Lightweight Overhead Crane System

Lightweight overhead crane systems with capacity of 500kg, 1ton, 2 ton, 3 ton, 4 ton, 5 ton to 10 ton for hoisting light loads, light duty overhead crane.

Category: Light Crane & Portable Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Electric & Manual Overhead Crane

Light Duty Overhead Crane & Lightweight Overhead Crane System

Lightweight overhead crane systems with capacity of 500kg, 1ton, 2 ton, 3 ton, 4 ton, 5 ton to 10 ton for hoisting light loads, light duty overhead crane.

Comprehensive Guide to Choosing Light-Duty Overhead Cranes & Bridge Cranes

Light-duty overhead cranes and bridge cranes serve as essential assets across diverse industrial sectors, facilitating the seamless movement of goods and materials within confined spaces. These specialized cranes play a pivotal role in enhancing efficiency, productivity, and safety in various operational environments.

Light-duty overhead cranes, often referred to as bridge cranes, are lifting devices mounted on beams for horizontal movement along a track or rail system. They are designed to handle relatively lighter loads within specific weight capacities, typically up to 10 tons, making them ideal for numerous applications across industries.

These cranes employ a hoist and trolley mechanism, allowing them to lift and transport materials horizontally along the span of the crane. The overhead design maximizes floor space utilization, enabling efficient handling of goods without obstructing ground operations.

Selecting the appropriate light-duty overhead or bridge crane holds immense significance for industries ranging from manufacturing and logistics to construction and beyond. The tailored choice of crane impacts operational efficiency, safety standards, and ultimately, the bottom line of any business.

Different industries have unique requirements in terms of load capacity, span, operational conditions, and customization needs. Choosing a crane that aligns with these specific demands ensures smoother workflows, minimizes downtime, and enhances workplace safety.

Light-Duty Overhead Cranes and Bridge Cranes

The terms "overhead cranes" and "bridge cranes" are often used interchangeably, but they do have distinctive features. An overhead crane is a type of crane where the hoist and trolley mechanism move along a horizontal beam that runs along the ceiling or elevated runway structure. On the other hand, a bridge crane specifically refers to a type of overhead crane that has parallel runways with a traveling bridge spanning the gap between them.

Light-duty overhead cranes are specifically designed to handle relatively lighter loads compared to their heavy-duty counterparts. These cranes typically have a lifting capacity ranging from a few hundred pounds to around 10 tons. Their applications are diverse, spanning industries such as small-scale manufacturing, workshops, maintenance bays, and warehouses where moderate material handling needs exist.

Their versatility and ability to cover a smaller working area make them ideal for tasks like assembly lines, product positioning, and transferring materials within confined spaces.

Types of Light Duty Overhead Cranes Based on Different Terms and Standards

Top Running Light Duty Bridge Cranes: These cranes have a single girder or double girder configuration running along the top of the runway beams. They are suitable for handling lighter loads efficiently and are commonly used in various industrial settings.

Under Running Light Duty Bridge Cranes: With a single or double girder structure running underneath the runway beams, these cranes offer flexibility and are often preferred for space-restricted environments or where overhead clearance is limited.

Top Running vs. Under Running Cranes

- Top Running Cranes: These cranes move along the top of the runway beams and are supported by the building's structure. They are suitable for applications requiring heavy lifting capacities and long spans.

- Under Running Cranes: Also known as underhung cranes, they run along the bottom flange of the runway beam and are supported by the building's roof structure. These cranes are beneficial for facilities with limited space and lower lifting requirements.

Features and Advantages of Different Types

Each type of light-duty overhead or bridge crane offers distinct features and advantages. Single girder cranes are more economical and suitable for lower lifting capacities, while double girder cranes provide enhanced stability and greater lifting capacities.

Top running cranes are optimal for heavier loads and longer spans, whereas under running cranes are beneficial in space-restricted environments, offering flexibility in movement within confined areas.

Suitability for Various Industrial Sectors (Manufacturing, Warehousing, etc.)

The suitability of different crane types varies across industries:

- Manufacturing: Double girder cranes might be preferred for heavier manufacturing operations, while single girder cranes can efficiently handle smaller assembly tasks.

- Warehousing: Top running cranes could be suitable for high-bay warehouses, while under running cranes might be ideal for smaller storage facilities with limited space.

Electric susepnsion light duty overhead crane

Underhung design lightweight overhead crane system is a type of light duty overhead travelling crane, which is attached to the workshop existing roof structure , with no requirement of the supporting columns. Being mounted on the ceiling of the workshop, the Underhung design lightweight overhead crane system makes the entire workshop area available for production. By taking advantage of the existing roof structure, the electric susepnsion light duty overhead crane can save your time and cost to a large extend and also the installation of stand-alone steel superstructures makes the electric susepnsion light duty overhead crane adaptable to changed production requirements

Due to being mounted to the ceiling structure, the roof structure has to be inspected to make sure it has the ability to support the weight of the electric susepnsion light duty overhead crane and the load to lift. Free consultation on the suspension is offered and please leave us a message about your roof structure to get your electric susepnsion light duty overhead crane design.

European FEM Standard electric susepnsion light duty overhead crane

European type electric susepnsion light duty overhead crane is a type of overhead travelling bridge crane designed based on the European crane standards and FEM standards,, mounted on the roof of the workplace without bracket, offering larger space for production and lowering cost. The crane trolley is compact and small in volume which enables the loads to be lifted to the place as near as possible to the wall of the facility. The moving range of crane trolley can exceed crane span through side jib. The lifting capacity of European electric susepnsion light duty overhead crane is from 1 ton to 20 ton and the crane duty class is A5. Customized overhead travelling underslung crane is available.

Main parameters of European electric susepnsion light duty overhead crane

- Overhead Travelling Crane Type:NLX European type electric susepnsion light duty overhead crane

- Lifting Capacity of European Standard electric susepnsion light duty overhead crane: 1~20t

- Span Length of European Standard electric susepnsion light duty overhead crane: ≥ 6m

- Working Class of European Standard electric susepnsion light duty overhead crane:A5

- Ambient Temperature of European Standard electric susepnsion light duty overhead crane: -25~40℃

Single girder underhung cranes are typically adopted for lighter duty material handling with capacity to 10 ton or less. Our overhead Underhung design lightweight overhead crane system are designed to improve crane safety and reduce load cycle times during production in your workshops.

Single girder electric susepnsion light duty overhead crane

- European standard single girder electric susepnsion light duty overhead crane helps you to take the most of your existing plant by mounting directly on the existing roof structure and saves the cost of rail supporting beam which is needed for the non-suspension overhead travelling crane.

Double girder electric susepnsion light duty overhead crane

NLX European standard double girder electric susepnsion light duty overhead crane is usually grouped into the following two crane types:

- 1) The electric susepnsion light duty overhead crane is equipped with hanged I beam rails and the electric hoist is moving on the rails on top of upper cover plate of the main bridge girders or hanged on the lower web plates of the two bridge girders.

- 2) The suspension underslung cranes run on support rail beam of plant, the lifting hoist is suspended on two bridge girders' web-plates.

Our overhead crane design engineers will offer you the customize electric susepnsion light duty overhead crane design for you based on your specialized plant structure,, making the best use of your existing workshops or new workshop effectively and reasonably.

Traditional single girder electric susepnsion light duty overhead crane

China traditional electric susepnsion light duty overhead crane is a single girder overhead travelling crane, with single beam girder running on the suspension track, and usually equipped with CD1 type single speed wire rope hoist and/or MD1 type double speed wire rope electric hoist.The electric susepnsion light duty overhead crane / underhung crane is consisted of main bridge girder, cross beam, electric hoist, electric parts, lifting mechanic devices, etc.

The single girder electric susepnsion light duty overhead crane is a kind of light duty single girder Overhead Crane, The lifting capacity of the single girder suspension overhead travelling crane is 1 – 10 ton, and the crane span is 3m to 15 m, and the traveling speed is 20 m/min and 30m/min. Custom designed overhead travelling electric susepnsion light duty overhead crane is provided according to application conditions and lifting requirements.

Main parameters of traditional single girder electric susepnsion light duty overhead crane

- Product Type : LX Traditional single girder suspension / electric susepnsion light duty overhead crane

- Lifting capacity of electric susepnsion light duty overhead crane: 1~10t

- Span length of electric susepnsion light duty overhead crane: 3~15m

- Working class of electric susepnsion light duty overhead crane: A3

- Ambient temperature of electric susepnsion light duty overhead crane: -20~40℃

The standard under slung crane is supposed to used in the general material handling environment in machinery assembly, warehouse, storage, where no dangerous substance or media to ensure the safety of applications.

Usually, the overhead electric susepnsion light duty overhead crane is single girder design but under special conditions, double girder design is also available.

- Single girder electric susepnsion light duty overhead crane:A single girder Underhung design lightweight overhead crane system usually adopt the Under slung hoist and underslung trolley as the lifting mechanism, travelling along the bottom flange of the bridge beam girder.

- Double girder Underhung design lightweight overhead crane system:A double girder Underhung design lightweight overhead crane system can move its electric hoist and trolley along on the top or on the bottom of the bridge beam girders.

Single girder electric susepnsion light duty overhead crane

Double girder electric susepnsion light duty overhead crane

Note: The single girder design ceiling mounted electric susepnsion light duty overhead crane is widely used for lighter duty service and lower-capacity material handling whereas the double girder electric susepnsion light duty overhead crane design is used for higher capacity material handling or to get larger lifting height but with higher crane cost.. If you need electric susepnsion light duty overhead crane with special crane design, please leave a message below and reply will be given within 24 working hours.

Electric monorail light duty overhead crane

Electric monorail lightweight overhead crane is also named as ceiling mounted monorail crane or ceiling crane which offers an overhead travelling crane solution for workshops with limited space to make the most of the available space and the existing building structure, with the adding columns if required for heavy duty lifting or more complex design.

Main parameters of the monorail crane system

The ceiling mounted monorail crane also known as ceiling crane offers an overhead material handling solution for workshops with limited space to make the most of the available space and the existing building structure, with the adding columns if required for heavy duty lifting or more complex design.Customized monorail Underhung design lightweight overhead crane system are available for your customized applications. Contact us to get your monorail electric susepnsion light duty overhead crane design and monorail electric susepnsion light duty overhead crane price.

Types of Monorail Light-Duty Overhead Cranes:

Monorail light-duty overhead cranes are designed with a single rail system for lifting and moving loads along a specific path. Here's a breakdown of the types mentioned:

I-Beam Monorail Cranes:

- Design and Functionality: These monorail cranes operate on a single I-beam track or rail system mounted overhead. They are versatile and allow for the movement of hoists or trolleys along the beam.

- Usage: Ideal for straight-line material handling within a specific area or assembly lines in industries where precision and efficiency in load movement are required.

- Advantages: Offer a cost-effective solution for light-duty lifting tasks, providing a simple yet effective method of moving loads along a fixed path.

Curved Track Monorail Cranes:

- Design and Functionality: Curved track monorail cranes utilize a single rail system with a curved track. They enable the movement of loads along a predefined path with curves or bends.

- Usage: Suitable for applications where materials need to follow a specific curved path during handling or production processes.

- Advantages: Allow efficient material transport around corners or in areas with non-linear paths, enhancing workflow within the designated space.

Ceiling Mounted Monorail Overhead Cranes:

- Design and Functionality: These monorail cranes are installed on the ceiling structure, utilizing a single rail system for lifting and moving loads overhead.

- Usage: Commonly used in workshops, manufacturing, or assembly areas where overhead space is available, providing efficient material handling without occupying floor space.

- Advantages: Optimizes floor space while enabling precise and controlled movement of loads within the overhead workspace.

Floor Mounted Monorail Overhead Cranes:

- Design and Functionality: These cranes are mounted on the floor level and operate on a single rail system, providing material handling capabilities within specific work areas.

- Usage: Suitable for applications where ceiling mounting isn't feasible or in facilities where floor-based solutions are preferred for light-duty lifting tasks.

- Advantages: Offers flexibility in installation and usage, providing efficient material handling within confined or designated areas on the ground level.

Monorail light-duty overhead cranes, whether utilizing I-beam tracks, curved tracks, ceiling mounting, or floor mounting, offer efficient and controlled movement of loads within specific paths or areas. Their configurations cater to diverse material handling needs across various industries while optimizing space and enhancing workflow efficiency.

Electric KBK light duty overhead crane

KBK design lightweight overhead crane system are light duty crane systems which are offered with process crane designs to meet your particular applications.

Our suspension kbk light duty crane systems are available with the following options:

- Loading capacity of electric kbk lightweight overhead crane: 50kg-3.2t ,

- Span of electric kbk lightweight overhead crane:0.7m-12m,

- Working class of electric kbk lightweight overhead crane: A1-A6

Due to the light crane system design, the monorail kbk cranes are usually attached or suspended to the ceiling roof structures or other existing structures of the building facilities, with the features of Cost-effective due low material cost and building costs for supportive columns or structures,Maximize your floor space when no additional supportive columns required and offering large lifting height for being attached to roof ceiling structures, etc. Contact us to get more information.

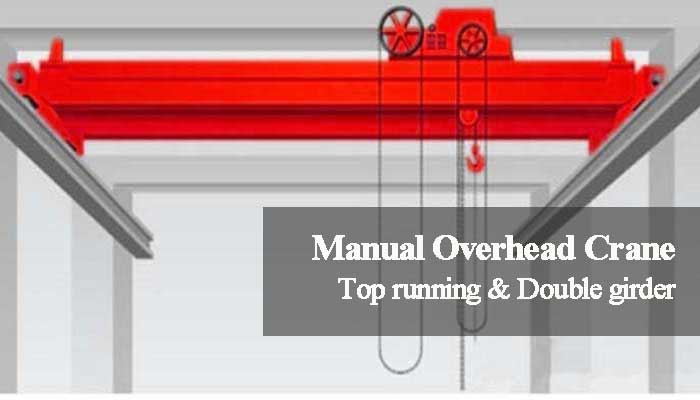

Manual power lightweight overhead crane system for light loads lifting without electric power in single girder & double girder, top running & underhung Manual power lightweight overhead crane system designs. 3- 10 ton Manual power lightweight overhead crane system for sale.

Types of Light KBK Rail Workstation Cranes

Ceiling Mounted Light KBK Rail Workstation Cranes:

- Design and Functionality: These cranes utilize KBK rail systems installed on the ceiling structure. They feature modular components, allowing for flexible and precise material handling within a designated workspace.

- Usage: Ideal for efficient and controlled movement of materials or products within a specific area without occupying floor space. Commonly used in manufacturing, assembly lines, or workshops.

- Advantages: Maximizes floor space, provides versatility in handling, and allows for efficient workflows within confined work areas.

Floor Mounted Light KBK Rail Workstation Cranes:

- Design and Functionality: These KBK rail workstation cranes are installed at the floor level and provide flexible and efficient handling within specific workstations or areas.

- Usage: Suitable for applications where ceiling mounting isn't feasible or when floor-level solutions are preferred for light-duty material handling tasks.

- Advantages: Offers adaptability to changing operational needs, easy installation, and efficient material handling within designated workstations or localized areas.

Single Girder KBK Rail Light Duty Overhead Cranes:

- Design and Functionality: These overhead cranes feature a single girder design utilizing KBK rail systems for lifting and moving lighter loads within a specific area.

- Usage: Suitable for applications where precise and controlled material handling is required within limited spaces or confined workstations.

- Advantages: Provides an efficient and cost-effective solution for light-duty lifting tasks while utilizing the versatility of KBK rail systems.

Double Girder KBK Rail Light Duty Overhead Cranes:

- Design and Functionality: Similar to single girder cranes but with enhanced stability and higher load capacities due to the presence of dual girders.

- Usage: Offers increased lifting capacities for light-duty applications, providing efficient material handling within specific work areas or stations.

- Advantages: Provides higher stability and increased lifting capabilities while utilizing the flexibility and modular nature of KBK rail systems.

These variations of KBK rail workstation cranes, whether ceiling-mounted, floor-mounted, single girder, or double girder, offer versatile and efficient material handling solutions within specific workspaces or designated areas, catering to diverse operational requirements and load capacities. The KBK Rail Workstation Cranes are characterized by their modular design, flexibility, and suitability for lighter loads in localized work areas, offering various mounting options (ceiling or floor) to optimize material handling and improve workflow efficiency in workshops, production lines, or warehouses. These types of cranes provide maneuverability and precision in handling tasks while minimizing interference with other operations within the workspace.

Manual power lightweight overhead crane system

Manual power lightweight overhead crane systems are classified into two types: single-girder overhead cranes and double-girder overhead cranes. Gear and wheels are controlled by a drive chain, and the lifting and running power is provided by manpower. Suitable for overhauling and installing equipment in no-power warehouses, workshops, and other locations with low handling volumes and no consider for power or speed.

Top running manual power lightweight overhead crane system

Top running Manual power lightweight overhead crane system can be decided into single girder Manual power lightweight overhead crane system & double girder Manual power lightweight overhead crane system, which can be selected as per your specific applications. As for the detailed specifications please feel free to contact us. WhatsApp/ WeChat: + 86 151 3981 1597.

Manual power lightweight overhead crane system - Double girder crane

Manual power lightweight overhead crane system main parameter

Lifting height | Working system | Trolley travelling speed(m/min) | Crab travelling speed(m/min) | Width of track | |

1 ton Manual power lightweight overhead crane system | 3-10 | A1- A2( light) | 5.2 | 5.3 | 37-51 |

2 ton Manual power lightweight overhead crane system | 3-10 | A1- A2( light) | 5.2 | 5.9 | 37-51 |

3 ton Manual power lightweight overhead crane system | 3-10 | A1- A2( light) | 5.2 | 4.7 | 37-51 |

5 ton Manual power lightweight overhead crane system | 3-10 | A1- A2( light) | 4.3 | 4.7 | 37-51 |

10 ton Manual power lightweight overhead crane system | 3-10 | A1- A2( light) | 4.3 | 4.2 | 37-51 |

Aside from the above-mentioned Manual power lightweight overhead crane system, custom manual crane designs are available depending on the crane requirements or your workshop drawing specifications; please contact us for additional information or leave a message below. We will provide you with a Manual power lightweight overhead crane system that will completely meet your needs.

Features of top running Manual power lightweight overhead crane system

Bridge frame, drive mechanism, trolley traveling and lifting section, and other components make up a Manual power lightweight overhead crane system.The primary beam is welded to two end beams to form the bridge frame. The main beam is equipped with a trolley track.

There are two types of Manual power lightweight overhead crane system drive mechanisms.

- The 5-10 ton transmission mechanism is a first-class transmission; each segment shaft is directly connected via coupling, drive sprocket, and driving wheel, which allows the crane to move back and forth.

- The 16-20 ton transmission mechanism is a second-class transmission that connects each segment by gears and couplings. The gear drives the driving wheel rotation, and the driven wheel rotates with it, causing the crane to move back and forth.

Trolley travel parts: the driving sprocket rotates the driving wheel, causing the trolley to move back and forth along the track.

Lifting components: a driving sprocket rotates the drum; a cable looped on the drum lifts the hook at the same time; the descending distance is controlled by a braking device.

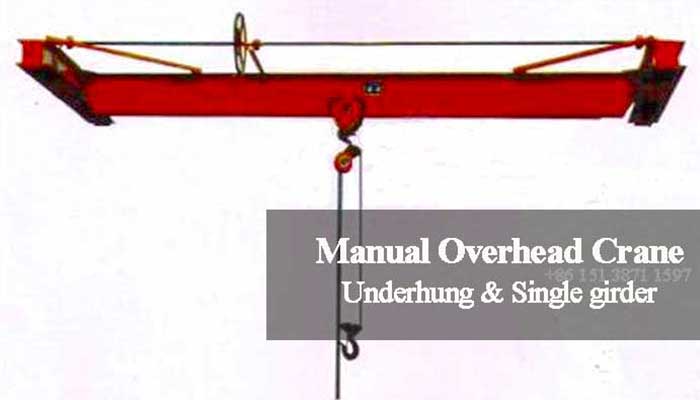

Under running Manual power lightweight overhead crane system

Installed on the top of the plant, a manual suspension overhead crane is suited for no power plant of small and light load handling and does not pay more attention to efficiency and speed. The traveling track of a manual suspension crane differs from that of a top running Manual power lightweight overhead crane system; the traveling track of a manual suspension crane is an I-steel fixed to the top of the plant. It features a modest travel speed, reliable operation, little noise, no pollution, a small footprint, and is simple to operate. It can be utilized in shops, warehouses, and other manufacturing, assembling, and repairing situations, and it can significantly reduce labor intensity and enhance job efficiency.

Manual suspension crane- Single girder crane

Manual suspension crane specification

Lifting height | Working system | Trolley travelling speed(m/min) | Crab travelling speed(m/min) | Width of track | |

1 ton manual suspension crane | 3-10 | A1- A2( light) | 5.2 | 5.3 | 37-51 |

2 ton manual suspension crane | 3-10 | A1- A2( light) | 5.2 | 5.9 | 37-51 |

3 ton manual suspension crane | 3-10 | A1- A2( light) | 5.2 | 4.7 | 37-51 |

5 ton manual suspension crane | 3-10 | A1- A2( light) | 4.3 | 4.7 | 37-51 |

10 ton manual suspension crane | 3-10 | A1- A2( light) | 4.3 | 4.2 | 37-51 |

Push/Pull Manual power lightweight overhead crane system

The ability to manage the speed of push/pull type overhead bridge cranes is one of their major advantages. Operator-controlled push/pull cranes accelerate and decelerate at the same pace as the operator. In many circumstances, this is more efficient than using powered (motorized) cranes with preset speed points to handle the same loads.The most cost-effective bridge cranes are those with standard I-beam construction and underhung push/pull manual cranes.

Push / Push Manual power lightweight overhead crane system

Push/pull Manual power lightweight overhead crane system features:

- Manipulates modest loads in a cost-effective manner

- When crane operation is not too high, this is the best option.

- Some situations, such as slick floors and regions with many floor impediments, may not be suitable to this type of system due to the applied force required to move the bridge crane.

- Exceptional control of speed.

Hand Chain Drive Manual Underhung Cranes

Bridge cranes with chain drives are moved by pulling the hand chain that drives the geared wheels in one way or the other. While this gearing makes moving goods easier than a push/pull method, it also slows down the process. This makes it much easier to place a load at a precise area.Underhung manual overhead bridge cranes are generally less expensive than top-running cranes of same capacity, but they are also more robust and simple to operate.

Features of Manual power lightweight overhead crane system:

- Moves loads up to 15 tons for a low cost.

- Allows for precise spotting.

- Pumping stations, assembly applications, and maintenance bays are all good candidates.

Manual chain hoists, air hoists, electric hoists, and air balancers all operate well with Manual power lightweight overhead crane system. If you have any inquiry or question, please feel free to contact us to get your customized maual overhead crane.

Light Duty Overhead Cranes Based on Mounting Types

Light Duty Wall Mounted Jib Crane:

- Design and Functionality: This type of crane is designed for wall mounting and offers a jib arm that can rotate around a central pivot point. It is specifically engineered for lighter loads and provides localized lifting within a limited radius.

- Usage: Ideal for applications where precise and light-duty material handling is required within confined spaces or workstations. Commonly used in workshops, assembly lines, or areas where small-scale lifting operations are frequent.

- Advantages: Provides flexibility and efficient material handling without occupying floor space. The wall-mounted design optimizes space utilization and offers a clear working area on the ground.

Light Duty Wall Travelling Jib Cranes:

- Design and Functionality: These cranes are wall-mounted and equipped with mechanisms that allow horizontal travel along the wall, providing extended coverage within the working area.

- Usage: Suitable for applications requiring lateral movement or broader coverage for light-duty lifting tasks. They offer versatility in material handling across a larger horizontal area while still maintaining a small footprint.

- Advantages: Allows efficient material handling within a limited radius, along with horizontal movement capabilities, enhancing flexibility and coverage during lifting operations.

Wall Travelling Bridge Cranes:

- Design and Functionality: Workstation bridge cranes are mounted on walls or ceilings and feature a bridge beam or trolley system for moving loads within a specific workstation area.

- Usage: Ideal for lifting and moving materials within a designated workstation or assembly area, providing efficient workflow and material handling.

- Advantages: Maximizes floor space, offers flexibility in handling materials, and enables easy movement of loads within confined workstations or assembly lines.

These wall-mounted or wall-traveling cranes, such as light-duty wall-mounted jib cranes, wall-traveling jib cranes, and workstation bridge cranes, are designed to optimize space utilization, provide efficient material handling, and cater to specific lifting needs within confined workspaces or designated areas.

Light Duty Ceiling-Mounted or Ceiling-Traveling Cranes

Ceiling-mounted light-duty bridge cranes refer to overhead cranes installed on the ceiling structure using a single girder design, specifically engineered for lighter load capacities and efficient material handling within limited spaces. Here are the key aspects of ceiling-mounted light-duty bridge cranes:

Light Duty Ceiling Mounted Cranes Types

Ceiling Mounted Workstation Cranes:

- Design and Functionality: These cranes are installed on the ceiling structure and are designed for material handling within specific workstations or areas. They typically feature a bridge beam or jib arm for lifting and moving loads.

- Usage: Ideal for light-duty lifting tasks in workshops, assembly lines, or production areas where localized material handling is required without using floor space.

- Advantages: Maximizes floor space, offering efficient material handling within confined work areas without obstructing ground-level operations.

Light Ceiling Monorail Cranes:

- Design and Functionality: Ceiling-mounted monorail cranes use a single rail attached to the ceiling structure for lifting and transporting loads. They provide linear movement along the rail, suitable for light-duty applications.

- Usage: Commonly used in production lines or assembly areas where straight-line material handling is needed. They offer versatility and space efficiency in moving materials.

Light Duty Telescoping Bridge Crane:

- Design and Functionality: Telescoping bridge cranes are ceiling-mounted and equipped with telescopic arms or beams that extend and retract, providing flexibility in reach and coverage.

- Usage: Suitable for applications where varying coverage or reach is required, allowing for efficient material handling in different areas within a workspace.

- Advantages: Offers adjustable reach, providing flexibility in lifting and moving loads across various workstations or points within the operational area.

These types of ceiling-mounted or ceiling-traveling cranes offer specific functionalities tailored for light-duty material handling needs in workshops, production areas, or assembly lines. They optimize space utilization and provide efficient lifting and movement of loads within confined or specific work areas without hindering ground-level operations.

Design and Functionality:

- Single Girder Configuration: These cranes feature a single horizontal beam (girder) attached to the ceiling structure via supports or hangers. The single girder design optimizes the crane's weight and is suitable for handling lighter loads.

- Ceiling-Mounted: Installed on the ceiling, they free up floor space and provide a clear working area below for other operations or machinery.

Usage and Applications:

- Light-Duty Material Handling: Ideal for handling lighter loads in workshops, assembly lines, or smaller production areas.

- Confined Workspaces: Suitable for facilities with limited space or low headroom where floor-based cranes might not be practical.

Advantages:

- Space Optimization: Maximizes available floor space for other operations or equipment since the crane is mounted overhead.

- Versatility: Provides flexibility in lifting and moving materials within the designated area without obstructing ground-level operations.

Features and Benefits:

- Efficient Handling: Offers efficient and precise material handling for tasks that involve smaller loads or require localized lifting and movement.

- Cost-Effective Solution: Light-duty bridge cranes are often a cost-effective option for facilities with specific lifting needs while optimizing space utilization.

Customization and Adaptability:

- Tailored Solutions: Can be customized to suit specific load capacities, lifting heights, and workspace requirements.

- Adaptable Control Systems: Integration of modern control systems allows for easier operation and enhanced safety features.

Ceiling-mounted light-duty bridge cranes provide an efficient and space-saving solution for handling lighter loads in confined or limited working spaces. Their overhead installation ensures minimal interference with ground-level operations while offering precise and controlled material handling within the designated area.

Floor Mounted Light Duty Cranes

Freestanding Light Duty Bridge Crane:

- Design and Functionality: These cranes feature a single or double girder design, providing overhead lifting capabilities. They are freestanding and do not require attachment to building structures.

- Usage: Ideal for localized lifting and material handling within specific workstations or confined areas where overhead support structures may be limited.

- Advantages: Offer efficient lifting without depending on building support, allowing flexibility in positioning and usage within the workspace.

Freestanding Light Gantry Crane:

- Design and Functionality: Gantry cranes have a self-supporting structure with legs that straddle the working area. They provide horizontal movement along the gantry beam, offering flexibility in lifting and moving loads.

- Usage: Suitable for areas where overhead support might not be feasible. These cranes are commonly used in workshops, warehouses, or outdoor settings for versatile material handling tasks.

- Advantages: Allow easy movement and relocation within the workspace without the need for fixed overhead support structures.

Freestanding Light Jib Cranes:

- Design and Functionality: Jib cranes have a vertical post or pillar mounted to the floor with a horizontal jib arm that rotates. They provide localized lifting within a limited radius, offering versatility in handling lighter loads.

- Usage: Commonly used in workshops, production lines, or areas where precision lifting and positioning of materials are required within a limited workspace.

- Advantages: Provide efficient lifting and maneuverability within a smaller radius, suitable for workstations or specific points where overhead clearance might be restricted.

These floor-mounted, freestanding light-duty cranes offer specific functionalities and advantages suited for different operational requirements. They provide efficient lifting solutions while offering flexibility, mobility, and localized material handling capabilities within industrial or workshop settings.

Light Portable Cranes

Portable cranes offer flexibility and mobility, allowing them to be easily moved and utilized across various work areas. Here's an overview of the different types of light portable cranes:

- Design and Functionality: A portable gantry crane features a movable structure with wheels or casters that can be easily transported. It consists of a horizontal beam supported by vertical legs, providing overhead lifting capabilities.

- Usage: Ideal for temporary lifting needs or in locations where a fixed overhead structure isn't available. Commonly used in workshops, construction sites, or warehouses for versatile material handling tasks.

- Advantages: Offers mobility and easy relocation, allowing for flexible usage across different workstations or job sites.

- Design and Functionality: Portable jib cranes have a base designed for mobility and easy repositioning. They typically feature a vertical post or pillar with a horizontal jib arm that rotates, providing localized lifting within a limited radius.

- Usage: Suitable for applications where precise and flexible lifting is required in different areas within a workspace or job site. Commonly used in workshops, construction sites, or maintenance facilities.

- Advantages: Provide maneuverability and ease of use, offering a compact lifting solution for various workstations or temporary job requirements.

- Design and Functionality: These cranes are constructed from lightweight aluminum materials, offering durability and corrosion resistance. They are designed for portability and can be easily moved between work areas.

- Usage: Suitable for tasks requiring lightweight lifting in different work environments. Commonly used in industries such as maintenance, inspection, or assembly where mobility and ease of use are essential.

- Advantages: Lightweight and easily transportable, providing flexibility and efficient lifting solutions in diverse work settings.

These types of light portable cranes offer mobility, versatility, and ease of use, making them suitable for various applications across different industries. Their portability allows for flexible material handling solutions in different work environments, providing efficient lifting capabilities wherever needed.

These classifications based on crane structure design and mounting type provide insights into the different configurations available for light-duty overhead cranes, catering to specific load capacities, space limitations, and operational requirements in various industries and work environments.

Operational Classifications:

Operational classifications of cranes are essential to understand their functionalities and operation modes. Here's a detailed explanation:

Manual Cranes:

- Design and Functionality: These cranes are operated entirely by human effort, utilizing hand-controlled mechanisms like handwheels or levers for lifting and movement.

- Usage: Commonly employed in applications where precision, smaller loads, or infrequent lifting operations are involved. They're utilized in smaller workshops, maintenance tasks, or places where automation isn't necessary or feasible.

- Advantages: Simple operation, low maintenance, and cost-effectiveness. They offer versatility for lighter loads and specific tasks but may require more human effort and time.

Semi-Automated Cranes:

- Design and Functionality: These cranes are equipped with semi-automated features, including electric hoists or simplified controls, assisting manual operations.

- Usage: Used in applications where some level of automation is needed to assist manual labor, improving efficiency and reducing physical strain. They're suitable for repetitive lifting tasks or where precise movements are necessary.

- Advantages: Provide a balance between manual operation and automation, offering increased efficiency and reduced physical exertion for the operators. They are adaptable to various industries and tasks requiring moderate automation.

Both manual and semi-automated cranes serve specific purposes based on operational requirements, workload, and precision needed in material handling tasks. Manual cranes offer simplicity and cost-effectiveness, while semi-automated cranes provide a balance between human effort and automation to enhance efficiency and reduce physical strain during lifting operations.

Specific Use Classifications:

Light Assembly Cranes:

- Design and Functionality: These cranes are specifically designed for assembly line tasks or smaller production processes that demand precise and controlled handling of materials or components.

- Usage: Commonly utilized in manufacturing settings where there's a need for controlled, repetitive movements during assembly operations. They are ideal for precise positioning and placement of components or materials.

- Advantages: Offers precise and controlled material handling, enhancing the efficiency of assembly processes. They optimize workflow by facilitating smooth and accurate placement of parts or items during production.

Maintenance Cranes:

- Design and Functionality: Maintenance cranes are primarily used in maintenance bays, workshops, or service areas to lift and handle tools or equipment during repair or servicing tasks.

- Usage: Utilized for lifting heavy tools, machinery, or parts during maintenance activities. They facilitate the safe and efficient handling of components, aiding maintenance and repair work.

- Advantages: Enhances safety and efficiency during maintenance tasks by providing a reliable means of lifting and positioning tools or equipment. They contribute to smoother maintenance operations by ensuring safe handling and precise positioning of heavy components or machinery.

Both light assembly cranes and maintenance cranes serve specific purposes in different industrial settings. Light assembly cranes focus on precise handling during assembly processes, optimizing production efficiency. On the other hand, maintenance cranes facilitate safe and efficient lifting and handling of tools or equipment during maintenance tasks, ensuring smoother repair or service operations.

These classifications highlight the variations in load capacities, functionalities, and specialized uses of light-duty overhead cranes, catering to the specific needs of smaller workshops, factories, and light industrial operations that handle loads typically up to 5 tons or less.

Factors to Consider When Choosing a Light-Duty Crane

Load Capacity and Weight Considerations

Determining the load capacity is crucial when selecting a light-duty overhead or bridge crane. Analyzing the weight of the heaviest load to be lifted helps in choosing a crane that meets the required lifting capacity while considering potential future load increases. It's essential to ensure the crane's lifting capacity aligns with operational demands without overloading the system.

Span and Working Area Requirements

The span, which refers to the distance between the runways, directly influences the crane's coverage area. Understanding the working area dimensions and the crane's required span helps in choosing the appropriate crane configuration. Additionally, considering aisle widths, clearance heights, and any obstacles within the operational space is vital for optimal crane functionality.

Hoist Speed, Control Systems, and Safety Features

Hoist speed plays a critical role in operational efficiency. Assessing the required hoist speed based on production needs helps in selecting a crane that meets those speed requirements without compromising safety. The control system's sophistication and safety features like limit switches, emergency stops, and overload protection should also align with operational safety standards and regulatory requirements.

Environmental and Operational Conditions

Evaluate the environmental conditions where the crane will operate. Factors such as temperature, humidity, dust, and corrosive elements can impact crane performance and longevity. Selecting components and materials suitable for the specific operational environment ensures optimal crane functionality and longevity.

Customization Options for Specific Industry Needs

Different industries often have unique requirements. Crane manufacturers provide customization options to tailor the crane to specific industry needs. These options include specialized hoists, trolleys, controls, and additional safety features, ensuring that the crane is optimized for a particular industry's demands.

Customized Specifications for Light-Duty Cranes

Understanding Specialized Requirements

Industries often have unique and specialized material handling needs that demand tailored solutions. Understanding these specific requirements is crucial when considering the customization of light-duty overhead or bridge cranes. This involves analyzing factors such as load characteristics, operational constraints, and any special handling needs within the industry.

Customization Options: Hoist Type, Trolley Configuration, etc.

Crane manufacturers offer a myriad of customization options to meet diverse industrial needs. These options include variations in hoist types, such as wire rope or chain hoists, and trolley configurations, which can range from manual to motorized or even automated systems.

Additionally, customization may involve selecting specific control systems, adding auxiliary equipment like lights or warning systems, or integrating specialized safety features. Each customization option aims to optimize the crane's functionality for specific operational requirements.

Importance of Consulting with Crane Manufacturers for Tailored Solutions

Collaborating with experienced crane manufacturers is integral to achieving tailored solutions. These manufacturers possess extensive knowledge and expertise in designing and building light-duty overhead and bridge cranes. By engaging in consultations, buyers can leverage this expertise to articulate their specific needs and explore available customization options.

Selecting the Right Light-Duty Crane for Specific Industries

Manufacturing Sector: Matching Cranes to Production Needs

In the manufacturing sector, the choice of light-duty overhead or bridge cranes depends on the production processes and handling requirements. For instance, in assembly lines, single girder cranes with swift movement capabilities might be ideal. In contrast, double girder cranes could suit facilities dealing with heavier materials or larger product assemblies.

Warehousing and Logistics: Efficient Material Handling Solutions

Efficiency is key in warehousing and logistics. Top running cranes might be preferred in high-bay warehouses to maximize vertical storage space. Under running cranes, on the other hand, are beneficial in smaller storage spaces, ensuring flexible and precise material handling while optimizing available area.

Construction Industry: Adaptability for On-Site Operations

The construction industry demands cranes that can adapt to various on-site requirements. Portable or mobile light-duty cranes can provide flexibility for lifting and placing materials in different construction zones. These cranes must also adhere to safety standards and maneuverability for diverse on-site applications.

Other Industries: Agriculture, Automotive, Aerospace, etc.

Industries such as agriculture, automotive, and aerospace have unique material handling needs. Agriculture might benefit from cranes for handling produce or equipment, while the automotive sector may require precision in assembly tasks, demanding specialized hoists and controls. Aerospace might need cranes capable of handling delicate and heavy components safely.

Buying Guide and Market Overview

Researching Reliable Crane Manufacturers and Suppliers

Thorough research is crucial when considering crane manufacturers and suppliers. Evaluate their reputation, experience, and track record in delivering quality light-duty overhead and bridge cranes. Customer reviews, referrals, and industry certifications serve as reliable indicators of a manufacturer's credibility.

Evaluating Quality, Reliability, and Service Support

Quality and reliability are paramount when investing in a light-duty crane. Assess the materials used, engineering standards adhered to, and the overall build quality. Additionally, examine the manufacturer's service support, including after-sales services, technical support, and availability of spare parts.

Budget Considerations and Cost Analysis

Establishing a budget is essential and should encompass the entire cost spectrum, including crane purchase, installation, and ongoing maintenance. Conduct a comprehensive cost analysis, considering long-term operational savings against the initial investment. Balance between affordability and the quality of the crane to ensure value for money.

Understanding Warranty, Installation, and Maintenance Services

Understanding warranty coverage, installation processes, and available maintenance services is crucial. A comprehensive warranty ensures protection against potential manufacturing defects. Additionally, inquire about installation requirements and associated costs. Assess the availability of maintenance services and their terms to ensure the crane's consistent performance and longevity.

Get Your Custom Light Duty Overhead Cranes

Choosing the right light-duty overhead or bridge crane entails careful consideration of several factors. Elements such as load capacity, working area requirements, control systems, environmental conditions, and customization options significantly impact the effectiveness and suitability of the crane for a particular industry.

Tailored solutions are pivotal in ensuring optimal performance and efficiency. Industries with specific material handling needs can benefit immensely from customized light-duty cranes. These solutions not only enhance productivity but also streamline processes, improve safety, and adapt seamlessly to evolving operational demands.

Collaborating with crane experts and manufacturers is instrumental in making informed decisions. Their expertise, combined with a comprehensive understanding of industry needs, aids in identifying the most suitable crane configuration. Engaging in consultations ensures that the chosen crane aligns precisely with operational requirements and industry standards.

In conclusion, the selection of a light-duty overhead or bridge crane involves a comprehensive assessment of requirements, considerations, and available options. By focusing on tailored solutions and seeking expert guidance, industries can effectively address their material handling challenges and optimize operational efficiency.

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch