, where every detail counts, overhead cranes are like the trusty sidekicks that make sure everything runs smoothly. They're not just machines; they're the reason your trailers are known for their quality and reliability.

Applications of Overhead Crane in trailer manufacturing factory workshops

In a trailer manufacturing facility, overhead cranes play a crucial role in various manufacturing procedures, workshops, and warehouses. Here's how overhead cranes are typically used in different areas of the facility:

Welding Shop:

- - Overhead cranes in the welding shop are used to lift and position heavy steel or aluminum materials for fabrication.

- - They help transport large sections of trailer frames and components to welding stations.

- - Cranes assist in flipping or rotating large trailer assemblies for welding from different angles.

Assembly Shop:

- - Overhead cranes are employed to move trailer components into position for assembly.

- - They assist in aligning and attaching axles, wheels, suspensions, and other critical components to the trailer frame.

- - Cranes are used for lifting and placing walls, roofs, or other sections of the trailer's structure.

Painting Shop:

- - Overhead cranes in the painting shop help transport trailers to different painting and finishing stations.

- - They can lower trailers into paint booths or drying areas for the application of coatings.

Quality Control and Inspection Areas:

- - Overhead cranes are used to move completed trailers or sections of trailers to inspection areas.

- - Inspectors can access various parts of the trailer for quality checks and final inspections.

Storage and Warehousing:

- - Warehouses in the facility often use overhead cranes for efficient material handling and storage.

- - Cranes can move raw materials, components, and finished trailers within the warehouse.

- - They facilitate the stacking and retrieval of trailers in storage, optimizing space usage.

Loading/Shipping Area:

- - Overhead cranes assist in moving trailers to the loading docks for transportation to dealers or customers.

- - They can also be used for loading finished trailers onto transport vehicles.

Maintenance Workshop: - Maintenance workshops within the facility may have overhead cranes for servicing and repairing the factory's own equipment, including cranes themselves.

Key features and considerations for overhead cranes used in trailer manufacturing procedures and facilities may include:

- - Load Capacity: Overhead cranes are selected based on the weight and size of the materials or trailers they need to lift and move.

- - Span and Reach: The crane's span and reach should be suitable for the size and layout of the work area.

- - Controls: Modern overhead cranes often come equipped with remote control systems for precise positioning.

- - Safety Features: Safety is paramount, and cranes should include features like emergency stop buttons, limit switches, and load monitoring systems to ensure safe operation.

- - Regular Maintenance: Overhead cranes require regular inspection and maintenance to ensure they function correctly and safely.

The efficient use of overhead cranes in different areas of a trailer manufacturing facility helps streamline production, reduce manual labor, and enhance safety and quality control.

Practical Uses of Overhead Cranes in Trailer Manufacturing

In trailer production, overhead cranes do much more than just lift stuff. These versatile machines are at the core of various jobs that help the industry run smoothly and efficiently. Let's dive into how overhead cranes are practically used in trailer manufacturing facilities.

Welding and Fabrication

- Handling Heavy Steel Parts: Trailer making involves working with hefty steel components. Overhead cranes are like the strong arms that lift and place these heavy parts precisely for welding.

- Getting It Just Right for Welding: Welding needs things to be super precise. Overhead cranes make sure the pieces fit perfectly, making the welds strong and trailers sturdy.

Assembly

- Putting Parts Together Efficiently: Building a trailer is like a big puzzle with lots of pieces. Overhead cranes speed up the process by lifting and placing these parts quickly and accurately.

- Keeping the Production Line Smooth: Overhead cranes help materials flow smoothly along the production line. They make sure parts get where they need to be, reducing delays and keeping things moving.

Painting and Finishing

- Getting Trailers Ready for the Road: Before trailers hit the road, they need a good paint job. Overhead cranes are used to move trailers to the painting area, making sure they're ready for their protective coat.

- Making Sure It Looks Great: Painting needs to be done just right. Overhead cranes help position trailers so they get a good, even coat, making sure they not only look good but also last a long time.

Quality Control and Inspection

- Checking Finished Trailers: Quality control is a big deal in trailer manufacturing. Overhead cranes help move completed trailers to inspection areas, where they're checked to make sure they're safe and work properly.

- Meeting Safety Standards: Trailers have to meet certain safety rules. Overhead cranes help inspectors get to all parts of the trailer to make sure they're safe and reliable.

Loading and Shipping

- Getting Trailers Ready for the Road: Before trailers go on long trips, they need to be loaded onto trucks or trailers safely and quickly. Overhead cranes are the go-to helpers for lifting and placing trailers onto transport vehicles.

- Making Shipping Faster: In an industry where timing matters a lot, overhead cranes speed up loading and shipping. They make sure trailers are loaded up fast so they can hit the road on time, meeting customer demands.

In the world of trailer manufacturing, where getting things just right is super important, overhead cranes are like the ultimate sidekicks. They don't just lift things; they make sure everything runs smoothly and helps create trailers known for their quality and dependability.

Enhancing Trailer Manufacturing Industry with Custom Overhead Cranes: A Capacity-Boosting Success Story

In the rapidly advancing landscape of the trailer manufacturing industry, the demand for precision and efficiency has never been greater. To meet this challenge, a leading crane manufacturer delivered a game-changing solution to a prominent trailer plant. This case study unveils how expertise, innovation, and tailored crane solutions have elevated the production capabilities of the trailer manufacturer.

Background and Challenges

As the trailer industry expanded, the need to enhance production capacity became evident. To address this, the trailer manufacturing plant embarked on an ambitious project to establish four new warehouses. However, the key to unlocking their full potential lay in selecting the right overhead crane solutions.

Approach

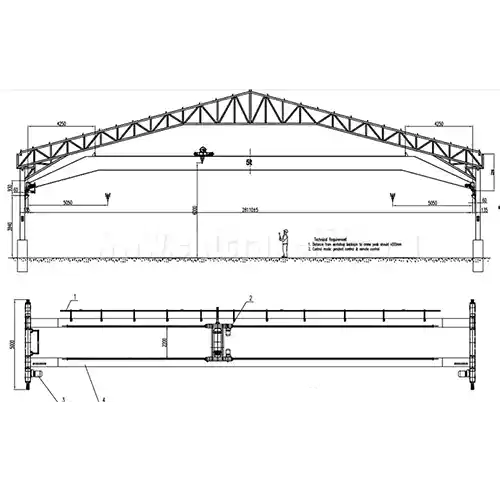

To satisfy the client's unique requirements, a series of European single girder overhead cranes were custom-designed, each meticulously crafted to align with the plant's workshops and specific application needs.

Main Parameters of Complete Overhead Cranes System

The solution comprised:

- European single girder overhead crane—5 sets

- Lifting capacity: 5 tons

- Span: 13 meters

- Lifting height: 7 meters

- Power supply: 415V 50HZ 3P

- European single girder overhead crane—10 sets

- Lifting capacity: 5+5 tons

- Span: 13 meters

- Lifting height: 7 meters

- Power supply: 415V 50HZ 3P

- European single girder overhead crane—5 sets

- Lifting capacity: 10 tons

- Span: 13 meters

- Lifting height: 7 meters

- Power supply: 415V 50HZ 3P

Production and Quality Assurance

Transparency was maintained throughout the production process by regularly sharing photos, assuring the quality of the European single girder overhead cranes at every stage.

Ingeniously overcoming logistical challenges, the crane span was divided into two parts for safe delivery. Upon arrival, the client successfully assembled the cranes with support from installation manuals and electrical drawings.

Impressed by the crane's quality and exceptional service, the client completed the installations with ease. The manufacturer stands by its promise of a warranty, ready to provide free replacements for any quality-related parts.

This case study underscores the commitment to delivering tailor-made solutions that empower clients to enhance their production capabilities, even in the most challenging environments. With precision, innovation, and dedication, the crane manufacturer is elevating industries worldwide, one crane at a time.

Main girder of 5 ton and 10 ton bridge crane for trailer manufacturing factory plant

Trailer processing factory use overhead crane 5 ton, 10 ton , main girder

Trailer factory electric overhead travelling crane main finished production

Electric wire rope hoist for trailer factory and plant

5 ton overhead crane hoist for trailer manufacturing facility

End carriages and end girder of trailor processing

Overhead Crane Users' Top Concerns in Trailer Manufacturing Facilities

In the trailer manufacturing industry, electric overhead cranes, also known as bridge cranes or EOT (Electric Overhead Traveling) cranes, play a crucial role. However, users of these powerful machines often encounter common concerns that demand attention to ensure seamless operations, safety, and overall efficiency within their facilities. Let's explore the primary concerns of electric overhead crane users within the trailer manufacturing industry.

Safety

- Ensuring Safe Crane Operations: Safety takes the highest priority for users of electric overhead cranes. Operators and personnel working near these cranes must adhere to strict safety protocols, which include maintaining safe distances, utilizing proper protective gear, and following standardized operating procedures.

- Preventing Accidents and Injuries: The immense lifting capabilities of electric overhead cranes bring inherent risks. Users must focus on accident prevention by conducting regular safety audits, implementing safety features, and providing ongoing safety training for operators and staff.

Maintenance and Reliability

- Keeping Cranes in Prime Condition: Electric overhead cranes are complex machines that require routine maintenance to function optimally. Concerns often revolve around scheduling and executing maintenance tasks, such as inspecting components, lubricating parts, and addressing wear and tear.

- Reducing Downtime and Costs: Unplanned downtime can disrupt production schedules and increase operational costs. Users are concerned about minimizing downtime through proactive maintenance practices, thereby mitigating the financial impact of unexpected breakdowns.

Operator Training

- Proper Training for Crane Operators: Operators are the linchpin of safe and efficient crane operations. Users are often concerned with providing comprehensive training programs to ensure that operators have the necessary skills and knowledge to operate electric overhead cranes competently.

- Ensuring Competence and Efficiency: Operator competence directly affects crane performance and safety. Users must regularly assess operators' skills and provide ongoing training to enhance efficiency, reduce errors, and improve overall crane operations.

Compliance with Standards

- Meeting Regulatory and Industry Standards: Electric overhead cranes must adhere to strict regulatory and industry standards to ensure safety and performance. Users are concerned about staying up to date with evolving standards and ensuring that their cranes meet all necessary requirements.

- Adhering to Safety and Performance Guidelines: Compliance with standards extends beyond installation to encompass ongoing operations. Users are responsible for maintaining cranes in a manner that aligns with safety and performance guidelines, requiring constant vigilance.

Customization

- Tailoring Cranes to Specific Needs: Trailer manufacturing facilities have diverse requirements, often necessitating crane customization to handle unique materials, components, or spatial constraints. Users seek solutions that align with their specific operational needs.

- Optimizing Crane Performance: Customization isn't merely about meeting basic needs; it's about optimizing crane performance. Users are concerned with extracting the maximum potential from their electric overhead cranes, whether through adjustments in load capacity, integration of specialized attachments, or implementation of advanced control systems.

Addressing these top concerns is pivotal in harnessing the full potential of electric overhead cranes within trailer manufacturing facilities. By emphasizing safety, investing in maintenance, focusing on operator competence, ensuring compliance, and embracing customization, users can navigate these challenges and reap the benefits of heightened productivity, efficiency, and overall success.

Frequently Asked Questions (FAQs) about Electric Overhead Cranes in Trailer Workshops

Navigating the world of electric overhead cranes, including bridge cranes and EOT cranes, in trailer manufacturing can raise several questions. To assist you in making informed decisions and ensuring the safe and efficient operation of these critical tools, we've compiled some frequently asked questions (FAQs) and provided concise answers.

What Safety Measures Should I Implement When Using Electric Overhead Cranes?

Tips for Safe Crane Operations:Regularly inspect the crane for any signs of wear, damage, or malfunction.

- Ensure that operators are trained, certified, and follow strict safety protocols.

- Maintain clear communication between operators and ground personnel during crane operations.

- Establish safety zones and barriers to keep unauthorized personnel at a safe distance.

- Implement overload protection systems to prevent exceeding the crane's capacity.

- Conduct routine safety audits and address any identified hazards promptly.

How Do I Choose the Right Electric Overhead Crane for My Trailer Manufacturing Plant?

Factors to Consider When Selecting an Electric Overhead Crane:Determine your specific lifting needs, including load capacity and reach.

- Consider the layout of your facility, including ceiling height and available floor space.

- Think about the type of materials and components you handle, including their dimensions and weight.

- Evaluate your budget and the total cost of ownership, encompassing maintenance and operational expenses.

- Consult with crane manufacturers or suppliers to explore various electric overhead crane types and customization options.

What Maintenance Practices Are Crucial for Electric Overhead Cranes?

Best Practices for Crane Maintenance:Establish a routine maintenance schedule that includes inspections, lubrication, and component replacements.

- Maintain comprehensive maintenance records to track crane performance and identify patterns.

- Address any signs of wear or damage immediately to prevent breakdowns and ensure safety.

- Regularly check critical components, such as wire ropes, hooks, and safety devices.

- Collaborate with crane manufacturers or service providers for specialized maintenance tasks.

How Can I Ensure Operator Competency and Safety?

Training and Certification for Crane Operators:Enroll operators in accredited crane operator training programs.

- Ensure that operators receive thorough training in crane operations, safety procedures, and emergency protocols.

- Require operators to pass written and practical exams to obtain certification.

- Encourage ongoing training and re-certification to keep operators updated on best practices and safety standards.

- Foster a culture of safety awareness and accountability among all crane operators.

Can Electric Overhead Cranes Be Customized to Suit Unique Needs?

The Benefits of Customizing Electric Overhead Cranes:Yes, electric overhead cranes, including bridge cranes and EOT cranes, can be customized to align with your unique requirements, such as handling specialized materials or fitting into tight spaces.

- Customization options encompass adjustments in load capacities, incorporation of specialized attachments, and integration of advanced control systems.

- Tailoring electric overhead cranes to specific requirements optimizes performance and ensures they meet the demands of your trailer manufacturing plant.

These FAQs offer valuable insights into the world of electric overhead cranes, including bridge cranes and EOT cranes, in trailer workshops. Remember that safety, proper selection, maintenance, operator competency, and customization are key factors to consider for successful crane operations in your facility.

Conclusion: Elevate Your Trailer Manufacturing with Electric Overhead Cranes

In the fast-paced world of trailer manufacturing, where precision, efficiency, and safety are paramount, electric overhead cranes, including bridge cranes and EOT cranes, emerge as the unsung heroes that elevate your operations to new heights. As you navigate the intricate landscape of trailer production, here's a summary of key takeaways to help you unleash the full potential of these powerful cranes:

Partnering with a Trusted Crane Manufacturer

Choosing the right electric overhead crane, whether a bridge crane or EOT crane, begins with a trusted partnership. Seek reputable crane manufacturers who not only deliver cutting-edge technology but also offer comprehensive support, from initial selection to customization and ongoing maintenance. A strong partnership ensures that your crane is tailored to your unique needs, setting the stage for success.

Maximizing Efficiency and Safety

Electric overhead cranes are the backbone of efficiency in your trailer manufacturing facility. Their precision lifting, space optimization, and streamlined material flow expedite production, allowing you to meet customer demands and stay ahead in a competitive market. Safety must always remain a top priority, with strict adherence to safety protocols, regular maintenance, and operator training to prevent accidents and injuries.

Future-Proofing Your Trailer Manufacturing Facility

As the trailer manufacturing industry evolves, future-proofing your facility is essential. Electric overhead cranes, including bridge cranes and EOT cranes, can be customized to adapt to changing demands, ensuring that your operations remain efficient and versatile. Stay up to date with industry standards and regulations, and be prepared to embrace technological advancements that enhance crane performance and safety.

Elevate your trailer manufacturing with electric overhead cranes, including bridge cranes and EOT cranes, that not only lift heavy burdens but also lift your standards of quality, reliability, and excellence. These powerful machines are the keys to precision, efficiency, and safety in an industry where every detail matters. Partner with trusted manufacturers, maximize efficiency, prioritize safety, and future-proof your facility to thrive in the dynamic world of trailer manufacturing.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch