Outdoor Crane: Overhead Crane, Gantry & Jib Crane for Outdoor Use

Outdoor gantry crane, overhead crane & jib crane for sale, good price. Custom cranes and hoists for outdoor use. Check outdoor overhead crane safety devices.

Category: Overhead Crane for Your Use

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Outdoor Cranes for Sale, Types of Outdoor Cranes for Material Handling

Overhead Crane, Gantry & Jib Crane for Outdoor Use

The frequent use of gantry cranes and overhead cranes in poor weather or other challenging conditions presents difficulties for both the manufacturer and the end user. Outdoor crane usage guidelines and restrictions must be made clear by the manufacturer, and equipment maintenance is the responsibility of the final user. There really is no such thing as "maintenance free" or iron that will "never rust," no matter how hard you might strive to make maintenance-free outdoor equipment. In order to achieve the best results and retain a product that looks and functions nicely years after installation, equipment needs to be maintained, just like a fine automobile.

Outdoor Overhead Crane for Sale, Safe & Efficient Bridge Crane

Outdoor overhead crane for sale, good price. Custom outdoor crane designs & protective devices to ensure overhead crane for outdoor use.Custom overhead crane for sale.

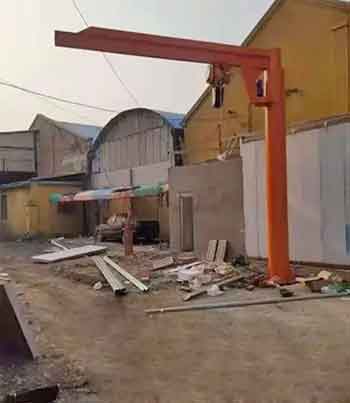

Outdoor Jib Crane, Freestanding Jib Crane for Outdoor Use

Freestanding jib crane for outdoor use. Customized outdoor jib crane with rainproof cover to ensure safety. Custom jib crane for sale now.

Outdoor Gantry Crane for Sale, Custom Gantry Crane for Outdoor Use

Outdoor gantry crane for sale. Types of outdoor gantry cranes, i.e, single & double girder, truss girder, box girder gantry crane are designed or you.

The outdoor cranes come with the required bearing enclosures for outdoor operation, zinc-plated hardware, and yellow enamel for outdoor safety. The usage of stainless steel anchor bolts, a no-load parking mechanism, a hoist doghouse, and an outside tight wire kit are further alternatives.

If an outdoor crane arrives before installation can begin, storage arrangements must be prepared. Before storing, all crane component parts should be visually inspected, and any shipping defects should be notified right away to the carrier. Any damage to the product that occurred during unloading should be reported and remedied as needed.

Types of outdoor gantry crane for sale

Outdoor gantry cranes are classified into several types, including A-frame type, L-leg type, and U- frame type. Different structural features provides various functions. It can be used in railway lines, ports, and other construction sites due to its wide operating range, adaptability, and versatility.

The outdoor gantries has two modes of operation: ground and operating room. There are two types of controlling rooms: open and closed, and they can be installed on either the left or right side depending on the situation. In various situations, different approaches meet the user's preferences.

Single Girder Gantry Crane for Outdoor Use

A single-girder outdoor gantry crane can lift large objects to the cantilever end. Its lifting capacity ranges from 5 to 32 tons, its span ranges from 18 to 35 meters, its lifting height ranges from 6 to 18 meters, and its work duty is typically A5. It is used to load, unload, lift, and transport materials and goods in outdoor freight yards and along railway lines.

Single girder outdoor gantry crane parameters:

- Load capacity: 3-20t

- Span: 8-35m

- Lifting height: 6-18m

- Lifting speed: 0.33-8m/min

- Trolley running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A3, A4

Double girder gantry crane for outdoor use

Due to the numerous benefits of double girder gantry cranes—including their high load capacity, wide span, outstanding stability, and variety of types—they are extensively used in the lifting business. box type girder and truss type girder are available. Besides , box-type girders are more common. Due to the steel plate used in the box type girder's welding, it is more safe and reliable.

Double girder crane parameters:

- Lifting Capacity: 5t~500t

- Span Length: 18~35m

- Lifting Height: 6~18m

- Lifting Speed: 1.5~11.5m/min

- Trolley Traveling Speed: 10~40.1m/min

- Crane Traveling Speed: 16~50m/min

- Working Class: A3-A7

- Provide Custom Option

Semi gantry crane for outdoor use

A semi-gantry crane is a type of gantry crane which has one supporting legs, travelling on the track imbeded on the ground and the other side supported on the overhead rails on the wall. When compared to a full gantry crane, this type of crane can save some money and workspace space due to its design and compact structure.

Semi gantry crane for outdoor use

- Lifting Capacity: 5t~32t

- Span Length: 12~30m

- Lifting Height: 6~12m

- Lifting Speed: 6~11.5m/min

- Trolley Traveling Speed: 37~40.1m/min

- Crane Traveling Speed: 37.7~40.1m/min

- Working Class: A3-A6

- Provide Custom Option

L-type leg single girder gantry crane for outdoor use

The L type outdoor gantry crane can lift large items to the cantilever end. Its lifting capacity ranges from 5 to 50 tons, its span ranges from 18 to 35 meters, its lifting height ranges from 6 to 18 meters, and its work duty is typically A5. It is used to load, unload, lift, and transport materials and goods in outdoor freight yards and along railway lines.

L types electric gantry crane parameters:

- Lifting Capacity: 5t~50t

- Span Length: 18~35m

- Lifting Height: 6~12m

- Lifting Speed: 5.9~11.2m/min

- Trolley Traveling Speed: 36.6~39.7m/min

- Crane Traveling Speed: 39.7~48.2m/min

- Working Class: A3-A5

- Provide Custom Option

U frame gantry crane for outdoor use

The U frame outdoor gantry crane is a rail-mounted gantry crane that is used to lift and transport containers from one location in a port or pier to another. It has a high work duty and a fast travel speed.

Double girder container gantry crane parameters:

- Lifting Capacity: 30t~50t

- Span Length: 18~35m

- Lifting Height: 12.3~21m

- Lifting Speed: 9.2~12.5m/min

- Trolley Traveling Speed: 45~56m/min

- Crane Traveling Speed: 42~50m/min

- Working Class: A6-A8

- Provide Custom Option

RTG type double girder gantry crane for outdoor use

The RTG type outoodr gantry cranes is a type of mobile gantry crane, which are used in a wide range of applications. The mobile outdoor gantry crane is available with spans ranging from five to eight containers wide and lifting heights ranging from one to six containers high.

Rubber tyred gantry crane parameters:

- Lifting Capacity: 10t~50t

- Span Length: 18~35m

- Lifting Height: 6~18m

- Lifting Speed: 5.9~13.3m/min

- Trolley Traveling Speed: 31.3~40.1m/min

- Crane Traveling Speed: 40.1~44m/min

- Working Class: A5-A6

- Provide Custom Option

Outdoor overhead crane designs and configurations

Outdoor overhead crane for sale good price. Custom outdoor crane designs & protective devices to ensure overhead crane for outdoor use.Custom overhead crane for sale.

Weather conditions are not always ideal for outdoor installations. However, don't worry there are various types of safety devices or measures to ensure your outdoor overhead crane safetys.

Outdoor overhead crane - Signle girder overhead crane series

- Load capacity: 1-20 ton

- Span: 7.5-28.5m

- Lifting height: 6-18m

- Lifting speed: 0.8/5m/min

- Hoist running speed: 2-20m/min

- Crane running speed: 3-30m/min

- Work duty: A5

- Custom designs available

Outdoor overhead crane - Double girder overhead crane series

- Load capacity:5 ton -320 ton

- Span:10.5-31.5m

- Lifting height:6-24m

- Lifting speed:2.1-11.5m/min

- Trolley running speed:27-40m/min

- Crane running speed:42-75m/min

- Work duty:A3-A7

Outdoor overhead crane with freestanding bridge crane design

Outdoor jib crane for various applications

Freestanding jib crane for outdoor use. Customized outdoor jib crane with rainproof cover to ensure safety. Custom jib crane for sale now.

Jib cranes frequently installed in harsh or outside conditions, which pose difficulties for both the crane manufacturer and the end user. Outdoor jib crane usage guidelines and restrictions must be made clear by the manufacturer, and equipment maintenance is the responsibility of the final user. There really is no such thing as "maintenance free" or iron that will "never rust," no matter how hard you might strive to make maintenance-free outdoor hoisting equipment. In order to achieve the best performance and preserve a product that looks and functions pleasantly years after installation, equipment needs to be maintained, just like a nice automobile.

Free standing jib crane with electric chain hoist with rain cover for outdoor use

Floor mounted jib crane with full cover over cantilever with electric chain hoist for oudoor use

Column mounted jib crane for oudoor door use

Outdoor jib cranes with grab bucket for outdoor loads handling

Outdoor jib crane for waterside material handling

Outdoor jib crane for outdoor applications

What to consider when design cranes for outdoor use?

While constructing a crane for outside use, extreme weather and location must be considered. Sunlight, heat, cold, precipitation, wind, lightning, and a variety of other factors can all constitute extreme weather. While operating an overhead crane outside, regardless of the weather, there are several factors to take into account. We'll discuss a few design factors for your upcoming outdoor overhead crane project in this post.

The weather can impact overhead cranes used outside, therefore it's crucial to know how much time will be spent exposed to the weather. A crane can be stored inside a building or not, and it can be operated outdoors 100% of the time or less, depending on your ultimate project design. Different design considerations apply to outdoor cranes that are only used and kept outdoors as opposed to cranes that might also be utilized indoors or outdoors.

Environmental Conditions Affect Crane Designs

Environmental Conditions Affect Crane Designs

Rain, thunderstorms, and strong winds can have an impact on lifting operations when they are being done outside.

Rain and waterproof covers for ourdoor cranes and hoists

All outdoor cranes should have had their equipment and sensitive components designed with the proper Ingress Protection (IP) enclosures and shelters.

Water proof covers for Components

When a crane is used outdoors without a building cover, covers designed to fit over the hoist, hoist motor, end truck motors, and electrical panel are required. Protecting these components from rain, snow, and sunlight extends their service life and provides additional protection against the elements.

In addition, everyone is aware that water and electronics do not mix well. Temperature and moisture both have an impact on a crane's electrical parts. It is crucial that these components can still operate securely in the presence of these factors. The hoist and end truck motors, and other crane parts, are built with characteristics like drain holes, additional insulation, and specific bearings and seals when they are intended for outside operation. Use a cable designed for outdoor use for festooning and other electrical components. Festooning cable made of rubber rather than PVC may have characteristics that make it more suitable for outdoor use. The requirements for electrical components vary depending on where you are. Contact us to get more information.

Humidity & high temperatue

Corrosion

The possibility of corrosion on crane components increases in sites with salt air, excessive water, and high humidity. More regular lubrication is needed for locations where temperature changes cause moisture or crane corrosion. Cranes that are only occasionally used should undergo more frequent inspections to check for strange noises, proper functioning, and all functional operational mechanisms. A designated person shall evaluate and resolve the results of this inspection so that the crane is kept in safe working condition.

No matter how well-made the paint is, it will eventually rust. In the case that a crane rusts, the following steps can be followed to maintain the product's appearance and functionality:

Anti-corrosion paint - Repair surface procedure

Apply the following process to all nicks and blemishes:

- Areas affected by sand

- Thoroughly clean the area with the prescribed paint prep.

- Apply the appropriate primer in one coat.

- After the primer has dry, use the recommended topcoat paint finish to apply two coats of topcoat.

- The final mil thickness ought to range from 3 to 5.

Additionally, all rotating and lifting (hoist) parts of a crane must be operated through a full rotation each month in order to prevent deterioration whenever it is unattended or unused for a prolonged period (longer than one month).Keep that overhead crane looking as good as the day you bought it!

Strong Winds and Wood proof Anchor Devices

When wind speeds exceed those advised in the manufacturer's specifications, the gantry cranes and overhead cranes must never be used. Stop all lifting operations if there are severe gusts, and then secure the overhead crane and gantry crane using a wind restraint mechanism.

Wind Force Calculations

A wind force calculation must be done as you collaborate with your crane manufacturer or dealer to build a crane for outdoor operation. You need to take into account the type of weather that passes through your area depending on where you are geographically placed. A crane working in places, hundreds of miles from the shore, may have a different wind force calculation than one built for outdoor operation in a hurricane zone along the coast. The crane's movement, both with and without a load, is influenced by wind. Larger travel drives are typically required for cranes used outside to combat wind pressures. Wind locks are needed for heavy installations to keep the crane in place in strong winds. Creating the crane with the needs of the local wind in mind is

Windproof anchor devices

In order to secure your outdoor gantry crane and outdoor overhead cranes firmly at the workstation site, windproof anchor devices are a type of crucial large gantry crane safety device.

Oudoor overhead crane in cold weather

Typically, when you think of "severe weather," you don't picture cold conditions. On the other hand, cold weather may have a considerable effect on overhead cranes. In cold weather, the crane's tensile strength will decrease and it could possibly break.

An overhead crane's hydraulic system may degrade in colder climates. So, you should reduce your load weight by 25% in below-freezing weather. If the temperature is lower than -20 degrees Fahrenheit, reduce the load weight by 40%.

Additional precautions for cold weather include:

- Enclosing the trolley in a track to prevent ice from damaging it.

- Adding a special finish for cold climates to the crane.

- By using conductor bars, the joints of the crane are shielded.

- Purchasing a winter-appropriate motor.

Using a crane in the snow or at very low temperatures is risky. Under these circumstances, you should proceed with great caution.

Cold weather on steel and other metals

The effects of temperature on steel and electrical components can be profound. Typically, as the temperature drops, steel becomes more fragile. Fortunately, by altering the components of steel, producers may create goods that can be used in cold climates. When getting a crane price, make sure the crane manufacturer and dealer are aware that it will be used outside so that materials may be optimized.

When an overhead crane will be used outside, it's crucial to factor in extra concerns while designing the final product. The crane's performance may be impacted by the wind, sun, high and low temperatures, rain, snow, and other precipitation. When you collaborate with an expert crane manufacturer or crane dealer, these and many other factors are taken into account. Check how to ensure overhead crane safety in extreme weather.

What are the tips for outdoor crane maintenance?

Regular Inspections

More frequent inspections of outdoor crane and hoist equipment by qualified and certified experts are advised. Depending on how frequently the lifting crane is used and how hostile the environment is, inspections should be performed every six months or more frequently. Lubrication for outdoor crane equipment dries up more quickly, grease can melt off in extreme heat, rubber parts become more brittle in the cold, and environmental debris is blown into the equipment. All of this implies that equipment used outdoors should undergo more frequent inspections and maintenance than equipment used in interior installations.

The outdoor crane will undergo some standard maintenance during inspections, and inspectors will also look for wear and tear before it can stop operating. By reducing downtime, having a qualified pair of eyes on your equipment more frequently will save you money over time.

The Problem Caused by Extreme Weather and Maintenace Tips

Outdoor overhead cranes are unquestionably subjected to harder working conditions than cranes located inside of buildings, from the rain and summer heat to the significant seasonal temperature fluctuations.

Summertime Situations

Your outdoor crane and hoists equipment will suffer from the summertime heat and precipitation. With extreme heat, grease melts, and rain seeps into machinery. This implies that parts will need to be replaced, adjusted, and maintained more frequently. Hoists should "rest" under a cover when not in use to avoid exposure to the elements in order to prevent environmental wear.

Winter Conditions

Rubber and plastic become brittle when exposed to extreme cold. Metal components become fragile in very cold temperatures as well. The accumulation of snow and ice can slow down operations or damage equipment.

When not in use, hoists should "rest" under a cover.

In order to keep things moving, heated rails, heated buss bars, and panel heaters can be provided to prevent cold damage. Before using, snow and ice should be cleared away. Winter loading requires being wary of snow and ice accumulations that could prevent crane operation.

Debris

Dust, mud, pallets, and other types of dunnage are only a few examples of the debris that gets into moving parts and onto runways and rails. Moving parts should be cleaned or lubricated as part of pre-operational inspections and weekly inspections of lifting equipment and rails to keep them free of debris, dust, and outside contaminants. Hoist units should be placed under cover while not in use to shield them from the elements. An outdoor crane's rails easily become clogged with garbage. They need to be regularly checked, including weekly, biannual inspections, and each time they are used. Debris on the rails will cause the outdoor overhead crane to move more slowly, wear out parts more quickly, or stop it totally. Regularly check your rails.

Stocking components and parts

It is a good idea to stock worn parts on-site to enable maintenance to be completed much more quickly because exterior cranes will require wear parts replacement more frequently. Your inspector/maintenance team should have wire ropes, slings, brake disks, contractors, buss bar components, and contactors on available so they can quickly replace worn out parts.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch