Rolling Gantry Crane Types, Specifications & Selections 2 T, 3T, 5T 10 Ton

Rolling gantry crane on wheels for sale . Guide on rolling gantry crane designs, types, specifications & Selection tips. Get custom rolling gantry crane now!

Category: Featured

Your Trusted Rolling Gantry Crane Manufacturer & Supplier

Rolling Gantry Crane Types, Specifications & Selections 2 T, 3T, 5T , 6 T, 7 T, 8 T, 9 T10 Ton

Rolling gantry crane on wheels for sale . Guide on rolling gantry crane designs, types, specifications & Selection tips. Get custom rolling gantry crane now!

Comprehensive Guide to Rolling Gantry Cranes

Rolling gantry cranes represent a crucial component in the landscape of industrial equipment, offering unparalleled versatility and functionality across a spectrum of applications. These cranes, equipped with wheels for mobility, serve as indispensable aids in lifting and transporting heavy loads within factories, warehouses, construction sites, and various other industrial settings. The significance of rolling gantry cranes lies in their ability to streamline material handling processes, enhance operational efficiency, and ensure workplace safety.

In today's fastpaced industrial environments, where the demand for productivity and precision is paramount, rolling gantry cranes stand out as indispensable assets. Their adaptability to different environments, coupled with their ability to handle diverse loads, renders them indispensable across a wide array of industries. Whether it's lifting machinery in manufacturing facilities, moving materials in logistics centers, or aiding in construction projects, rolling gantry cranes play a pivotal role in optimizing workflow and minimizing downtime.

The purpose of this comprehensive guide is to delve into the intricate world of rolling gantry cranes, providing a detailed exploration of their design types, features, applications, and specifications. By offering insights into the various types of rolling gantry cranes available, their key features, and their suitability for different environments, this guide aims to assist buyers and users in making informed decisions when selecting the most appropriate rolling gantry crane for their specific needs. Moreover, it seeks to address common concerns and questions that arise during the procurement and utilization of rolling gantry cranes, offering practical solutions to maximize their effectiveness and costefficiency.

Your Trusted Rolling Gantry Crane Manufacturer & Supplier

Rolling Gantry Crane Design Types

Rolling gantry cranes come in various design types, each tailored to specific applications and operational requirements. Understanding these design variations is crucial in selecting the most suitable crane for a particular task. Below are some common rolling gantry crane design types:

Small Rolling Cranes on Castor Wheels

These compact and maneuverable cranes are equipped with castor wheels, allowing for easy movement and positioning within confined spaces. Ideal for lightduty lifting tasks in workshops, laboratories, and smallscale production facilities, small rolling cranes on castor wheels offer flexibility and convenience where larger cranes may not be practical.

Steel Rolling Gantry Cranes

Steel Rolling Gantry Cranes are robust and durable material handling solutions designed for a wide range of industrial applications. Constructed from steel, these cranes offer superior strength, stability, and longevity, making them suitable for heavyduty lifting tasks in demanding environments. Steel Rolling Gantry Cranes are available in various configurations, including fixed or adjustable height, electric or manual driving, and different span options to accommodate diverse lifting requirements. They are commonly used in warehouses, manufacturing facilities, construction sites, and other industrial settings where heavy loads need to be lifted and moved efficiently. With their rugged construction and reliable performance, steel Rolling Gantry Cranes provide a dependable solution for businesses seeking durable and highcapacity material handling equipment.

Steel rolling gantry cranes are robust and versatile solutions widely used across industries for medium to heavyduty lifting operations. They offer exceptional strength and durability, making them suitable for demanding environments. Within this category, there are two main subtypes:

Fixed Height Rolling Gantry Crane on Wheels:

Fixed height rolling gantry crane with electric motor

Fixed height manual rolling gantry crane on wheels

These cranes maintain a constant height above the ground, offering stability during lifting operations. They are available in both electric and manual driving configurations, providing flexibility in operation based on the available power sources and user preferences.

Electric Driving: Powered by electric motors, these cranes offer smooth and efficient operation, suitable for repetitive lifting tasks requiring precision and control.

Manual Driving: Operated by manual effort, these cranes are costeffective and suitable for applications where power sources are limited or where occasional lifting tasks are required.

Adjustable Height Rolling Gantry Crane on Wheels:

Adjustable height manual rolling gantry crane

Adjustable height motor travelling and rolling gantry crane on castor

These cranes feature adjustable height capabilities, allowing users to vary the lifting height based on the specific requirements of the task at hand. Similar to fixed height cranes, they are available in both electric and manual driving configurations, providing versatility in operation.

Electric Driving: Equipped with electric actuators or hydraulic systems, these cranes offer effortless height adjustment, enhancing efficiency and adaptability in diverse lifting scenarios.

Manual Driving: Designed with userfriendly mechanisms for manual height adjustment, these cranes provide a costeffective solution for applications where variable lifting heights are needed infrequently.

Each subtype of steel rolling gantry crane offers distinct advantages and is suitable for different environments and lifting requirements. Understanding the specific features and capabilities of each type is essential in selecting the most appropriate crane for a particular application.

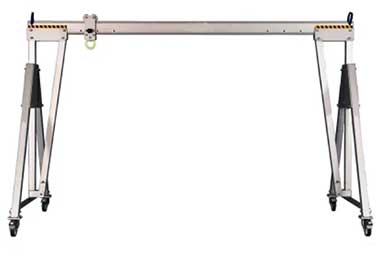

Aluminum Rolling Gantry Cranes:

Aluminum Rolling Gantry Cranes offer a lightweight and versatile solution for material handling applications across various industries. These cranes are engineered using aluminum, a material known for its strengthtoweight ratio, corrosion resistance, and durability. Designed to be portable and adaptable, Aluminum Rolling Gantry Cranes are ideal for indoor and outdoor use in environments where steel cranes may be impractical or where corrosion resistance is essential. With options for fixed or adjustable height, electric or manual driving, and various span configurations, these cranes can be tailored to suit specific lifting requirements. Aluminum Rolling Gantry Cranes are valued for their ease of maneuverability, quick setup, and ability to handle light to mediumduty lifting tasks efficiently. They provide a costeffective and environmentally friendly solution for businesses seeking reliable material handling equipment with minimal maintenance requirements.

Fixed Height Portable Rolling Gantry Crane on Wheels:

Fixed height lightweighted rolling gantry crane

Aluminum rolling gantry crane

Aluminum rolling gantry cranes are favored for their lightweight yet robust construction, making them suitable for various lifting applications where portability is key. The fixed height portable rolling gantry crane on wheels offers specific advantages:

Electric Driving:

Electricallydriven Mechanism: These cranes are equipped with electric motors that power the movement of the crane, providing smooth and efficient operation.

Precise Positioning: Electric driving allows for precise positioning of loads, enhancing productivity and safety during lifting operations.

Remote Control Option: Many electricallydriven models come with remote control capabilities, enabling operators to control the crane from a safe distance, further improving safety and convenience.

Suitable Applications: These cranes are wellsuited for environments where frequent load movement is required, such as assembly lines, workshops, and manufacturing facilities. They excel in scenarios where rapid and precise material handling is essential.

Manual Driving:

Versatility and Flexibility: Manual driving fixed height portable rolling gantry cranes provide a versatile lifting solution, especially in locations where access to electricity may be limited or impractical.

Ease of Operation: Operators can easily maneuver the crane manually using handoperated controls, allowing for precise positioning of loads with minimal effort.

Portability: The lightweight design of these cranes, coupled with their manual driving mechanism, makes them highly portable and suitable for use in outdoor or remote locations.

Applications: Manual driving portable rolling gantry cranes find utility in a wide range of industries, including agriculture, construction, and maintenance, where temporary lifting requirements exist or where infrastructure limitations prevent the use of powered equipment.

Additional Features:

Both electric and manual driving variants may feature adjustable span capabilities, allowing for customization to suit varying load sizes and workspace configurations.

Safety features such as emergency stop buttons, overload protection, and locking mechanisms ensure safe operation in all conditions.

Construction materials may include highgrade aluminum alloys for durability and corrosion resistance, ensuring longevity even in harsh environments.

Portability features such as foldable designs or detachable components further enhance ease of transportation and storage, making these cranes highly adaptable to changing work environments.

Aluminum Adjustable Height Portable Rolling Gantry Crane on Wheels

Aluminum adjustable height portable rolling gantry cranes offer versatility and adaptability, allowing operators to customize the crane's height to suit specific lifting requirements.

Lightweight aluminum adjsutable height rolling gantry crane

Lightweight aluminum adjsutable height rolling gantry crane

Key features of Aluminum Adjustable Rolling Gantry design include:

Electric Driving:

Height Adjustment Mechanism: Equipped with electric actuators or hydraulic systems, these cranes enable smooth and effortless height adjustments, enhancing operational flexibility.

Precise Control: Electric driving ensures precise positioning of the crane's lifting beam at various heights, facilitating efficient load handling and placement.

Remote Control Capability: Many electricallydriven models come with remote control functionality, allowing operators to adjust the crane's height remotely for added convenience and safety.

Applications: Ideal for environments where the elevation of loads may vary, such as production lines with different workstations or facilities with varying ceiling heights. They are also suitable for applications requiring frequent height adjustments, such as maintenance tasks in multilevel structures.

Manual Driving:

Height Adjustment Flexibility: Manual driving adjustable height portable rolling gantry cranes provide operators with the flexibility to adjust the crane's height manually using handoperated controls.

Simple Operation: With manual driving, operators can easily raise or lower the crane's lifting beam to the desired height, making them suitable for applications where power sources may be limited or inaccessible.

CostEffective Solution: Manual driving cranes offer a costeffective alternative to electricallydriven models, providing reliable height adjustment capabilities without the need for electrical components.

Applications: Commonly used in settings where occasional height adjustments are required, such as workshops, maintenance facilities, and construction sites.

Adjustable Span Aluminum Movable Rolling Gantry Cranes on Wheels:

Adjustable Span Aluminum Movable Rolling Gantry Cranes on Wheels

Adjustable Span Aluminum Movable Rolling Gantry Cranes on Wheels

Customizable Span: These gantry cranes feature an adjustable span, allowing users to extend or retract the distance between the crane's support legs to accommodate various load sizes and workspace configurations.

Enhanced Flexibility: The adjustable span feature enables users to optimize the crane's footprint based on specific lifting requirements, maximizing efficiency and workspace utilization.

Ease of Mobility: Equipped with wheels, these cranes are highly mobile, allowing for easy relocation within the facility or between different work areas.

Applications: Suitable for environments where flexibility in load handling and spatial constraints are common, such as manufacturing facilities with varying aisle widths or irregularly shaped workspaces.

Foldable Aluminum Profile Rolling Gantry:

Foldable rolling gantry crane, undlfolded for material handling operation

Foldable gantry crane folded to save your space

Space Saving Design: These gantry cranes feature a foldable aluminum profile structure, allowing for compact storage and transportation when not in use.

Quick Setup: The foldable design facilitates rapid deployment and assembly, minimizing downtime and maximizing productivity.

Durability and Portability: Constructed from lightweight yet sturdy aluminum profiles, these cranes offer a balance of durability and portability, making them suitable for both indoor and outdoor applications.

Applications: Ideal for temporary lifting tasks in settings where space is limited, such as event venues, construction sites, and workshops. They are also popular in industries where frequent crane relocation is required, such as maintenance and repair operations.

Heavy Duty Rolling Gantry Cranes on Rubber Tyred Wheels

Heavy Duty Rolling Gantry Cranes on Rubber Tyred Wheels are powerful material handling solutions designed for heavyduty lifting tasks in industrial environments. These cranes are engineered with robust steel frames and equipped with durable rubber tyred wheels, allowing them to navigate various surfaces with ease, including concrete, gravel, and uneven terrain. With lifting capacities ranging from 10 tons to over 200 tons, Heavy Duty Rolling Gantry Cranes on Rubber Tyred Wheels are capable of handling large and heavy loads with efficiency and precision.

These cranes are highly customizable, with options for fixed or adjustable heights, variable spans, and electrically powered drive systems for smooth and efficient operation. They are commonly used in industries such as construction, manufacturing, mining, and shipbuilding, where the handling of heavy materials and equipment is required. The mobility provided by the rubber tyred wheels enables these cranes to be easily relocated within the facility or between job sites, providing flexibility and versatility in material handling operations.

Heavy Duty Rolling Gantry Cranes on Rubber Tyred Wheels are designed for durability and reliability, with heavyduty components and robust construction that ensure longterm performance in demanding industrial environments. They offer a costeffective solution for businesses seeking efficient and versatile material handling equipment capable of handling heavy loads with ease.

Rubber Tyre Wheel Rolling Gantry Crane with A Frame Gantry

Rubber Tyre Wheel Rolling Gantry Crane with U Frame Gantry

Features of Heavy Duty Rolling Gantry Cranes on Rubber Tyred Wheels:

Robust Construction: Heavyduty rolling gantry cranes on rubber tyred wheels are engineered to withstand the demands of highcapacity lifting and rugged operating environments.

High Load Capacity: These cranes are designed to lift and move heavy loads with ease, making them suitable for applications requiring substantial lifting capabilities.

Enhanced Mobility: Equipped with durable rubber tyred wheels, these cranes offer excellent mobility and can traverse a variety of surfaces, including concrete floors, gravel, and uneven terrain.

Stability and Maneuverability: Despite their heavyduty construction, these cranes provide stable lifting operations while offering maneuverability to navigate through congested work areas.

Versatile Applications: Heavyduty rolling gantry cranes find application in industries such as manufacturing, shipbuilding, mining, and heavy construction, where lifting and transporting large, heavy components are commonplace.

Customization Options: These cranes often come with customization options to suit specific application requirements, including adjustable heights, spans, and lifting capacities.

Safety Features: Due to the nature of their operation and the loads they handle, heavyduty rolling gantry cranes prioritize safety features such as overload protection, emergency stop buttons, and locking mechanisms to ensure safe lifting operations.

Durability and Reliability: Constructed from highstrength materials such as steel or reinforced aluminum, these cranes are built to withstand harsh operating conditions and provide longterm reliability.

CostEffective Solutions: While heavyduty rolling gantry cranes may represent a significant investment upfront, their high load capacities and robust construction offer a costeffective solution for handling heavy loads over the long term, minimizing downtime and maintenance costs.

These cranes are indispensable assets in industries where heavy lifting is a routine part of operations, providing reliable and efficient material handling solutions to meet the demands of modern industrial environments. Whether lifting large machinery in manufacturing plants or handling heavy components in construction projects, heavyduty rolling gantry cranes on rubber tyred wheels offer the strength, mobility, and reliability required to get the job done safely and efficiently.

Features of Rolling Gantry Cranes Solutions

Rolling gantry cranes are distinguished by a multitude of features that contribute to their efficiency, safety, and suitability for various applications. Understanding these features is essential for selecting the right crane to meet specific operational requirements. Below are detailed explanations of the key features of rolling gantry cranes:

Structural Design Considerations:

Rolling gantry cranes are designed with a sturdy framework to withstand the stresses of lifting and moving heavy loads.

The structural design may vary based on the intended application, with considerations for factors such as load capacity, span, height clearance, and environmental conditions.

Material Specifications:

The choice of materials for construction plays a crucial role in the durability and performance of rolling gantry cranes.

Common materials include steel, aluminum, and alloy combinations, each offering unique properties such as strength, corrosion resistance, and weight.

Load Capacities:

Rolling gantry cranes are rated for specific load capacities, indicating the maximum weight they can safely lift and transport.

Load capacities vary widely depending on the crane's design, with options available for lightduty, mediumduty, and heavyduty applications.

Mobility Options:

Mobility is a key feature of rolling gantry cranes, allowing them to be easily repositioned as needed.

Cranes may be equipped with different types of wheels, such as castor wheels, rubber tyred wheels, or trackmounted systems, depending on the intended use and surface conditions.

Safety Features:

Safety features are paramount in rolling gantry crane design to prevent accidents and ensure the wellbeing of operators and bystanders.

Common safety features include overload protection, emergency stop buttons, limit switches, and locking mechanisms to secure the crane during operation.

Environmental Considerations (Indoor/Outdoor):

Rolling gantry cranes may be designed for indoor or outdoor use, with considerations for environmental factors such as temperature, humidity, and exposure to corrosive substances.

Outdoor cranes may require additional weatherproofing and corrosionresistant coatings to withstand harsh outdoor conditions, while indoor cranes may focus more on spacesaving designs and noise reduction.

By carefully evaluating these features in relation to specific operational requirements and environmental conditions, users can select the most suitable rolling gantry crane for their needs. Additionally, adherence to safety guidelines and regular maintenance practices are essential to ensure the continued safe and efficient operation of rolling gantry cranes throughout their service life.

Your Trusted Rolling Gantry Crane Manufacturer & Supplier

Typical Applications of Rolling Gantry Cranes

Rolling gantry cranes find a multitude of applications across various industries, thanks to their versatility, mobility, and lifting capabilities. From smallscale workshops to large industrial facilities, these cranes play a pivotal role in streamlining material handling processes and improving operational efficiency. In this section, we will explore some typical applications where rolling gantry cranes excel, ranging from indoor to outdoor environments and encompassing a wide range of industries.

Indoor Rolling Gantry Cranes:

Indoor Rolling Gantry Cranes are versatile material handling solutions designed for use in indoor environments such as warehouses, manufacturing facilities, workshops, and storage yards. These cranes are typically mounted on wheels or tracks, allowing them to move along designated pathways within the indoor space. With various configurations available, including fixed or adjustable heights, different span lengths, and electric or manual driving systems, indoor rolling gantry cranes offer flexibility and efficiency in lifting and moving materials.

Indoor Requirements for Rolling Gantry Cranes:

- Overhead Clearance: Adequate overhead clearance is essential to ensure that the crane can operate safely without obstruction. The indoor space should be free from lowhanging obstacles such as ductwork, pipes, or structural elements.

- Floor Surface: The floor surface should be level, smooth, and capable of supporting the crane's weight and the loads it will lift. Any unevenness or debris on the floor can affect the crane's stability and operation.

- Ventilation and Lighting: Proper ventilation and lighting are important for indoor working environments to ensure visibility and air quality. Adequate lighting reduces the risk of accidents and enhances productivity, while ventilation helps maintain a comfortable and safe working environment.

- Power Supply: Indoor rolling gantry cranes require access to a reliable power supply to operate electrically powered components such as motors, controls, and lighting. The power supply should be sufficient to meet the crane's electrical requirements without overloading the circuit.

- Space Availability: Sufficient space is needed for the crane to maneuver and perform lifting operations safely. The layout of the indoor space should allow for clear pathways and designated areas for loading, unloading, and storage of materials.

Common Problems with Indoor Rolling Gantry Crane Operations:

- Limited Space: Indoor environments often have limited space, which can pose challenges for maneuvering the crane and positioning loads. Tight spaces may require careful planning and coordination to avoid obstacles and ensure safe operation.

- Overhead Clearance Issues: Inadequate overhead clearance can restrict the crane's movement and limit its lifting height. It is essential to ensure sufficient clearance above the crane's path to prevent collisions with overhead obstacles.

- Floor Conditions: Uneven or damaged floor surfaces can affect the stability and smooth operation of the crane. Regular maintenance of the floor is necessary to prevent tripping hazards and ensure safe crane operation.

- Electrical Issues: Electrical components of the crane, such as motors, controls, and wiring, may experience malfunctions or failures due to electrical issues or power supply problems. Regular inspections and maintenance are essential to identify and address electrical issues promptly.

- Safety Concerns: Indoor rolling gantry crane operations require adherence to strict safety protocols to prevent accidents and injuries. Lack of proper training, inadequate safety measures, or disregard for safety guidelines can lead to accidents and damage to property or equipment.

- Material Handling Challenges: Efficient material handling requires careful planning, coordination, and precision to avoid damage to materials and ensure smooth workflow. Improper loading, unloading, or handling of materials can result in accidents, delays, and productivity losses.

Addressing these indoor requirements and potential problems with proactive planning, proper maintenance, and adherence to safety protocols ensures the smooth and safe operation of indoor rolling gantry cranes in industrial environments.

Small Rolling Gantry Crane Design Features:

Small rolling gantry cranes are often utilized in workshops, production lines, and assembly areas where space is limited.

Their compact size and maneuverability make them ideal for lifting and transporting small to mediumsized loads with precision.

These cranes may feature lightweight construction, adjustable heights, and ergonomic controls to enhance usability in confined spaces.

Indoor Rolling Gantry Cranes for Sale:

Low Headroom Portable Rolling Gantry Crane on Wheels:

Low headroom portable rolling gantry cranes are designed for facilities with limited vertical clearance, such as warehouses or workshops with low ceilings.

These cranes feature a compact design that allows them to operate effectively in spaces with restricted overhead space.

They may incorporate features like telescoping booms or adjustable height configurations to maximize lifting capabilities while minimizing headroom requirements.

Adjustable Height Rolling Gantry Cranes:

Adjustable height rolling gantry cranes offer flexibility in lifting operations, allowing operators to adapt the crane's height to varying load sizes or workspace configurations.

These cranes are commonly used in environments where multiple workstations or different lifting heights are present, such as manufacturing facilities or maintenance workshops.

The ability to adjust the crane's height ensures optimal positioning of loads and enhances overall operational efficiency.

Standard Mobile Rolling Gantry Cranes:

Standard mobile rolling gantry cranes are versatile solutions for indoor material handling tasks in diverse industrial settings.

Equipped with robust wheels, these cranes can be easily moved between different work areas, providing flexibility in lifting operations.

They are suitable for lifting a wide range of loads, from small components to larger machinery, making them indispensable in production, assembly, and logistics operations.

These indoor rolling gantry cranes cater to a variety of needs, offering efficient and reliable solutions for lifting and transporting materials within confined indoor spaces. Whether it's navigating tight aisles, adjusting to low ceiling heights, or accommodating different load sizes, these cranes are designed to optimize workflow and maximize productivity in indoor environments.

Outdoor Rolling Gantry Cranes

Outdoor Rolling Gantry Cranes are robust material handling solutions designed for use in outdoor environments such as construction sites, shipping yards, and outdoor storage facilities. These cranes are typically mounted on wheels or tracks, allowing them to move freely across uneven terrain and navigate outdoor obstacles. Outdoor rolling gantry cranes are engineered to withstand exposure to weather elements such as rain, wind, and temperature fluctuations, making them ideal for outdoor applications where heavy loads need to be lifted and moved with precision.

Outdoor Requirements for Rolling Gantry Cranes:

- Weather Resistance: Outdoor rolling gantry cranes must be constructed from materials that are resistant to corrosion, rust, and deterioration caused by exposure to weather elements. Stainless steel, galvanized steel, or aluminum are commonly used materials for outdoor crane construction.

- Terrain Adaptability: Outdoor environments often feature uneven terrain, gravel, or dirt surfaces that may pose challenges for crane mobility. Outdoor rolling gantry cranes should be equipped with rugged wheels or tracks capable of navigating various outdoor surfaces with ease.

- Overhead Clearance: Similar to indoor requirements, outdoor rolling gantry cranes require adequate overhead clearance to operate safely without obstruction from trees, power lines, or other overhead structures.

- Power Supply: Outdoor rolling gantry cranes may require access to a reliable power supply for electrically powered components such as motors, controls, and lighting. In remote outdoor locations, alternative power sources such as diesel generators may be necessary.

- Wind Considerations: Wind can affect the stability and operation of outdoor rolling gantry cranes, particularly when lifting heavy loads. Wind speed and direction should be monitored, and appropriate precautions should be taken to ensure crane stability and safety during windy conditions.

Common Problems with Outdoor Rolling Gantry Crane Operations:

- Weather Exposure: Exposure to weather elements such as rain, snow, and sunlight can cause wear and tear on crane components, leading to rust, corrosion, and deterioration. Regular inspection and maintenance are essential to address weatherrelated damage and ensure crane performance.

- Terrain Challenges: Uneven terrain, gravel, or dirt surfaces may affect the stability and maneuverability of outdoor rolling gantry cranes. Cranes equipped with inadequate wheels or tracks may struggle to navigate outdoor obstacles, leading to operational inefficiencies and potential safety hazards.

- Temperature Extremes: Extreme temperatures, whether hot or cold, can impact the performance and functionality of outdoor rolling gantry cranes. Components such as hydraulic systems, electrical wiring, and lubricants may be susceptible to temperaturerelated issues, requiring special considerations for operation in extreme climates.

- Wind Stability: High winds can pose a significant challenge for outdoor rolling gantry crane operations, particularly during lifting activities. Crane operators must exercise caution and implement wind speed restrictions to ensure crane stability and prevent accidents or tipovers.

- Dust and Debris: Outdoor environments may contain dust, dirt, and debris that can accumulate on crane components and affect performance. Regular cleaning and maintenance are necessary to remove debris and prevent damage to crane mechanisms and systems.

Addressing these outdoor requirements and potential problems with proper equipment selection, maintenance practices, and safety protocols ensures the reliable and safe operation of outdoor rolling gantry cranes in various outdoor environments.

Outdoor Rolling Gantry Cranes for Sale:

Small Rolling Gantry Crane Design Features:

Small outdoor rolling gantry cranes are versatile tools used in various outdoor applications, such as construction sites, shipyards, and storage yards.

Designed for portability and maneuverability, these cranes feature compact dimensions and lightweight construction, allowing them to navigate uneven terrain and tight spaces with ease.

They may be equipped with allterrain wheels or tracks to ensure stability and traction on rough surfaces, such as gravel, dirt, or grass.

These cranes often incorporate weatherresistant materials and corrosion protection to withstand exposure to the elements in outdoor environments.

Heavy Duty Rubber Tyred Wheel Rolling Gantry Crane Design Features:

Heavyduty rubber tyred wheel rolling gantry cranes are specifically engineered to handle large, heavy loads in outdoor settings where robust lifting capabilities are essential.

These cranes feature a rugged construction with reinforced frames, sturdy gantry beams, and highcapacity hoisting mechanisms to withstand heavyduty lifting tasks.

Equipped with durable rubber tyred wheels, these cranes offer excellent mobility and stability on outdoor surfaces, including gravel, asphalt, and concrete.

They may include advanced safety features such as antisway systems, overload protection, and emergency braking mechanisms to ensure safe operation in challenging outdoor conditions.

Heavyduty outdoor gantry cranes are commonly used in industries such as construction, mining, shipping, and material handling, where lifting and transporting large components or materials are routine operations.

These outdoor rolling gantry cranes are indispensable assets in outdoor work environments, providing reliable and efficient lifting solutions for a wide range of applications. Whether it's lifting construction materials on a job site or loading cargo onto ships in a port, these cranes are designed to withstand the rigors of outdoor use while delivering exceptional performance and productivity.

Hot Sale Types of Rolling Gantry Cranes

When it comes to rolling gantry cranes, several models stand out as hot sellers due to their popularity, reliability, and versatility. Below are the main specifications of some of the most soughtafter models in the market:

Model: Portable Steel Rolling Gantry Crane

Load Capacity: Up to 5 tons, 10 Ton

Span: 3 meters to 10 meters

Height: Adjustable from 2 meters to 6 meters

Mobility: Equipped with heavyduty castor wheels for easy maneuverability

Features: Steel construction for durability, adjustable height and span, manual or electric operation options

Model: Aluminum Adjustable Height Portable Rolling Gantry Crane

Load Capacity: Up to 2 tons

Span: Adjustable from 2 meters to 5 meters

Height: Electrically adjustable from 5 meters to 4 meters

Mobility: Fitted with nonmarking rubber tyred wheels for indoor and outdoor use

Features: Lightweight aluminum construction, adjustable height and span, remote control operation, foldable design for easy storage

Model: Heavy Duty Rubber Tyred Wheel Rolling Gantry Crane

Load Capacity: Up to 100 tons

Span: Customizable based on customer requirements

Height: According your requirement

Mobility: Heavy duty rubber tyred wheels with swivel locks for stability

Features: Robust steel construction, high load capacity, adjustable height and span, safety features including overload protection and emergency braking system

Model: Foldable Aluminum Profile Rolling Gantry

Load Capacity: Up to 3 tons

Span: 2 meters to 4 meters

Height: Adjustable from 1 meter to 3 meters

Mobility: Lightweight design with foldable aluminum profiles for easy transportation

Features: Foldable design for compact storage, adjustable height and span, manual operation, corrosionresistant aluminum construction

These hot sale types of rolling gantry cranes offer a wide range of options to suit various lifting requirements and applications. Whether it's lightweight portability, heavyduty lifting capacity, or adjustable height and span capabilities, these models are preferred choices among customers seeking reliable and efficient material handling solutions.

Comparison of Features and Capabilities

- Load Capacity: The load capacity of each model varies, ranging from lightduty options suitable for small workshops to heavyduty cranes capable of lifting large machinery and equipment.

- Span and Height Adjustability: Some models offer adjustable span and height features, allowing users to customize the crane's configuration based on the size of the workspace and the height of the loads being lifted.

- Mobility: Mobility options differ between models, with some equipped with castor wheels for easy maneuverability in indoor settings, while others feature rubber tyred wheels designed for outdoor use on various terrains.

- Construction Materials: The construction materials vary, with options including steel, aluminum, and alloy combinations. Steel cranes offer durability and strength, while aluminum cranes are lightweight and corrosionresistant, making them suitable for outdoor use.

- Operation: Operation can be manual or electric, with electrically driven cranes offering powered movement and precise control, while manual cranes provide a costeffective solution for applications where power sources may be limited.

- Safety Features: Safety features such as overload protection, emergency stop buttons, and locking mechanisms are essential components of all models, ensuring safe lifting operations and preventing accidents.

- Applications: Each model is designed to cater to specific applications, with some ideal for indoor use in workshops and production facilities, while others are suitable for outdoor environments such as construction sites, shipyards, and storage yards.

- Price and Costeffectiveness: Pricing varies based on factors such as load capacity, features, and construction materials. Customers should consider the overall value and costeffectiveness of each model in relation to their specific lifting requirements and budget constraints.

By comparing the features and capabilities of different models, customers can identify the rolling gantry crane that best meets their needs, ensuring optimal performance and efficiency in their material handling operations.

Application Suitability:

Portable Steel Rolling Gantry Crane:

Suitable for light to mediumduty lifting tasks in workshops, warehouses, and production facilities.

Ideal for applications requiring frequent repositioning of loads or workstations.

Aluminum Adjustable Height Portable Rolling Gantry Crane:

Wellsuited for indoor and outdoor use in settings such as maintenance workshops, construction sites, and event venues.

Perfect for applications where adjustable height and portability are essential, such as lifting equipment or materials to different levels.

Heavy Duty Rubber Tyred Wheel Rolling Gantry Crane:

Designed for heavyduty lifting operations in industries such as construction, mining, and shipbuilding.

Ideal for handling large and heavy loads in outdoor environments where ruggedness and reliability are paramount.

Foldable Aluminum Profile Rolling Gantry:

Suited for light to mediumduty lifting tasks in workshops, retail stores, and assembly lines.

Particularly useful in applications where space is limited, as the foldable design allows for easy storage and transportation.

Each type of rolling gantry crane is designed to excel in specific applications and environments, offering tailored solutions to meet the diverse needs of different industries. By considering the application suitability of each model, customers can ensure that they select the right crane for their specific lifting requirements, maximizing efficiency and productivity in their operations.

Your Trusted Rolling Gantry Crane Manufacturer & Supplier

Concerns and Questions of Rolling Gantry Crane Buyers and Users

Structural Integrity and Safety:

Buyers and users often express concerns regarding the structural integrity and safety features of rolling gantry cranes. They want assurances that the crane's construction meets industry standards and that safety features such as overload protection and emergency stop buttons are in place to prevent accidents.

Buyers and users are often concerned about the structural integrity of rolling gantry cranes and the safety measures in place to prevent accidents.

Questions may arise regarding the crane's design, construction materials, safety features, and adherence to industry standards and regulations.

Users may seek assurance of regular inspections and maintenance to ensure continued safety and reliability.

From the perspective of a rolling gantry crane manufacturer, addressing buyers and users' concerns regarding structural integrity and safety features is paramount to ensuring customer satisfaction and confidence in our products. Here's how we can effectively address these concerns:

- Compliance Assurance: We meticulously adhere to industry standards and regulations in the design and manufacturing process of our rolling gantry cranes. Our products undergo rigorous testing and certification procedures to ensure compliance, providing buyers and users with the assurance that our cranes meet the highest safety standards.

- Transparent Specifications: We provide comprehensive specifications detailing the structural components of our rolling gantry cranes, including the materials used, design features, and load capacities. By offering transparent and detailed information, we instill confidence in the strength, reliability, and safety of our products.

- Emphasis on Safety Features: Our rolling gantry cranes are equipped with advanced safety features such as overload protection systems, emergency stop buttons, and limit switches. We prioritize safety in our designs to prevent accidents and protect both personnel and equipment during lifting operations.

- Demonstrations and Testing: We conduct thorough demonstrations and testing of our rolling gantry cranes to showcase the effectiveness of their safety features. Whether through live demonstrations or video presentations, we provide buyers and users with visual evidence of how our cranes operate safely in realworld scenarios.

- Customer Testimonials and Case Studies: We share testimonials and case studies from satisfied customers who have experienced the reliability and safety of our rolling gantry cranes firsthand. These testimonials serve as compelling evidence of our commitment to delivering highquality, safe, and dependable products.

- Training and Education: We offer comprehensive training programs and educational resources to users on the proper operation, safety procedures, and maintenance practices of our rolling gantry cranes. By empowering users with knowledge and skills, we enhance safety awareness and promote accident prevention.

- Continued Support: Our commitment to customer satisfaction extends beyond the initial purchase. We provide ongoing support, technical assistance, maintenance services, and access to spare parts throughout the lifecycle of our rolling gantry cranes. Our dedicated support ensures that buyers and users receive prompt assistance and solutions to any safety concerns or issues that may arise.

By adopting these strategies, we demonstrate our unwavering dedication to addressing buyers and users' concerns regarding structural integrity and safety features in our rolling gantry cranes. We prioritize safety, reliability, and customer satisfaction in everything we do, ensuring that our products meet and exceed the expectations of our valued customers.

Load Capacity and Handling:

Understanding the crane's load capacity and capabilities is crucial for buyers and users. They want to ensure that the crane can handle the types of loads they need to lift safely and efficiently. Questions may arise regarding the crane's lifting capacity, reach, and compatibility with different load sizes and shapes.

Understanding the crane's load capacity and its ability to handle various types of loads is crucial for buyers and users.

Questions may arise regarding the crane's lifting capabilities, load distribution, and proper load handling techniques.

Users may seek guidance on load calculations, weight distribution, and the use of lifting accessories to ensure safe lifting operations.

As a rolling gantry crane manufacturer, addressing buyers and users' concerns regarding load capacity and handling capabilities is essential to demonstrate the effectiveness of our products. Here's how we can show that our rolling gantry crane can solve their concerns:

- Comprehensive Load Capacity Information: We provide detailed specifications outlining the load capacity of our rolling gantry cranes, including both maximum and rated capacities. This information helps buyers and users understand the crane's lifting capabilities and ensures they can safely lift their desired loads.

- Customized Solutions: We offer customization options to tailor our rolling gantry cranes to meet specific load handling requirements. Whether it's adjusting the crane's span, height, or adding specialized lifting attachments, we can customize the crane to accommodate different load sizes, shapes, and weights.

- Load Testing and Validation: We conduct rigorous load testing and validation procedures to verify the lifting capacity and performance of our rolling gantry cranes. By testing the crane under various load conditions, we ensure that it can handle the intended loads safely and efficiently.

- Visual Demonstrations: We provide visual demonstrations or simulations showcasing our rolling gantry crane lifting various types of loads. This allows buyers and users to see firsthand how the crane operates and how it handles different load sizes and shapes with ease.

- Case Studies and Success Stories: We share case studies and success stories from satisfied customers who have successfully used our rolling gantry cranes to handle a wide range of loads. These realworld examples demonstrate the crane's versatility and reliability in different applications.

- Expert Consultation: Our team of experts is available to provide consultation and guidance to buyers and users on selecting the right rolling gantry crane for their specific load handling needs. We offer personalized recommendations based on factors such as load weight, dimensions, and lifting frequency.

- Continuous Improvement: We continuously invest in research and development to enhance the load handling capabilities of our rolling gantry cranes. By staying abreast of industry trends and advancements, we ensure that our products remain at the forefront of innovation in load handling technology.

By implementing these strategies, we can effectively demonstrate to buyers and users that our rolling gantry crane is capable of solving their concerns regarding load capacity and handling. We emphasize safety, reliability, and efficiency in our products, providing customers with confidence in their ability to safely and efficiently handle their desired loads.

1 ton rolling gantry crane , custom for cleanroom application

3 ton gantry crane with rolling crane design for truck loading and unloading

5 ton + 5 ton portable gantry crane with double hoists and low headroom design

2 ton small rolling gantry crane for subway construction

10 ton gantry crane with rolling gantry design and double girder for heavy loads handling

30 ton double girder gantry crane with rubber tyred wheels for precast concrete part handling

Mobility and Terrain Adaptability:

Users operating rolling gantry cranes outdoors or in environments with uneven terrain may have concerns about the crane's mobility and adaptability. They want to know if the crane's wheels or tracks can navigate various surfaces effectively and if it can withstand exposure to outdoor elements such as rain, wind, and temperature fluctuations.

Buyers and users may have concerns about the crane's mobility and its ability to navigate different types of terrain.

Questions may arise regarding the suitability of the crane's wheels or tracks for specific surfaces, such as concrete, gravel, or grass.

Users may seek recommendations for terrain adaptations or additional equipment, such as outriggers or stabilizers, to enhance stability and maneuverability.

To address buyers and users' concerns regarding mobility and terrain adaptability of our rolling gantry cranes, we, as the manufacturer, can demonstrate how our products solve these concerns effectively:

- AllTerrain Mobility: Our rolling gantry cranes are designed with robust wheels or tracks that can navigate various surfaces with ease, including concrete, gravel, dirt, grass, and uneven terrain. We conduct extensive testing to ensure that our cranes maintain stability and maneuverability in diverse outdoor environments.

- WeatherResistant Construction: Our cranes feature weatherresistant materials and coatings to withstand exposure to outdoor elements such as rain, wind, and temperature fluctuations. We prioritize durability and longevity, ensuring that our cranes can withstand the rigors of outdoor use over extended periods.

- Stability Enhancements: We incorporate stability enhancements such as adjustable outriggers, leveling mechanisms, and swivel locks to improve the crane's stability on uneven terrain. These features provide additional support and security, minimizing the risk of accidents or tipping in challenging outdoor conditions.

- Terrain Adaptation Features: Our rolling gantry cranes are equipped with features that facilitate terrain adaptation, such as pneumatic tires, articulated axles, and suspension systems. These features allow the crane to adjust to changes in terrain and maintain optimal performance across different surfaces.

- Demonstrations and Testing: We conduct demonstrations and testing of our rolling gantry cranes in realworld outdoor environments to showcase their mobility and terrain adaptability. By witnessing the crane's performance firsthand, buyers and users can gain confidence in its ability to operate effectively outdoors.

- Customer Testimonials: We share testimonials and feedback from customers who have successfully used our rolling gantry cranes in outdoor settings. These testimonials serve as evidence of our cranes' reliability, durability, and effectiveness in overcoming mobility and terrain challenges.

- Tailored Solutions: We offer customization options to tailor our rolling gantry cranes to specific outdoor environments and applications. Whether it's adding specialized wheels, reinforcing the frame, or incorporating weatherproofing features, we can customize the crane to meet unique terrain and weather conditions.

By emphasizing the mobility and terrain adaptability features of our rolling gantry cranes and providing evidence of their effectiveness through testing, demonstrations, and customer testimonials, we can assure buyers and users that our products are wellequipped to handle outdoor operations with ease and reliability.

Maintenance and Serviceability:

Maintenance requirements and serviceability are important considerations for buyers and users looking to invest in a rolling gantry crane. They want to know about routine maintenance tasks, recommended service intervals, and availability of spare parts. Additionally, they may seek information on warranty coverage and aftersales support from the manufacturer or supplier.

Maintenance requirements and serviceability are essential considerations for buyers and users to ensure the longevity and reliability of rolling gantry cranes.

Questions may arise regarding recommended maintenance schedules, lubrication procedures, and troubleshooting techniques.

Users may seek information on the availability of spare parts, access to technical support, and training for inhouse maintenance personnel.

To address buyers and users' concerns regarding maintenance requirements and serviceability of our rolling gantry cranes, we, as the manufacturer, can demonstrate how our products solve these concerns effectively:

- Comprehensive Maintenance Guidelines: We provide detailed maintenance guidelines outlining routine tasks, recommended service intervals, and lubrication schedules for our rolling gantry cranes. These guidelines ensure that users can properly maintain their cranes to optimize performance and longevity.

- Easy Access to Spare Parts: We maintain a comprehensive inventory of spare parts for our rolling gantry cranes, ensuring quick availability and delivery to minimize downtime in the event of component failure or wear. Users can easily procure genuine replacement parts directly from us, guaranteeing compatibility and reliability.

- UserFriendly Design: Our rolling gantry cranes are designed with userfriendly features that simplify maintenance tasks and serviceability. Accessible service points, toolless component removal, and clear labeling facilitate efficient maintenance and troubleshooting, reducing the time and effort required for servicing.

- Training and Support: We offer training programs and technical support to users on proper maintenance procedures, troubleshooting techniques, and repair protocols for our rolling gantry cranes. Through comprehensive training and ongoing support, users gain the knowledge and skills necessary to maintain their cranes effectively.

- Warranty Coverage: Our rolling gantry cranes are backed by warranty coverage to provide users with peace of mind and assurance of quality. We offer generous warranty periods and comprehensive coverage for parts and labor, ensuring that users are protected against defects and malfunctions during the warranty period.

- AfterSales Service: We provide dedicated aftersales service and support to assist users with any maintenancerelated inquiries, issues, or concerns. Our experienced service team is available to provide prompt assistance, technical advice, and onsite support to address maintenance needs and ensure customer satisfaction.

- Continuous Improvement: We continually strive to improve the maintenance requirements and serviceability of our rolling gantry cranes through feedback from users and ongoing research and development efforts. By implementing enhancements and updates based on user input and technological advancements, we ensure that our cranes remain easy to maintain and service over their lifecycle.

By highlighting these strategies and demonstrating our commitment to providing comprehensive maintenance support and serviceability features, we can assure buyers and users that our rolling gantry cranes are designed for reliability, longevity, and ease of maintenance.

Cost-effectiveness and Return on Investment:

Costeffectiveness is a significant concern for buyers evaluating the purchase of a rolling gantry crane. They want to assess the total cost of ownership, including initial purchase price, installation costs, ongoing maintenance expenses, and potential energy consumption. Buyers also seek information on the expected return on investment, considering factors such as increased productivity, reduced labor costs, and improved workplace safety.

Buyers and users are concerned about the overall costeffectiveness of rolling gantry cranes and the return on investment over their lifecycle.

Questions may arise regarding initial purchase costs, operating expenses, and potential savings or efficiencies gained through crane use.

Users may seek costbenefit analyses, financial projections, and recommendations for maximizing ROI through proper usage and maintenance practices.

To address buyers and users' concerns regarding costeffectiveness and return on investment (ROI) of our rolling gantry cranes, we, as the manufacturer, can demonstrate how our products solve these concerns effectively:

- Total Cost of Ownership Analysis: We provide buyers with a comprehensive analysis of the total cost of ownership (TCO) associated with our rolling gantry cranes. This includes not only the initial purchase price but also installation costs, ongoing maintenance expenses, and estimated energy consumption over the crane's lifecycle. By transparently presenting the TCO, buyers can make informed decisions and evaluate the longterm affordability of our cranes.

- Customized Solutions for Specific Applications: We offer customized solutions tailored to meet the specific needs and requirements of buyers' applications. Whether it's adjusting the crane's size, capacity, or features, we work closely with buyers to optimize the crane's performance and minimize unnecessary costs. Our tailored solutions ensure that buyers only invest in the features and capabilities they truly need, maximizing costeffectiveness.

- ROI Calculation: We assist buyers in calculating the expected return on investment (ROI) of our rolling gantry cranes. This involves analyzing potential productivity gains, labor cost savings, and improvements in workplace safety resulting from the crane's deployment. By quantifying the anticipated ROI, buyers can assess the financial benefits of investing in our cranes and make informed investment decisions.

- Efficiency Enhancements: Our rolling gantry cranes are designed for efficiency, with features such as smooth operation, quick setup, and minimal downtime. These efficiency enhancements contribute to increased productivity and reduced operational costs, further enhancing the overall costeffectiveness of our cranes.

- Energy Efficiency: We prioritize energy efficiency in the design of our rolling gantry cranes, incorporating energysaving features such as variable frequency drives (VFDs), regenerative braking systems, and lowpower consumption components. By minimizing energy consumption, our cranes help buyers reduce their operating costs and environmental footprint, enhancing longterm costeffectiveness.

- Case Studies and Success Stories: We share case studies and success stories from satisfied customers who have realized significant cost savings and ROI with our rolling gantry cranes. These realworld examples serve as proof of the tangible financial benefits that our cranes can deliver, inspiring confidence in their costeffectiveness.

- Continuous Improvement: We continually innovate and improve our rolling gantry cranes to enhance their costeffectiveness and ROI for buyers. By incorporating feedback from customers and leveraging advancements in technology, we ensure that our cranes remain competitive and deliver maximum value over their lifecycle.

By demonstrating these strategies and showcasing the costeffectiveness and ROI potential of our rolling gantry cranes, we can assure buyers and users that our products offer compelling financial benefits and represent a smart investment for their material handling needs.

Environmental Impact and Regulations:

Environmental considerations and compliance with regulations are increasingly important for buyers and users of rolling gantry cranes. They may have questions about the crane's energy efficiency, emissions, and potential environmental impact. Additionally, they want assurance that the crane meets relevant safety standards and regulations set forth by governing bodies in their region.

Environmental considerations and compliance with regulations are important concerns for buyers and users of rolling gantry cranes.

Questions may arise regarding emissions, noise levels, and waste management practices associated with crane operation.

Users may seek guidance on environmental regulations, such as emissions standards, noise ordinances, and waste disposal requirements, to ensure compliance and minimize environmental impact.

To address buyers and users' concerns regarding environmental impact and regulations associated with our rolling gantry cranes, we, as the manufacturer, can demonstrate how our products solve these concerns effectively:

- EnvironmentalFriendly Design: Our rolling gantry cranes are designed with a focus on environmental sustainability. We prioritize energy efficiency by incorporating features such as regenerative braking systems, variable frequency drives (VFDs), and lowpower consumption components. By minimizing energy consumption, our cranes reduce greenhouse gas emissions and lower their environmental footprint.

- Compliance with Regulations: We ensure that our rolling gantry cranes comply with all relevant safety standards and regulations set forth by governing bodies in the regions where they are deployed. Our products undergo rigorous testing and certification processes to verify compliance, providing buyers with assurance of their safety and legality.

- Emissions Reduction: Our rolling gantry cranes are engineered to minimize emissions and pollutants during operation. By employing clean and efficient technologies, such as electric motors and batterypowered systems, we reduce air and noise pollution in the surrounding environment. This commitment to emissions reduction aligns with global sustainability goals and regulatory requirements.

- Environmental Impact Assessment: We conduct environmental impact assessments for our rolling gantry cranes, evaluating factors such as noise levels, air quality, and habitat disturbance. This comprehensive assessment helps us identify potential environmental risks and implement mitigation measures to minimize our cranes' impact on the environment.

- Recyclability and Sustainable Materials: We source recyclable and sustainable materials for the construction of our rolling gantry cranes wherever possible. By prioritizing ecofriendly materials and manufacturing processes, we reduce waste generation and promote circular economy principles. Additionally, we offer recycling and disposal services for endoflife crane components to minimize environmental impact.

- Educational Resources: We provide educational resources and training programs to buyers and users on environmental best practices and regulatory compliance. Our aim is to empower users with the knowledge and tools needed to operate our cranes in an environmentally responsible manner, ensuring compliance with regulations and minimizing ecological harm.

- Continuous Improvement: We continuously strive to improve the environmental performance of our rolling gantry cranes through research, innovation, and technology development. By staying abreast of emerging environmental trends and regulations, we proactively adapt our products to meet evolving sustainability requirements and customer expectations.

By implementing these strategies and demonstrating our commitment to environmental stewardship, we can assure buyers and users that our rolling gantry cranes are designed to minimize environmental impact and comply with regulations, providing sustainable material handling solutions for their operations.

Addressing these concerns and questions effectively is essential for providing buyers and users with the information and confidence they need to make informed decisions about selecting and using rolling gantry cranes. By addressing these topics comprehensively, manufacturers and suppliers can demonstrate their commitment to safety, quality, and customer satisfaction.

Conclusion: Custom Rolling Gantry Cranes, Your Cost-effective Gantry Crane Solution

In conclusion, the discussion on rolling gantry cranes has highlighted several key points that are crucial for buyers and users to consider.

Firstly, we explored the diverse range of rolling gantry crane types available, each with unique features and capabilities tailored to specific applications. From small portable cranes to heavyduty models, the versatility and adaptability of rolling gantry cranes make them indispensable in various industries.

Secondly, we addressed the concerns and questions that buyers and users commonly have regarding structural integrity, safety, load capacity, mobility, maintenance, costeffectiveness, and environmental impact. These considerations underscore the importance of thorough evaluation and informed decisionmaking when selecting the right rolling gantry crane for specific needs.

Furthermore, we discussed the solutions available to address these concerns, including consultation and assessment services, customization options, training and support for operation and maintenance, warranty and aftersales service, recommendations for optimal use and efficiency, and compliance with industry standards and regulations.

It is evident that selecting the right rolling gantry crane is paramount to ensuring safe, efficient, and costeffective material handling operations. By understanding the unique requirements of their applications and considering factors such as load capacity, mobility, and safety features, buyers and users can make informed decisions that maximize productivity and ROI.

Looking ahead, future trends and advancements in rolling gantry crane technology are expected to focus on innovation in materials, design, automation, and digitalization. These advancements aim to further enhance crane performance, reliability, and efficiency, catering to the evolving needs of modern industrial environments.

In summary, the selection of the right rolling gantry crane is a critical decision that requires careful consideration of various factors. By prioritizing safety, efficiency, and suitability for specific applications, buyers and users can harness the full potential of rolling gantry cranes to optimize their material handling operations and drive productivity in their industries.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch