Warehouse Crane System: Stacker & Overhead Cranes in Warehouses

Warehouse cranes systems for in-stock & out-stock operation in your warehouses . There are various types of cranes for warehouses such as, warehouse overhead cranes with single girder & double girder design, top running & underhung design, warehouse gantry cranes with full gantry & semi-gantry design & overhead stackers cranes with suspension kbk design, etc. Customized cranes for warehouses for efficient and safe goods handling to improve your productivity and lower your goods damages to make great value for your business.

Why you need ware house cranes?

The logistics sector is currently one of the world's fastest expanding industries. The demand for diverse logistics equipment has increased as the industry's size has risen, and technical performance has substantially improved. In the logistics equipment, various kinds of overhead lifting equipment take up a very important role, especially in the logistics warehouse.

Warehouses are not only important places to store goods, but they are also the primary location for goods turnover. Because the loading and unloading operation in warehouses is very frequently, it is inefficient and very time -consuming if solely relying on manpower. As a result, there are types of cranes in warehouses to help loading and unloading operation. In warehouses and stores, a warehouse crane is used to load, unload, and transport products. With the overhead crane systems, the lifting of goods through the entire area of the warehouse can be achieved.

The efficiency and storage capabilities of a warehouse is only as good as the overhead warehouse crane system it uses. Apart from the structrues itself, materials handling crane allows warehouse personnel to carry, lift, and store various objects and commodities in a warehouse in an efficient and safe manner. The critical role that warehouse cranes can play in your warehouse materials handling needs is sometimes ignored. These crane systems are used to help workers transport very huge and heavy goods, as well as other machinery. They allow workers in manufacturing warehouses to position large goods with precision that they would not otherwise be able to attain.

Warehouse stacker crane

The warehouse stacker cranes is a types of suspension kbk crane with hoist for loads handling in warehouses. Because the trolley of a warehouse stacker crane is much smaller than that of a standard double-girder overhead crane, stacker cranes are commonly used when the distance between rail and roof is restricted.

Warehouse stackers are used in mechanical processing workshops, metallurgical factories and subsidiary workshops, warehouses, material yards, and power plants for transferring, assembly, inspection maintenance, and load unload procedures due to their compact exterior dimensions, low construction headroom, light dead weight, and light wheel load advantages. It can also take the place of a standard double-girder overhead crane, which is commonly used in light textile and food manufacturing workshops.

The kbk stacker crane, which consists of a double girder suspension kbk crane and a one-of-a-kind stacking trolley, is a cost-effective and versatile material handling crane for warehouses, stores, and logistics. The warehouse stacker crane is widely used to in-stock, out-stock, transport, sort, store, and access a variety of loads, including cargo, vessels, stacking pallets, and others, in applications with dense equipment, short distance delivery, and high operation frequency.

Intelligent warehousing bridge cranes

Intelligent warehousing has become essential for many e-commerce businesses as the warehousing industry has grown and online commerce has grown. Intelligent warehouse stacking crane system was developed to reduce labor intensity of allocation and save warehouse space, and it has since become a core piece of intelligent storage equipment.

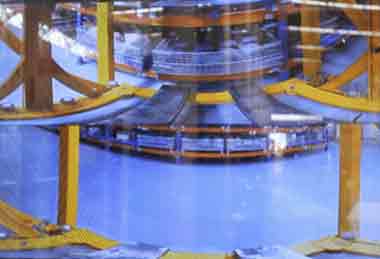

Intelligent warehouse crane system

The stacker bridge crane can handlie goods with a volume of 1.2m * 1.2m * 0.7m and has a capacity of 1.5t. In addition, the shelf has 28 columns, 7 rows, 8 layers, 1568 cargo spaces, and a total load of 2352t.

Uses & applications of stacker bridge cranes

The warehouse stacker crane system has a wide range of applications:

The warehouse crane stacker can be used in workshops, large retail beverage supermarkets, and pharmaceutical company warehouse storage. It is appropriate for a variety of industries, including the chemical industry, textiles, auto parts, electronic products, supermarket warehouses, and so on.

Features of warehouse bridge crane systems

Bridge Crane system: positioning system, anti-sway system, HMI (human-computer interaction), crane remote control, wireless network settings, background server and crane control, and so on.

High precision positioning

Automatic reclaim

WCS and WMS management, code scanning device, warehouse management system software, video monitoring system, wireless and wired network system, production docking MES interface.

Interactive interface

CCTV monitor

The storage area's safety and warning system: safety management of the crane's working area, safety management of the ground sidewalk, safety management of the vehicle passage, various safety management indicators, alarms, and safety barriers, and so on.

The stacker is primarily used in conjunction with the goods shelf and is easy to move while in use, which can save power while also reducing the stacker's occupied area.

Stransfer equiment

The automated 3D warehouse stacker greatly simplifies the logistics transportation and large-scale warehousing industries. The crane stacker can not only increase efficiency but also reduce product damage. This system can protect the surface of the goods from damage to the greatest extent possible during the working process.

Warehouse bridge cranes

This warehouse bridge crane design allows the hoist to access and manipulate objects on three axes of movement beneath the bridge structure. Warehouse overhead cranes are frequently used in single-story warehouse operations such as manufacturing.

The warehouse overhead crane is the most commonly used lifting device in the warehouse, and it can do a lot of large and heavy work that manpower cannot. As a result, users will benefit greatly from using this warehouse crane.

Overhead cranes can be mounted on steel columns. As a result, it is frequently utilized to increase worker productivity and the operating conditions of critical machinery in factories, mines, ports, warehouses, and other material handling locations. It will make the best space utilization because it will be situated on the upper space of the facility.

Single Girder Warehouse Overhead Cranes

The electric single girder warehouse overhead crane has a tonnage of 0.5-20 ton and is made up of a single girder beam, monorail hoist, end carriage with motor, and complete panels.

Double Girder Warehouse Overhead Cranes

Double girder warehouse bridge crane is composed of main beam, cross traveling mechanism, long traveling mechanism, and electrical equipment. The double girder cranes are widely used in steel mills, construction industries, warehouses, freight yards, cement plants, and other heavy-duty operations.

FEM Standard Warehouse Overhead Cranes

The European Model warehouse overhead crane is built to the FEM standard. It's renowned for its compact size and light dead weight.

In comparison to traditional cranes, our European type overhead crane's limiting distance from hook to wall is the minimum, and headroom is the smallest, allowing the overhead cranes to work closer to the front, and lifting height is higher, covering more effective workplace working area.

Because the dead weight and wheel pressure are low, new workshops can be built to be smaller and have more functions.

Underhung Warehouse Overhead Cranes

Warehouse overhead crane with underruning design is a light duty material handling crane. It can be suspended from a girder or beam of a steel structure, or on the beam of warehouse supporting structure.

They are primarily intended for light loads (up to 10000kg) , such as, Parts assembly, manufacturing and processing industries, pallet shipping, injection molding, warehousing loading and unloading, equipment maintenance, and so on.

Features of overhead cranes in warehouse

EOTCRANEKIT warehouse overhead cranes have a high level of stiffness, a low dead weight, and an outstanding construction design that ensures long service life and high quality.

- Overhead cranes in warehouses can minimize factory space and investment costs due to their small overall size, low clearance height, and small wheel load.

- Overhead warehouse crane stands out in the similar types of hoisting items due to advanced technology and great professional understanding.

- Excellent after-sale service and skilled advice relieve you of material handling concerns.

- With a competitive price and high quality, a warehouse overhead crane is the best option.

- There are two different types of control for the overhead crane in the warehouse: ground control with a rope handle and remote control. Our firm will also manufacture a customized warehouse crane system based on specific specifications.

Gantry Cranes

Because it can run on the ground rather than on elevated runways, a gantry cranes in warehouses can be an excellent alternative to an overhead crane. As a result, no supporting columns or above runways are required for the warehouse gantry crane. The warehouse gantries are durable and operate excellently, allowing you to significantly enhance your productivity. We offer a variety of overhead gantry cranes to match your specific lifting requirements.

Double girder gantry crane in warehouses for heavy duty loads handling with capacity up to 500 ton

Single girder gantry cranes in warehouse with capacity up to 32 ton

Prominent Benefits of Using A Warehouse Gantry Crane

Because a gantry crane is useful for moving heavy goods in your warehouse or workshop, it is popular among potential crane users. Users of gantry cranes will benefit from having a suitable warehouse gantry crane design for the following reasons:

Cost-effective: It is a cost-effective solution for most indoor and outdoor lifting situations, as well as a viable alternative to overhead cranes.

- Strong mobility: When compared to other types of lifting equipment, gantry cranes can be mobile, allowing them to move from one location to another quickly and easily.

- High adaptability: These electric gantry cranes can handle a wide range of lifting tasks in your industry, including manufacturing, repair, and assembly lines.

- Large capacity: it can handle a variety of materials ranging in weight from a few tons to dozens of tons.

- Excellent safety: By combining the use of proper crane control and sturdy construction, the warehouse gantry crane provided will ensure a safe lifting operation, not only the safety of the staff, but also the efficiency of production.

- Reliable and long-lasting performance: The gantry cranes are extremely dependable and long-lasting. They have smooth movements and less crane downtime.

- Furthermore, they require little maintenance. The equipment also makes little noise while moving.

Gantry Crane vs. Overhead Crane, Which One Is Best For Your Warehouse?

Both gantry cranes and overhead cranes can significantly improve warehouse efficiency and productivity. The question is, which type is best suited to your requirements? To find out the answer, you should first understand the similarities and differences between these various types.

Overhead Crane

Overhead cranes are distinguished by an elevated runway beam on which the crane is mounted. The bridge crane is commonly used in various indoor facilities, and the overhead crane can be configured into top running and underhung cranes to fit different application conditions in facilities.

Gantry Crane

Gantry cranes are similar to overhead cranes in most ways, except that they are supported by legs. Instead of running along an overhead runway, it can travel along ground rails or on wheels, allowing for greater mobility and transportation. The gantry crane is appropriate for both indoor and outdoor work environments.

How to Choose a Proper Warehouse Crane

Because overhead lifting equipment is critical to the warehouse's smooth operation, selecting the right crane is critical. Each type of lifting equipment has advantages, and when selecting the right crane for your warehouse, consider the following factors: your specific lifting requirements, facility conditions, convenience of operation, and, of course, your budget.

The products you'll be handling, as well as the specifications for your overhead crane, such as the crane's lifting capability, lifting height, and span.

kbk stacker crane -light warehouse overhead crane

- Preferred types of cranes in warehouse . Warehouse overhead cranes, warehouse gantry cranes, and warehouse hoists are all widely used cranes in warehouses.

- The frequency of the crane use. Some cranes are light duty and cannot be utilized in a high-volume, frequent-use setting, while others are heavy duty and can perform heavy work on a continuous basis. As a result, you must decide how frequently you will use the cranes in your warehouses.

- The crane cost you intend to pay. How much money do you plan to spend on a warehouse crane? Which type do you prefer? Within your budget, we can provide the best crane option.

- The crane control operation of crane in warehouse. Pendant control, remote control, and cab operation are the three most common ways. Depending on your needs, you can choose one of them or two combinations.

We recommend that you consider these considerations carefully, and then we will assist you in selecting the best warehouse crane solution. We also offer specialized overhead lifting equipment.