Monorail Cranes & Monorail Hoist System

Monorail crane & monorail hoist system-Ceiling monorail & Free standing monorail- A cost-effective alternative to bridge crane,gantry crane & conveyor belt in workstations.

| Lifting Capacity | 250kg-15000kg |

| Lifting Height | 3m-120m |

| Working Duty | A3, A4 |

| Mounting Type | Ceiling mounted or floor mounted |

| Rail Type | I beam or H beam |

Category: Light KBK Crane

Your Trusted Overhead Travelling Cranes Manufacturer & Supplier

Ceiling & Free Standing, Straight & Curve

Monorail Cranes & Monorail Hoist

Monorail Crane Systems including Ceiling monorail crane & Free standing monorail crane is an ideal and cost-effective alternative to bridge crane, gantry crane and conveyor belt in workstation. The monorail crane system is equipped with monorail hoist system, either electrical hoist or manual hoist , chain hoist or wire rope hoist, running on H beam or I beam, straight or curved, for material handling in production section, assembly lines and various workplaces to improve working efficiency.

What is a Monorail Crane System ? A monorail crane system is a simple and effective overhead travelling crane solution. A monorail crane is equipped with a monorail hoist attached with a trolley moving along a I beam or H beam, either straight or curved to lift and move the loads along the beam to the designated location.

The i beam or H beam of monorail hoists can be directed hung on the ceiling structure or mounted on a floor mounted column, which is determined by the ceiling elevation and the lifting capability required.The monorail crane and hoist system can be installed in the workstation and factory without much change to the building structure with high adaptability.

Ceiling mounted monorail crane system

The ceiling mounted monorail crane also known as ceiling crane offers an overhead material handling solution for workshops with limited space to make the most of the available space and the existing building structure, with the adding columns if required for heavy duty lifting or more complex design.Main parameters of the monorail crane system

- Lifting capacity of the monorail crane:250kg-15000kg

- Lifting height of of the monorail crane:3m-120m

- Working duty of of the monorail crane:A3, A4

- Mounting types of of the monorail crane: Ceiling mounted or floor mounted

- Types of monorail hoists: Electric hoists or manual hoists , Chain hoists or Wire rope hoist

- Rail type of the monorail crane: I beam or H beam

The ceiling mounted monorail crane also known as ceiling crane offers an overhead material handling solution for workshops with limited space to make the most of the available space and the existing building structure, with the adding columns if required for heavy duty lifting or more complex design.

Curved ceiling mounted monorail cranes

Ceiling mounted European suspension crane

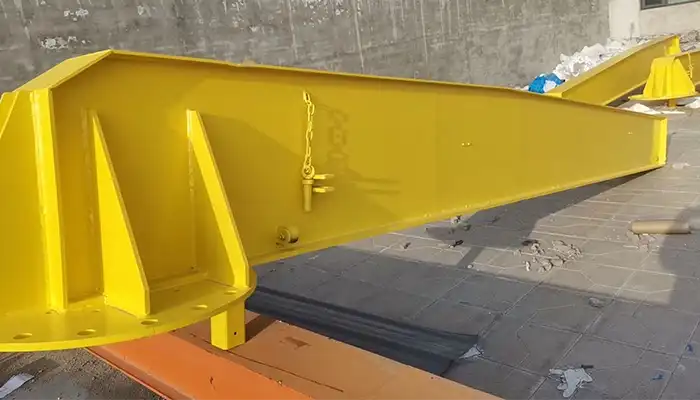

Floor mounted monorail crane system

The floor mounted monorail system also known as free standing monorail crane provides a lifting solution with fast speed, long span and heavy duty for applications where no supporting structure is available.

Main parameters of free-standing Monorail Crane

- Loading capacity of free standing monorail cranes : 1t-20t

- Travelling length of free standing monorail cranes: as customized

- Working class of free standing monorail cranes: A4, A5

- Process free standing monorail cranes are also available.

Freestanding monorail cranes offer permanent overhead travelling cranes with large capacity, long span and fast speed. The freestanding monorail cranes are ideal solution for loads lifting when there is no mounting structures available. The free standing cranes are offered with process crane design to fit your particular applications in terms of cantilevered systems, H-frames,and U shapes, etc.

Freestanding monorail crane

Freestanding overhead monorail crane

Freestanding kbk monorail crane

Ceiling mounted monorails cranes vs. Free standing monorails cranes

Monorail cranes systems are often adopted in industrial manufacturing workshops or facilities as part of a complete overhead travelling cranes solution. Monorail crane systems can be designed into various types and configurations. In terms of supporting structures, the monorail cranes systems can be designed into ceiling mounted monorails and floor mounted type monorail system.

Ceiling mounted monorail cranes -The ceiling mounted monorail crane also known as ceiling crane offers an overhead material handling solution for workshops with limited space to make the most of the available space and the existing building structure, with the adding columns if required for heavy duty lifting or more complex design.

Freestanding monorailcranes -Free standing monorail cranes are widely used when the ceiling hung systems isn't feasible because of the ceiling weight restrictions or other limitations. Free standing monorails doesn't requirement the support of your building structure but supported on floor mounted columns.

Monorail cranes can be suspended directly to the ceiling structure of a workshop or warehouse and also it can be supported on the floor-mounted column, which is determined by the ceiling elevation and the demanded lifting capability. The overhead monorail hoist crane system will be the most cost-competitive overhead crane solution for your workshop, warehouse, workstation and other applications. Click to learn more Ceiling Suspended Monorail & Freestanding Monorail Lifting System

Your Trusted Monorail Manufacturer & Supplier

Which Type of Monorails to Choose ?

Straight Monorails & Curved Monorails

The monorail lifting crane can move in a straight line, simply on a H beam or I beam suspended on the roof or building structure to improve efficiency and also the monorail crane can move on a rail system which includes curves, loops and elevation changes.

Overhead H beam crane & I beam cranes

A straight monorail crane is a type of lifting device for carrying a load from point A to point B, which can carry the object efficiently along a predefined path.

Suspension monorail

Suspension monorail crane, Chinese suspension crane

Ceiling mounted European suspension crane

Curved monorails

The curved monorails should be designed based on the configuration of the site. Curved monorail crane systems are attached directly to a concrete slab or a steel structure of building facility or to a self-supporting structure, which is consisted of couple beams and base assembly,etc.

Curved monorail chain hoist crane

Curved monorail chain hoist crane

Curved monorail wire rope hoist crane

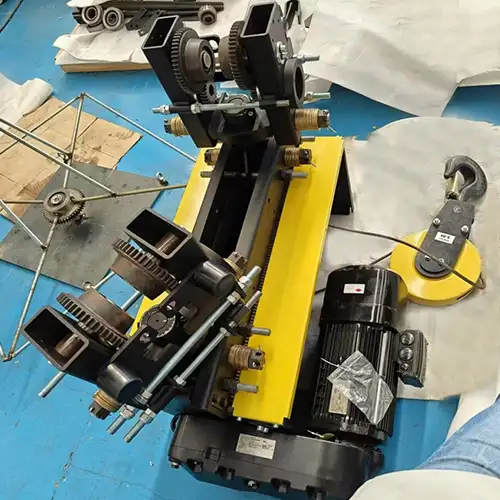

Monorail hoists

What is a monorail hoist? A monorail hoist is designed for monorail cranes for efficient material handling with high safety. Monorail hoists are widely adopted on monorail cranes either in straight or curved, and on single girder overhead crane, monorail jib crane, and monorail gantry crane, or H beam crane or I beam cranes, etc.

European Style Monorail Electric Hoist

The monorail hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder cranes, etc.

Chinese Style Monorail Electric Wire Rope Hoist

The Chinese type monorail hoists are applicable for various types of single girder overhead travelling crane, single beam crane, H beam crane, I beam crane, monorail crane, and other types of single girder cranes, etc.

Electric Trolley Monorail Electric Chain Hoist

Types of monorail crane hoist designes are available for your single girder overhead travelling crane. Contact us to get your overhead crane design and good overhead crane price.

Low Headroom Monorail Electric Chain Hoist

Types of monorail crane hoist designes are available for your single girder overhead travelling crane. Contact us to get your overhead crane design and good overhead crane price.

Mini Small Monorail Electric Chain Hoist with Single Phase

Mini electric wire ropes hoists - fixed hoist design & electric trolley type- 0.2 ton- 1 ton mini rope lift, single phase mini electric hoists, cheap small hoist for sale.

Monorail manual and Hand Chain Hoist & Chain Block

Manual chain block & manual chain hoist for sale. Light,economical & handy manual hoists & hand hoists of 250kg, 1 ton, 1.5 ton , 2 ton , 3 ton , 4 ton , 5 ton , 6 ton,etc.

In terms of hoisting system, the monorail cranes can be grouped into manual monorail crane & electric monorail lifting crane. Generally, the monorail crane can be equipped with various types of hoists, such as manual monorail hoist,monorail chain block, monorail chain pulley block,electric chain fall hoist, electric wire rope hoist, and other customized hoists, etc.

Features of Monorail Crane

- Small-size hardened reducer is adopted in overhead monorail cranes with high efficiency and high accuracy to ensure stability of during crane operation.

- Three-in-one driven equipment and Multiple- speed-adjustable control are used, with features of free maintenance.

- Selection of power supply - safe &seamless slide line, or soft cable.

- Direct control- The motor is controlled by electric contactor, which realize the single&double speed or positive&negative turn.

- National standardized submerged automatic arc welding modes are used.

- Customized designs and configurations are available for the monorail hoist crane system in term of girder length or shape, mounting types, hoist types and others, etc.

- Latest power feed technologies and radio and inverter control are used to ensure the driving and hoisting smooth.

- Full set of protection system- Short -circuit protection, out- voltage protection, emergency stop button, overload limiter, over height limiter, and interlocking devices, etc.

Benefits of Monorail Cranes

Although there are many types of monorail hoist cranes, they all share the same advantage and benefits:- Customized design , High Adaptability- With various designs & configurations , the monorail cranes can be customized to your applications with high adaptability . According to the features of applications and lifting requirements, the monorail hoist crane can be customized in terms of crane mounting, monorail hoisting system, rail design, crane control, below hook devices, and others specialized devices to adapt to your application fully.

- High Flexibility, Good alternative- Monorail cranes are very flexible and can be used in tiny areas, space limited areas or areas with many obstacles where a forklift or other overhead travelling crane is awkward or impractical. Compared with a conveyor belt or other similar lifting and transferring system, a monorail crane system can make full use of your workshop space and save your floor from blockages, which will be a better and cos-effective alternative for overhead crane, gantry crane, and conveyor in particular applications.

- Optimized rail path, efficient material handling- With optimized rail path design,the monorail cranes can move loads to the designated location directly in the most efficient way, avoiding long routes when navigating the obstacles.

- Easy Control, Safe operation- With automated control system , the monorail hoist crane can be controlled easily and correctly. Correct operation will ensure the safety of crane operation.

Application

With various designs and configurations, the monorail hoist crane systems have a very wide application due to its high flexibility and adaptability and cost-effectiveness.- Usually, the monorail crane and hoist system is widely used for material handling in application where loads are required to move from one place to anther location repetitively.

- And also the monorail crane are widely used in restricted place where an overhead travelling crane is not possible.

- The monorails cranes are good optional solutions for applications where loads are too heavy or bulky to move with lift trucks or workstation cranes.

- The monorail cranes are widely adopted to applications where there is no requirement for long travel, such as automobile manufacturing, workshop maintenance and many other industrial applications, etc.

What is monorail crane systems?

A monorail crane system is a stationary overhead track on which trolley and monorail hoist move loads throughout a facility from one location to another. Because they improve production workflow and foster a secure working environment, monorail cranes are the perfect choice for linear, overhead material handling.

Main parts and components of monorail crane

These are the main components of a monorail system: Monorail hoist, festoon, trolley, and a monorail beam

The monorail beam, which is a solitary stationary beam either strainght or curved supported by the ceiling- or floor-mounted frame, is the path taken by the hoist and trolley. The monorail is suspended under the monorail beams or tracks.

Options & Accessories

Optional: aluminum and accessories (add-ons) include interlocks/transfers, switches, curves, and special finishes based on application requirements.

What is main types of monorails ?

The versatility of monorail overhead cranes allows the development of a wide range of solutions. Our monorail cranes are guaranteed to satisfy the needs of your particular applications. The main types of monorail crane systems are listed below, including:

Types of monorail cranes

- To increase floor area, ceiling-supported monorail systems are most frequently used.

- If the structure of your building is insufficient to sustain the monorail crane system, floor supported monorails are also an option.

- Single beams offer greater versatility by allowing for straight monorail or curved monorail portions.

- Monorail crane systems frequently include interlocks and/or switches to make switching between systems simple.

What are the benefits and limitations of monorail crane system?

Monorail cranes work best in manufacturing settings when goods need to be transferred repeatedly from one place to another. For applications requiring a small lifting capacity, the monorail crane, hoist and trolley are a more affordable option than overhead crane or gantry cranes.

The transportation of materials to workstations, assembly activities, and lines where parts are blasted, painted, or coated are a few examples. In locations where a bridge overhead crane is impractical, monorails can be used as an alternate method of material handling.

Monorail cranes may be used in practically any building thanks to their simple design.

Large items may need to be moved around factories or building sites throughout the day. Nonetheless, you might need to take into account the building you're using when erecting a crane to lift these materials. Certain buildings lack the space required for conveyor belts or a standard overhead crane to operate. A monorail crane may be useful in this situation. They can conserve floor space and are simple to install on the majority of structures. As a result, you can transport your heavy goods from one location to another without running out of room or endangering the structure you're using.

A monorail crane can be altered to suit both indoor and outdoor operations.

A monorail can be utilized both indoors and outdoors, whether you have an indoor factory and need a crane to move goods for an outdoor setting. Also, they can be modified as necessary to reflect changes to your project. So, your monorail system can be customized to your new configuration if you need to make modifications to your setup.

Monorail cranes are fast and simple to use for moving objects.

Sometime the traditional cranes can be difficult to operate. With so many variables such as leverage, speed, weight, and so on, moving products can take more time and energy than expected. Monorail cranes are simple to operate and transport items in a timely and safe manner. So you can get set up quickly and start working right away.

What are the limitations of monorail cranes?

Monorail crane system have only two hook movement axes: up/down with the electric hoist hook movement and forward/back along the monorail beam and monorail track. If your application needs lateral motion, you'll need to consider other options, such as an overhead crane or gantry crane.

What Can Monorail Cranes Do for You?

The light monorail cranes have a wide range of applications in a variety of sectors.The monorail crane systems can be used to

- move, store, and queue up materials above the ground, etc.

- hoist a load over a predetermined route.

- Multiple lines and storage.

- Material switching and transfer.

When to use monorail crane and curved monorail system?

Monorail cranes are made to tackle the time-consuming, repetitive tasks that lead to staff burnout. A monorail crane can speed up the process and boost efficiency at the workplace in applications where materials need to be transferred laterally from one place to another. Our monorail crane systems are an affordable substitute for larger, more complex bridge cranes and gantry cranes.

A monorail crane system will precisely follow your current framework.

- Lift along both a straight and curved path.

- Enable for the movement of goods through narrow passageways.

- Be transformed into a girder crane system.

A monorail system could be the solution if you routinely handle products that are too large or cumbersome to transfer with lift trucks or workstation cranes. Monorail cranes maximize the vertical space in your business while providing superior power and load management. They are often utilized for heavy-duty applications in almost every sector of the economy, including the production of automobiles, power generation, and more. Waste water treatment plants, loading docks, assembly lines, and manufacturing processes typically use monorails.

How Is a Monorail Different from an Overhead Crane?

A monorail crane has no moving girder, in contrast to bridge and gantry cranes. Instead, a supporting I-beam is followed by the trolley as it pulls the hoist. Only up and down as well as along the I-track beam's can the load be shifted in three dimensions.

The monorail crane configuration has the enormous benefit of not requiring a linear I-beam, which is one of its main advantages. It is actually possible for it to be curved, which would allow the hoist to travel through a complicated course between stations. Moreover, the plan may have branches, switches, and even elevation changes.

Installations of monorail cranes are typically tailored for certain purposes. They are frequently used, for instance, to move products through a production process or along an assembly line.

Monorails

Monorail cranes are distinct from other types of cranes since they are made to move loads in a single linear path. This simple solution, which is likely the best for linear overhead material handling, improves facility productivity and safety.

Comparison Between Overhead Crane and Monorail Crane

Both for material handling works.

Both overhead crane and monorail cranes perform the same type of material handling works.

The running track is clearly different.

- Overhead crane for longitudinal moving along crane rails. In the overhead crane, its crane rails and tracks are laid on the both side of the crane girder, and the birdge crane move on both sides of elevated longitudinal running. Of course, it's a running lifting trolley on the lateral bridge. As a result, it provides an excellent solution for lifting heavy materials while not impeding ground equipment.

- Monorail crane for straight and curved movement along track for liner movement. Whereas, a monorail crane has a hoisting mechanism. It can move along the monorail crane mechanism's track direction. The electric hoist suspends to drive on track and hoist to do simple linear movement along the track direction.

Crane application is different

Even though both overhead cranes and monorails are used for material handling their application and operation conditons are different .

- The ovehread cranes are widely used for docks and opens in both indoor and outdoor warehouses, with capacity from 1 ton to 320 ton. They can be used for a variety of purposes that are tailored to specific movements.

- Monorail cranes, on the other hand, are ideal for making a noticeable difference. It is primarily used to lift heavy objects and takes into account linear interval applications, with capacity up to 20 ton.

Easy lifting mechanism

Overhead crane for material handling in 3 dimension space

- Crane travelling or long travelling along crane rail for horizontal movement

- Cross travelling of crane hoist along crane girder

- Vertical travelling of hoist hook

Monorail crane for material handling in 2 direction - vertical and liner movement

- Monorails hoist movement along crane rail or track path for liner movement

- Monorail hoist hook move for vertical lifting

Why the price of monorail cranes is more economical than overhead crane?

A monorail crane system is one of the most affordable crane systems on the market.

A typical monorail crane will cost roughly half the price of a bridge crane, depending on capacity. This is due in part to the fact that a monorail crane is more minimal and thus has a lighter-weight structure, as well as the fact that it does not require motorized end trucks to operate the hoist's linear motion.

Another cost consideration is that monorail cranes require less maintenance than overhead bridge cranes due to fewer moving parts. This means that they have lower long-term operating costs than bridge cranes. Click to check Overhead Crane vs.A Frame Gantry Crane, Monorail Cranes

Is a monorail crane right for my application and uses?

Because of all of the obvious advantages of a monorail crane system, there are only two factors that will influence whether you install one or not.

- Is your manufacturing or production process following the same linear path?

- Is the cost of a bridge crane over budget?

If your crane needs to pick up and set down a load along the same linear path, there is no better solution than a monorail crane.

Aside from being specifically designed for this task, it also has the advantage of being:

- Simple to use.

- Approximately half the cost of an overhead bridge crane.

- Capable of covering large distances.

- Totally customizable to fit any production space.

- Capable of operating in an environment with no structural support options.

Why to choose our monorail crane and hoist system ?

We are aimed to deliver superior customer service together with high-quality crane systems and components. We are committed to the following when you purchase monorail hoist and crane system from us:

- Safety: Monorail cranes will adhere to all applicable ISO, OSHA, and CE regulations.

- Quality: To help ensure that the cranes we make meet our high standards for quality, we invest in laser cutting technology.

- Technical support: Our highly qualified engineering team members can address any problems that may come up so you may utilize your monorail crane to its full potential.

- Worry free after sale services: Timely after sale services sand spare parts are available to solve your problems.

How to get your customized monorail?

Even though the actual specification of monorail crane and hoist system varies from organization to organization, in general, the following specifications of monorails cranes and hoists should be provided :

- Lifting capacity

- Height of the lift

- Travel length

- Trolley type

- Hoist type

- Application description

- Power supply

- Control panel

Contact us to get your customized monorail hoists and monorail crane systems.

Types of KBK crane systems for your selection

KBK light crane system includes KBK monorail suspension crane, KBK single girder suspension crane, KBK double girder suspension crane, KBK telescopic girder suspension crane, KBK stacker crane, rigid kbk crane system, and combined-type KBK cranes, and other forms, etc.

How to customized your kbk crane system ?

- Lifting capacity of light kbk crane: __Kg

- Width (S)=__m, H=__m, L=__m, L1=__m, L2=__m

- Hoist type of light kbk crane:Electric chain hoist or Wire rope hoist or Manual chain hoist?

- Crane travel type of light kbk crane: Electrical type or Manual type?

- Voltage of light kbk crane: ____V____Hz____Phase (If electrical type)

- Control Mode of light kbk crane: Remote control or Pendant control?

- How many KBK cranes are running on the same track?

- Transportation: tell us the sea port name near you, we can quote you shipping freight.

If need more details or request a quote to our overhead kbk crane system , welcome to contact us freely to check what we can do for your workstation material handling.

3 Units 1 ton Monorail Hoists for U type Track for Sale United Arab Emirates

Monorail hoist - electric chain hoist for U shaped monorail

First inquiry- electric wire rope hoist 1 ton

The customer from the UAE sent us an electric wire rope hoist inquiry through our website and requested a quote for a 1t-5m two-speed electric hoist.

Second inquiry - Electric chain hoist on curved U shape rail

3 months later, the UAE client emailed us and changed his needs as following:

- Greeting of the day.

- I hope you are doing well.

- With reference to hoist crane. we are looking for 1 ton chain type crane with U type track. At the present time we are using 0.5ton hoist crane. it is looking like very old model type

- Can you provide us full solution with U track for my existing Plant?

- Crane -3 nos. for more details I have attached image.

- Thanks & Regards,

----------------------

We are looking for double speed hoist crane, lifting height 5 meter, Low Speed 6MPM, fast speed 12 MPM, CT. speed 17 MPM.

With U type traveling track.

You can tell that his needs have altered. As requested, we adjusted the electric chain hoist quote for our UAE customers.

Third revision - lifting speed of electric chain hoist 1 ton

Is it applicable for electric chain hoist to run on the curved U shape rail?

The customer was concerned that the electric chain hoist would not be able to run on his existing U-type traveling track and sent us track drawings for confirmation.

Lifting speed of 1 ton electric chain hoist

At the same time, he requested that the electric chain hoist's lifting speed be increased. The electric hoist his team is using has a lifting speed of 7m/min. The new electric hoist lifting speed should be between 8-10m/min. The monorail hoist solution must be redesigned.

Finally, the monorail hoist 1 ton was installed successfully in client’s workshop and workstation in UAE. If you have any need, please feel free to contact us.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch