KBK Telescopic Crane, kbk Overhung Crane & Extending Cranes

kbk overhung crane & extending crane with telescopic beam makes load handling near barriers or between columns easy &economical. KBK telescopic crane for sale.

| Capacity | 125kg, 250kg, 500kg, 1000kg, |

| Span length | 3500- 8500mm |

| Lifting height | As your request |

| Noted | Process crane design of telescopic beam kbk crane are available. |

Category: Light KBK Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

KBK Telescopic Crane & Telescoping KBK Crane

kbk Overhung Crane & Extending Cranes for Tight or Obstructed Spaces

Telescopic beam kbk crane is a type of special designed kbk crane with overhung telescopic beam extending out of the main crane beam working area for loads hoisting and moving, which can effectively increase the auxiliary work area, overcoming the barriers or obstacles taking the best utilization of the space. kbk overhung crane & extending crane with telescopic beam makes load handling near barriers or between columns easy &economical. KBK telescopic crane for sale.

Telescopic beam of the light kbk crane system can extending out at one side or two sides with the overhanging distance up to 2.5 m, which enables the kbk telescopic beam crane to handle loads outside the working area of main beam ,and makes your material handling possible below the line, the heating pipe,and between the columns of the factories, etc.

Based on your actual needs of extension and expansion,telescopic beam kbk crane system can be processed and assembled respectively with the standard KBK components and KBK components.

What is a Telescoping KBK Crane?

A telescoping KBK crane is an advanced version of the traditional KBK crane system. It features a telescoping beam that can extend and retract, providing greater reach and flexibility compared to standard crane systems. This functionality allows the crane to access new work areas without the need for reconfiguring or installing additional equipment.

KBK telescopic crane system

Telescoping crane with sliding cantilever for limited and obstructed space

The telescoping feature of the crane is made possible by a sliding beam mechanism, which is supported by the crane's main frame. The telescoping beam can extend outward from one or both sides of the main crane structure. This extension capability allows the crane to reach areas that would otherwise be out of reach due to obstructions such as columns, beams, or equipment. The extension can be up to 2.5 meters, which means it can provide access to additional working areas without requiring any major rework or alterations to the existing crane setup.

This functionality is especially valuable in confined spaces or environments where installation of traditional cranes may be challenging due to structural limitations. The telescoping crane can adapt quickly to changing operational requirements by simply adjusting the length of the beam, offering flexibility and efficiency without the need for new infrastructure.

Key Difference Between Standard and Telescoping Cranes

The main difference between a standard KBK crane and a telescoping KBK crane lies in the ability of the telescoping crane to extend its working reach. While a standard KBK crane typically provides fixed coverage based on the rail system's length, the telescoping crane introduces an extendable beam, allowing it to service additional workstations or areas without the need for extensive modification.

Here are some of the key distinctions:

- Reach and Flexibility: A standard KBK crane operates within the confines of its installed rail system, while a telescoping KBK crane can extend its reach up to 2.5 meters, allowing it to service areas beyond its original track layout.

- Application Range: Standard cranes are best suited for areas with fewer obstructions and where the layout allows easy access. In contrast, telescoping cranes are ideal for working in areas with obstacles like columns, beams, or other fixed structures that limit the reach of standard cranes.

- Adaptability: Telescoping KBK cranes are particularly beneficial in dynamic environments where space or operational needs change regularly. Their telescoping function allows them to be adjusted easily, offering more versatility without having to invest in new cranes or infrastructure.

In summary, while both standard and telescoping KBK cranes offer modular and flexible solutions, the telescoping option expands the crane's ability to access areas that would otherwise be difficult or impossible to reach, making it a more versatile tool for challenging workspaces.

kbk crane system with telescopic cantilever

Telescoping kbk modular crane system

Design and Features of the Telescoping KBK Crane

The telescoping KBK crane is a highly adaptable system that combines traditional KBK crane components with an innovative telescoping feature. This allows for greater reach and flexibility, making it suitable for a wide range of industrial applications. Below, we explore the key design elements and features that make the telescoping KBK crane a versatile lifting solution.

Main Beam and Telescoping Beam Design

The main beam of a telescoping KBK crane forms the backbone of the system. It is typically a solid, fixed structure that supports the telescoping beam, which is the key feature providing the crane's extended reach.

- Main Beam: The main beam is made from high-strength steel and serves as the base for the crane's movement. It is designed to carry the load while maintaining stability during operation. The beam typically has mounting points for end carriages, which allow the crane to move along the track.

- Telescoping Beam: The telescoping beam is mounted onto the main beam, and it can slide out to extend the reach of the crane. This beam is typically lighter than the main beam to facilitate smooth extension and retraction. The telescoping mechanism is engineered to be strong yet flexible, allowing the crane to move in and out with ease.

How the Telescoping Mechanism Works

The telescoping mechanism is a sliding beam system that allows the crane's beam to extend and retract based on the operational needs. The mechanism typically uses trolley and rail systems that support the beam while ensuring smooth, controlled movement. The beam can extend from either one or both sides of the crane, depending on the design.

- Track and Guide System: A dedicated track or guide rail helps the telescoping beam extend or retract with minimal friction, ensuring stability and smooth movement during operation.

- Drive Mechanism: The extension is powered either manually or by an electric motor. In more advanced setups, the telescoping movement is integrated with the crane's travel system, allowing for synchronized operation and increased efficiency.

This mechanism allows the crane to access new work areas that were previously unreachable or difficult to service with a standard KBK crane, making it ideal for tight spaces or areas with obstacles like columns, beams, or machines.

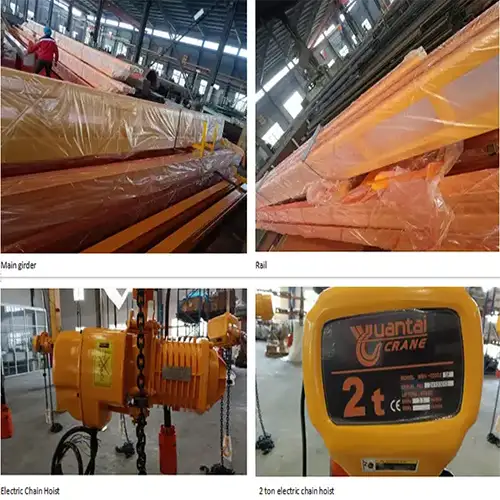

Structures & Components of Telescopic Beam KBK Crane

The telescopic kbk cranes are made of standard kbk crane parts and components including a telescopic girder equipped under the main beam, which can extended from one side or both sides out of orbit based on different crane design. The telescopic crane beam makes the difficult material handling close to columns or other obstacles possible and easy.

According to your actual operation requirements and the required overhanging and adjustable size, telescopic kbk crane system are available with tailored light kbk crane solutions. The detailed pictures of the overhung telescopic crane and extending crane are presented for your reference. More information, please feel free to contact us.

Allowable overhang varies according to raw material and crane type and also limited by rated load weight.

Model | KBK I | KBK II-L | KBK III |

Single girder telescoping kbk crane | - | 1,500 | 1,800 |

Double girder telescoping kbk crane | 1,600 | 2,300 | 2,500 |

Allowable overhang varies according to profile and crane type; also limited by payload

| Extra extended length IA1 max [mm] | ||

| Model | KBK II-L | KBK II |

| A 1/1 | 1,500 | 1,800 |

| B 2/1 | 1,500 | 2,000 |

| B 2/2 | 2,300 | 2,500 |

Advantages of Using a Telescoping KBK Crane

The telescoping KBK crane offers a range of benefits that enhance operational efficiency, flexibility, and cost-effectiveness in various industrial environments. Below are the key advantages that make this crane system an invaluable tool for modern manufacturing, warehousing, and logistics operations.

- KBK telescopic crane provides a cost-effective solutions compared with the conventional hoisting system , especially in the workshops with limited working height and space.

- With modular design, the kbk crane can be processed with various features and multi-functions, providing a safe and reliable overhead traveling crane solution in practice.

- Strong and durable design and high standard quality and fabrication ensure the kbk crane a longer service life with low maintenance rate. .

- With overhung and extending crane design, the telescopic beam kbk cranes offer greater room to manoeuvre and make the best utilization of the available space.

Increased Flexibility and Accessibility

One of the primary advantages of a telescoping KBK crane is its ability to provide increased flexibility and accessibility, particularly in spaces that are difficult to navigate with traditional lifting equipment.

- Reaching Additional Workstations or Restricted Areas: The extendable beam allows operators to service multiple workstations or restricted areas within a factory or warehouse. This feature is especially useful in assembly lines, machine shops, or warehouses where equipment, racks, or structural pillars may limit access. The crane can extend to reach difficult-to-access zones without requiring the operator to move or reposition equipment.

- Ability to Service Both Large and Small Spaces with One System: Whether you need to handle large, heavy components or smaller materials, the telescoping crane offers versatility in one system. Its beam can extend up to 2.5 meters, enabling it to service both large production areas and smaller workspaces. This adaptability ensures that the same crane can handle a wide variety of tasks, reducing the need for different lifting systems in the same facility.

Space Optimization

In modern industrial environments, optimizing space is crucial to maintaining efficient workflows. The telescoping KBK crane offers several ways to maximize space and ensure that facilities are used to their full potential.

- Maximizing Workspace in Facilities with Obstacles: The telescoping design of the crane allows it to reach areas that would otherwise be obstructed by columns, machines, or storage racks. In tight spaces, this feature ensures that unused or underutilized space can be accessed for storage, loading, and other operational tasks. It helps to make the most of the available space without the need for costly facility redesigns or additional equipment.

- Enabling Installation in Areas Where Fixed Cranes Cannot Be Used: In areas where traditional, fixed overhead cranes would be difficult or impossible to install—due to limited headroom, structural interference, or other space constraints—the telescoping KBK crane provides a viable solution. Its ability to extend and retract means it can fit into confined spaces and be installed in areas where conventional cranes could not reach, enhancing the flexibility of a facility's material handling operations.

Cost Efficiency

In addition to the operational and functional benefits, the telescoping KBK crane is cost-effective compared to other lifting solutions. It helps reduce overall costs in both initial investment and long-term maintenance.

- Reduced Need for Additional Lifting Equipment: By combining the ability to handle a wide range of load sizes and access difficult areas, the telescoping KBK crane reduces the need for additional specialized lifting equipment. Rather than having separate cranes or hoists for different tasks, the telescoping crane can handle everything, saving money on purchasing and maintaining multiple machines.

- Lower Installation and Maintenance Costs Due to Modular Design: The telescoping KBK crane system is modular, meaning it can be easily adjusted and expanded to meet changing requirements without requiring significant modifications to the existing infrastructure. This modularity reduces installation costs, as components can be added or modified without extensive downtime or costly rework. Furthermore, the crane's simple design and fewer moving parts make it easier to maintain, keeping maintenance costs low over its lifespan.

Features of KBK Telescopic Beam Extending Crane

Our process telescopic crane solutions can meet your specific requirements with the following features:

- Depending on process crane design, telescopic beam girders can be extended at one or both sides

- Extending cranes are usually consist of a fixed KBK crane section and a telescopic crane beam section that can extend in both directions as requested.

- The extending girder or telescopic beam can extend up to 2,500 mm beyond the runway span

- Telescopic crane beam makes the difficult material handling close to columns or other obstacles possible and easy.

- KBK telescopic crane with process crane designs can meet your needs satisfactorily at competitive kbk crane price.

Types of Telescoping Beams (Single or Double-Sided Extension)

The telescoping KBK crane is available in two primary configurations based on how the beam extends:

- Single-Sided Extension: In this design, the telescoping beam extends from one side of the main beam. This configuration is typically used in scenarios where access is required to one side of the crane, such as in narrow aisles or areas where equipment on the opposite side would obstruct movement.

- Double-Sided Extension: The double-sided extension allows the beam to extend from both sides of the crane. This configuration provides a broader range of movement and is ideal for situations where the crane needs to reach multiple workstations or cover a wider area without repositioning.

Both configurations offer a high degree of flexibility, but the choice of design largely depends on the operational space, the number of workstations that need to be served, and the presence of obstacles.

Extension Range and Reach

One of the most important features of the telescoping KBK crane is its ability to extend the reach of the crane, allowing it to service areas that a standard KBK crane cannot access. The extension range plays a significant role in determining how effectively the crane can meet the needs of various industries.

- Extension Distance (Up to 2.5 Meters): The telescoping beam can extend up to 2.5 meters, providing significant additional reach. This range allows the crane to move loads into areas where standard cranes would not be able to reach, such as under low ceilings, between columns, or over obstacles like machinery and pipes. This extension also allows the crane to reach parts of the workspace that may otherwise be unusable, increasing the overall productivity of the facility.

- Impact on Workspace Coverage: The ability to extend and retract the beam gives the crane a dynamic range of motion, enabling it to serve multiple workstations or navigate through confined spaces with ease. This flexibility maximizes the workspace coverage without needing to move or reconfigure the crane itself. Whether you're lifting equipment in a tight assembly line or moving materials around a congested warehouse, the telescoping feature significantly enhances operational efficiency.

Customization Options

The telescoping KBK crane is highly customizable to suit specific industrial needs. From adjusting the reach of the telescoping beam to choosing components suited for different environments, the crane system can be tailored to maximize performance in various applications.

Variability in Design Based on Industrial Needs: The telescoping crane can be designed to meet the unique requirements of different industries. For instance, in an automotive assembly plant, the crane might be customized to handle heavy parts with a higher lifting capacity, while in a warehouse, a lighter, more compact design might be used to move pallets and smaller loads.

Possible Configurations for Different Industries: The flexibility of the telescoping KBK crane allows it to be configured in multiple ways, including:

- Height and Load Capacity Adjustments: Depending on the weight of the loads being lifted, the crane can be customized with a hoist and lifting mechanism that matches the required load capacity.

- Integration with Automated Systems: In some industries, the telescoping crane can be integrated into automated systems, where the beam extension and retraction can be synchronized with other equipment like conveyors or robotic arms.

- Workstation Coverage: The crane can be adapted for specific workstations, providing tailored reach and flexibility for areas with complex layouts.

Structural Integrity and Durability

For the telescoping KBK crane to be effective in demanding industrial environments, it must be designed with strength and durability in mind. The crane's structure is built to endure the stresses and strains of continuous operation, while also ensuring long-term reliability.

- Materials Used for Longevity and Heavy-Duty Use: The crane's components, especially the main and telescoping beams, are constructed from high-strength steel alloys. These materials are chosen for their ability to withstand heavy loads and resist wear and tear over time. The trolley and hoist mechanisms are also designed with durable materials to handle frequent movement and lifting operations.

- Anti-Corrosion Design Considerations for Harsh Environments: In industrial environments, especially those exposed to moisture, chemicals, or extreme temperatures (such as foundries, marine areas, or chemical plants), anti-corrosion coatings and treatments are essential for ensuring the crane's longevity. The telescoping KBK crane can be equipped with anti-corrosion coatings, such as galvanized steel or powder-coated finishes, to protect against rust and degradation. These coatings help maintain the structural integrity of the crane, reduce maintenance costs, and increase the crane's operational life in harsh environments.

In summary, the telescoping KBK crane combines robust design with advanced functionality, offering superior flexibility, reach, and durability. Its modular and customizable components make it ideal for a wide range of industries, from heavy manufacturing to logistics, where space constraints and access challenges are common.

Applications of the Telescoping KBK Crane

The telescoping KBK crane is an incredibly versatile and flexible lifting solution, especially in environments where traditional cranes may struggle to reach or maneuver around obstacles. Its ability to extend and retract the crane beam makes it ideal for servicing tight or obstructed spaces, providing enhanced operational reach without the need for additional infrastructure. Here, we explore the various applications and industries where telescoping KBK cranes prove to be particularly beneficial.

KBK Telescopic Crane, KBK Overhung Crane & Extending Cranes, Telescoping KBK Cranes

Applications in Tight or Obstructed Spaces

One of the standout features of the telescoping KBK crane is its ability to work in tight or obstructed spaces where traditional cranes or fixed overhead systems cannot operate efficiently. The telescoping beam extends beyond the fixed track system, making it ideal for maneuvering around physical obstacles or providing access to challenging areas.

- Reaching Over or Around Obstacles (Columns, Beams, Pipes): In industrial environments, space is often limited, and cranes may need to navigate around obstacles like columns, beams, pipes, or other structures. The telescoping crane excels in these situations because the extendable beam can reach over, under, or around these barriers without requiring a complete reconfiguration of the workspace. For instance, a telescoping crane can extend past a column to service areas that would otherwise be inaccessible with a traditional crane setup.

- Lifting Loads in Areas That Are Difficult to Access (e.g., Under Ceilings, Between Machines): The telescoping crane's ability to extend its beam up to 2.5 meters is particularly useful when lifting heavy loads in low-clearance environments or between machines. In factories with low ceilings, or where heavy equipment is positioned closely together, the telescoping feature allows operators to reach hard-to-reach spaces without compromising the crane's lifting capacity. For example, it can lift loads under an existing ceiling or maneuver between tightly arranged machines to position or transport materials.

Industries That Benefit from Telescoping KBK Cranes

The flexibility of the telescoping KBK crane makes it an asset across multiple industries. Its adaptability and extended reach provide significant advantages in settings where space is at a premium or where access is obstructed by infrastructure or equipment. Here are some key industries that benefit from the use of telescoping KBK cranes:

- Manufacturing (Automotive, Aerospace, Machinery): In the automotive and aerospace industries, the telescoping KBK crane is commonly used for assembly line operations, particularly in automotive plants where vehicle parts are large, heavy, and often located in confined or difficult-to-reach spaces. The crane can be used to move parts like engines, chassis, or large panels, especially in areas where traditional overhead cranes cannot reach. Its flexibility is also beneficial in machinery manufacturing for lifting and moving equipment between machines or beneath fixed infrastructure.

- Warehousing and Logistics: In warehouses or logistics centers, the telescoping crane enhances the ability to reach into narrow aisles or beneath shelving units. The crane's extendable beam allows operators to service multiple storage areas without having to reposition the crane frequently. In environments where space is often restricted, the telescoping KBK crane allows for more efficient handling of goods and materials, ensuring that valuable storage space can be fully utilized.

- Steel Mills and Foundries: In steel mills and foundries, the need to lift and move heavy metal parts or molten materials requires robust crane systems. The telescoping feature in KBK cranes is invaluable in these environments, where space is often congested with equipment, and the temperature and material handling conditions are demanding. The ability to extend the crane's reach allows workers to access hard-to-reach areas, especially in factories with large equipment and overhead infrastructure like pipes or ventilation systems.

Examples of Specific Use Cases

The telescoping KBK crane can be applied in a variety of unique scenarios where it provides significant benefits over traditional crane systems. Below are some examples of specific use cases that illustrate how this crane can meet the challenges of various industries:

- Servicing Areas with Limited Headroom: One of the most common challenges in industrial facilities is working in areas with low headroom, such as beneath low ceilings, mezzanines, or ducts. In these situations, a telescoping KBK crane can extend beyond its fixed track system, reaching over obstacles and providing access to parts of the workspace that were otherwise unusable. For example, a telescoping crane might be used in a manufacturing facility with limited vertical clearance, where workers need to lift components or equipment without exceeding the available headroom.

- Handling Long or Heavy Loads in Confined Spaces: The telescoping crane is particularly well-suited for handling long or heavy loads in confined spaces. For example, in an automotive plant, where large vehicle parts such as chassis, bumpers, or engine blocks need to be lifted and moved through tight aisles, the crane can extend its beam to reach into tight spaces without needing to reposition or move other equipment. Similarly, in a warehouse, the crane's ability to extend can help handle long materials like beams, pipes, or rolls of wire, which might otherwise be difficult to move in narrow aisles.

- Working Around Obstructions in Assembly Lines: In assembly lines, where various machines and tools are installed in close proximity to each other, a telescoping KBK crane allows operators to access specific machines or workstations that are obstructed by other equipment. For example, the crane might be used to transport parts across the line while avoiding interference from pillars, walls, or other machines, ensuring that production processes are not interrupted.

The telescoping KBK crane is an innovative solution for industrial environments that require flexibility, extended reach, and the ability to navigate around obstacles. Whether it's reaching over beams and pipes, lifting heavy loads in tight spaces, or servicing hard-to-access areas like beneath ceilings or between machines, the telescoping KBK crane provides a highly adaptable solution. Its applications across a range of industries—from automotive and aerospace to warehousing and steel mills—make it a valuable tool for improving operational efficiency, maximizing workspace coverage, and addressing the unique challenges of modern industrial environments.

Safety Features and Compliance

Ensuring safety during crane operations is paramount, and the telescoping KBK crane is equipped with a range of safety features designed to protect both operators and equipment. These features are designed not only to meet safety regulations but also to enhance operational reliability in various industrial environments.

Safety Features in Design

- Load Sensors and Overload Protection: One of the key safety features of the telescoping KBK crane is its load sensor system. These sensors continuously monitor the weight of the load being lifted, providing real-time feedback to prevent overloading. The system automatically triggers a safety shutdown if the load exceeds the crane's rated capacity, preventing damage to the crane and reducing the risk of accidents caused by overloaded lifting.

- Anti-Collision Mechanisms for Telescoping Movement: Given the nature of the telescoping mechanism, where the beam extends and retracts to reach challenging workspaces, the crane is designed with anti-collision systems to prevent damage to surrounding structures or other equipment. Sensors track the position of the telescoping beam to ensure that the beam does not come into contact with obstacles during its extension or retraction. Additionally, buffer mechanisms are often employed to soften any impacts if the crane's beam accidentally comes into contact with an obstacle.

Conclusion: Customized Telescoping KBK Crane for Sale, Send Us an Inquiry

The telescoping KBK crane is a versatile, efficient, and safe solution for material handling in challenging and constrained environments. Its ability to extend and retract its beam makes it an invaluable tool for accessing hard-to-reach areas, increasing flexibility, and optimizing workspace. Below, we summarize its key benefits and look at the future of crane technology.

The telescoping KBK crane brings numerous advantages across a variety of industrial sectors:

- Increased Accessibility: The crane's extendable design allows it to reach areas that traditional cranes cannot access, such as tight spaces, under beams, or between machinery.

- Space Optimization: By maximizing the use of available space and enabling installation in areas with structural limitations, the telescoping crane improves workflow efficiency.

- Cost Efficiency: With its modular design, the telescoping crane reduces the need for multiple lifting systems, thus lowering initial investment and maintenance costs.

- Safety and Compliance: The crane is built with multiple safety features, such as load sensors, anti-collision mechanisms, and overload protection, and meets the highest industry standards, ensuring safe operation in diverse environments.

The telescoping KBK crane is an invaluable asset for any modern industrial facility. Its versatility, space-saving design, and safety features make it a go-to solution for material handling tasks in tight or obstructed spaces. Whether in manufacturing, warehousing, steel mills, or other industries, this crane is capable of handling a wide range of lifting challenges. As crane technology continues to evolve, the telescoping KBK crane will likely play a pivotal role in the next generation of industrial lifting solutions, providing even greater flexibility, automation, and efficiency.

This outline covers all key aspects of the Telescoping KBK Crane, from design and applications to safety, installation, and maintenance, providing a comprehensive framework for a detailed article.

Types of KBK Crane Systems for Your selection

KBK light crane system includes KBK monorail suspension crane, KBK single girder suspension crane, KBK double girder suspension crane, KBK telescopic girder suspension crane, KBK stacker crane, rigid kbk crane system, and combined-type KBK cranes, and other forms, etc.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch