How to Design Overhead Crane for your Plumbing Factory Workshop

5 T & 10 T Overhead crane for plumbing factory for reference. Custom bridge crane design for plumbing factory, optimal single & double girder design.

Category: Featured

Your Trusted 5 Ton and 10 Ton Overhead Crane Manufacturer & Supplier

How to Design Overhead Crane for your Plumbing Factory Workshop

5 T & 10 T Overhead crane for Plumbing Factory , Custom bridge crane Solution for Plumbing Manufacturing Facility

5 T & 10 T Overhead crane for plumbing factory for reference. Custom bridge crane design for plumbing factory, optimal single & double girder design.

How Overhead Cranes Boosted Home Pipeline Co., Ltd.'s Production

5 Ton and 10 Ton Overhead Bridge Cranes for Plubing Factory Workshops

Meet Home Pipeline Co., Ltd., your go to source for top notch pipeline solutions and bathroom materials! Since our founding on May 17, 2022, we've been committed to delivering quality products across various sectors like water supply, drainage, heating, and more. With production hubs in Foshan, Tianjin, Hubei, Shaanxi, Chongqing, and a wide global reach, we're proud to serve customers in over 100 countries. But like any growing business, we faced some challenges, especially when it came to lifting and moving materials efficiently during production. That's where our hero enters: the overhead crane! We decided to bring in some heavy lifting help to boost our production efficiency.

Lifting Requirements:

Heavy Lifting Hurdles: We struggled with lifting and moving materials smoothly within our production facilities.

Efficiency Dips: Our old material handling methods weren't cutting it, and it was slowing down our workflow.

Overhead Cranes Solution for Plumbing Factory Workshops

To tackle these challenges head on, we decided to spice things up with a trio of overhead crane solutions:

10 Ton Overhead Crane

Heavy Duty Material Handling: Lift and transport heavier raw materials, such as large metal pipes or bulk quantities of materials, from storage to production areas with ease.

Equipment Installation: Aid in the installation of heavy machinery and equipment used in various manufacturing processes, such as extrusion machines or injection molding equipment.

Mold Handling: Assist in the movement and positioning of molds used in injection molding processes for producing plumbing components.

5 Ton Overhead Crane :

Handling Raw Materials: Efficiently unload and transport raw materials such as metal sheets, pipes, and plastic components from delivery trucks to designated storage areas within the facility.

Small Component Assembly: Assist in the assembly of smaller plumbing components such as valves, fittings, and connectors by lifting and positioning parts for assembly workers.

Inspection and Testing: Transport finished products to inspection and testing stations for quality control checks, ensuring compliance with industry standards.

Handling Raw Materials: Efficiently unload and transport raw materials such as metal sheets, pipes, and plastic components from delivery trucks to designated storage areas within the facility.

Small Component Assembly: Assist in the assembly of smaller plumbing components such as valves, fittings, and connectors by lifting and positioning parts for assembly workers.

Inspection and Testing: Transport finished products to inspection and testing stations for quality control checks, ensuring compliance with industry standards.

2 Ton Overhead Crane

Component Transfer: Transport smaller plumbing components between workstations or assembly lines, facilitating seamless workflow and minimizing manual handling.

Maintenance Support: Assist maintenance personnel in lifting and replacing smaller components of machinery or equipment, contributing to the upkeep of production machinery.

Tool and Die Handling: Lift and transport tooling and dies used in metal fabrication processes, ensuring they are readily available for production activities.

These trusty cranes became our production superheroes, swooping in to save the day with their lifting prowess!

Safety and Efficiency Achieved:

Efficiency Boost: Thanks to our new crane pals, our material handling got a major upgrade, turbocharging our production efficiency.

Safety First: With their fancy safety features, our cranes made sure everyone stayed out of harm's way, reducing the risk of accidents.

Flexibility Galore: Whether it's lifting heavy loads or lighter ones, our crane squad handled it all like pros, giving us the flexibility we needed to keep things running smoothly.

With our trusty overhead cranes by our side, Home Pipeline Co., Ltd. soared to new heights in production efficiency. Not only did they make our workflow smoother than ever, but they also helped us raise the bar on workplace safety. So here's to our crane buddies for being the real MVPs and helping us keep the pipeline flowing, one lift at a time!

Integrating Overhead Crane Solutions in Plumbing Manufacturing to Improve Safety and Efficiency

In plumbing manufacturing, efficiency isn't just a goal—it's a necessity. Every aspect of the production process, from raw material handling to final product assembly, must be optimized for maximum productivity. This is where overhead crane solutions step in as silent heroes, revolutionizing material handling and production processes in plumbing manufacturing facilities.

From the moment a plumbing manufacturing facility is conceived, the integration of overhead crane solutions becomes a cornerstone of success. These solutions aren't just tools; they're strategic assets that can make or break the efficiency of the entire operation. That's why we're excited to guide you through the structured outline that outlines the benefits of overhead crane solutions at each stage of facility design and production operations.

Integrating Overhead Crane Solutions into Facility Design

When it comes to designing a plumbing manufacturing facility, success hinges on meticulous planning and strategic foresight. At the heart of this process lies the integration of overhead crane solutions—a critical component that can elevate efficiency and streamline operations from the get go. Let's dive into how this integration begins with a thoughtful approach to facility design.

Collaborative Approach: Maximizing Efficiency Through Partnership

In the facility design, collaboration is key. By fostering early partnerships between overhead crane solution providers and facility designers/architects, a wealth of benefits can be unlocked. These collaborative efforts ensure that crane solutions are seamlessly integrated into the facility's blueprint, optimizing spatial layout and functionality right from the start.

In the dynamic landscape of facility design, collaboration emerges as the linchpin of success. Cultivating partnerships between overhead crane solution providers and facility designers/architects at the onset lays the groundwork for unlocking a myriad of benefits. This collaborative approach ensures that crane solutions seamlessly intertwine with the facility's blueprint, heralding a new era of optimized spatial layout and enhanced functionality right from the outset.

- Leveraging Diverse Expertise: By bringing together the diverse expertise of overhead crane solution providers and facility designers/architects, a comprehensive understanding of both the technical requirements and spatial constraints of the facility is achieved. This collaborative synergy allows for the creation of tailored crane solutions that harmonize seamlessly with the facility's architectural vision, optimizing efficiency and performance.

- Early Integration for Seamless Execution: Early integration of crane solutions into the facility's blueprint paves the way for seamless execution during the construction phase. Through close collaboration, potential challenges or conflicts are identified and addressed proactively, mitigating the risk of costly redesigns or modifications down the line. This proactive approach streamlines the construction process, ensuring timely completion and minimizing disruptions to operations.

- Optimizing Spatial Layout and Functionality: The collaborative efforts between crane solution providers and facility designers/architects yield innovative solutions that optimize spatial layout and functionality within the facility. By strategically integrating cranes into the architectural design, space utilization is maximized, and workflow efficiency is enhanced. This meticulous planning ensures that every square foot of the facility serves a purpose, driving productivity and performance.

- Enhancing Safety and Ergonomics: The collaborative approach extends beyond spatial considerations to encompass safety and ergonomics. By working hand in hand, crane solution providers and facility designers/architects devise solutions that prioritize worker safety and comfort. From optimizing crane placement to integrating safety features seamlessly into the facility's design, every aspect is meticulously crafted to create a safe and ergonomic work environment.

- Driving Innovation and Continuous Improvement: Through collaborative partnerships, a culture of innovation and continuous improvement is fostered. By pooling resources and expertise, new technologies and best practices are embraced, driving advancements in crane solutions and facility design. This commitment to innovation ensures that facilities remain agile and adaptable in the face of evolving industry demands, positioning them for long term success.

In essence, the collaborative approach between overhead crane solution providers and facility designers/architects serves as the cornerstone of facility design excellence. By leveraging diverse expertise, early integration, optimized spatial layout, enhanced safety, and a commitment to innovation, this collaborative partnership sets the stage for transformative outcomes in the plumbing manufacturing industry.

Identifying Requirements: Tailoring Crane Solutions to Facility Needs

To design the overhead crane solution for your factory, the key is your specific material handling needs and spatial constraints of the plumbing manufacturing facility . Whether it's the lifting of heavy raw materials or the precise positioning of assembly components, a thorough assessment of requirements ensures that overhead crane solutions are tailored to meet the facility's unique demands.

- Thorough Needs Assessment: At the outset, it's essential to conduct a thorough needs assessment, delving into the specific material handling challenges and operational requirements unique to the plumbing manufacturing facility. This involves examining factors such as the types of materials handled, the frequency of lifts, and the spatial layout of production areas. By gaining a deep understanding of these intricacies, stakeholders can identify the precise functionalities and capabilities required of overhead crane solutions.

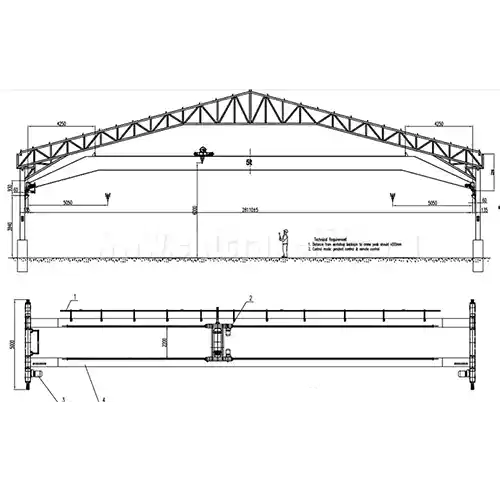

- Customized Solutions for Unique Demands: Armed with insights from the needs assessment, crane solution providers collaborate closely with facility stakeholders to develop customized solutions tailored to address the facility's unique demands. Whether it's a single girder crane for lighter loads or a double girder crane for heavier lifting tasks, the goal is to match the crane's specifications with the facility's requirements with precision. This bespoke approach ensures that the crane solution seamlessly aligns with the facility's workflow, optimizing efficiency and productivity.

- Consideration of Spatial Constraints: In addition to operational requirements, spatial constraints play a pivotal role in shaping crane integration efforts. Facility designers and crane solution providers work hand in hand to navigate these constraints, optimizing crane placement and runway configuration to maximize space utilization while minimizing interference with other operations. This meticulous attention to spatial planning ensures that the crane seamlessly integrates into the facility's layout, enhancing both functionality and safety.

- Future Proofing for Scalability: Beyond addressing immediate needs, effective crane integration involves future proofing for scalability. As the facility evolves and expands, the crane solution should have the flexibility to adapt to changing requirements seamlessly. This forward thinking approach involves designing crane systems with modular components and scalable features, allowing for easy upgrades and modifications as the facility grows. By future proofing crane solutions, stakeholders can ensure long term viability and investment protection.

In essence, identifying the specific requirements of the plumbing manufacturing facility serves as the cornerstone of effective crane integration. Through a meticulous needs assessment, customization of solutions, consideration of spatial constraints, and future proofing for scalability, stakeholders can lay the groundwork for seamless crane integration that enhances efficiency, productivity, and adaptability in the ever evolving manufacturing landscape.

Customized Solutions: Optimizing Crane Integration for Facility Efficiency

One size does not fit all in the world of overhead crane solutions. Recognizing this, tailored approaches offer a significant advantage. By customizing crane solutions to align with the facility's layout and workflow, inefficiencies are minimized, and productivity is maximized. From single girder to double girder configurations, the flexibility of customized solutions ensures optimal performance and seamless integration into the facility's operations.

- Understanding Facility Dynamics: No two facilities are alike, each harboring its own set of challenges, layouts, and operational nuances. Customized crane solutions begin with a deep dive into understanding these unique dynamics. Through collaborative discussions and on site assessments, crane solution providers gain invaluable insights into the facility's workflow, spatial constraints, and material handling requirements. This intimate understanding forms the bedrock upon which customized solutions are built, ensuring a seamless fusion of crane functionality with facility operations.

- Tailored Configurations for Optimal Performance: Armed with insights gleaned from facility assessments, crane solution providers embark on the task of crafting tailored configurations that optimize performance and efficiency. Whether it's a single girder crane for lighter loads or a double girder behemoth for heavy duty lifting tasks, the key lies in aligning crane specifications with facility requirements. Customized crane configurations offer a level of flexibility and adaptability that transcends off the shelf solutions, empowering manufacturers to meet evolving production demands with ease.

- Seamless Integration into Facility Workflow: The hallmark of a successful crane solution lies in its seamless integration into the facility's workflow. Customized configurations are meticulously designed to harmonize with existing operations, minimizing disruptions and maximizing productivity. From strategically placed runways to optimized lifting capacities, every aspect of the crane is fine tuned to complement the facility's layout and workflow. The result is a symbiotic relationship where crane and facility work in tandem to drive operational excellence.

- Flexibility to Meet Evolving Needs: In the ever evolving landscape of manufacturing, adaptability is key. Customized crane solutions offer the flexibility to meet changing needs and accommodate future growth. Modular designs and scalable features enable manufacturers to easily expand or modify crane systems as production requirements evolve. This forward thinking approach ensures that crane solutions remain aligned with facility objectives, providing long term value and investment protection.

- Unlocking the Potential of Customization: In essence, customized crane solutions represent a paradigm shift in facility optimization, where one size fits all solutions make way for tailored configurations designed to unlock the full potential of manufacturing operations. By understanding facility dynamics, tailoring configurations for optimal performance, seamlessly integrating into workflow, and embracing flexibility for the future, manufacturers can harness the transformative power of customization to drive efficiency, productivity, and success.

In essence, the journey towards an efficiently designed plumbing manufacturing facility begins with a holistic approach to overhead crane integration. By embracing collaboration, understanding requirements, and embracing customized solutions, facilities can lay the groundwork for success, setting the stage for streamlined operations and enhanced productivity. Stay tuned as we continue to explore the transformative impact of overhead crane solutions in plumbing manufacturing facilities.

Types of Overhead Cranes for Optimal Performance in Plumbing Manufacturing Facilities

In the bustling world of plumbing manufacturing, where precision and efficiency reign supreme, selecting the right overhead crane is paramount. Different facilities have diverse needs, and understanding the various types of overhead cranes available can significantly impact productivity and workflow. Let's explore the different crane designs tailored to meet the unique requirements of plumbing manufacturing plants:

Single Girder Overhead Cranes:

Overview: Single girder overhead cranes feature a single horizontal beam (the girder) supported by end trucks, making them ideal for facilities with lighter lifting requirements and limited space availability.

Benefits:

Space Saving Design: Suited for compact layouts, single girder cranes optimize vertical space while providing efficient material handling capabilities.

Cost Effective Solution: With fewer components than their double girder counterparts, single girder cranes offer a budget friendly option for facilities seeking reliable lifting solutions without breaking the bank.

Versatile Applications: Single girder cranes are adaptable to various tasks, including loading and unloading materials, positioning components for assembly, and transporting finished products.

Double Girder Overhead Cranes:

Overview: Double girder overhead cranes boast two parallel horizontal beams (girders) supported by end trucks, providing enhanced stability and lifting capacity compared to single girder cranes.

Benefits:

Heavy Duty Performance: With robust construction and increased lifting capabilities, double girder cranes are well suited for handling heavy loads commonly encountered in plumbing manufacturing, such as pipes, fittings, and machinery components.

Wide Span Coverage: Double girder cranes offer greater span coverage, making them suitable for facilities with larger work areas or spanning multiple production zones.

Precision Handling: The dual girder design provides superior stability and control, allowing for precise load positioning and movement, critical for intricate manufacturing processes.

Overview: Underslung overhead cranes, also known as underhung cranes, are mounted beneath the runway beam, offering a space saving solution for facilities with limited overhead clearance.

Benefits:

Maximizes Headroom: By mounting the crane beneath the runway beam, underslung cranes optimize vertical space, making them ideal for facilities with low ceilings or overhead obstructions.

Smooth Movement: Underslung cranes operate on a lower profile, providing smoother and more precise load movement, essential for delicate plumbing components and assembly tasks.

Minimal Interference: The compact design of underslung cranes minimizes interference with overhead fixtures or machinery, allowing for seamless integration into existing facility layouts.

Overview: Wall mounted jib cranes are fixed to a wall or building column, offering localized lifting and maneuverability within a specific area of the facility.

Benefits:

Localized Lifting: Wall mounted jib cranes provide targeted lifting capabilities, ideal for handling materials or components in confined spaces or specific workstations within the facility.

Versatile Placement: With the ability to mount directly to existing structures, wall mounted jib cranes offer flexibility in placement, adapting to the layout and workflow requirements of the plumbing manufacturing facility.

Easy Installation: The straightforward installation process of wall mounted jib cranes minimizes downtime and disruption to production activities, allowing for quick deployment and immediate operational benefits.

Overview: Workstation bridge cranes, also known as monorail cranes, feature a single bridge beam supported by a fixed or ceiling mounted runway, providing localized lifting and transport capabilities.

Benefits:

Workspace Optimization: Workstation bridge cranes are designed for efficient material handling within specific work areas or production cells, optimizing workflow and minimizing unnecessary movement.

Ergonomic Design: The compact and lightweight nature of workstation bridge cranes reduces operator fatigue and strain, promoting a safer and more ergonomic working environment.

Precise Load Control: With precise control over load positioning and movement, workstation bridge cranes enhance productivity and accuracy in assembly, testing, and packaging processes.

In summary, the choice of overhead crane for a plumbing manufacturing facility depends on various factors, including lifting requirements, space constraints, and production workflow. Whether opting for a single girder crane for compact layouts or a double girder crane for heavy duty applications, each crane type offers unique benefits tailored to meet the specific needs of the facility. By carefully evaluating these factors and considering the advantages of each crane design, plumbing manufacturers can optimize material handling operations and drive efficiency and productivity in their facilities.

Applications of Overhead Crane Applications in Plumbing Manufacturing Facilities

Overhead cranes find numerous applications in plumbing manufacturing facilities, serving various workshops and procedures with distinct load handling requirements. Here's an overview of their applications, typical loads or object handling, and the features and benefits associated with overhead crane design:

Raw Material Receiving Area:

Applications: Unloading raw materials such as metal sheets, pipes, and fittings from delivery trucks.

Typical Loads/Object Handling: Heavy metal coils, large pipes, pallets of fittings.

Overhead Crane Design: Single girder or double girder crane with appropriate lifting capacity and span.

Features and Benefits: Enhanced lifting capacity for heavy loads, precise positioning for unloading trucks efficiently, reducing manual handling and associated risks.

Material Storage Warehouse:

Applications: Storing and organizing raw materials and finished products.

Typical Loads/Object Handling: Metal bars, pipes, storage containers, pallets of finished products.

Overhead Crane Design: Single or double girder crane with suitable lifting capacity and span to cover the warehouse area.

Features and Benefits: Efficient movement of materials within the warehouse, optimizing storage space, facilitating inventory management, and reducing manual handling.

Production Workshops (e.g., Extrusion, Machining, Assembly):

Applications: Transporting materials between workstations, aiding in assembly processes.

Typical Loads/Object Handling: Raw materials, semi finished components, assembled products.

Overhead Crane Design: Single or double girder crane with appropriate lifting capacity and span, possibly with specialized lifting attachments for different materials.

Features and Benefits: Improved workflow efficiency, reduced production cycle times, ergonomic material handling, and precise positioning for assembly operations.

Quality Control and Inspection Stations:

Applications: Transporting finished products to inspection areas for quality checks.

Typical Loads/Object Handling: Finished plumbing components, inspection equipment.

Overhead Crane Design: Single girder crane with sufficient lifting capacity for product transportation.

Features and Benefits: Timely quality control inspections, efficient movement of products between stations, ensuring compliance with quality standards.

Maintenance and Repair Workshops:

Applications: Assisting in maintenance activities and repairs on manufacturing equipment.

Typical Loads/Object Handling: Heavy machinery components, tools, maintenance equipment.

Overhead Crane Design: Single or double girder crane with suitable lifting capacity and span for workshop layout.

Features and Benefits: Safe and efficient lifting of heavy machinery, assisting maintenance personnel, reducing downtime, and enhancing workplace safety.

Shipping and Dispatch Area:

Applications: Loading finished products onto trucks for distribution.

Typical Loads/Object Handling: Packaged plumbing products, shipping containers.

Overhead Crane Design: Single girder crane with adequate lifting capacity and span for loading bay requirements.

Features and Benefits: Streamlined loading operations, optimized shipping processes, reduced loading times, and increased dispatch efficiency.

Overall, overhead cranes offer versatile solutions for material handling across various workshops and procedures in plumbing manufacturing facilities, contributing to improved efficiency, productivity, and safety throughout the production process.

Lifting Devices for Different loads or Objects Handling

In a plumbing factory, a diverse range of materials and components are handled throughout various stages of production. Among the typical loads or objects managed are raw materials essential for manufacturing plumbing fixtures and fittings. These include metal sheets, coils, and bars, as well as plastic pellets or granules used in the production of pipes and fittings. Additionally, plumbing factories handle PVC or metal pipes, brass or copper fittings, and rubber gaskets and seals, which form the foundational components of plumbing systems.

- As the manufacturing process progresses, various components and parts are assembled to create plumbing fixtures. This entails handling valves such as ball valves and gate valves, faucets, taps, pipe fittings like elbows and tees, and drainage components including traps and strainers. Finished products also form a significant part of the load, comprising assembled plumbing fixtures like sinks, toilets, and bathtubs, along with packaged plumbing supplies and custom made plumbing solutions.

- Moreover, tools and equipment necessary for manufacturing and assembly tasks are prevalent in plumbing factories. These may include power tools such as drills and saws, welding equipment, and various measuring instruments. Assembly jigs and fixtures aid in the efficient assembly of plumbing components, while maintenance and repair tools ensure the upkeep of machinery and equipment.

- Packaging materials play a vital role in preparing products for distribution. Cardboard boxes, plastic bags, shrink wrap, and wooden pallets or crates are commonly used for packaging finished goods. Finally, waste and scrap materials generated during the manufacturing process, such as metal cutoffs, plastic trimmings, and cardboard waste, require proper handling and disposal to maintain a clean and organized work environment.

Throughout these processes, different handling methods and equipment are employed to transport and manipulate materials efficiently. Overhead cranes, forklifts, conveyors, and manual handling techniques are utilized to move materials between production areas, assembly lines, packaging stations, and shipping docks, ensuring smooth and seamless operations within the plumbing factory.

In a plumbing factory, various specialized below hook devices are commonly used for handling loads efficiently and safely. These devices are designed to attach to the lifting mechanism of overhead cranes or other material handling equipment and provide secure attachment points for specific types of loads or objects. Some common below hook devices used in plumbing factories include:

- Lifting Magnets: Lifting magnets are used for handling ferrous materials such as metal sheets, pipes, and fittings. These magnets are activated electronically or mechanically to create a magnetic field that securely holds the load during lifting and transporting operations.

- Vacuum Lifters: Vacuum lifters are ideal for handling non porous materials like plastic pipes, glass fixtures, and ceramic components. They utilize suction cups or vacuum pads to create a seal on the surface of the load, allowing it to be lifted and moved without causing damage.

- C hooks: C hooks are designed to handle coiled materials such as metal coils or plastic tubing. They feature a curved shape that cradles the coil securely, preventing it from unwinding or shifting during lifting and transport.

- Spreader Bars: Spreader bars are used to distribute the load weight evenly when lifting bulky or oversized objects such as large plumbing fixtures or assemblies. They feature multiple attachment points for slings or chains, allowing for balanced lifting and minimizing the risk of tipping or tilting.

- Lifting Beams: Lifting beams are similar to spreader bars but are typically used for lifting longer or irregularly shaped loads. They provide multiple attachment points along the beam's length, allowing for flexible positioning and secure lifting of various objects.

- Drum Lifters: Drum lifters are specialized devices used for handling barrels or drums containing liquids, chemicals, or other materials commonly used in plumbing manufacturing processes. They feature gripping mechanisms or clamps designed to securely lift and transport cylindrical loads without causing damage to the container.

These below hook devices are essential tools in the plumbing industry, allowing manufacturers to handle a wide range of materials and products efficiently while maintaining safety and precision in their operations.

These loads or objects vary in size, weight, and shape, requiring different handling methods and equipment within the plumbing factory. Overhead cranes, forklifts, conveyors, and manual handling techniques are often used to transport and manipulate these materials throughout various stages of production, assembly, packaging, and shipping.

Benefits of Overhead Crane Solutions in Facility Construction and Installation

As the blueprint of a plumbing manufacturing facility takes shape, the integration of overhead crane solutions emerges as a cornerstone of success. Let's delve into the myriad benefits that arise during the construction and installation phases, paving the way for seamless operations and enhanced safety.

Early integration of overhead crane solutions into facility design isn't just about foresight—it's about efficiency. By incorporating crane requirements from the outset, installation processes are streamlined, minimizing disruptions and delays. With a well coordinated approach, crane infrastructure can be seamlessly integrated into the facility's framework, ensuring a smooth transition from construction to operation.

Streamlined Installation: Maximizing Efficiency from the Start

In the dynamic landscape of facility design, early integration of overhead crane solutions emerges as a cornerstone of operational efficiency. Here's a closer look at why streamlined installation is crucial for plumbing manufacturing facilities:

- Efficiency Through Integration: The adage "measure twice, cut once" rings true in the realm of facility design. By incorporating overhead crane requirements into the initial design phase, manufacturers lay the groundwork for seamless integration. This proactive approach eliminates the need for costly retrofits or modifications down the line, saving both time and resources.

- Minimizing Disruptions and Delays: Time is of the essence in the fast paced world of manufacturing. By addressing crane requirements early in the design process, installation processes are streamlined, minimizing disruptions and delays. Instead of scrambling to retrofit infrastructure post construction, manufacturers can hit the ground running, maximizing uptime and productivity.

- Coordinated Approach for Success: Success lies in coordination, and early integration fosters a well coordinated approach to facility design. By aligning stakeholders—from architects and engineers to crane solution providers—manufacturers ensure that crane infrastructure seamlessly integrates into the facility's framework. This collaborative effort lays the foundation for a smooth transition from construction to operation, setting the stage for long term success.

- Seamless Transition to Operation: A facility's true test lies in its operational readiness. By incorporating overhead crane solutions from the outset, manufacturers ensure a seamless transition from construction to operation. Crane infrastructure becomes an integral part of the facility's DNA, ready to support material handling and production processes from day one. This holistic approach sets the stage for operational excellence, empowering manufacturers to meet and exceed their production goals.

In essence, streamlined installation isn't just about foresight—it's about maximizing efficiency and setting the stage for success. By incorporating overhead crane solutions into facility design from the outset, manufacturers lay the groundwork for seamless integration, minimizing disruptions, and maximizing operational efficiency.

Structural Considerations: Optimizing Support for Crane Operations

Designing a facility with overhead cranes in mind allows for optimized structural support and runway placement. By factoring in crane loads and runway configurations during the design phase, structural elements can be reinforced accordingly, ensuring robust support for crane operations. This proactive approach not only enhances safety but also prevents costly retrofitting efforts down the line.

When it comes to designing a facility with overhead cranes in mind, structural considerations play a pivotal role in ensuring operational efficiency and safety. Here's a deeper dive into why structural optimization is key for plumbing manufacturing facilities:

- Robust Support for Crane Operations: At the heart of every successful crane operation lies robust structural support. By factoring in crane loads and runway configurations during the design phase, engineers can reinforce structural elements to withstand the demands of crane operations. This proactive approach not only ensures the safety of personnel and equipment but also prevents structural failures that could disrupt production processes.

- Enhanced Safety Measures: Safety is non negotiable in any industrial setting, and structural optimization is a critical component of ensuring a safe working environment. By designing structural elements with overhead crane operations in mind, manufacturers can minimize the risk of accidents and injuries. Reinforced support beams, appropriately sized columns, and sturdy foundations provide a solid backbone for crane operations, enhancing overall safety within the facility.

- Preventing Costly Retrofitting Efforts: One of the hallmarks of effective facility design is foresight. By considering overhead crane requirements early in the design phase, manufacturers can prevent the need for costly retrofitting efforts down the line. Structural elements can be tailored to accommodate crane loads and runway configurations, eliminating the need for last minute modifications that could disrupt production schedules and incur additional expenses.

- Seamless Integration into Facility Layout: A well designed facility is like a well oiled machine—every component works in harmony to drive operational efficiency. By optimizing structural support for overhead cranes, manufacturers can seamlessly integrate crane infrastructure into the facility's layout. This strategic placement of support beams, columns, and foundations ensures that cranes can operate smoothly without impeding other production processes, maximizing floor space utilization and workflow efficiency.

In essence, structural considerations are a cornerstone of designing a facility with overhead cranes in mind. By optimizing structural support and runway placement, manufacturers can enhance safety, prevent costly retrofitting efforts, and seamlessly integrate crane infrastructure into the facility's layout, setting the stage for operational excellence and success.

Safety Integration: Crane Safety Devices

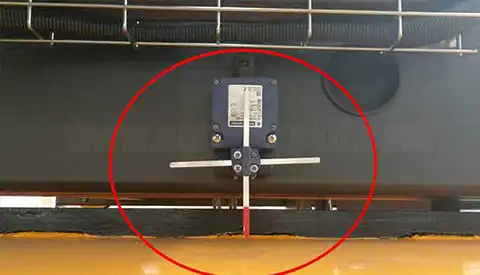

Safety is paramount in any manufacturing environment, and early integration of overhead crane solutions reinforces this commitment. During facility construction, safety features such as load monitoring systems and collision avoidance technology can be seamlessly integrated into crane infrastructure. By incorporating these safety measures from the outset, the risk of accidents and injuries is significantly reduced, fostering a safer work environment for all. Here's an in depth exploration of why safety integration is a cornerstone of overhead crane solutions in plumbing manufacturing facilities:

- Early Incorporation of Safety Measures: The early stages of facility construction present a prime opportunity to embed safety features seamlessly into overhead crane infrastructure. Load monitoring systems and collision avoidance technology are among the key safety measures that can be integrated into crane operations from the outset. By doing so, manufacturers demonstrate a proactive commitment to safety, laying the foundation for a secure work environment from day one.

- Mitigating Risk of Accidents and Injuries: Accidents can disrupt production, jeopardize personnel safety, and incur significant costs. By integrating safety features into overhead crane solutions during facility construction, manufacturers proactively mitigate the risk of accidents and injuries. Load monitoring systems provide real time data on weight distribution, preventing overloading and potential accidents. Similarly, collision avoidance technology detects obstacles in the crane's path, reducing the likelihood of collisions and workplace incidents.

- Fostering a Culture of Safety: Safety isn't just about implementing technology—it's about cultivating a culture of awareness and responsibility. By prioritizing safety integration in overhead crane solutions, manufacturers instill a culture of safety consciousness among employees. When safety features are seamlessly integrated into daily operations, workers are empowered to make informed decisions and prioritize safety in their actions, further enhancing the overall safety culture within the facility.

- Compliance with Regulatory Standards: Adherence to regulatory standards is non negotiable in the manufacturing industry. By incorporating safety features into overhead crane solutions during facility construction, manufacturers ensure compliance with stringent regulatory requirements. Whether it's OSHA regulations or industry specific standards, early safety integration demonstrates a commitment to regulatory compliance and upholding the highest safety standards in the workplace.

In summary, safety integration is a fundamental aspect of overhead crane solutions in plumbing manufacturing facilities. By embedding safety features into crane infrastructure during facility construction, manufacturers mitigate the risk of accidents and injuries, foster a culture of safety awareness, and ensure compliance with regulatory standards, ultimately creating a safer work environment for all personnel involved in the manufacturing process.

In essence, the benefits of overhead crane solutions extend far beyond the production floor—they begin with the very construction of the facility itself. By embracing streamlined installation processes, optimizing structural considerations, and prioritizing safety integration, plumbing manufacturing facilities set the stage for success from day one. Stay tuned as we continue to explore the transformative impact of overhead crane solutions throughout the production journey.

Optimizing Material Flow: Elevating Efficiency in Material Handling and Production

In the fast paced facilities of plumbing manufacturing, every second counts. That's why the strategic integration of overhead crane solutions plays a pivotal role in enhancing material handling and production processes. Let's explore how these solutions revolutionize efficiency from the ground up. Let's delve deeper into how overhead cranes revolutionize material movement, optimizing production processes from start to finish:

- Seamless Navigation Across Production Areas: Imagine overhead cranes gliding gracefully across the production floor, effortlessly transporting materials from storage zones to designated workstations. With their agile maneuverability and versatile lifting capabilities, overhead cranes navigate through congested spaces with ease, eliminating the need for cumbersome manual material handling.

- Minimizing Congestion and Bottlenecks: In the fast paced world of manufacturing, every second counts. Overhead cranes play a pivotal role in reducing congestion and eliminating bottlenecks by swiftly moving materials along designated pathways. By bypassing traffic prone areas and delivering materials directly to point of use, overhead cranes keep production lines running smoothly, ensuring uninterrupted workflow and optimal throughput.

- Just in Time Delivery for Precision Production: Precision is paramount in plumbing manufacturing, and overhead cranes deliver materials with pinpoint accuracy. By orchestrating just in time delivery of components and supplies, overhead cranes ensure that materials are readily available exactly when needed, minimizing idle time and maximizing operational efficiency. This synchronized approach to material handling streamlines production processes, allowing manufacturers to meet tight deadlines and customer demands with ease.

- Eliminating Costly Delays: Time is money in the world of manufacturing, and delays can have far reaching consequences. With overhead cranes at the helm, materials flow seamlessly through the production cycle, eliminating costly delays and downtime. By facilitating swift and efficient material movement, overhead cranes optimize resource utilization, keeping production schedules on track and minimizing the risk of project delays.

- Maximizing Throughput and Productivity: At the heart of every manufacturing operation lies the quest for increased throughput and productivity. Overhead cranes play a pivotal role in achieving these goals by optimizing material flow and streamlining production processes. By minimizing idle time, reducing handling errors, and maximizing resource utilization, overhead cranes empower plumbing manufacturing facilities to achieve peak performance and drive profitability.

In essence, overhead cranes serve as the linchpin of efficient material flow in plumbing manufacturing facilities. By seamlessly navigating production areas, minimizing congestion, and orchestrating just in time delivery, overhead cranes optimize throughput, eliminate costly delays, and propel productivity to new heights.

Alleviating Manual Labor: Elevating Safety and Ergonomics with Overhead Cranes

Overhead cranes alleviate the burden of manual material handling, sparing workers from the physical strain associated with lifting heavy loads. By mechanizing material movement, overhead cranes minimize the risk of injuries and ergonomic strains among workers, fostering a safer and more ergonomic work environment. This not only enhances worker well being but also boosts morale and productivity across the board. How overhead cranes revolutionize material handling, alleviating the burden of manual labor while enhancing safety and ergonomics:

- Relieving Workers from Physical Strain: Manual material handling poses significant risks to worker health and safety, especially when it involves lifting heavy loads repeatedly throughout the day. Overhead cranes offer a welcome reprieve from this physical strain by mechanizing material movement. Instead of relying on manual lifting and carrying, workers can delegate these tasks to overhead cranes, sparing them from the physical demands of heavy lifting.

- Minimizing the Risk of Injuries: Injuries stemming from manual material handling are a prevalent concern in manufacturing facilities. Strained muscles, back injuries, and repetitive strain injuries are all too common among workers tasked with heavy lifting. By reducing reliance on manual handling, overhead cranes minimize the risk of these injuries, creating a safer work environment for all. This not only protects workers from harm but also mitigates the associated costs and downtime resulting from workplace injuries.

- Enhancing Ergonomics and Comfort: Ergonomics play a crucial role in maintaining worker comfort and well being. Overhead cranes contribute to ergonomic excellence by allowing workers to perform material handling tasks with minimal physical exertion. By eliminating awkward lifting postures and repetitive motions, overhead cranes promote ergonomic best practices, reducing the risk of musculoskeletal disorders and enhancing overall worker comfort.

- Boosting Morale and Productivity: A workforce free from the burden of manual labor is a happier and more productive workforce. By alleviating the physical strain of material handling, overhead cranes boost worker morale and job satisfaction. With fewer injuries and less fatigue, workers can focus their energy on productive tasks, driving efficiency and productivity across the board. This positive work environment fosters a culture of safety and teamwork, leading to enhanced performance and bottom line results.

In summary, overhead cranes serve as a beacon of safety and efficiency in plumbing manufacturing facilities, alleviating manual labor burdens while enhancing safety, ergonomics, and productivity. By mechanizing material handling tasks, overhead cranes create a safer, more ergonomic work environment, empowering workers to perform at their best while minimizing the risk of injuries and strains.

Increased Productivity:Accelerating Efficiency with Overhead Crane Solutions

By enabling faster material handling and streamlined production processes, overhead cranes unlock unparalleled productivity gains. Quantify the impact: reduced cycle times, increased throughput, and shorter lead times—all made possible by the seamless integration of overhead crane solutions. With every lift, productivity soars, driving profitability and ensuring a competitive edge in the market. Check how these innovative solutions supercharge efficiency, unlocking unparalleled gains in productivity:

- Faster Material Handling:Overhead crane solutions are the accelerators of material movement. With their unparalleled lifting capabilities and swift traversing motions, overhead cranes expedite material handling processes, reducing cycle times and enhancing overall efficiency. Whether it's transporting raw materials to production areas or moving finished products to storage, overhead cranes get the job done swiftly and seamlessly.

- Streamlined Production Processes:Overhead cranes are the architects of streamlined production processes. By seamlessly integrating into the manufacturing workflow, overhead cranes optimize material flow, minimizing bottlenecks and optimizing throughput. With materials moving seamlessly from one workstation to the next, production cycles are streamlined, lead times are shortened, and productivity soars to new heights.

- Quantifiable Impact: By quantifying the impact of overhead crane solutions, facilities can showcase real world improvements in cycle times, throughput, and lead times. Whether it's a 20% reduction in cycle times or a 30% increase in throughput, the benefits of overhead crane solutions speak volumes, driving profitability and ensuring a competitive edge in the market.

- Driving Profitability:With overhead crane solutions at the helm, facilities can maximize productivity, minimize downtime, and optimize resource utilization. Every lift translates into tangible gains in profitability, ensuring that every operation contributes to the bottom line. By harnessing the power of overhead crane solutions, facilities can thrive in a rapidly evolving market, driving profitability and securing their position as industry leaders.

In summary, overhead crane solutions are the catalysts of productivity in plumbing manufacturing facilities, accelerating material handling processes, streamlining production workflows, and driving tangible gains in efficiency. With their unmatched lifting capabilities and seamless integration into the manufacturing environment, overhead cranes are the key to unlocking unparalleled productivity gains and ensuring long term success in the competitive marketplace.

In essence, the benefits of overhead crane solutions extend far beyond mere material handling—they transform production processes from the ground up. By optimizing material flow, reducing manual handling, and driving productivity gains, overhead crane solutions empower plumbing manufacturing facilities to reach new heights of efficiency and success. Stay tuned as we continue to uncover the transformative potential of overhead crane solutions in the manufacturing landscape.

Elevating Quality Control with Overhead Crane Solutions

In the intricate realm of plumbing manufacturing, quality control is not just a process—it's a commitment to excellence. Here's how overhead crane solutions play a pivotal role in supporting and enhancing quality control and assurance efforts:

- Seamless Inspection Processes: Picture this: a finished plumbing fixture glides effortlessly across the production floor, guided by the precise movements of an overhead crane. As it reaches the designated inspection station, quality control checks are executed with meticulous attention to detail. With overhead cranes facilitating the seamless movement of materials and finished products between inspection stations, quality control processes are expedited, ensuring timely inspections and adherence to stringent quality standards.

- Accurate Positioning: Precision is paramount in the world of quality control, and overhead cranes deliver on this front with unmatched accuracy. From lifting and positioning components during assembly to delicately maneuvering finished products for testing, overhead cranes ensure that every element is precisely positioned for inspection. With their precision lifting capabilities, overhead cranes play a crucial role in upholding quality standards and ensuring the integrity of every product that rolls off the production line.

- Compliance and Consistency: Compliance isn't just a checkbox—it's a commitment to consistency and excellence. Integrated overhead crane solutions contribute to consistent quality standards and regulatory compliance throughout the manufacturing process. By providing reliable lifting and handling capabilities, overhead cranes enable manufacturers to meet regulatory requirements and maintain the highest levels of quality assurance. From ensuring proper material handling to facilitating accurate testing procedures, overhead cranes are indispensable allies in the quest for quality excellence.

In summary, overhead crane solutions are indispensable assets in the quest for quality excellence in plumbing manufacturing. From facilitating seamless inspection processes to ensuring accurate positioning and upholding regulatory compliance, overhead cranes play a pivotal role in supporting and enhancing quality control and assurance efforts. With their precision, reliability, and seamless integration into the manufacturing environment, overhead crane solutions elevate quality standards and ensure the delivery of superior products to customers.

Prioritizing Safety: The Crucial Role of Overhead Crane Solutions in Risk Mitigation

In the fast paced environment of plumbing manufacturing, safety isn't just a priority—it's a non negotiable imperative. Fortunately, overhead crane solutions stand as stalwart guardians, actively mitigating risks and fostering a secure work environment. Let's explore how these solutions bolster safety from every angle.

- Hazard Reduction: Manual material handling poses inherent risks, from slips and trips to musculoskeletal strains. Here, overhead crane solutions emerge as powerful allies, minimizing workplace hazards with every lift. By mechanizing material movement, these cranes significantly reduce the risk of accidents associated with manual handling, safeguarding worker well being and promoting a culture of safety across the facility.

- Emergency Preparedness: In times of crisis, swift and decisive action is paramount. Overhead crane solutions play a pivotal role in emergency response scenarios, offering a lifeline during critical moments. With their unparalleled lifting capabilities, overhead cranes facilitate rapid evacuation procedures, ensuring the swift and safe removal of personnel from hazardous areas. Moreover, these cranes provide essential access for maintenance personnel during emergency repairs, enabling timely interventions to mitigate potential risks.

- Proactive Risk Mitigation: Prevention is always better than cure, and overhead crane solutions embody this ethos through proactive risk mitigation measures. Equipped with features such as overload protection and anti sway technology, these cranes preemptively address potential hazards before they escalate. By detecting and correcting deviations in load stability and crane operation, these advanced features enhance overall safety in the facility, minimizing the risk of accidents and equipment damage.

In essence, the safety of personnel and assets is paramount in the plumbing manufacturing environment, and overhead crane solutions serve as indispensable guardians of well being. From hazard reduction to emergency preparedness and proactive risk mitigation, these solutions epitomize safety at its finest, ensuring a secure and resilient workplace for all. Stay tuned as we continue to explore the transformative impact of overhead crane solutions in enhancing safety across the manufacturing landscape.

Pioneering Progress: Overhead Crane Solutions as Catalysts for Continuous Improvement

In plumbing manufacturing, standing still is not an option. Continuous improvement and adaptation are the cornerstones of success, and overhead crane solutions emerge as formidable catalysts in this ongoing journey of progress. Let's explore how these solutions drive innovation, flexibility, and efficiency, propelling manufacturing facilities towards excellence.

- Operational Insights: Data is the lifeblood of informed decision making, and overhead crane systems serve as invaluable sources of operational insights. By collecting and analyzing data on crane performance, material flow, and production processes, these systems offer unprecedented visibility into facility operations. Armed with this wealth of information, stakeholders can identify bottlenecks, pinpoint inefficiencies, and implement targeted improvement initiatives, driving continuous enhancement across the board.

- Flexibility and Scalability: In a landscape marked by constant change, adaptability is paramount. Overhead crane solutions exemplify flexibility, seamlessly accommodating evolving production requirements and facility expansions. Whether scaling up production volumes or diversifying product lines, these solutions can be tailored to meet the shifting needs of the facility. With their modular designs and customizable features, overhead crane solutions ensure long term operational efficiency, empowering manufacturing facilities to thrive in an ever changing environment.

- Innovation and Technology Integration: Innovation is the lifeblood of progress, and overhead crane solution providers are at the forefront of technological advancement. By staying abreast of the latest industry trends and emerging technologies, these providers offer innovative solutions that push the boundaries of efficiency and competitiveness. From automation and remote monitoring to predictive maintenance and artificial intelligence, overhead crane solutions integrate cutting edge technologies to optimize performance and drive continuous improvement.

In essence, overhead crane solutions transcend their role as mere tools—they are agents of transformation, driving continuous improvement and adaptation in plumbing manufacturing facilities. By harnessing operational insights, embracing flexibility and scalability, and embracing innovation and technology integration, these solutions pave the way for sustained excellence and competitive advantage. Stay tuned as we continue to explore the transformative impact of overhead crane solutions in shaping the future of manufacturing.

Elevating Efficiency, Safety, and Success: The Power of Overhead Crane Solutions in Plumbing Manufacturing

As we draw the curtains on our exploration of overhead crane solutions in plumbing manufacturing, it's time to reflect on the profound impact these solutions have across every stage of design and production. From streamlining material handling to fostering a culture of safety and driving continuous improvement, overhead crane solutions emerge as indispensable allies in the pursuit of excellence.

In essence, overhead crane maximize efficiency, enhance safety, and foster productivity, all while supporting long term growth and success in the plumbing manufacturing industry. If you need any cutom overhead crane or bridge crane design for your plumbing manufacturing workhsops, please feel free to contact us to check what we can do for you.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch