1 Ton to 25 Ton EOT Crane Prices: What Affects the Cost?

1 to 25 Ton EOT Crane Prices: Key Considerations for Buyers. Crane prices depend on capacity, features, voltage & specific needs, influencing total cost.

Category: Ask for Hoist And Crane Price

Your Trusted Overhead Travelling EOT Crane Manufacturer & Supplier

1 Ton to 25 Ton EOT Crane Prices: What Affects the Cost?

Key Considerations for Buyers on Selecting Single Girder & Double Girder Eot Cranes

Crane prices for 1-25 tons depend on capacity, features, voltage, and specific plant needs, influencing total cost.

Eot Crane for Sale and Crane Price

EOT (Electric Overhead Traveling) cranes are essential in many industries. They are used to lift and move heavy materials with precision. Whether it's in manufacturing, warehouses, or construction sites, these travelling cranes make material handling much easier and safer.

When looking to buy an EOT crane, you'll find a wide range of prices, especially for models with capacities between 1 to 25 tons. The crane prices can vary based on factors like the lifting capacity, crane type, and additional features. For example, a 1-ton eot crane may cost around $2,200, while a 25 ton overhead crane could go up to $56,000.

There are a few key people involved in buying these cranes:

- Indirect Sourcing Teams need to find the best price and ensure the right supplier is chosen.

- Financial Officers are focused on budget planning, looking at both upfront costs and long-term expenses.

- Plant Engineers care about the technical side – making sure the material handling crane fits the space, meets operational needs, and is safe for workers.

Overview of Factors Affecting EOT Crane Prices

The price of an Electrical Travelling EOT crane can vary significantly depending on various factors. The key factors influencing the price include lifting capacity, crane span, and lifting height. Let's explore each factor in detail.

Lifting Capacity:

- Price Increases Based on Higher Lifting Capacities. As the lifting capacity of the crane increases, so does its price. Electric Travelling Cranes with higher lifting capacities require more powerful motors, stronger structural components, and often more advanced technology to handle the increased load. This all adds to the overall cost of the eot crane. For instance, a 1 ton eot crane will be much more affordable than a 25 ton overhead crane due to the difference in materials, design, and power requirements.

- Differences Between Single Girder and Double Girder Cranes for Different Capacities. The type or mold of crane also plays a role in the price. Single girder eot cranes are typically used for lighter loads (up to about 20 tons) and are more cost-effective. Double girder eot cranes, on the other hand, are used for heavier loads (from 5 tons up to 63 tons) and are more complex in design. Double girder cranes have two main beams that provide extra stability and support, which makes them more expensive than single girder cranes. The choice between single and double girder cranes depends on the required lifting requirement, lifting capacity and the application.

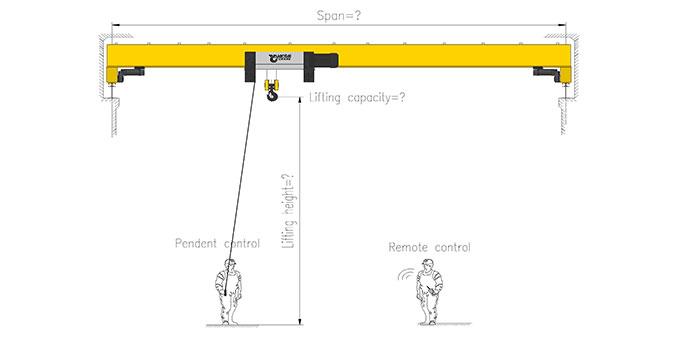

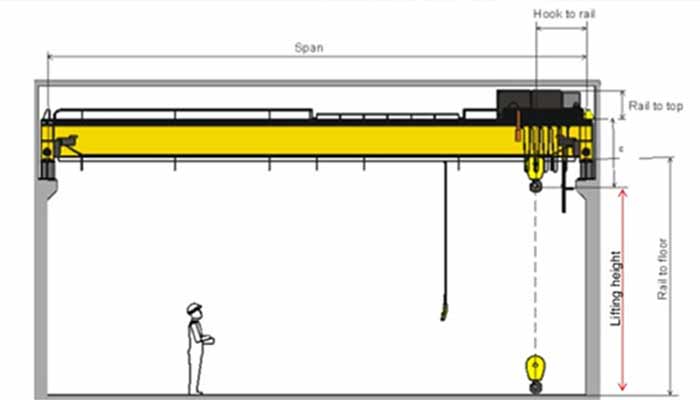

Span and Lifting Height

- How Crane Span and Lifting Height Influence Crane Design and Pricing. The span refers to the distance between the rails on which the crane travels, while the lifting height refers to the maximum height the crane can lift the load. Both factors directly impact the crane's design and price. A larger span requires a more robust and longer structure, while a higher lifting height demands longer hoist ropes and additional mechanical components. Both factors increase the complexity and cost of the crane.

- Customization of Crane Span and Height for Specific Plant Requirements. Cranes can be customized to meet the specific needs of a plant, especially in terms of span and lifting height. If a plant has unique space constraints or needs to lift loads to specific heights, the crane will need to be designed accordingly. Customizing the span or height might involve adjusting the crane's overall size, which can increase the price. However, these customizations ensure the crane will perform optimally in the given environment, providing the necessary lifting capabilities without compromising on safety or performance.

In summary, the price of an EOT crane depends on factors like lifting capacity, the type of girder used, and the span and height required for the specific application. Understanding these factors helps businesses choose the right crane for their needs while balancing cost and performance.

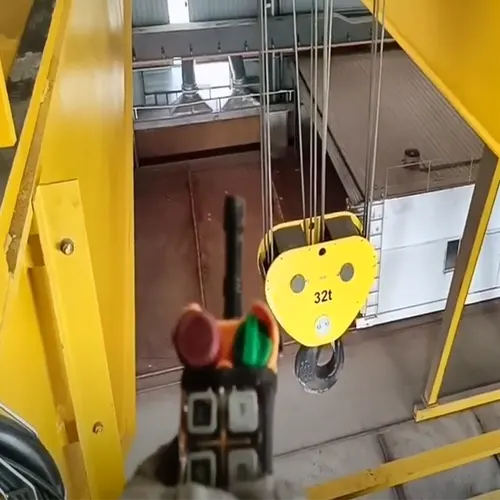

Single Girder EOT Cranes and Crane Price

- Single girder EOT cranes are lighter and more cost-effective, making them ideal for lower lifting capacities, typically ranging from 1 to 32 tons. They feature a single main beam (girder) supported by end trucks. This simpler design allows for lower manufacturing and maintenance costs, making single girder cranes a great option for light-duty applications in factories, warehouses, and smaller industrial settings.

- Price Comparison for Different Capacities. As the lifting capacity increases, the price of a single girder EOT crane also rises, but it generally remains more affordable compared to double girder cranes. A single girder crane for 1 ton is significantly cheaper than a 32-ton single girder crane, though it still costs less than the equivalent double girder crane.

European Standard Underhung Overhead EOT Crane 1 ton,3 ton, 5 ton to 10 ton

Underrunning Single Girder EOT Crane Chinese Type, Economical Hoist Crane 0.5ton, 3 ton, 5 ton to 10 ton for limited workshops.

FEM / DIN Top Running Single Girder EOT Crane 3.2ton, 3 ton, 5 ton 10 ton ton 16ton with advanced & smart low headroom hoist .

Chinese Style Top Running Single Girder EOT Crane 1 ton, 3 ton, 5 ton,10 ton up to 20 ton, economical solution for adequte space workshop.

Explosion Proof Single Girder EOT Crane 1 ton, 3 ton, 5 ton,10 ton up to 20 ton for hazarourouse environment to ensure safe operation.

Partial Hung Low Headroom Single Girder EOT Crane, 1 ton, 3 ton, 5 ton,10 ton up to16 ton, economical single girder crane with increashed lifting height.

Low headroom Hoist Single Girder EOT Crane, designed for low ceiling or limited facility with capacity 1 ton, 3 ton, 5 ton,10 ton up to32 ton. etc.

Single Girder EOT Crane for Ladle Handling , Designed for hot ladle handling is small steel mills with capacity of 1 ton, 3 ton, 5 ton, 10 ton.

Single Girder EOT Cranes Price Breakdown

Here are the price ranges for single girder EOT cranes based on different lifting capacities:

- 1 Ton Eot Crane: $2,200 – $40,000. Price variations are influenced by power supply options, span, lifting height, and control systems.

- 2 Ton Eot Crane: $2,500 – $40,800. Similar to the 1-ton crane, but prices can increase with customization features such as remote control or manual operation options.

- 3 Ton Eot Crane: $2,600 – $41,000. The cost reflects the combination of lifting speed, crane components, and additional attachments for material handling.

- 5 Ton Eot Crane: $3,000 – $41,500. The increase in price accounts for stronger structural components, increased span, and more complex power supply requirements.

- 10 Ton Eot Crane: $4,000 – $45,000. Higher lifting capacities require stronger motors and more durable materials, contributing to a higher price.

- 16 Ton Eot Crane: $5,000 – $48,000. The crane's design complexity increases with this lifting capacity, including higher-duty components and advanced control systems.

- 20 Ton Eot Crane: $6,000 – $50,000. At this level, the crane is designed for heavy-duty operations with potential features like explosion-proof or corrosion-resistant coatings, driving up the cost.

Double Girder EOT Cranes

- Double girder EOT cranes are more robust, making them suitable for higher lifting capacities, typically from 5 to 63 tons. These cranes have two parallel beams providing additional strength and stability, which is necessary for handling heavy loads. They are commonly used in larger industrial facilities or applications requiring higher-duty operations.

- Price Comparison for Different Capacities. Double girder EOT cranes are generally more expensive due to their stronger construction and complex design. As the lifting capacity increases, the price difference between single and double girder cranes becomes more noticeable. For example, a 5-ton double girder EOT crane will cost considerably more than a 5-ton single girder crane, reflecting the additional components and design complexity.

Chinese Style Double Girder EOT Crane 3 Ton to 550 Ton , Overhead electric winch trolley crane is China traditional heavy duty double girder eot crane equipped winch trolley,Robust & Sturdy, Affordable industrial overhead cranes.

Chinese Style double girder Electric Hoist EOT Crane 5 Ton to 63 Ton, with rope hoist trolley / chain hoist trolley, competitive hoist trolley crane system, cheaper hoist trolley crane price, good electric eot crane solution.

European Style Double Girder Open Winch EOT Crane, European standard double girder eot crane with open winch trolley, a heavy duty winch crane up to 320 ton, wide specifications hook cranes for wide application. Get FEM / DIN open winch travelling EOT Crane now!

European style double girder hoist trolley crane- Advanced double girder eot crane based on European DIN/FEM Standard with 5 ton-80 ton electric wire rope hoist trolley for hoisting industrial materials with weight of 1 ton to 80 ton !

Ladle crane: 5 ton -74 ton & 5 ton up 320 ton ladle crane- Ladle cranes for 5 ton -320 ton ladle or liquid metal lifting, heavy duty ladle crane for steel mill, foundry, furnace, and casting factory. Good priced ladle crane, charging crane, casting crane & foundry crane !

Electromagnetic cranes & Electromagnets- Double girder eot cranes eqiuippted with electromagnetic chucks or magnetic carrier beams for handling steel scraps, billet, slab,wire, coil, pipe, plate, etc.,with efficiency and safety.

Rotary Eot Crane with Electro- magnet Beam Spreader- Magnetic crane is a double girder eot crane with rotary crane design & electromagnet beam spreader, lifting long & larger steels, safe & efficient rotary eot crane.

5 Ton 10 Ton 16 Ton 20 Don Double Girder Eot Crane with Grab Bucket- Grab buekt eot cranes with orange peeler grabs or clamshell grab buckets for scattered material handling in power station, steel mill, port, cement plant,storage & waste recycling station, etc

Double Girder EOT Cranes Price Breakdown

Double girder EOT cranes are designed for heavier-duty operations, offering superior load-bearing capacity and durability compared to single girder cranes. Below is the price breakdown for double girder EOT cranes with capacities ranging from 1 ton to 25 tons, along with the factors that influence these price variations.

Price Ranges for Double Girder EOT Cranes

The price of double girder EOT cranes varies based on the lifting capacity, customization, and additional features. Here's an overview of the typical price ranges for different lifting capacities:

- 1 Ton Eot Crane: $4,000 – $60,000. The price range reflects basic configurations, but additional features like remote controls or corrosion-resistant coatings can increase costs.

- 2 Ton Eot Crane: $4,500 – $62,000. For a 2-ton crane, customization options such as specific power supply configurations or hoist features can push the price upwards.

- 3 Ton Eot Crane: $5,000 – $66,000. The cost increases with capacity, along with any specific requirements for lifting mechanisms or enhanced operational speed.

- 5 Ton Eot Crane: $5,800 – $72,000. As the lifting capacity grows, the price is affected by more robust construction and additional operational features like advanced control systems.

- 10 Ton Eot Crane: $6,500 – $79,000. With this capacity, cranes are typically used in high-demand environments, leading to higher prices for heavy-duty components and greater customization.

- 16 Ton Eot Crane: $7,800 – $86,000. At this capacity, the crane design becomes more complex, with factors like high-speed lifting, multiple hoists, and more advanced safety features contributing to the cost.

- 20 Ton Eot Crane: $8,600 – $95,000. Cranes designed for heavy industrial applications will have higher prices due to the need for higher structural integrity and more robust safety features.

- 25 Ton Eot Crane: $9,800 – $110,000. The largest capacity cranes are used for the heaviest loads, with specialized lifting mechanisms and the highest quality materials, which significantly raise the price.

Basic Parameters Affecting EOT Crane Costs

The basic crane parameters, such as lifting capacity, lifting height, span, and voltage specifications, can significantly influence the price. Here's a breakdown of how each factor contributes to the overall cost:

Lifting Capacity, Lifting Height, and Span

- Lifting Capacity: A higher lifting capacity requires stronger materials, more powerful motors, and advanced design to handle the heavier loads, leading to an increase in the crane's cost.

- Lifting Height: Cranes designed to lift materials to greater heights will often require longer components, additional reinforcement, and adjustments to the hoist, which adds to the cost.

- Span: The distance between the rails, or the span, influences the crane's structure. A larger span requires a more robust frame, which increases the cost. Custom spans can also drive up the price based on specific plant needs.

Lifting Capacity

- Impact on Price: Cranes with higher lifting capacities require stronger materials, more powerful motors, and advanced engineering to handle heavier loads. The added strength and capability come at an increased cost.

- Why It's Needed: To ensure safe and efficient handling of heavier materials, the crane must be designed with more robust components, leading to higher production and material costs.

Lifting Height

- Impact on Price: Cranes designed for greater lifting heights require longer components, reinforced structures, and modifications to the hoist system. These adjustments increase the complexity and cost of the crane.

- Why It's Needed: Lifting height determines how high a crane can elevate materials. The taller the height, the more engineering is needed to maintain stability and performance, thus raising the price.

Span

- Impact on Price: The span refers to the distance between the rails that the crane operates on. A larger span requires a more robust frame and additional reinforcement, which increases the cost.

- Customization: Custom spans tailored to specific plant needs also influence the price. A custom design often involves unique engineering and more precise materials, driving up the overall cost.

Voltage Configurations:

Voltage configurations are a crucial part of the crane's design and directly impact the motor price:

- 220-480/50 (standard voltage): This voltage setup is the most commonly used and tends to keep the crane's price at a standard rate.

- 220-480/60 (60 Hz motor): This configuration increases the motor price by around 20%, mainly due to the need for more advanced components and adjustments to power systems.

- 460-480/50 (high-voltage setup): This requires specialized equipment, which also raises the crane price by about 10%.

Voltages Affects on Crane Price

Voltage configurations are an essential consideration in crane design, as they directly impact the price due to the requirements for different power systems and components.

220-480/50 (Standard Voltage):

- Price Impact: This is the most common voltage setup used in EOT cranes. It generally keeps the crane's price at a standard rate as it is widely available and doesn't require specialized components.

220-480/60 (60 Hz Motor)

- Price Impact: This configuration increases the motor price by approximately 20%. The 60 Hz motor requires more advanced components and adjustments to the power systems, leading to a higher overall cost.

460-480/50 (High-Voltage Setup)

- Price Impact: This high-voltage setup requires specialized equipment and components, raising the crane price by about 10%. It's necessary for certain heavy-duty or specific industrial applications.

The voltage configuration also affects the crane's delivery time. Cranes that use less common voltage setups, such as 220/60 or 460-480/50, typically have longer lead times. These configurations require specialized components and may be manufactured to order, which can delay production schedules and delivery timelines.

Electrical and Equipment Costs

The crane's electrical system, including the motors, control systems, and wiring, varies depending on the chosen voltage configuration. Cranes with higher voltage configurations require more advanced electrical components, which increase both the material and manufacturing costs. As a result, the total price of the crane will be higher, reflecting the need for more powerful and specialized electrical systems.

Operation Mode & Eot Crane Price

The operation mode significantly impacts the cost of the EOT crane. The more complex the operation mode, the higher the price due to the additional components and systems required. Here's a breakdown of the typical operation modes, listed from lowest to highest price:

- Manual Operation:. The most basic mode, involving manual operation via hand controls. It's the most cost-effective option, suitable for light-duty applications with lower frequency use.. Price: Lowest

- Remote Control Operation:. This mode allows the operator to control the crane from a distance, offering more flexibility and safety. Remote controls increase the price due to the additional technology involved.. Price: Moderate

- Cabin Operation:. The highest-priced option, where the operator is housed in a cabin on the crane itself. This mode is ideal for heavy-duty, continuous operations in large plants. It requires extensive safety features and additional operational components, making it the most expensive choice.. Price: Highest

The basic parameters and operation mode affect the price helps buyers make more informed decisions about the crane they need. Choosing the right combination of lifting capacity, height, span, voltage, and operation mode ensures the crane suits the specific needs of the plant while managing costs effectively.

Manual vs Remote Control vs Cabin Operation

The operation mode refers to how the crane is controlled, whether manually, via remote control, or by an operator in a cabin. The choice of operation mode can affect the price, comfort, and efficiency of crane use.

- Manual Operation: The least expensive, suitable for simpler, less frequent lifting tasks.

- Remote Control: More expensive than manual due to the added control mechanisms.

- Cabin Operation: The most costly due to operator comfort, safety features, and the more complex control systems required.

Cost Comparison (from lowest to highest):Manual → Remote Control → Cabin Operation.

EOT Crane Working Duty Class

The working duty class of an EOT crane significantly impacts both its cost and performance.

- Impact on Pricing. The duty cycle classification (A3, A4, A5) indicates the frequency and weight of the operations the crane will handle. Cranes designed for higher duty cycles (A4, A5) are built with stronger components to endure frequent use and heavy loads, making them more expensive. For example, an A5 duty crane costs more than an A3 duty crane due to its enhanced durability and ability to handle intense workloads.

- Choice of Components and Operational Efficiency. Higher-duty cranes come with more durable components, such as stronger motors and gears, which enable better long-term operational efficiency. While the initial price is higher, these cranes are designed to perform well in demanding environments, providing better reliability and lower maintenance costs in the long run.

Ambient Temperature and Environment

EOT cranes need to operate reliably under various environmental conditions, from extreme temperatures to hazardous environments.

- Considerations for Extreme Environments. Cranes used in extreme conditions, such as high-temperature environments or those exposed to corrosion, require specialized features. EOT cranes may need explosion-proof components or corrosion-resistant coatings to ensure safe and efficient operation in these harsh conditions. These features add to the cost but are necessary for maintaining performance and safety in such environments.

- Impact on Price for Harsh Conditions. Cranes designed to withstand extreme conditions come at a higher price due to the use of special materials and certifications. For example, cranes used in high-temperature environments or those requiring explosion-proof designs demand more expensive components. Corrosion-resistant coatings also increase the crane's cost but ensure that it performs well and lasts longer in corrosive environments.

Power Supply and Electrical Requirements

The crane's power supply configuration can also influence its price due to different electrical needs and installation challenges.

- Price Variations Based on Power Supply Configurations. EOT cranes typically run on three-phase power, often with configurations of 220-480V/3/50Hz. If the crane requires a different voltage, such as 220-480V/60Hz or another variation, the price will rise. Custom electrical setups can require additional components like transformers or specialized wiring, which add to both the initial purchase cost and ongoing maintenance costs.

- Custom Power Supply Options. Some plants may require customized power supply options, such as cranes that operate on a specific voltage or require backup power systems. These customizations might include voltage stabilizers, generators, or upgraded electrical systems to meet plant requirements. While these custom power setups increase the cost of the crane and its installation, they ensure that the crane will operate efficiently and safely in unique environments.

In conclusion, several factors such as crane type, duty class, environmental conditions, and power supply requirements all affect the pricing of an EOT crane. By considering these factors, buyers can make informed decisions that balance cost with the crane's long-term performance and suitability for their specific needs.

Other Requirements

Other requirements include the configuration of components, the crane's duty class, speed, and environmental factors. These elements contribute to the crane's adaptability to specific applications and harsh working conditions.

Configuration of Components

- Domestic Components tend to be less expensive compared to imported components or specified brand components.

- Brand Influence: Cranes built with well-known international brands or high-quality parts usually come with a higher price tag.

Working Duty Class: The duty class of the crane (A3 to A8) impacts the price. Higher-duty cranes (A5, A6, A7, A8) are built for more frequent, heavier lifting and therefore cost more.

Speed (Lifting and Running Speed)

- Faster speed results in a higher price.

- Increased speed requires more powerful motors, sophisticated control systems, and higher quality components, all of which add to the overall cost.

Environmental Temperature Specifications: Cranes designed to operate in extreme temperatures (either below -20°C or above 40°C) will have additional costs due to the need for special materials and components to maintain performance under harsh conditions.

Operational Conditions

Operational conditions, such as altitude and motor protection, also influence crane pricing. Cranes designed for higher altitudes or specific environmental conditions will have additional costs for specialized components and features.

Altitude Considerations: For cranes that need to operate at altitudes over 1000 meters, motor adjustments are required to compensate for lower air density, increasing the crane price.

Motor Protection and Cooling Methods

- IP protection levels (e.g., IP54), required for environments with high dust or moisture, add to the cost due to more robust sealing and protection.

- Cooling Systems: Liquid-cooled motors tend to be more expensive than air-cooled motors due to the additional components needed for heat dissipation.

Special Features Increasing Price

When it comes to EOT cranes, certain special features can add complexity and increase the overall cost. These enhancements are typically required for specific industries and demanding work environments. Here's a breakdown of how these features affect crane pricing:

Steel Plate Sandblasting

- Impact on Price: Sandblasting steel plates before applying protective coatings adds to the overall cost due to the labor-intensive nature and specialized equipment required for the process.

- Why It's Needed: Sandblasting ensures a smooth surface and better coating adhesion, which is essential for cranes exposed to harsh conditions, like extreme weather or corrosive materials.

Active Running Platforms

- Impact on Price: Adding active running platforms for maintenance or operation increases the crane's price due to the additional structural complexity required.

- Why It's Needed: These platforms are often necessary for facilities that require frequent maintenance access or have a high level of operational complexity, improving safety and ease of access.

Disconnection Functions

- Impact on Price: Cranes with emergency disconnection or automatic stop features cost more due to the advanced safety systems involved.

- Why It's Needed: These safety features are crucial in high-risk environments to prevent accidents and ensure operational safety, making them a valuable addition despite the increased price.

Lifting Attachments for EOT Cranes

Lifting attachments are critical components that enhance the versatility of an EOT crane, enabling it to handle a variety of materials efficiently. The type of attachment, the weight of the materials being lifted, and the operational requirements all contribute to the overall cost of the crane. Understanding these factors helps ensure that you select the right attachment for your needs while keeping within your budget.

EOT cranes come with various types of lifting attachments, each tailored for specific tasks and material handling. The choice of lifting attachment has a direct impact on both the crane's functionality and its cost.

- Mechanical Grab Buckets: A cost-effective option, ideal for general-purpose lifting operations. These are simpler and typically used in less complex material handling environments.

- Electric or Electric-Hydraulic Grab Buckets: More expensive than mechanical buckets due to their advanced control systems. These attachments offer better precision and are suitable for more specialized operations that require improved control and efficiency.

- Diesel-Driven Grab Buckets: The most costly option, typically used in locations where electricity is unavailable. Diesel-driven grab buckets have higher operational costs due to the need for fuel and the diesel engine components.

- Material Size: Larger materials require stronger magnets to lift them, which naturally increases the price of the electromagnetic lifter. The stronger the magnet, the higher the cost.

- Temperature Range: Cranes designed to lift materials at higher temperatures (up to 600°C) require specialized magnets and materials that can withstand the heat, adding additional cost.

- Magnetic Hold Time: Standard electromagnetic lifters can hold the magnetic force for 10 minutes. However, if a longer hold time is needed, such as for heavy-duty lifting tasks, the price increases due to the requirement for more powerful magnets.

When selecting an EOT crane, it is much important to know the key factors that affectotthe eot crane price. From voltage and operation mode to the types of lifting attachments and the materials being handled, each element plays a role in determining the overall cost. By carefully evaluating these parameters, businesses can choose the right crane to meet both their budget and operational requirements, ensuring long-term reliability and efficiency in their lifting operations.

Key Considerations for Different Stakeholders When Purchasing an EOT Crane

When purchasing an EOT crane, each stakeholder—Indirect Sourcing Teams, Financial Officers, and Plant Engineers—has specific concerns to address. These concerns help ensure the purchase meets the company's needs and goals.

Indirect Sourcing Teams

Indirect sourcing teams focus on securing the best value for the company. Here are the key factors they look at:

- Cost-Effectiveness & Negotiating Better Prices: Indirect sourcing teams prioritize finding the best price for the electric travelling overhead crane. They negotiate with suppliers for competitive prices and added benefits like extended warranties or free installation.

- Supplier Selection and Vendor Reliability: Choosing a reliable supplier is essential. Sourcing teams assess the supplier's track record for delivering on time and offering quality support. A trusted supplier reduces the risk of delays or product issues.

- Contract Terms, Delivery Timelines, and After-Sales Support: Clear contract terms are crucial. Sourcing teams focus on delivery timelines, payment terms, and after-sales support. A supplier offering strong post-purchase support is highly valued to avoid disruptions during installation and operation.

Financial Officers

Financial officers handle the budget and ensure the purchase fits the company's financial goals. Here's what they need to consider:

Capital Budgeting and Evaluating Long-Term Investments: Financial officers assess how the crane purchase fits within the overall budget. They look at the crane's long-term value and how it will contribute to improving operations and generating returns.

Total Cost of Ownership (TCO): The total cost of ownership includes more than just the purchase price. Financial officers calculate expenses such as installation, maintenance, and energy consumption. Cranes that are cost-effective over time offer better value.

Financial Analysis (ROI, Depreciation, Payback Period): Financial officers calculate key financial metrics, such as:

- ROI (Return on Investment): Measures how much return the crane will generate.

- Depreciation: Affects the company's financial statements and tax planning.

- Payback Period: Shows how long it will take for the crane to pay for itself.

Plant Engineers

Plant engineers focus on the technical side of the overhead travelling crane, ensuring it fits with the facility and operations. Their concerns include:

- Crane Specifications and Compatibility with Existing Infrastructure: Engineers ensure the overhead crane meets the specific requirements of the facility, such as lifting capacity, span, and height. They check if the workhop crane fits the layout and is compatible with existing infrastructure like rails and power sources.

- Safety Features, Ease of Operation, and Maintenance: Safety is a priority for engineers. They look for the industrial cranes with safety features such as overload protection, emergency stops, and anti-collision systems. The industrial overhead crane should also be easy to operate and maintain to reduce downtime and improve efficiency.

- Future Scalability and Flexibility for Plant Expansions: Engineers consider whether the processed or engineered eot crane can be easily upgraded to meet future needs. If the plant grows or new requirements arise, the overhead crane should be flexible enough to handle increased capacity or additional features without requiring a full replacement.

Each stakeholder has different priorities when it comes to purchasing an EOT crane. By addressing cost, technical fit, and long-term financial considerations, each group helps make the best decision for the company's operations and goals.

Conclusion

When purchasing an EOT crane, various factors influence its price, such as lifting capacity, span, height, voltage configurations, and environmental conditions. Additionally, the type of operation mode, the required crane features, and the choice of lifting attachments all affect the overall cost. It's essential to understand the long-term implications, including maintenance, energy consumption, and operational efficiency, before making a final decision.

Key Takeaways for Different Stakeholders:

- Indirect Sourcing Teams: Focus on negotiating cost-effective prices, ensuring vendor reliability, and understanding the terms of delivery and after-sales support.

- Financial Officers: Pay attention to capital budgeting and the total cost of ownership (TCO), including ongoing operational and maintenance costs.

- Plant Engineers: Ensure the crane is compatible with your plant's infrastructure and operational needs, while considering safety, ease of use, and long-term scalability.

Long-term planning and budgeting are essential to ensure that the crane remains efficient, cost-effective, and adaptable to future plant expansions and changes.

Are you ready to purchase an EOT crane for your plant? Contact us today for a personalized quote and get the most up-to-date pricing tailored to your specific needs. Our team is here to assist you in making the best investment decision, ensuring that your crane meets both current and future requirements efficiently. Don't hesitate—reach out for more information or to request a detailed consultation on the electrical travelling overhead crane !

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch