Wireless Remote Control EOT Crane for Sale 3Ton to 80 Ton

Wireless remote control EOT cranes enhance safety and efficiency, enabling operators to manage heavy loads from a safe distance effortlessly.

Category: Featured

Your Trusted Wireless Remote Control Overhead Crane Manufacturer & Supplier

Wireless Remote Control EOT Crane for Sale 3Ton to 80 Ton

Wireless remote control EOT cranes enhance safety and efficiency, enabling operators to manage heavy loads from a safe distance effortlessly.

Overhead cranes are vital equipment in various industrial applications, playing a crucial role in material handling and logistics. These cranes enable the safe and efficient movement of heavy loads, such as machinery, steel beams, and large components, within warehouses, manufacturing plants, and construction sites. Their ability to lift and transport items across a defined area helps streamline operations, improve productivity, and enhance safety in busy work environments.

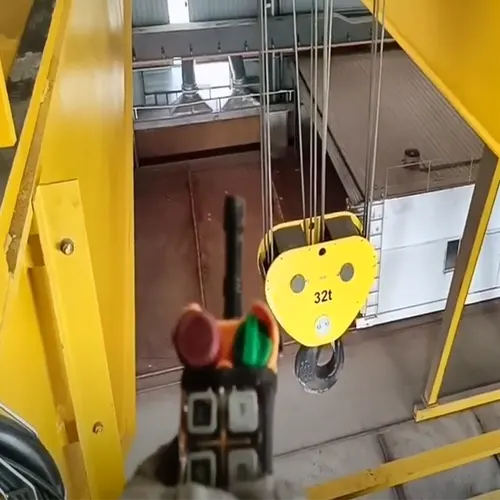

The introduction of wireless remote control technology has revolutionized crane operations. This advancement allows operators to control cranes from a safe distance, minimizing their exposure to potential hazards. Wireless systems offer greater flexibility and precision, enabling smoother maneuvers and improved visibility. As a result, companies can achieve higher efficiency and safety standards in their operations.

Types of Wireless Remote Control EOT Cranes for Sale

Single girder EOT cranes consist of a single bridge girder that supports the hoist and trolley. They are particularly advantageous for lighter loads, typically ranging from 1 ton to 20 tons. Their design allows for efficient space utilization, making them suitable for warehouses, manufacturing plants, and assembly lines. The wireless remote control enhances operator safety by allowing control from a distance, minimizing the risk of accidents during lifting operations. Additionally, these cranes are often more cost-effective and easier to install compared to their double girder counterparts.

Double girder EOT cranes are built with two parallel girders, providing greater stability and capacity for heavier loads, typically ranging from 10 tons to over 100 tons. Their robust design enables them to span larger distances, making them ideal for heavy industrial applications like steel mills and heavy manufacturing. The added strength of double girder cranes allows for more extensive lifting capabilities, and the wireless remote control feature ensures precision and safety during operation. Operators can maneuver large items efficiently, reducing downtime and enhancing productivity.

Underrunning EOT cranes, also known as underhung cranes, run on tracks that are mounted beneath the support structure, allowing for a more compact design. These cranes are ideal for low-headroom applications and are often used in environments where space is at a premium, such as smaller workshops or factories. The wireless remote control system enables operators to easily navigate tight spaces and handle loads efficiently while maintaining a safe distance from potential hazards. Underrunning cranes are particularly effective for light to medium-duty tasks, offering flexibility in various operational settings.

Explosion-proof EOT cranes are specifically designed for use in hazardous environments where flammable gases, vapors, or dust may be present. These cranes are constructed with specialized materials and features that prevent ignition, ensuring safety in industries such as oil and gas, chemical processing, and mining. The incorporation of wireless remote control technology allows operators to maintain a safe distance from potential dangers while still effectively managing heavy loads. This combination of explosion-proof construction and remote operation significantly reduces the risk of accidents and enhances operational safety in high-risk areas.

Choosing the right type of wireless remote control EOT crane is essential for maximizing safety and efficiency in material handling operations. Each type—whether single girder, double girder, underrunning, or explosion-proof—offers unique advantages tailored to specific applications. Consider your operational needs to select the most suitable crane for your facility.

Specialized EOT Cranes with Wireless Remote Control

These include customized EOT cranes tailored for specific applications, such as those used in steel mills, shipyards, or power plants. They may feature specialized hoists or attachments for handling unique loads. Wireless remote control systems enhance operational efficiency and safety in these specialized environments.

Steel Mill Cranes

- Description: Designed for heavy lifting of hot metal and steel products, these cranes feature high-temperature resistant materials and magnetic hoists.

- Wireless Control: Enables operators to manage loads safely from a distance, reducing exposure to heat and potential hazards.

Shipyard Cranes

- Description: Built for the assembly and maintenance of large vessels, these cranes have longer spans and high lifting capacities.

- Wireless Control: Provides precise maneuvering in tight spaces, allowing operators to lift multiple components simultaneously without physical interference.

Power Plant Cranes

- Description: Tailored for handling heavy machinery like turbines and generators, these cranes offer increased lifting heights and enhanced stability.

- Wireless Control: Facilitates safe operation in complex environments, enabling distance control to avoid hazards associated with heavy lifting.

Automotive Manufacturing Cranes

- Description: These cranes are equipped with adjustable hoist systems for precise positioning of automotive parts during assembly.

- Wireless Control: Simplifies the operation process, allowing quick adjustments and enhancing efficiency on assembly lines.

Construction Cranes

- Description: Modular and rugged, these cranes are designed to lift heavy construction materials in various job site conditions.

- Wireless Control: Increases safety by allowing operators to control lifts from a safe distance, particularly in busy construction environments.

Mining Cranes

- Description: Engineered to operate in harsh environments, these cranes are built for heavy-duty lifting of mining equipment and materials.

- Wireless Control: Enhances safety by enabling remote operation in hazardous conditions, reducing risks to personnel.

Custom Specialty Cranes

- Description: Tailored to specific applications across various industries, such as hazardous materials handling or precision assembly tasks.

- Wireless Control: Allows for specialized remote operations, enhancing safety and efficiency based on the unique requirements of each application.

Specialized EOT cranes with wireless remote control technology are crucial for improving safety and operational efficiency across various industries. By allowing operators to manage heavy loads from a safe distance, these cranes mitigate risks associated with lifting in challenging environments, ultimately enhancing productivity and safety.

Applications and Features

When selecting a wireless remote control EOT crane, it's essential to consider the specific needs of your operation, including load capacity, environment, and space constraints. Each type of crane offers distinct advantages, and integrating wireless technology can significantly enhance safety and efficiency in material handling. Explore available options to find the best fit for your operational requirements.

Steel Mill Cranes with Wireless Remote Control

Steel Mills Specialty cranes in steel mills are built to handle heavy and hot materials, such as molten metal and large steel beams. They may include high-temperature resistant components and advanced hoisting systems. Features like magnetic lifts or ladle handling attachments are often integrated to facilitate the safe movement of hot metal and heavy steel products. The wireless remote control system enhances operational efficiency, allowing operators to manage complex lifting tasks from a safe distance.

Types of Steel Mill Cranes

Ladle Cranes

- Description: Specifically designed to handle molten metal, ladle cranes feature high-temperature resistant components and specialized attachments for ladles.

- Wireless Control: Allows operators to maneuver loads from a safe distance, minimizing exposure to extreme heat and reducing the risk of accidents.

Magnetic Lifting Cranes

- Description: Equipped with magnetic hoists, these cranes are ideal for moving steel sheets and beams. The magnetic system securely grips ferromagnetic materials for efficient handling.

- Wireless Control: Facilitates precise control over lifting and positioning, enhancing safety by allowing operators to manage heavy loads without direct contact.

Double Girder EOT Cranes

- Description: Designed for heavy-duty applications, these cranes provide increased stability and capacity for lifting large steel products. Their dual girder design offers superior strength.

- Wireless Control: Enhances operational flexibility by allowing remote management of loads, thus improving safety and efficiency in high-stress environments.

Single Girder EOT Cranes

- Description: Suitable for lighter loads, these cranes are compact and versatile, making them ideal for various tasks in steel mills, including handling smaller components and scrap materials.

- Wireless Control: Simplifies operation and reduces the need for extensive operator training, promoting safety and efficiency in everyday lifting tasks.

Crane Systems with High-Speed Hoists

- Description: These cranes are equipped with advanced hoisting systems that allow for rapid lifting and lowering of materials, crucial in fast-paced steel production environments.

- Wireless Control: Provides operators with the ability to perform quick maneuvers, reducing cycle times and enhancing productivity while maintaining a safe distance from hazardous materials.

Steel mill cranes with wireless remote control are essential for handling heavy and hot materials safely and efficiently. Their specialized designs cater to the unique challenges of steel production, while wireless technology enhances operational control, reducing risks associated with high-temperature environments. By investing in these advanced cranes, steel mills can significantly improve both safety and productivity.

Shipyard Cranes with Wireless Remote Control

Shipyards In shipyards, specialty cranes are used for heavy lifting of ship components, including hull sections and engines. These cranes often have longer spans and higher lifting capacities to accommodate large maritime structures. Some models may feature dual hoists or specialized trolleys for simultaneous lifting and positioning of multiple loads. The incorporation of wireless remote control ensures precise maneuvering in tight spaces, improving safety and productivity during ship assembly and repair operations.

Types of Shipyard Cranes

Gantry Cranes

- Description: Designed for heavy lifting, gantry cranes have a robust structure that allows them to span large areas, making them ideal for moving hull sections and heavy ship components.

- Wireless Control: Enables operators to maneuver loads with precision from a distance, enhancing safety in busy shipyard environments.

Overhead Cranes

- Description: These cranes are mounted on elevated tracks, providing a high lifting capacity and the ability to lift large, heavy items like engines and complete assemblies.

- Wireless Control: Allows for intuitive operation and precise control during complex lifting tasks, minimizing the risk of accidents.

Floating Cranes

- Description: Used in wet docks and harbors, floating cranes are designed for marine environments and can handle heavy loads directly from the water.

- Wireless Control: Offers the ability to control lifting operations from a safe distance, crucial for operations involving large, cumbersome loads in challenging conditions.

Dual Hoist Cranes

- Description: Equipped with two hoists, these cranes can lift multiple components simultaneously, improving efficiency during ship assembly.

- Wireless Control: Provides operators with enhanced flexibility and safety, allowing for coordinated lifting of large parts without physical proximity.

Specialized Trolley Cranes

- Description: Featuring adjustable trolleys, these cranes can move along the length of the shipyard, allowing for efficient handling of various loads and complex assembly tasks.

- Wireless Control: Facilitates precise positioning and control, crucial for navigating tight spaces and ensuring safe operations.

Shipyard cranes with wireless remote control technology play a vital role in the efficient and safe handling of large ship components. Their specialized designs and advanced control systems enhance operational flexibility, reduce risks associated with heavy lifting, and improve overall productivity during ship assembly and repair. Investing in these advanced cranes allows shipyards to streamline their operations while prioritizing safety and efficiency.

Power Plant Cranes with Wireless Remote Control

Power Plants Cranes used in power plants are designed for the handling of heavy equipment, such as turbines and generators. These specialty cranes may have features such as increased lifting heights and enhanced stability to accommodate the specific operational requirements of power generation facilities. Wireless remote control systems are crucial in these settings, allowing operators to navigate complex environments while minimizing exposure to potential hazards.

Types of Power Plant Cranes

Turbine Installation Cranes

- Description: Specifically designed for the heavy lifting of turbines, these cranes feature increased lifting capacities and height to accommodate the unique requirements of power generation.

- Wireless Control: Enables operators to position heavy turbines precisely from a safe distance, reducing the risk of accidents during installation.

Generator Handling Cranes

- Description: Built for the safe and efficient handling of generators, these cranes often include specialized attachments for secure lifting and maneuvering.

- Wireless Control: Facilitates remote operation, allowing for safer navigation around heavy and bulky equipment.

Bridge Cranes

- Description: These cranes are installed on tracks that span the facility, providing the ability to lift and move heavy loads across significant distances within the plant.

- Wireless Control: Enhances operational flexibility, allowing operators to control movements without being directly underneath the load, thus minimizing exposure to hazards.

A-Frame Cranes

- Description: A-Frame cranes are designed for lifting heavy components in confined spaces, often used in maintenance and repair applications within power plants.

- Wireless Control: Offers improved maneuverability in tight areas, enabling safe and efficient operation during critical tasks.

Maintenance Hoists

- Description: These cranes are specifically designed for routine maintenance of power plant equipment, featuring lighter construction for ease of use while still maintaining sufficient lifting capacity.

- Wireless Control: Simplifies operations by allowing technicians to perform tasks safely from a distance, reducing the chance of accidents during maintenance activities.

Cranes used in power plants are essential for the safe and efficient handling of heavy equipment like turbines and generators. Their specialized designs and the integration of wireless remote control systems enhance operational safety and efficiency, allowing operators to navigate complex environments with minimal exposure to hazards. By investing in these advanced cranes, power plants can significantly improve their operational capabilities while prioritizing the safety of their workforce.

Advantages of Specialty Cranes

Customization

Specialty cranes can be specifically designed and tailored to meet the unique requirements of various industries, such as steel mills, shipyards, and power plants. This customization enhances their functionality, ensuring they can effectively handle the specific types of loads and operational challenges faced in each environment. Features like specialized hoists, attachments, and construction materials are incorporated to maximize performance and efficiency.

Safety

Safety is a paramount concern in industrial settings, and specialty cranes are equipped with advanced safety features. These may include anti-collision systems that prevent accidents by detecting obstacles and adjusting movements accordingly, as well as load monitoring systems that ensure loads are within safe operating limits. Such enhancements significantly reduce the risk of accidents, particularly in high-stakes environments where heavy lifting is routine.

Operational Efficiency

The integration of wireless remote control technology allows for improved load management and maneuverability. Operators can manage lifting tasks from a safe distance, enabling more precise control over heavy loads. This not only reduces the time required for each lift but also streamlines workflows, leading to faster cycle times and increased productivity. By minimizing delays and improving coordination, specialty cranes contribute to more efficient operations overall.

The advantages of specialty cranes—customization, enhanced safety features, and operational efficiency—make them invaluable assets in various industrial applications. By investing in these advanced lifting solutions, companies can ensure they meet their specific operational needs while prioritizing safety and productivity.

Specialty cranes play a vital role in industries with unique lifting requirements, offering tailored solutions that enhance safety and operational efficiency. By integrating wireless remote control technology, these cranes provide operators with greater control and flexibility, making them essential for successful material handling in specialized environments.

Key Features of Wireless Remote Control EOT Cranes

User-Friendly Remote Controls

Wireless remote control EOT cranes are equipped with ergonomic designs and intuitive interfaces that make operation straightforward. The remotes typically feature well-placed buttons and easy-to-navigate controls, allowing operators to manage the crane's movements with minimal effort. This user-centric design significantly reduces the time needed for training, enabling new operators to become proficient quickly. As a result, businesses can enhance productivity while ensuring that their workforce can handle the equipment safely and effectively.

Wireless Technology Advantages

One of the standout benefits of wireless remote control technology is the extended operational range it provides. Operators can control the crane from a distance, enhancing visibility and safety while maneuvering loads in complex environments. This flexibility is particularly advantageous in large facilities where visibility may be limited. Additionally, eliminating cumbersome wires reduces tripping hazards and prevents damage to the crane's electrical components, further enhancing safety in the workplace.

Safety Features

Safety is a paramount concern in any industrial setting, and wireless remote control EOT cranes are designed with various safety features. Emergency stop functions allow operators to halt all crane operations instantly, providing an essential safeguard in unexpected situations. Additionally, many systems include anti-collision technologies that use sensors to detect obstacles, preventing potential accidents. Load monitoring systems also provide real-time data about the weight being lifted, helping operators avoid overloading the crane and ensuring safe operations.

Durability and Reliability

The construction of wireless remote control EOT cranes is tailored to withstand harsh industrial environments. Built from robust materials, these cranes can endure heavy use while maintaining their performance. The reliability of these systems is crucial, especially for continuous operations where downtime can be costly. High-quality designs ensure that the cranes remain operational even under challenging conditions, giving businesses confidence in their equipment's longevity.

Compatibility with Various Applications

Wireless remote control EOT cranes offer remarkable flexibility in terms of compatibility with existing systems and various crane types. They can be integrated into older crane models or adapted for use across different applications, making them a versatile choice for businesses. Use cases span multiple industries, including manufacturing, construction, and logistics, where they effectively handle heavy loads and improve overall operational efficiency. This adaptability ensures that organizations can upgrade their equipment without extensive overhauls, maximizing their return on investment.

Enhancing Safety in Operations with Wireless Remote Control

Safety Impact of Remote Control Technology

The safety impact of wireless remote control technology in crane operations is significant. In traditional crane setups, operators often work in close proximity to the lifting equipment, exposing themselves to various hazards such as falling loads and mechanical malfunctions. In contrast, remote operation allows operators to control the crane from a safe distance, minimizing their exposure to potential dangers. This distance not only enhances personal safety but also improves situational awareness, enabling operators to monitor their surroundings more effectively.

In hazardous environments, such as construction sites or manufacturing plants with heavy machinery, reducing operator exposure is crucial. Wireless remote control technology enables operators to manage lifts from safer locations, thereby decreasing the likelihood of injuries and accidents in high-risk areas.

Features that Enhance Operator Safety

Distance operation through wireless remote controls brings numerous benefits in minimizing injuries. By allowing operators to maintain a safe distance from the load and equipment, the risk of accidents due to falling objects or unexpected movements is significantly lowered.

Additionally, many wireless systems are equipped with specific safety protocols and certifications that enhance operational safety. These may include features such as redundant control systems, which provide backup options in case of failure, and comprehensive training programs that ensure operators are well-versed in safe operating practices. Such protocols help establish a culture of safety within organizations, further promoting responsible crane operation.

Safety Improvements

Numerous case studies and testimonials highlight the real-world safety improvements achieved through the implementation of wireless remote control cranes. For instance, a manufacturing facility reported a 40% reduction in workplace accidents after integrating remote-controlled systems. Operators noted that the ability to control the crane from a safe distance allowed them to avoid hazardous situations, leading to a safer working environment.

Statistics also underscore the effectiveness of remote crane technology. Many organizations have observed significant decreases in accident rates, with some reporting reductions of up to 30% in injuries following the adoption of wireless remote control systems. These improvements not only enhance the safety of the workforce but also contribute to greater operational efficiency and lower costs associated with workplace incidents. By prioritizing safety through advanced technology, companies can foster a safer and more productive work environment.

Industry Applications

Wireless remote control overhead cranes are being successfully utilized across various sectors, including manufacturing, construction, logistics, and energy. In manufacturing, these cranes efficiently handle heavy machinery components and large assemblies, enabling streamlined production processes. In the construction industry, they are invaluable for lifting and positioning steel beams, concrete panels, and other substantial materials, demonstrating their versatility in handling a wide range of loads.

Additionally, in logistics and warehousing, remote control cranes facilitate the movement of pallets and bulk materials, optimizing the flow of goods in busy distribution centers. The adaptability of these cranes makes them suitable for diverse applications, enhancing operational efficiency across different industries.

Customer Experiences

Numerous users have shared positive testimonials after implementing wireless remote control overhead cranes. For instance, a large automotive manufacturer reported, "Switching to remote control has transformed our assembly line. We've seen a 30% increase in productivity and a notable improvement in operator safety. The ability to control the crane from a distance has allowed our workers to focus on their tasks without the constant concern of hazards."

Another client in the construction sector stated, "The efficiency gains have been remarkable. Our teams can now move loads more quickly and safely, reducing project timelines and improving overall job site safety." These experiences highlight how adopting remote control technology not only boosts efficiency and productivity but also creates a safer working environment.

Performance Metrics

A thorough analysis of performance metrics before and after the adoption of wireless remote control technology reveals significant improvements. For example, one company noted a 25% reduction in operational delays due to faster load handling and fewer accidents. Additionally, they reported a decrease in maintenance costs, as remote monitoring capabilities allowed for timely maintenance interventions before issues escalated.

In terms of return on investment (ROI), many businesses found that the initial costs of upgrading to remote control systems were quickly offset by the savings achieved through improved safety and efficiency. Over time, the long-term benefits include enhanced employee morale due to a safer work environment, reduced insurance costs from lower accident rates, and increased overall productivity. These metrics demonstrate that integrating wireless remote control overhead cranes can yield substantial advantages, making them a wise investment for companies looking to improve their operations.

Conclustion

In summary, wireless remote control EOT and overhead cranes offer a range of key benefits that significantly enhance industrial operations. Their user-friendly interfaces and ergonomic designs make them easy to operate, reducing training time for new users. The wireless technology not only expands operational range and flexibility but also eliminates the risks associated with cumbersome cables, allowing for safer and more efficient maneuvering of heavy loads.

The safety features integrated into these cranes, such as emergency stop functions, anti-collision systems, and load monitoring, play a vital role in minimizing risks in hazardous environments. By enabling operators to control cranes from a safe distance, these systems reduce the likelihood of accidents and injuries, fostering a culture of safety in the workplace.

The efficiency gains from adopting wireless remote control cranes are also noteworthy. Organizations report significant improvements in productivity, with faster load handling and streamlined operations leading to shorter project timelines. The return on investment is often rapid, as companies experience reduced downtime, lower maintenance costs, and enhanced overall performance.

As industries continue to prioritize safety and efficiency, it is essential for businesses to consider the advantages of wireless remote control cranes. We encourage you to explore purchasing options and request quotes to see how these innovative systems can transform your operations. Investing in wireless remote control technology is a strategic step toward enhancing both safety and productivity in your workplace.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch