How Low Headroom Hoist Cranes Save Space & Costs

Low headroom hoist cranes maximize space, reduce crane price, and optimize span, weight, and ceiling height for efficiency.

Category: Featured

Your Trusted Low Headroom Hoist Crane Manufacturer & Supplier

How Low Headroom Hoist Cranes Save Your Space & Lower Crane Price

1 to 20 Ton Single Girder Low Headroom Electric Hoist Crane Span, Weight, and Shop Ceiling

How Low Headroom Hoist Cranes Save Space & Costs

Low headroom hoist cranes are designed for spaces with limited ceiling height. These cranes provide a compact structure that allows them to operate efficiently in areas with lower headroom. This makes them ideal for factories, warehouses, and workshops where every inch of space matters.

Optimizing space and lowering crane costs are essential for many industries today. As facility sizes shrink and real estate costs rise, businesses need to make the most of their available space. Low headroom hoist cranes are a practical solution, helping to maximize vertical space without compromising performance or increasing costs.

Key factors that influence crane selection include:

- Span: The distance between the crane's supports, which impacts the area it can cover.

- Weight: The crane's weight affects its structure and load-handling capacity.

- Shop Ceiling: The height of the facility's ceiling directly influences which cranes are suitable.

Choosing the right crane involves balancing these factors to ensure optimal use of space, efficiency, and cost.

Single Girder Low Headroom Hoist Cranes

What is a Low Headroom Hoist Crane ? A low headroom hoist crane is designed to operate in areas with limited ceiling height. It features a compact structure with a hoist that is positioned closer to the crane's beam. This setup reduces the overall height, making it ideal for spaces where every inch of headroom counts.Key Features:

- Compact Design: The hoist is designed to be closer to the crane beam, minimizing height requirements.

- Efficient Operation: Despite the reduced height, the crane can lift heavy loads, offering similar performance to standard cranes.

- Space-Saving: Perfect for workshops, warehouses, and factories with limited vertical space.

Difference Between Standard Headroom and Low Headroom Cranes:

- Standard Headroom Cranes: These cranes have more space between the hoist and the crane beam, requiring higher ceiling clearance.

- Low Headroom Cranes: These cranes have a shorter distance between the hoist and beam, enabling them to work in areas with lower ceiling heights.

Benefits of Low Headroom Hoist Cranes

Maximizing Vertical Space Utilization: Low headroom hoist cranes are perfect for environments with limited ceiling height. They make the most of available vertical space, allowing for increased storage and workspace without needing to expand the facility. This makes them highly valuable in industries like manufacturing, warehousing, and distribution.

Lower Crane Price: The compact design of low headroom hoist cranes often leads to reduced structural components. With fewer materials used in the crane's construction, these cranes are typically more affordable than standard headroom cranes. The savings on material costs can help businesses invest in other areas of their operation.

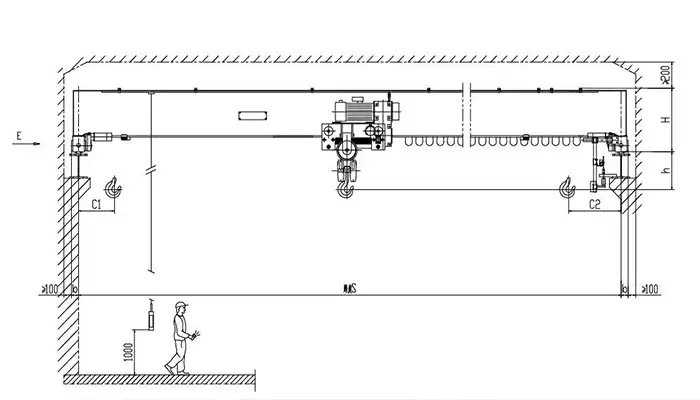

crane drawing of single girder low headroom hoist crane with European style design

Space Optimization with Low Headroom Cranes

Maximizing Ceiling Space in Your Shop

Low headroom cranes are specifically designed to save valuable ceiling space. By reducing the vertical clearance needed, these cranes allow you to make the most of the space above your operations. This is especially important in factories and warehouses where ceiling height is limited.

How Low Headroom Cranes Save Vertical Space:

- The hoist and other crane components are positioned closer to the crane's main beam, minimizing the space required for operation.

- By reducing the need for excessive headroom, businesses can operate efficiently without the costly option of raising the building's ceiling.

Ideal Applications: Low headroom cranes are perfect for industries where ceiling height is a constraint:

- Manufacturing Plants: Where equipment and machinery need to be accessed without sacrificing space for other processes.

- Warehouses: Especially those with multi-level racking or where maximizing storage space is crucial.

- Tight Workspaces: In facilities where the building's structure cannot be altered to provide more headroom.

Efficient Use of Floor Space

The compact design of low headroom cranes does more than just optimize vertical space—it also affects the overall layout of your shop floor. With reduced height requirements, businesses can plan their floor space more effectively, allowing for smoother workflows and increased storage.

How Reduced Height Affects Shop Floor Layout:

- Better Floor Utilization: With more available height, you can stack goods higher, place equipment closer to the crane tracks, and make better use of the floor area.

- Improved Flow: A low headroom crane requires less space for the crane's operation, which can lead to more open pathways for workers and other equipment.

Space-Saving Design Considerations:

- Crane Track Positioning: Positioning crane tracks efficiently ensures maximum floor space. Tracks should be placed strategically to avoid blocking critical work areas.

- Avoiding Obstructions: The lower crane height means fewer obstructions in the facility, allowing workers to maneuver equipment more easily.

In essence, low headroom cranes not only save vertical space but also improve the overall design and layout of the shop floor, ensuring better space utilization and smoother operations.

Specifications of European Style Low Headroom Hoist Crane Span, Weight & Overall Crane Height

1 Ton Low Headroom Crane

Lifting Capacity (t) |

Span (m) |

Weight |

Maximum Wheel Pressure (KN) |

Overall Crane Height(mm) |

||

Hoist (kg) |

Crane (kg) |

H |

h |

|||

1 |

7.5 |

380 |

1180 |

8.7 |

618 |

354 |

10.5 |

1900 |

9.5 |

||||

13.5 |

2250 |

10.4 |

698 |

|||

16.5 |

2674 |

11.5 |

768 |

|||

19.5 |

3269 |

13 |

798 |

|||

22.5 |

3900 |

14.5 |

858 |

|||

Low headroom hoist Crane 1 Ton

- Lifting Capacity (t): 1 ton

- Span (m): The span length ranges from 7.5 meters to 22.5 meters.

- Crane Weight (kg): The crane weight increases as the span length increases, ranging from 1180 kg (for 7.5m span) to 3900 kg (for 22.5m span).

- Crane Height (H) (mm): The height of the crane increases as the span length increases, from 618 mm to 858 mm.

- Hoist Weight (kg): The hoist weight remains the same at 380 kg, regardless of the span.

- Maximum Wheel Pressure (KN): Not provided, but this would typically depend on the load and span combination.

- Crane Rail Top to Hook Center (h): 354 mm, which is consistent across all span lengths.

Key Observations:

- Span and Crane Weight: As the span increases, both the crane weight and height increase, which is typical for overhead cranes. A larger span requires more material and a more robust structure to handle the load.

- Load Headroom: The required headroom for the crane is the sum of the crane height (H) and the hook center (h), where "h" is 354 mm in this case. A smaller headroom is generally desirable for low headroom applications.

- Hoist Consistency: The hoist weight and height remain constant across all span lengths, which allows for flexibility in using the same hoist across different crane configurations, as long as the lifting capacity is consistent (1 ton).

2 Ton Low Headroom Hoist Cranes

Lifting Capacity (t) |

Span (m) |

Weight |

Maximum Wheel Pressure (KN) |

Overall Crane Height(mm) |

||

Hoist (kg) |

Crane (kg) |

H |

h |

|||

2 |

7.5 |

380 |

1680 |

13.5 |

708 |

356 |

10.5 |

2060 |

14.4 |

||||

13.5 |

2430 |

15.5 |

778 |

|||

16.5 |

3164 |

17.4 |

818 |

|||

19.5 |

3753 |

18.9 |

888 |

|||

22.5 |

4320 |

20.3 |

968 |

|||

Low headroom hoist Crane 2 Ton

- Lifting Capacity (t): 2 tons

- Span (m): The span length ranges from 7.5 meters to 22.5 meters.

- Crane Weight (kg): The crane weight increases as the span length increases, from 1680 kg (for 7.5m span) to 4320 kg (for 22.5m span).

- Crane Height (H) (mm): The height of the crane increases as the span length increases, from 708 mm to 968 mm.

- Hoist Weight (kg): The hoist weight remains the same at 380 kg, regardless of the span.

- Maximum Wheel Pressure (KN): Not specified in the table.

- Crane Rail Top to Hook Center (h): 356 mm, which is consistent across all span lengths.

Explanation:

- Span and Crane Weight: As with the 1-ton crane, the crane's weight increases with the span length. This is typical for overhead cranes, where a larger span requires a heavier and more robust crane structure.

- Load Headroom: The total required headroom is the combined height "H" of the crane and the hook center distance "h" (356 mm), which is an important consideration in crane installation.

- Hoist Weight and Height: The hoist weight and height do not change with the span. It remains at 380 kg, and the height is consistent across spans.

Summary:

- Span and crane weight: As the span increases, both the crane weight and height increase.

- Headroom: The required headroom for the crane is the sum of the crane height (H) and hook center (h), which is 356 mm in this case.

- Hoist consistency: The hoist weight and height do not change, allowing the same hoist to be used across cranes of different spans, as long as the lifting capacity remains the same.

3.2 Ton Low Headroom Hoist Cranes

Lifting Capacity (t) |

Span (m) |

Weight |

Maximum Wheel Pressure (KN) |

Overall Crane Height(mm) |

||

Hoist (kg) |

Crane (kg) |

H |

h |

|||

3.2 |

7.5 |

380 |

1840 |

18.9 |

758 |

356 |

10.5 |

2070 |

20.1 |

||||

13.5 |

2667 |

21.8 |

808 |

|||

16.5 |

3324 |

23.5 |

908 |

|||

19.5 |

4100 |

25.4 |

948 |

|||

22.5 |

4725 |

27 |

1028 |

|||

3.2-Ton Low Headroom Hoist Cranes Specifications:

- Lifting Capacity (t): 3.2 tons

- Span (m): The span length ranges from 7.5 meters to 22.5 meters.

- Crane Weight (kg): The crane weight increases as the span length increases, from 2200 kg (for 7.5m span) to 6230 kg (for 22.5m span).

- Crane Height (H) (mm): The height of the crane increases as the span length increases, from 788 mm to 1258 mm.

- Hoist Weight (kg): The hoist weight remains the same at 450 kg, regardless of the span.

- Maximum Wheel Pressure (KN): Varies from 28.2 to 39.7, depending on the span.

- Crane Rail Top to Hook Center (h): The hook center height varies from 410 mm to 978 mm across different spans.

Key Observations:

- Span and Crane Weight: As with the smaller cranes, the crane weight increases with the span. A longer span requires more material and a stronger structure to maintain stability and load capacity.

- Crane Height (H) and Hook Center (h): Both the crane height (H) and the hook center (h) increase as the span increases, with "h" ranging from 410 mm to 588 mm. This increases the headroom requirement for installation.

- Maximum Wheel Pressure (KN): The maximum wheel pressure increases as the span increases, ranging from 28.2 KN (for 7.5m) to 39.7 KN (for 22.5m).

- Hoist Consistency: The hoist weight remains constant at 450 kg, allowing the same hoist to be used across cranes with different span lengths, as long as the lifting capacity is maintained at 3.2 tons.

Load Headroom:

The total headroom requirement for each crane is the sum of the crane height (H) and the hook center (h), which increases with the span length.

5 Ton Low Headroom Hoist Cranes

Lifting Capacity (t) |

Span (m) |

Weight |

Maximum Wheel Pressure (KN) |

Overall Crane Height(mm) |

||

Hoist (kg) |

Crane (kg) |

H |

h |

|||

5 |

7.5 |

450 |

2200 |

28.2 |

788 |

410 |

10.5 |

2521 |

29.7 |

||||

13.5 |

3200 |

31.8 |

908 |

|||

16.5 |

3928 |

33.8 |

978 |

|||

19.5 |

4598 |

35.6 |

1138 |

|||

22.5 |

6230 |

39.7 |

1258 |

|||

5-Ton Low Headroom Hoist Cranes Specifications:

- Lifting Capacity (t): 5 tons

- Span (m): The span length ranges from 7.5 meters to 22.5 meters.

- Crane Weight (kg): The crane weight increases as the span length increases, from 2200 kg (for 7.5m span) to 6230 kg (for 22.5m span).

- Crane Height (H) (mm): The height of the crane increases as the span length increases, from 788 mm to 1258 mm.

- Hoist Weight (kg): The hoist weight remains the same at 450 kg, regardless of the span.

- Maximum Wheel Pressure (KN): Varies from 28.2 to 39.7, depending on the span.

- Crane Rail Top to Hook Center (h): The hook center height varies from 410 mm to 978 mm across different spans.

Key Observations:

- Span and Crane Weight: The crane weight increases with the span, similar to other models. The larger the span, the more material is needed to support the crane and the load.

- Crane Height (H) and Hook Center (h): Both the crane height (H) and the hook center (h) increase as the span length increases. This results in greater headroom requirements for the installation, from 788 mm at 7.5 meters to 1258 mm at 22.5 meters.

- Maximum Wheel Pressure (KN): The maximum wheel pressure increases as the span increases, ranging from 28.2 KN (for 7.5m) to 39.7 KN (for 22.5m).

- Hoist Consistency: The hoist weight remains the same (450 kg) across all span lengths, so the same hoist can be used for cranes with different spans, as long as the lifting capacity is the same (5 tons).

Load Headroom:

The total headroom required for the crane is the sum of the crane height (H) and the hook center (h). As the span length increases, both H and h increase, meaning more headroom is needed for the crane.

10 Ton Low Headroom Hoist Cranes

Lifting Capacity (t) |

Span (m) |

Weight |

Maximum Wheel Pressure (KN) |

Overall Crane Height(mm) |

||

Hoist (kg) |

Crane (kg) |

H |

h |

|||

10 |

7.5 |

600 |

2660 |

51.8 |

908 |

465 |

10.5 |

3160 |

54.4 |

||||

13.5 |

4040 |

57.7 |

1008 |

|||

16.5 |

5257 |

60.8 |

1208 |

|||

19.5 |

6410 |

64 |

1308 |

|||

22.5 |

7640 |

67.2 |

1358 |

|||

Here is the detailed breakdown for the 10-Ton Low Headroom Hoist Cranes based on the table you provided:

10-Ton Low Headroom Hoist Cranes Specifications:

- Lifting Capacity (t): 10 tons

- Span (m): The span length ranges from 7.5 meters to 22.5 meters.

- Crane Weight (kg): The crane weight increases as the span length increases, from 2660 kg (for 7.5m span) to 7640 kg (for 22.5m span).

- Crane Height (H) (mm): The height of the crane increases as the span length increases, from 908 mm to 1358 mm.

- Hoist Weight (kg): The hoist weight remains the same at 600 kg, regardless of the span.

- Maximum Wheel Pressure (KN): Varies from 51.8 to 67.2, depending on the span.

- Crane Rail Top to Hook Center (h): The hook center height varies from 465 mm to 635 mm across different spans.

Key Observations:

- Span and Crane Weight: The crane weight increases significantly with the span. A larger span requires a stronger and more substantial structure, resulting in a heavier crane.

- Crane Height (H) and Hook Center (h): Both the crane height (H) and the hook center (h) increase as the span length increases. The hook center height ranges from 465 mm to 635 mm, which directly impacts the headroom requirements for installation.

- Maximum Wheel Pressure (KN): The maximum wheel pressure increases with the span, ranging from 51.8 KN (for 7.5m) to 67.2 KN (for 22.5m). This is a crucial consideration for ensuring the crane's structural integrity and operational safety.

- Hoist Consistency: The hoist weight remains constant at 600 kg across all span lengths, so the same hoist can be used with cranes of varying spans as long as the lifting capacity remains at 10 tons.

Load Headroom:

The total headroom required for the crane is the sum of the crane height (H) and the hook center (h), which increases as the span length increases.

16 Ton Low Headroom Hoist Cranes

Lifting Capacity (t) |

Span (m) |

Weight |

Maximum Wheel Pressure (KN) |

Overall Crane Height(mm) |

||

Hoist (kg) |

Crane (kg) |

H |

h |

|||

16 |

7.5 |

1500 |

4484 |

51.8 |

1000 |

820 |

10.5 |

5184 |

54.4 |

||||

13.5 |

6634 |

57.7 |

1220 |

|||

16.5 |

7789 |

60.8 |

1330 |

|||

19.5 |

9179 |

64 |

1480 |

|||

22.5 |

10514 |

67.2 |

1630 |

|||

16-Ton Low Headroom Hoist Cranes Specifications:

- Lifting Capacity (t): 16 tons

- Span (m): The span length ranges from 7.5 meters to 22.5 meters.

- Crane Weight (kg): The crane weight increases as the span length increases, from 4484 kg (for 7.5m span) to 10514 kg (for 22.5m span).

- Crane Height (H) (mm): The height of the crane increases as the span length increases, from 1000 mm to 1630 mm.

- Hoist Weight (kg): The hoist weight remains consistent at 1500 kg across all span lengths.

- Maximum Wheel Pressure (KN): Ranges from 51.8 to 67.2 KN, depending on the span.

- Crane Rail Top to Hook Center (h): The hook center height varies from 820 mm to 1630 mm across different spans.

Key Observations:

- Span and Crane Weight: As with other cranes, the weight of the crane increases significantly as the span length increases. A 7.5-meter span has a crane weight of 4484 kg, while a 22.5-meter span has a crane weight of 10514 kg.

- Crane Height (H) and Hook Center (h): The crane height and hook center both increase with span length. The crane height ranges from 1000 mm to 1630 mm, and the hook center height ranges from 820 mm to 1300 mm.

- Maximum Wheel Pressure (KN): The maximum wheel pressure increases with span length, ranging from 51.8 KN at 7.5m to 67.2 KN at 22.5m.

- Hoist Consistency: The hoist weight remains at 1500 kg for all span lengths, ensuring the same hoist can be used across different span configurations.

Load Headroom:

To calculate the total headroom required for the crane, you simply add the crane height (H) and the hook center height (h). As the span increases, both values grow, which impacts the overall headroom needed for installation.

20 Ton Low Headroom Hoist Cranes

Lifting Capacity (t) |

Span (m) |

Weight |

Maximum Wheel Pressure (KN) |

Overall Crane Height(mm) |

||

Hoist (kg) |

Crane (kg) |

H |

h |

|||

20 |

7.5 |

1500 |

4484 |

51.8 |

1000 |

820 |

10.5 |

5434 |

54.4 |

||||

13.5 |

6754 |

57.7 |

1250 |

|||

16.5 |

7904 |

60.8 |

1400 |

|||

19.5 |

9399 |

64 |

1580 |

|||

22.5 |

10719 |

67.2 |

1710 |

|||

20-Ton Low Headroom Hoist Cranes Specifications:

- Lifting Capacity (t): 20 tons

- Span (m): The span length ranges from 7.5 meters to 22.5 meters.

- Crane Weight (kg): The crane weight increases as the span length increases, from 4484 kg (for 7.5m span) to 10719 kg (for 22.5m span).

- Crane Height (H) (mm): The height of the crane increases as the span length increases, from 1000 mm to 1710 mm.

- Hoist Weight (kg): The hoist weight remains consistent at 1500 kg across all span lengths.

- Maximum Wheel Pressure (KN): Ranges from 51.8 to 67.2 KN, depending on the span.

- Crane Rail Top to Hook Center (h): The hook center height varies from 820 mm to 1710 mm across different spans.

Key Observations:

- Span and Crane Weight: The crane weight increases with the span, from 4484 kg at a 7.5m span to 10719 kg at a 22.5m span.

- Crane Height (H) and Hook Center (h): The crane height (H) increases from 1000 mm to 1710 mm, and the hook center height (h) increases from 820 mm to 1710 mm as the span length increases.

- Maximum Wheel Pressure (KN): The maximum wheel pressure increases as the span length increases, ranging from 51.8 KN at 7.5m to 67.2 KN at 22.5m.

- Hoist Consistency: The hoist weight remains the same at 1500 kg across all span lengths.

Load Headroom:

As the span increases, the total headroom (H + h) required for crane installation also increases. This means larger spans demand more vertical space in the facility. Click to learn more on European style single girder top running overhead crane specifications.

Price Reduction Factors: How Low Headroom Cranes Lower Costs

Impact of Reduced Headroom on Crane Price

One of the key reasons low headroom cranes are more affordable is their compact design. The reduced headroom directly impacts the overall crane height, which has several cost-saving benefits.

Cost Reduction Through Design:

- Material Savings: With a lower overall crane height, less material is needed in the structural components. This results in a lighter crane, which reduces the material costs for manufacturing.

- Simplified Design: The crane's design is more streamlined with fewer complex components. This simplifies the engineering process, reducing the cost of production.

- Smaller Load-Bearing Capacity: Since the reduced headroom typically accommodates smaller cranes, the load-bearing components required are less robust, lowering the cost of high-strength materials.

By cutting down on structural complexity, a low headroom crane can offer the same functionality at a more competitive price.

Reducing Overhead Costs and Operational Expenses

Beyond the initial purchase price, low headroom cranes help reduce long-term overhead and operational costs.

Lower Installation Costs:

- Simplified Setup: These cranes usually require fewer adjustments during installation, which reduces the cost of setup labor and associated installation expenses.

- Compact Design for Easier Installation: With a smaller overall footprint and lower ceiling height, the crane can be installed in a variety of building types without requiring modifications, lowering costs for retrofitting.

Reduced Operational and Maintenance Expenses:

- Fewer Components to Maintain: The simpler design means fewer moving parts, reducing the likelihood of breakdowns and lowering the cost of maintenance over time.

- Less Wear and Tear: With a more efficient design, low headroom cranes experience less strain during operations, leading to less frequent repairs and a longer lifespan.

In summary, low headroom cranes provide a more cost-effective solution by lowering both the initial purchase price and ongoing operational expenses. These savings can make a significant impact on businesses looking to optimize their crane investment.

Span and Weight Considerations for Low Headroom Hoist Cranes

Optimizing Span for Low Headroom Cranes

Span and Space Constraints:

The span refers to the horizontal distance between the crane's rails, and it plays a critical role in determining how much area the crane can cover. With low headroom cranes, the goal is to balance span with available space to maximize efficiency.

- Maximizing Coverage: Low headroom cranes are typically designed for areas with space limitations, so adjusting the span allows for optimized coverage. A wider span can extend the reach of the crane without increasing its height, making it ideal for spaces where ceiling height is a constraint.

- Space and Cost Efficiency: By fine-tuning the span, you can create an ideal configuration that maximizes crane coverage in tight spaces while keeping the crane's price low. A more efficient span means that the crane can cover more area with fewer adjustments to the facility's layout, lowering costs both in terms of installation and long-term operational space usage.

Adjusting the span appropriately ensures that low headroom cranes can work effectively in tight environments while maintaining low cost and high performance.

Weight and Load Capacity Impact

Balancing Crane Weight and Lifting Capacity:

Weight and load capacity are two important considerations when selecting a crane. For low headroom cranes, these factors must be carefully balanced to ensure efficient operation without exceeding weight limitations or design restrictions.

- Reduced Weight Benefits: One of the main advantages of low headroom cranes is their reduced weight. Lighter cranes typically have lower material costs and offer better operational efficiency. Reduced weight also means lower energy consumption and easier maneuverability, especially in smaller workspaces.

- Price and Durability: A reduced weight often leads to a lower crane price because fewer materials and simpler components are needed. However, this lighter design doesn't necessarily mean a compromise in durability. The materials used are still strong enough to handle the required load capacity without significantly increasing the price.

- Operational Efficiency: With a reduced weight, low headroom cranes can operate more smoothly and with less wear and tear. This can increase the overall lifespan of the crane and reduce maintenance costs. Furthermore, a well-balanced crane with the right lifting capacity ensures that operations run efficiently without overloading the structure.

In short, the relationship between weight, span, and load capacity is crucial in determining the performance, cost, and durability of low headroom hoist cranes. Adjusting these factors allows businesses to select a crane that fits their specific needs while optimizing both performance and cost-efficiency.

Shop Ceiling and Layout Considerations

Ceiling Height and Low Headroom Crane Compatibility

How Ceiling Height Affects Crane Selection:

Ceiling height is one of the most important factors when choosing a low headroom hoist crane. A low headroom design allows the crane to operate efficiently in areas with limited vertical space, but the ceiling height must be carefully considered to ensure compatibility with the crane's design and operational capabilities.

- Matching Crane Design to Ceiling Height: The primary goal is to ensure that the crane's total height doesn't exceed the available ceiling height in the shop. Low headroom cranes are ideal in this regard, as they have been specially designed to fit in spaces with reduced clearance.

- Clearance for Safe Operation: It's also essential to account for the required clearance between the crane and other structural elements in your shop. Having enough room for proper operation prevents damage to the crane or surrounding structures, reducing the risk of safety issues.

- Optimizing Vertical Space: Low headroom cranes maximize vertical space by minimizing the crane's height. This design allows you to make the most of your available ceiling height while still maintaining the ability to lift loads at the desired height.

By ensuring that the crane matches your shop's ceiling height, you can avoid costly adjustments or operational issues later.

Planning Your Shop Layout with Low Headroom Cranes

Designing Your Facility Layout:

Planning the layout of your facility around the crane is crucial for optimizing space and ensuring that the crane operates efficiently. When using low headroom cranes, thoughtful layout planning will help maximize your available space while maintaining safe and efficient crane operation.

- Efficient Use of Floor Space: Low headroom cranes are designed to take up less vertical space, but their floor space requirements must also be considered. Ensure that there's enough room for the crane to move freely across the shop floor without obstructing other equipment or work areas.

- Aligning Crane Specifications with Shop Ceiling Height: Your shop layout should be designed with the crane's specifications in mind. For instance, knowing the crane's lifting height and span will help you determine the optimal path for the crane's movement, avoiding potential clearance issues.

- Maximizing Workflow Efficiency: When planning the layout, think about how the crane will be used in conjunction with other machinery and workstations. A well-planned layout ensures that the crane's operation doesn't interfere with the workflow, ultimately improving productivity and reducing downtime.

Aligning your crane choice with your shop's ceiling height and layout creates a seamless integration of equipment, improving overall operational efficiency and helping you make the most of your facility's space.

Customization Options for Low Headroom Hoist Cranes

Custom Features to Fit Your Space

Adjustable Features to Meet Space Requirements:

Low headroom hoist cranes are designed with a variety of customizable options that make them adaptable to different facility layouts and shop requirements. These adjustments maximize space utilization without compromising the crane's performance or lifting capacity.

- Adjustable Hoist Heights: Many low headroom hoist cranes feature adjustable hoist systems, allowing the lifting height to be modified according to specific operational needs. This flexibility is particularly beneficial in environments with limited vertical space, as it enables the crane to lift at varying heights without requiring a complete redesign of the entire system.

- Flexible Crane Designs: The crane's overall structure can be tailored to fit the dimensions and layout of your shop or warehouse. By adjusting the crane's span, height, and hook position, you can ensure that it fits seamlessly into confined spaces or around obstacles. These modifications are especially useful in facilities with low ceilings or where space optimization is crucial for efficiency.

- Compact Crane Structures: In some cases, a customized crane design can reduce the overall size of the system, making it more compact and space-efficient. This is beneficial in facilities where maximizing floor space is a priority. A more compact design reduces the footprint of the crane, ensuring that it occupies the least amount of space while still providing the necessary lifting capabilities.

These customizable features not only help the crane fit into your available space but also contribute to reducing overall crane costs by optimizing the crane's structure and performance. The ability to adjust the crane to the specific requirements of your facility ensures you get the most efficient solution possible.

Additional Features that Enhance Performance

Advanced Features for Improved Crane Functionality:

In addition to basic customization, low headroom hoist cranes can be equipped with advanced features that significantly enhance their performance, safety, and long-term durability. While these features may increase the initial cost of the crane, they deliver significant benefits in terms of operational efficiency, safety, and reduced maintenance over time.

- Wireless Controls: Modern low headroom hoist cranes can be equipped with wireless control systems that allow operators to manage the crane from a safe distance. This reduces the need for workers to be near the crane's moving parts, which enhances safety by keeping operators away from potential hazards. Additionally, wireless controls eliminate the need for extensive wiring, cutting down on installation and maintenance costs.

- Explosion-Proof Designs: In facilities where hazardous or flammable materials are present, explosion-proof crane designs are crucial for preventing accidents. These designs ensure that the crane will not produce sparks or heat that could ignite volatile substances. While these features add to the initial cost of the crane, they provide invaluable protection, minimizing the risk of costly accidents, equipment damage, or downtime in sensitive environments.

- Anti-Corrosion Coatings: Low headroom hoist cranes used in harsh environments, such as marine areas, chemical plants, or outdoor settings, can benefit from anti-corrosion coatings. These coatings protect the crane from the effects of extreme weather conditions, high humidity, or exposure to chemicals, significantly extending the crane's lifespan. By reducing the need for frequent maintenance and preventing rust and deterioration, anti-corrosion coatings provide long-term savings and ensure the crane remains in peak working condition for years.

These advanced features not only improve the crane's overall performance but also contribute to a safer and more efficient work environment. While they may increase upfront costs, the long-term benefits—such as lower operational and maintenance expenses—can far outweigh the initial investment.

Conclusion: Contact Us to Get Your Custom Low Headroom Hoist Crane

Low headroom hoist cranes are a smart choice for facilities with limited ceiling height, offering excellent space optimization. These cranes are designed to maximize vertical space, allowing businesses to utilize every inch of available space effectively. With their compact structure, they not only fit into tight areas but also ensure smooth, efficient operations without taking up unnecessary room.

Key Advantages:

- Space Efficiency: Low headroom cranes help optimize ceiling height, offering more usable space in warehouses or factories.

- Cost-Effective: The design requires fewer structural components, resulting in lower crane prices.

- Customization: Features like adjustable hoist heights and flexible crane designs allow for a tailored fit to your shop's layout, enhancing operational efficiency.

Choosing the right crane for your facility means balancing space, performance, and costs. By selecting a low headroom hoist crane with adjustable features, businesses can improve operations, reduce unnecessary expenses, and make the most of their available space.

A well-chosen low headroom hoist crane will help you achieve both space optimization and cost savings. It's essential to understand your specific shop requirements and select a crane that will meet both your operational needs and your budget. With the right crane, your business can benefit from improved performance, reduced costs, and enhanced efficiency in the long run.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch