10 Ton Movable Gantry Cranes In Workshop Fabrications for Material Handling

10 ton portable gantry cranes for fabrication workshop for handling metal sheets, fabricated parts, welding materials in metalworking workshops, fabrication &welding operations.

Category: Mobile Gantry Crane For Sale

Your Trusted Movable Gantry Crane Manufacturer & Supplier

10 Ton Movable Gantry Cranes In Workshop Fabrications for Material Handling

Your Cost-effective Workshop Gantry Crane Small &Rolling & Economical Gantry Cranes

10 Ton Movable Gantry Cranes In Workshop Fabrications for Material Handling. 10 ton portable gantry cranes for fabrication workshop for handling metal sheets, fabricated parts, welding materials in metalworking workshops, fabrication &welding operations.

10 Ton Movable Gantry Cranes 10 Ton for Workshop Fabrication

In the fabrication workshop , the demand for efficient material handling solutions has never been more pronounced. As metalworking workshops and fabrication units strive for precision and productivity, the role of Movable Gantry Cranes 10 Ton has become increasingly significant. These robust and adaptable lifting solutions are not just equipment; they are pivotal in transforming fabrication processes, optimizing workflow efficiency, and elevating safety standards.

The contemporary workshop fabricator faces a myriad of challenges, from handling large metal sheets to intricately fabricated parts and welding materials. The growing demand for intricate and high-quality products necessitates a shift towards streamlined material handling processes. In response to this demand, Movable Gantry Cranes 10 Ton have emerged as indispensable assets, offering a versatile and efficient means of lifting and transporting materials within the workshop environment.

The significance of Movable Gantry Cranes 10 Ton lies in their ability to redefine the traditional approach to material handling in workshop fabrication. Unlike fixed cranes, these portable counterparts bring a level of flexibility and precision engineering that aligns seamlessly with the nuanced requirements of fabrication units. Swiveling wheels and adjustable height features make them agile, capable of navigating through tight spaces and adapting to varying tasks, ultimately enhancing the overall fabrication process.

As we delve deeper into the design features, load-handling capabilities, and practical applications of 10 Ton Movable Gantry Cranes 10 Ton in workshop fabrication, the multifaceted advantages they offer will become even more apparent. Let us explore how these cranes are shaping the landscape of workshop material handling, revolutionizing fabrication processes across various industries.

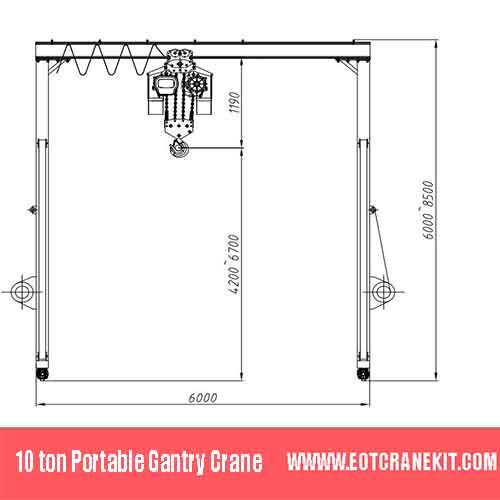

movable gantry crane 10 ton

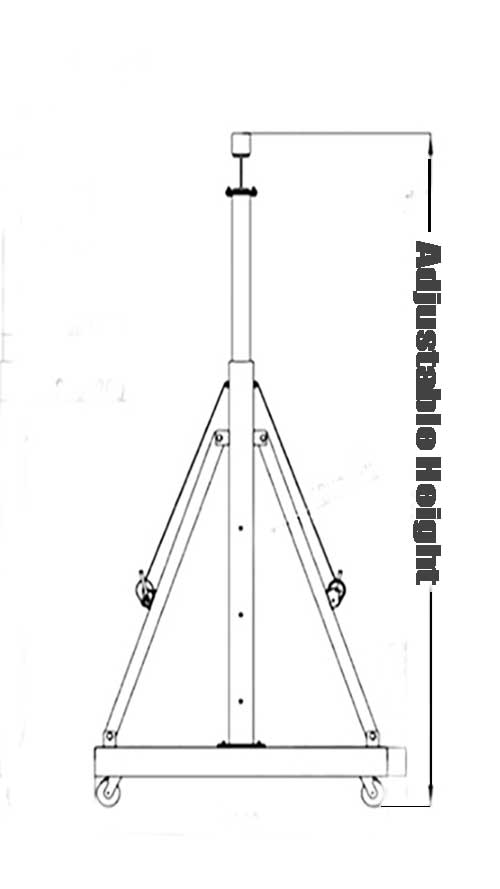

Design Features of Workshop Gantry Crane with Adjustable Height Design

Precision Engineering for Controlled Movements

In the realm of workshop fabrication, precision is paramount. The design features of a 10 Ton portable gantry crane play a pivotal role in ensuring controlled movements for seamless fabrication processes.

Swiveling Wheels and Maneuverability

- Swiveling Wheels: At the heart of precision engineering is the inclusion of swiveling wheels. These specialized wheels provide the gantry crane with unparalleled maneuverability. They enable operators to navigate through intricate workshop layouts with ease, reaching every corner without compromising on stability.

- Enhanced Maneuverability: The ability of the crane to move effortlessly in any direction ensures that no inch of the workshop is beyond reach. This feature is particularly valuable in crowded workshops where space optimization is crucial for streamlined operations.

Movable gantry crane wheel rolling and turning testing

Adjustable Height for Versatile Fabrication Requirements

- Versatility in Height Adjustment: The adjustable height feature of the gantry crane adds a layer of adaptability to its design. Fabrication requirements can vary widely, from working on large metal sheets to intricate welding tasks. The crane's adjustable height ensures that it can accommodate diverse tasks, providing operators with the flexibility needed for efficient material handling.

- Precision in Load Positioning: The controlled adjustment of height allows for precise positioning of loads. Whether lifting heavy metal sheets or placing fabricated parts with delicate precision, the crane's design ensures that the load is handled with accuracy and care.

As we explore further, these design features not only contribute to controlled movements during fabrication but also highlight the crane's versatility in handling different materials and tasks within the workshop environment. The combination of swiveling wheels and adjustable height positions these cranes as indispensable tools for the modern workshop fabricator.

ffixed height movable gantry crane

Adjustable height design of movable gantry crane

Adjustable height design drawing of movable gantry crane

Handling Loads of Movable Gantry Crane 10 Ton Fabrication Workshops

Handling Metal Sheets, Fabricated Parts, and Welding Materials

In the intricate world of workshop fabrication, the ability to handle diverse loads is a defining factor for material handling solutions. The 10 Ton portable gantry crane excels in this regard, showcasing its prowess in handling metal sheets, fabricated parts, and welding materials with precision and efficiency.

Load Capacity and Versatility

- Impressive Load Capacity: The 10 Ton load capacity of these gantry cranes positions them as robust workhorses in the workshop environment. This remarkable load capacity allows them to effortlessly lift and transport substantial metal sheets, large fabricated parts, and even the weighty materials used in welding processes.

- Versatility in Load Handling: Beyond sheer capacity, the gantry crane exhibits versatility in load handling. Fabrication units often deal with a spectrum of loads, each with unique shapes, sizes, and weight distributions. The crane's design accommodates this diversity, making it an ideal solution for the varied material handling needs of workshop fabrication.

Precision Control for Delicate Fabrication Components

- Engineered Precision: The crane's precision engineering extends to its control mechanisms, enabling operators to handle delicate fabrication components with utmost accuracy. This is particularly crucial in tasks that involve placing fabricated parts during assembly or carefully positioning materials for welding.

- Enhanced Control Systems: The incorporation of advanced control systems ensures that operators have the finesse required for intricate fabrication tasks. The crane responds promptly to commands, allowing for controlled movements and precise placement of loads, irrespective of their size or fragility.

As we delve into the applications of these cranes in metalworking workshops, fabrication units, and welding operations, the combination of load-handling capabilities and precision control emerges as a game-changer, contributing significantly to the overall efficiency of workshop fabrication processes.

Applications of 10 Ton Movable Gantry Cranes

The versatility and precision of 10 Ton Movable Gantry Cranes 10 Ton make them invaluable across a spectrum of applications within workshop fabrication. Let's explore how these cranes contribute to streamlining processes and enhancing efficiency in various facets of fabrication operations.

Ideal for Metalworking Workshops

Streamlining Fabrication Processes

In metalworking workshops, where efficiency and precision are paramount, the portable gantry crane proves to be an indispensable asset.

- Optimized Material Handling: The crane's ability to swiftly and precisely handle metal sheets and fabricated parts streamlines the fabrication process. This optimization results in reduced downtime, enabling workshop operators to focus on the actual fabrication tasks.

- Flexible Layout Adaptation: The swiveling wheels and adjustable height features allow the crane to adapt to the dynamic layout of metalworking workshops. It effortlessly maneuvers around workstations, reaching materials wherever they are needed, contributing to a seamless and well-organized workflow.

Enhancing Efficiency in Metal Sheet Handling and Welding Operations

- Efficient Metal Sheet Handling: When dealing with large and heavy metal sheets, the crane's load capacity and precision control ensure that these materials are moved with efficiency. This is crucial for tasks such as cutting, shaping, and assembly.

- Safer Welding Operations: The crane's versatility extends to welding operations, where it excels in the precise handling of welding materials. This not only contributes to the safety of the welding process but also enhances the overall efficiency of fabrication units.

Suitable for Fabrication Units

Adaptable to Varied Fabrication Tasks

- Fabrication units engage in a diverse range of tasks, from assembling intricate components to handling heavy materials. The gantry crane's adaptability makes it an ideal solution for these varied fabrication tasks.

- Handling Varied Loads: Whether it's lifting large fabricated parts or delicately placing components during assembly, the crane's load versatility ensures that it can seamlessly adapt to the specific requirements of different fabrication tasks.

Supporting Seamless Workflow Integration

- The crane's role in fabrication units goes beyond lifting and moving materials. It becomes an integral part of the overall workflow, supporting a seamless integration of tasks.

- Workflow Continuity: The efficient material handling facilitated by the crane ensures that there are no bottlenecks in the fabrication process. Tasks progress smoothly, and the crane becomes a catalyst for maintaining a continuous and efficient workflow.

Versatile in Welding Operations

Precision Handling of Welding Materials

- Welding operations demand precision and control over the materials being used. The gantry crane's precision engineering makes it an ideal companion in welding scenarios.

- Accurate Material Placement: Welding materials require accurate placement for successful and efficient welding. The crane's precision control ensures that these materials are positioned with the utmost accuracy, contributing to the quality and safety of welding processes.

Contributing to Safer and More Efficient Welding Processes

- Safety is a paramount consideration in welding operations. The gantry crane's design features and load-handling capabilities contribute to creating a safer and more efficient working environment for welders.

- Reduced Manual Handling: By handling and positioning welding materials, the crane reduces the need for manual lifting by welders. This not only enhances safety by minimizing the risk of injuries but also allows welders to focus on the technical aspects of their craft.

As we explore the diverse applications of 10 Ton Movable Gantry Cranes 10 Ton in metalworking workshops, fabrication units, and welding operations, it becomes evident that these cranes are catalysts for efficiency, safety, and precision in the intricate world of workshop fabrication. In the subsequent sections, we will delve into the advantages these cranes offer for workshop fabricators and how they contribute to a more optimized and streamlined fabrication environment.

Advantages of Movable Gantry Cranes 10 Ton for Workshop Fabrication

In the intricate world of workshop fabrication, the adoption of 10 Ton Movable Gantry Cranes 10 Ton brings forth a myriad of advantages, revolutionizing material handling processes and enhancing overall efficiency.

Improved Workflow Efficiency in Fabrication

- Swift Material Handling for Continuous Operations:The hallmark of a 10 Ton portable gantry crane lies in its ability to facilitate swift material handling. In the context of workshop fabrication, where time is of the essence, the crane ensures a continuous workflow by expediting the movement of materials. The seamless integration of swiveling wheels and adjustable height features allows for quick and precise material positioning, minimizing downtime and maximizing operational efficiency.

- Flexible Adaptation to Dynamic Workshop Layouts :Workshop layouts are dynamic, with fabrication processes often requiring adaptability to changing needs. The portable nature of these gantry cranes enables flexible adaptation to dynamic workshop layouts. Whether maneuvering through tight spaces or adjusting heights for varying tasks, the crane seamlessly aligns with the workshop's ever-changing requirements. This adaptability ensures that the fabrication process remains fluid and responsive to evolving production demands.

Cost-Effective Solutions for Fabrication Units

- Minimizing Infrastructure Modifications :Investing in a 10 Ton portable gantry crane translates to a cost-effective solution for fabrication units. Unlike traditional material handling systems that may necessitate extensive infrastructure modifications, these cranes are designed for ease of integration. The ability to operate within existing workshop layouts without the need for substantial modifications minimizes associated costs, making them a financially prudent choice for fabrication units.

- Optimizing Investment for Enhanced Fabrication Productivity :The strategic investment in a portable gantry crane yields dividends in enhanced fabrication productivity. The crane's efficiency in material handling, coupled with its adaptability to various tasks, optimizes the overall investment. Fabrication units benefit from increased throughput, reduced lead times, and improved overall productivity, making the crane a cornerstone in the pursuit of operational excellence.

As we navigate the realm of workshop fabrication, the advantages presented by these gantry cranes underscore their transformative impact. From swift material handling to cost-effective solutions, they stand as catalysts for heightened efficiency, ensuring that workshop fabrication processes remain at the forefront of innovation and productivity.

Case Studies of 10 Ton Movable Gantry Cranes

Real-World Examples of Successful Implementations

Illustrating Efficiency in Workshop Fabrication

Case Study: Precision Metalworking Workshop

In a bustling metalworking workshop, the integration of a 10 Ton portable gantry crane revolutionized fabrication processes. The swiveling wheels allowed seamless navigation through the workshop's intricate layout, reaching workstations with precision. The crane's load capacity facilitated the effortless handling of large metal sheets, expediting the assembly and fabrication of intricate components. This real-world example underscores how the crane's efficiency translated into accelerated production timelines and heightened overall efficiency in workshop fabrication.

Showcasing Adaptability in Handling Fabricated Parts and Welding Materials

Case Study: Dynamic Fabrication Unit

In a dynamic fabrication unit handling a spectrum of tasks, from welding to assembly, the adaptable nature of the portable gantry crane proved instrumental. Its adjustable height feature facilitated the precise positioning of fabricated parts during assembly, while the precision control system ensured delicate handling of welding materials. The crane seamlessly integrated into the workflow, showcasing its adaptability to varied fabrication tasks. This case study exemplifies how the crane's versatility enhances the overall functionality of a fabrication unit, contributing to safer and more efficient fabrication processes.

Considerations for 10 Ton Movable Gantry Crane Buyers

Assessing Workshop Layouts and Spatial Constraints

- Conducting Site Analysis for Optimal Crane Positioning: Before investing in a 10 Ton portable gantry crane, buyers must conduct a comprehensive site analysis to determine the optimal positioning within the workshop layout. This analysis considers spatial constraints, workshop workflows, and the specific tasks the crane will undertake.

- Collaborating with Manufacturers for Tailored Solutions :Effective collaboration with manufacturers is crucial for tailoring the gantry crane to the unique layout and operational requirements of the workshop. Customization options should be explored to ensure the crane aligns seamlessly with the spatial constraints of the workshop.

Ensuring Compatibility with Workshop Infrastructure

- Compatibility with Flooring and Foundation :Buyers should ensure that the crane is compatible with the workshop's flooring and foundation. Verification of load-bearing capacities and foundation requirements is essential to prevent any structural issues.

- Electrical Requirements and Power Supply :Assessing the electrical requirements of the gantry crane and ensuring compatibility with the workshop's power supply are critical considerations for a smooth integration process. Proximity to power sources and electrical infrastructure should be taken into account.

Compliance with Safety Standards and Regulations

- OSHA and Local Safety Regulations :Buyers must ensure that the selected gantry crane complies with Occupational Safety and Health Administration (OSHA) standards and local safety regulations. Adherence to safety standards is vital for creating a secure working environment.

- Operator Training and Safety Protocols :Prioritize the safety of workshop personnel by implementing comprehensive operator training programs and safety protocols. Proper training ensures that operators are equipped with the skills and knowledge to operate the crane safely.

In conclusion, the 10 Ton portable gantry crane with adjustable height design stands as a transformative tool in the realm of workshop fabrication. Its precision engineering, coupled with the ability to handle diverse loads, positions it as a cornerstone for efficient material handling. The crane's applications in metalworking workshops, fabrication units, and welding operations showcase its adaptability to varied tasks, contributing to enhanced workflow efficiency.

Advocating for the adoption of these cranes is not just an endorsement of advanced equipment; it is a strategic investment in the optimization of workshop fabrication processes. The real-world case studies presented illustrate the tangible benefits these cranes bring to fabrication units, from improved efficiency to heightened adaptability.

As workshops continue to evolve, embracing the efficiency and versatility of 10 Ton Movable Gantry Cranes 10 Ton becomes a proactive step towards staying at the forefront of modern fabrication practices. Their advantages in swift material handling, adaptability to dynamic layouts, and cost-effective solutions position them as indispensable assets in the ever-evolving landscape of workshop fabrication.

Custom Movable Gantry Crane 10 Ton for Your Needs

In concluding our exploration of 10 Ton Movable Gantry Cranes 10 Ton for workshop fabrication, it is imperative to recap the key design features and applications that make these cranes indispensable assets in the realm of material handling.

The precision engineering of these gantry cranes, featuring swiveling wheels for maneuverability and adjustable height for versatility, empowers workshops with enhanced material handling capabilities. From navigating tight spaces to delicately positioning loads, these design features contribute to the efficiency and precision required in modern workshop fabrication.

The case studies and considerations for buyers presented throughout this exploration underscore the value and impact of Movable Gantry Cranes 10 Ton in workshop fabrication operations. Advocating for their adoption is not merely a suggestion but a strategic move towards transforming fabrication processes. These cranes bring forth a paradigm shift in how workshops handle materials, contributing to increased productivity, adaptability, and safety.

By recognizing the profound advantages offered by 10 Ton Movable Gantry Cranes 10 Ton, workshops can elevate their material handling capabilities, streamline fabrication processes, and navigate the complexities of modern manufacturing with finesse. The journey towards enhanced efficiency and innovation in workshop fabrication begins with the thoughtful adoption of these advanced material handling solutions.

In the ever-evolving landscape of workshop operations, embracing the power of Movable Gantry Cranes 10 Ton is a proactive step towards staying at the forefront of efficiency, precision, and safety. As workshops continue to shape the future of fabrication, the adoption of these cranes becomes a testament to a commitment to excellence and a drive for continuous improvement in material handling practices.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch