5 Ton Electric Hoist for Sale – 90 Meter Lift, Cost-effective

Reliable 5-ton electric hoist with 90-meter lifting height, ideal for industrial projects in Bangladesh. High performance, low maintenance.

Category: Wire Rope Hoist Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Single Speed Hoists for Sale, Cost-effective Lifting Hoist

5 Ton Electric Hoist with 90 Meters Lifting Height for Sale in Bangladesh

Reliable 5-ton electric hoist with 90-meter lifting height, ideal for industrial projects in Bangladesh. High performance, low maintenance.

Overview of Electric Hoists for Industrial Applications

Electric hoists are widely used in industrial settings for lifting and moving heavy loads with ease and precision. They are integral to industries like construction, manufacturing, shipping, and logistics, where lifting heavy items such as machinery, building materials, and containers is a common requirement. By harnessing electric power, these hoists are capable of consistent, high-performance operation, making them an essential part of modern industrial infrastructure.

Types of Electric Hoists:

- Wire Rope Hoists: Used for high-lifting applications.

- Chain Hoists: Typically for lighter, less demanding jobs.

- Pneumatic Hoists: Suitable for environments where electricity is not available.

Key Benefits of Electric Hoists:

- Increased efficiency and productivity.

- Lower operational costs compared to manual hoisting.

- Enhanced safety features to prevent accidents.

Electric hoists are often chosen for their simplicity, durability, and the ability to handle a wide range of loads. Their versatility and range of designs allow them to be tailored to meet specific needs, whether it's for lifting heavy machinery in a factory or for moving construction materials at a high-rise building site.

Importance of Choosing the Right Hoist for Specific Project Requirements

Selecting the correct hoist for a project is critical to ensuring its success. The wrong choice can lead to operational inefficiencies, safety hazards, or even damage to the equipment being lifted. Several factors must be considered to make the best choice:

- Lifting Capacity: The hoist must be able to handle the weight of the loads being lifted. Overloading can damage the hoist or result in accidents.

- Lifting Height: The height at which the load needs to be lifted determines the hoist design. Taller buildings or high-rise projects need hoists with higher lifting capacities.

- Power Source: The hoist must be compatible with the available power supply at the site. Local electrical standards should be met to avoid issues during operation.

- Environmental Conditions: Hoists used in harsh environments, like coastal areas or high-temperature locations, may need special features, such as anti-corrosion coatings or explosion-proof components.

Choosing the right hoist not only impacts project efficiency but also safety. For example, a hoist that matches the load weight and height will reduce strain on the equipment, resulting in longer service life and reduced maintenance needs. In regions like Bangladesh, where industrial projects are growing rapidly, selecting a hoist suited to both the local power grid and environmental conditions is particularly important.

Brief Introduction to the 5 Ton Electric Hoist with 90 Meters Lifting Height Designed for Bangladesh

The 5 Ton Electric Hoist with a 90 Meter Lifting Height is a robust, high-performance hoist designed to meet the needs of heavy-duty industrial applications in Bangladesh. With a 5-ton lifting capacity, it can handle medium to heavy loads, making it suitable for a variety of applications such as construction, port operations, and power plants.

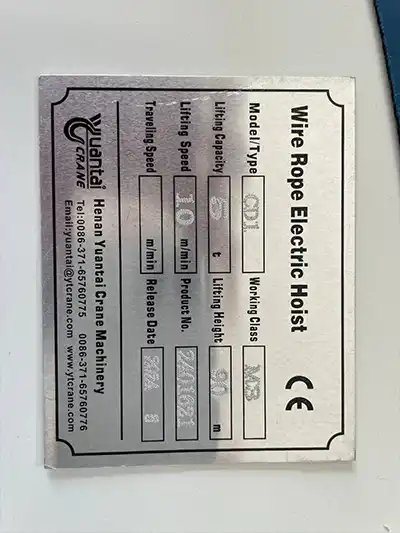

Key Specifications:

- Capacity: 5 tons, capable of lifting large, heavy loads.

- Lifting Height: 90 meters, ideal for tall structures like high-rise buildings and industrial projects requiring significant vertical lifting.

- Power Supply: 415V, 50Hz, 3-phase, which is compatible with local electrical standards in Bangladesh.

Design Features:

- CD Series: This hoist uses the CD series wire rope hoist design, offering a single-speed operation that ensures simple and reliable lifting performance.

- Single-Speed Design: Designed for ease of operation, this hoist offers smooth, predictable performance, reducing the complexity and maintenance compared to variable-speed models.

This hoist is built to withstand the rigorous demands of industrial projects in Bangladesh, offering both power and precision in lifting heavy loads at great heights. Whether for construction, heavy manufacturing, or large-scale infrastructure projects, the 5 Ton Electric Hoist with 90 meters lifting height is the ideal solution for high-lifting applications in the region.

5 Ton Electric Wire Rope Hoist with 90 Meters Lifting Height for Sale in Bangladesh

5 Ton Electric Hoist with 90 Meters Lifting Height for Sale in Bangladesh

5 Ton Singl Speed Electric Hoist with 90 Meters Lifting Height for Sale in Bangladesh

5 Ton Electric Hoist Wire Rope Hoist with 90 Meters Lifting Height for Sale in Bangladesh

Key Features of the 5 Ton Electric Hoist

Hoist Type: CD Series Wire Rope Electric Hoist, Single Speed Design

Explanation of CD Series: Reliable, Cost-Effective, and Suitable for Various Lifting Applications

The CD Series Wire Rope Electric Hoist is a popular choice in industrial applications due to its reliability and versatility. The design is based on proven technology, making it a trusted option for handling heavy loads across various industries. The CD series is known for being cost-effective, offering high performance at a reasonable price point, and its simple yet robust construction ensures long-term durability with minimal downtime.

Key Advantages:

- Reliable Performance: Known for consistent operation even in demanding environments.

- Cost-Effective: Lower initial cost and maintenance expenses compared to other more complex hoist systems.

- Wide Application: Suitable for use in warehouses, factories, and construction sites where dependable lifting is needed.

Single Speed Design: Simplicity, Ease of Use, and Low Maintenance

The single-speed design of this hoist contributes to its user-friendly operation. With just one lifting speed, it simplifies control and is ideal for tasks where precise, variable-speed adjustments are not necessary. This simplicity leads to lower maintenance and fewer mechanical complications, making it a highly practical solution for industrial settings that require consistent and reliable lifting.

Benefits of Single-Speed Design:

- Ease of Use: Operators don’t need to adjust speeds, making the hoist simple to operate.

- Low Maintenance: With fewer moving parts and no complex speed control systems, this design is less prone to failure and requires less upkeep.

- Cost Savings: The straightforward design reduces repair costs and downtime.

Hoist Capacity: 5 Ton

Suitable for Medium-Duty Industrial Lifting

The 5-ton capacity of this hoist makes it ideal for medium-duty lifting applications. It can handle a variety of loads, such as heavy machinery, building materials, and large components, making it a versatile choice for both manufacturing and construction industries.

Applications:

- Warehouses: Lifting and moving bulk items or equipment.

- Factories: Ideal for lifting parts, tools, and machinery.

- Construction Sites: Lifting construction materials like steel beams, concrete panels, and large equipment.

This capacity is perfectly suited for medium-scale projects where lifting capacities beyond 5 tons might not be required. It strikes a balance between power and practicality, providing enough lifting capacity without unnecessary excess.

Lifting Height: 90 Meters

Ideal for High-Rise Facilities and Specialized Projects

The 90-meter lifting height is one of the key features that set this hoist apart. It’s designed for applications that require significant vertical lifting, such as high-rise buildings, telecommunications towers, or industrial structures. The 90-meter range ensures that the hoist can reach the necessary heights to support construction and maintenance tasks at elevated levels.

Significance of High Lifting Heights:

- Tall Buildings: Lifting building materials, such as steel beams and concrete panels, for multi-story construction projects.

- Towers and Infrastructure: Useful for erecting or maintaining communication towers, wind turbines, or other tall structures.

- Specialized Projects: Ideal for industries that require lifting at significant heights, such as power plants or large industrial complexes.

The 90-meter lifting height allows operators to work safely at greater elevations, making it a crucial feature for projects where conventional hoists cannot reach the required levels.

Hoist Power: 415V, 50Hz, 3P

Overview of Power Requirements and Electrical Compatibility in Bangladesh

This hoist operates on a 415V, 50Hz, 3-phase power supply, which is compatible with the electrical infrastructure in Bangladesh. Bangladesh typically uses 220V-240V power in homes and 415V for industrial applications, making this hoist an ideal choice for large-scale industrial projects. The 3-phase power system offers efficient energy distribution and allows the hoist to operate smoothly and with minimal electrical strain.

Power Supply Considerations:

- Electrical Compatibility: The hoist is specifically designed to work within the local power specifications of Bangladesh, ensuring it can be easily integrated into industrial setups.

- Energy Efficiency: The use of 3-phase power ensures energy is distributed evenly, reducing electrical costs and minimizing the risk of overloads.

- Durability: The power system is designed to withstand the demands of heavy-duty industrial applications, ensuring long-term reliability and lower operational costs.

Energy Efficiency and Durability Considerations

With its 3-phase power system, this hoist is designed to be energy-efficient, providing reliable operation without consuming excessive power. This design ensures that energy is used efficiently, contributing to lower electricity bills and increased operational longevity. For industries in Bangladesh, where electricity costs and power stability can be a concern, this hoist’s power efficiency helps mitigate such issues.

- Long-Term Durability: The electrical components are built to handle continuous use, reducing the need for frequent repairs or replacements. This ensures the hoist remains in service for years without substantial maintenance costs.

- Cost-Effective Operation: The efficient power system minimizes wear on components, making the hoist an economical choice in the long term.

Technical Specifications of the Hoist

Capacity & Design

Load Capacity of 5 Tons – What It Means in Terms of Lifting Requirements and Typical Applications

The 5-ton load capacity of this hoist is designed to handle medium-duty lifting operations, making it suitable for a wide range of industrial applications. In practical terms, a 5-ton hoist can lift heavy machinery, construction materials, and equipment typically used in manufacturing, construction, and warehousing environments.

For most industries, a 5-ton hoist is more than adequate for lifting tasks that do not exceed this weight, making it both an efficient and cost-effective solution for day-to-day lifting operations.

Wire Rope Mechanism

Features of the Wire Rope System in the CD Series Hoist

The CD Series hoist uses a wire rope mechanism, which is widely regarded as one of the most reliable and durable systems for lifting heavy loads over long distances. Wire ropes provide excellent strength, flexibility, and wear resistance, which are essential for high-performance lifting.

Key Features of the Wire Rope System:

- High Strength: Wire ropes are designed to bear heavy loads, offering high tensile strength and resistance to breakage under strain.

- Smooth Operation: The flexible design of wire rope allows for smoother, more controlled lifting motions, reducing wear on both the hoist and the load.

- Durability: Wire ropes are highly resistant to wear, corrosion, and fatigue, making them ideal for long-term use in demanding environments.

Advantages of Using Wire Rope for Long Lifting Heights

Wire rope is especially effective for long lifting heights, like the 90-meter capacity of this hoist. This mechanism can handle extended vertical movements without compromising load safety or system integrity.

Key Advantages for Long Lifting:

- Stable Lifting: The strong wire rope ensures that heavy loads are lifted steadily, even at greater heights, without risking slippage or instability.

- Minimal Stretching: Wire ropes have minimal stretch compared to other lifting systems, maintaining the hoist’s precision over longer distances.

- Suitable for High Heights: Unlike chain hoists, wire ropes are ideal for applications that require lifting over 20 meters, making them perfect for high-rise construction, tower installation, and other specialized projects.

Power Supply Details

Explanation of Voltage, Frequency, and Phase (415V, 50Hz, 3P) Relevant to Bangladesh’s Infrastructure

The 415V, 50Hz, 3-phase power supply is a standard for industrial machinery in many parts of the world, including Bangladesh. In Bangladesh, the majority of large-scale industrial applications use this type of power supply, making the 5 Ton Electric Hoist perfectly suited to local power infrastructure.

Key Power Specifications:

- 415V: This voltage level is common for industrial equipment in Bangladesh and ensures stable power delivery for heavy-duty machinery.

- 50Hz Frequency: The 50Hz frequency is the standard for electricity in Bangladesh, ensuring compatibility with local grid systems and minimal power disturbances.

- 3-Phase Power: Three-phase power is essential for providing consistent energy and reducing the chances of power surges or interruptions during operation. It also supports efficient distribution of power to heavy machinery, ensuring smooth performance over time.

Considerations for Local Power Systems and Installation

When installing the 5 Ton Electric Hoist in Bangladesh, it is important to consider the local electrical system to ensure proper compatibility.

- Local Power Grid Compatibility: The hoist is designed to work seamlessly with the local 415V, 50Hz, 3-phase power system, minimizing the need for electrical modifications.

- Installation Needs: The installation should account for appropriate wiring, circuit protection, and grounding systems to ensure safety and proper functioning. Any modifications required for local power grid integration should be handled by certified electricians to meet local standards.

Safety Features

Safety Mechanisms Integrated into the Hoist, Such as Overload Protection and Limit Switches

Safety is a top priority in hoist design, and the 5 Ton Electric Hoist includes several built-in mechanisms to protect both the operator and the equipment. These safety features are vital in preventing accidents, protecting heavy loads, and ensuring smooth, trouble-free operation.

Key Safety Features:

- Overload Protection: The hoist is equipped with an overload protection system that prevents the hoist from operating beyond its rated capacity. This is essential to avoid strain on the motor, wire rope, and other components, reducing the risk of damage or accidents.

- Limit Switches: The hoist includes limit switches that automatically stop the movement when the hoist reaches its maximum height or lowest point. This prevents damage to the hoist and the lifting components and ensures the safety of the operator.

- Emergency Stop: A built-in emergency stop function is included to immediately halt the hoist’s operation in the event of an emergency. This feature enhances operator safety in case of malfunction or unsafe conditions.

Benefits of Safety Features:

- Minimized Risk of Damage: Overload protection and limit switches help prevent damage to the hoist, load, and surrounding infrastructure.

- Enhanced Operator Safety: The safety mechanisms reduce the risk of accidents during operation, providing peace of mind for operators working with heavy loads.

- Compliance with Industry Standards: These safety features ensure that the hoist meets or exceeds the required safety standards for industrial lifting equipment, ensuring compliance with local and international regulations.

By incorporating these advanced safety features, the 5 Ton Electric Hoist ensures both operational reliability and the well-being of its users.

Applications in Bangladesh

Industrial Use

The 5 Ton Electric Hoist with 90 Meters Lifting Height is a highly versatile piece of equipment, suitable for a wide range of industrial applications in Bangladesh. As the country continues to grow its infrastructure and industrial capabilities, the demand for efficient lifting systems is increasing. This hoist can be applied across multiple sectors, including construction, shipping, factories, and manufacturing.

- Construction: The hoist’s 5-ton capacity and 90-meter lifting height make it ideal for lifting heavy construction materials, such as steel beams, concrete panels, and large equipment, on building sites. It supports vertical construction and enables efficient handling of materials at significant heights for tall buildings and skyscrapers.

- Shipping & Logistics: In port operations, the hoist can be used for lifting containers, heavy machinery, and cargo, ensuring smooth loading and unloading processes in shipping yards. Its long lifting height makes it suitable for stacking containers and handling large cargo with precision.

- Factories & Manufacturing: In factory environments, this hoist is effective in lifting heavy components and machinery during assembly or maintenance. Its versatility allows for its application in different manufacturing sectors, such as automotive, steel, or heavy equipment production, to facilitate material handling and equipment positioning.

High-Rise Projects

Relevance of the 90-Meter Lifting Height in Vertical Construction Projects

The 90-meter lifting height is particularly beneficial for high-rise construction projects. In Bangladesh, urbanization is rapidly growing, and the demand for multi-story buildings, residential complexes, and commercial towers is high. This hoist is specifically designed to address the challenges posed by these vertical construction needs.

- Tall Buildings: The 90-meter lifting height ensures that construction materials, such as steel rods, cement, and large prefabricated units, can be easily lifted to significant heights, streamlining the construction process of high-rise buildings.

- Infrastructure Projects: Large-scale infrastructure projects, such as bridges and communication towers, also benefit from the high lifting capacity, enabling the efficient lifting and placement of heavy structural elements at elevated levels.

The combination of high capacity and extended lifting range makes the hoist invaluable for tackling the complex vertical demands of high-rise and infrastructure projects in Bangladesh.

Port and Harbor Operations

Use in Lifting Heavy Cargo, Machinery, and Containers in Ports

Ports and harbors are key hubs for the transportation of goods and materials in Bangladesh, and the 5 Ton Electric Hoist is ideal for the demanding lifting tasks in these environments. In ports, this hoist can be used to handle a variety of heavy loads, including cargo containers, bulk materials, and machinery.

- Container Handling: The hoist can be used to load and unload containers from ships, stacking them efficiently and allowing for better organization in port yards.

- Heavy Cargo Handling: It’s also suitable for lifting other heavy items, such as industrial equipment or machinery, that are often required to be moved in shipping yards.

- Precise Lifting: The hoist’s precise control system ensures that loads are handled with care, reducing the risk of damage to goods or infrastructure, which is critical in busy port environments.

In ports, the 5 Ton Electric Hoist enhances operational efficiency, ensuring fast and safe handling of cargo and containers, ultimately contributing to smoother logistics and transport systems in Bangladesh.

Power and Energy Projects

Role of High Lifting Heights in Energy Sector Projects

In the energy sector, especially for power plants and wind turbine installations, the need for lifting heavy equipment and machinery to significant heights is essential. The 90-meter lifting height is perfectly suited for these high-lift requirements.

- Power Plants: The hoist can be used for lifting large components such as turbines, generators, and structural supports required for power plants. With its long lifting height, it can support the vertical assembly and installation of tall equipment that cannot be easily handled by standard lifting systems.

- Wind Turbine Installations: In wind power projects, the hoist is valuable for assembling and installing wind turbines, where components often need to be lifted to great heights to assemble the towers.

- Oil & Gas Infrastructure: In the energy sector, the hoist is also suited for lifting heavy machinery or materials for oil and gas infrastructure, where space and height restrictions often make heavy lifting challenging.

By providing the necessary lifting capacity and height, this hoist supports efficient operations in the energy sector, helping Bangladesh meet its growing energy demands while maintaining safety and efficiency on large-scale projects.

In conclusion, the 5 Ton Electric Hoist with 90-meter lifting height serves multiple industrial sectors in Bangladesh. Its versatility makes it a crucial tool for construction, port operations, and energy projects, while its high lifting capacity and advanced safety features make it an excellent choice for high-rise, heavy-lifting applications in the country's rapidly developing industries.

Extending Lifespan

Tips for Prolonging the Lifespan of the Hoist, Particularly in Harsh Environmental Conditions

The longevity of the 5 Ton Electric Hoist depends on how well it is maintained, particularly when used in challenging environments. Factors such as extreme weather, dust, and corrosive materials can affect the hoist’s performance over time.

Protection Against Harsh Environments:

- Install the hoist in a clean, dry location when possible, especially if operating in factories or construction sites with high dust levels.

- For outdoor applications, use protective covers to shield the hoist from direct exposure to rain, snow, or dust.

- Ensure proper drainage around the hoist to avoid water accumulation, which can lead to rusting or corrosion of key parts.

Regular Cleaning:

- Clean the hoist components regularly to prevent the buildup of dust, debris, and grease. Use appropriate cleaning agents that are safe for the hoist’s materials.

- Wipe down electrical components with a dry cloth to prevent the buildup of moisture.

Temperature and Humidity Considerations:

- In areas with extreme temperatures, such as coastal or desert climates, ensure the hoist’s materials are rated for the specific temperature ranges.

- For locations with high humidity, ensure that the hoist is equipped with anti-corrosion coatings to protect against rust and degradation.

Anti-Corrosion Treatments and Precautions for Maintaining Hoist Performance

Corrosion is one of the most significant factors that can reduce the lifespan of a hoist, particularly in industries where it is exposed to chemicals, moisture, or saline environments. Applying anti-corrosion treatments can significantly improve the hoist's durability and maintain its optimal performance.

Anti-Corrosion Coatings:

- Use anti-corrosion coatings for components such as the wire rope, motor housing, and metal parts. These coatings act as a protective barrier, preventing rust and corrosion.

- In environments with high saline exposure, such as ports or coastal areas, opt for marine-grade coatings that provide an extra layer of protection against corrosion.

Corrosion-Resistant Materials:

- Ensure that the hoist is constructed with stainless steel or other corrosion-resistant materials, particularly for parts exposed to moisture or chemicals.

Sealing:

- Check that the hoist’s control box, electrical panels, and other sensitive components are properly sealed to prevent moisture ingress.

Troubleshooting Common Issues

Identification and Resolution of Common Operational Problems

Despite regular maintenance, some operational problems may arise from time to time. Understanding how to identify and resolve these issues is important for minimizing downtime and ensuring safe hoist operation.

Problem: Hoist Not Lifting the Load

- Cause: The hoist may be overloaded, or there may be an issue with the power supply.

- Solution: Check the load and ensure it does not exceed the rated capacity. Verify that the electrical system is providing stable voltage and check for power outages or issues with the circuit.

Problem: Unusual Noises During Operation

- Cause: The hoist may have worn-out gears, bearings, or cables.

- Solution: Inspect the mechanical components for wear and replace any damaged parts. Ensure proper lubrication is applied to reduce friction.

Problem: Slow Lifting Speed

- Cause: A sluggish motor or faulty electrical components may be to blame.

- Solution: Inspect the motor for signs of wear or overheating. Check the electrical system for poor connections or faulty wiring, and ensure the motor is receiving the correct voltage.

Problem: Hoist Stops Unexpectedly

- Cause: This could be caused by an overload condition or an electrical fault.

- Solution: Check the hoist's overload protection system to ensure it is functioning correctly. Inspect the limit switches and emergency stop mechanisms to ensure they aren’t engaged inadvertently.

Problem: Wire Rope Tangling or Misalignment

- Cause: Incorrect winding, misalignment on the drum, or damaged rope.

- Solution: Regularly inspect the wire rope and ensure it is properly aligned. If tangling persists, it may be necessary to replace the rope.

By understanding these common issues and following the recommended solutions, operators can troubleshoot and resolve problems quickly, ensuring the hoist continues to perform optimally.

Proper maintenance, regular inspections, and effective troubleshooting are key to extending the lifespan and ensuring the reliable operation of the 5 Ton Electric Hoist. By following these practices, particularly when working in harsh environments, operators can reduce the likelihood of unexpected breakdowns and maximize the efficiency of their lifting operations for years to come.

Advantages of Single Speed Electric Hoists

Simplicity and Efficiency

Benefits of a Single-Speed Design for Ease of Use, Cost-Effectiveness, and Low Maintenance

The single-speed electric hoist design offers significant benefits, making it an ideal choice for many industrial applications. Its simplicity is one of the primary advantages, as it eliminates the complexity found in multi-speed or variable-speed models. This straightforward design ensures ease of use, reducing the need for specialized training and allowing operators to focus on the task at hand.

Ease of Use:

- The single-speed mechanism allows for easy control, making it accessible to operators of varying experience levels. The straightforward design ensures that there are fewer controls to manage, simplifying the lifting process.

- It provides consistent performance without the need for complex adjustments, allowing for smooth operation in a wide range of environments.

Cost-Effectiveness:

- Single-speed hoists are generally more affordable upfront compared to variable-speed models. The simplicity of the system means fewer parts that can wear out or break, which leads to lower initial purchase and maintenance costs.

- Due to fewer components and less complex technology, maintenance costs are typically lower, and repair work is less frequent, contributing to long-term savings for businesses.

Low Maintenance:

- Fewer moving parts and simpler mechanisms make the single-speed hoist easier to maintain. With fewer components subject to wear and tear, operators can spend less time on repairs and more time on lifting tasks.

- Routine maintenance tasks are simplified, which reduces downtime and extends the operational life of the hoist.

Reliability in Various Environments

High Reliability and Performance in Both Indoor and Outdoor Environments, Particularly in Industries Like Construction and Port Operations

A key advantage of the single-speed electric hoist is its reliability across diverse environments, whether operating indoors or outdoors. This reliability is particularly valuable in industries where heavy-duty lifting is essential, such as construction and port operations.

Construction Sites:

- Construction projects, especially those involving high-rise buildings or large-scale infrastructure, require hoists that can perform consistently under heavy loads. The single-speed hoist is ideal for these environments as it offers dependable performance without complicated systems that could potentially fail under stress.

- The simplicity of the design ensures fewer chances of malfunctions or breakdowns, even in harsh working conditions such as high dust levels, moisture, or extreme temperatures.

Port and Harbor Operations:

- In ports and harbors, hoists are exposed to challenging environmental conditions like saltwater, wind, and heavy, repetitive lifting. The single-speed hoist is built to withstand these conditions and maintain high performance, reducing downtime and enhancing operational efficiency.

- Its robust and simple design ensures reliability when handling heavy cargo, containers, or machinery, crucial for port operations that demand frequent and heavy lifts.

The high reliability of single-speed hoists ensures that industries like construction and port logistics can rely on them for consistent performance, even in the most challenging environments.

Affordability

Comparison of Costs and Long-Term Savings with Single-Speed Hoists Versus Variable-Speed Models

When considering cost-effectiveness, single-speed electric hoists offer a distinct advantage over variable-speed models, both in terms of initial investment and long-term savings.

Lower Initial Cost:

- Single-speed hoists generally have a lower initial purchase price compared to variable-speed or multi-speed hoists. The simpler design, fewer components, and reduced complexity contribute to a more affordable upfront cost.

Reduced Maintenance Costs:

- Because single-speed hoists have fewer components (such as a simpler drive mechanism and fewer electronic parts), the likelihood of failure is lower, which reduces the need for expensive repairs and maintenance.

- Routine maintenance is less costly, as there are fewer parts to inspect and replace. This also means fewer operational disruptions, which translates into cost savings for businesses in the long run.

Energy Efficiency:

- Although variable-speed hoists offer more precise control over lifting speeds, they also consume more energy due to the additional electrical components required to regulate speed. Single-speed hoists operate at a constant power level, which can lead to more consistent energy use and lower electricity bills.

Long-Term Savings:

- The simplicity and durability of single-speed hoists contribute to lower total cost of ownership over time. With fewer repairs and replacements required, businesses save significantly on long-term operational costs, making it a practical investment for industries with tight budgets.

When comparing single-speed hoists to more complex models, businesses can expect a strong return on investment, thanks to affordable initial costs, low maintenance needs, and energy efficiency.

The single-speed electric hoist offers a combination of simplicity, reliability, and affordability that makes it an excellent choice for industries such as construction, ports, and factories. With its cost-effectiveness, ease of use, and low maintenance needs, it provides significant long-term savings while maintaining high performance in various working conditions. Whether handling heavy materials at a construction site or lifting containers in a busy port, the 5 Ton Single Speed Electric Hoist delivers consistent, reliable results that contribute to overall operational efficiency.

Why Choose This Hoist for Your Project in Bangladesh?

Fit for High Lifting Requirements

Why This 5-Ton Hoist with 90-Meter Lifting Capacity is Ideal for Large-Scale and Vertical Projects in Bangladesh

The 5-ton electric hoist with a 90-meter lifting height is an excellent choice for projects in Bangladesh that require high lifting capacities, especially in vertical construction and large-scale industrial applications.

- Perfect for Tall Buildings and Infrastructure:

Bangladesh's urban landscape is rapidly growing, with many high-rise buildings and large-scale construction projects underway. The 90-meter lifting capacity of this hoist makes it ideal for lifting heavy materials to great heights, enabling efficient vertical construction.From steel beams to construction equipment, the hoist can easily manage the weight and height demands of modern skyscrapers and multi-story structures. - Versatile for Large-Scale Industrial Projects:

This hoist is also well-suited for industries that require lifting heavy equipment or materials at considerable heights, such as energy, power plants, and shipping sectors. The ability to lift up to 90 meters provides the necessary flexibility for large-scale operations, from wind turbine installations to handling large cargo at ports.

By offering a high lifting range, this hoist enables efficient material handling in vertical construction and other large-scale projects, which are increasingly common in Bangladesh's growing industrial sector.

Energy Efficiency and Cost-Effectiveness

How the Power Specifications Align with Local Energy Needs, Leading to Lower Operational Costs

The 415V, 50Hz, 3-phase power specification of this hoist is perfectly aligned with the standard electrical infrastructure in Bangladesh, making it an energy-efficient choice for local industries and businesses.

- Compatibility with Bangladesh’s Power Supply: The 415V, 50Hz power supply is the standard in many industrial facilities in Bangladesh, meaning that the hoist can be easily integrated into existing electrical systems without the need for complex adjustments or upgrades. This compatibility reduces installation costs and ensures smooth, uninterrupted operation.

- Energy Efficiency: The simple design of the single-speed electric hoist minimizes power consumption. The hoist operates consistently at its rated power, without the energy fluctuations that can occur in more complex, variable-speed systems. This results in more predictable energy costs, reducing the overall operational expenses.

- Lower Operational Costs: With its energy-efficient design and lower maintenance needs, this hoist is a cost-effective solution for projects in Bangladesh. Businesses can expect to save on electricity bills and maintenance costs, making it a smart investment in the long term.

In addition to being cost-effective, this hoist helps local businesses in Bangladesh meet their energy needs without burdening their operational budget.

Durability and Low Maintenance

The Long-Term Benefits of a Low-Maintenance Hoist in Industrial Settings

The 5-ton electric hoist is designed for durability and low-maintenance operation, making it a strong choice for businesses in Bangladesh that want to ensure long-term reliability in demanding industrial environments.

- Built to Last in Harsh Conditions: Whether it’s a construction site, port operations, or manufacturing facility, the hoist’s durable build ensures it can withstand the wear and tear of heavy daily use. It’s built with high-quality materials and anti-corrosion features, making it suitable for operations in challenging environments, such as high humidity or coastal areas.

- Low Maintenance: The single-speed design eliminates the need for complex adjustments or repairs, ensuring minimal maintenance. Regular checks and basic lubrication are sufficient to keep the hoist operating at peak performance. This means less downtime and fewer costly repairs over the hoist’s lifetime.

- Longer Lifespan: The hoist’s low-maintenance nature extends its lifespan, offering significant value for money over the years. This is especially beneficial for Bangladesh’s rapidly growing industrial sector, where uptime is critical for maintaining productivity and operational efficiency.

The durability and low-maintenance requirements of the hoist make it a reliable, long-term solution for industries in Bangladesh, ensuring consistent performance without frequent repairs.

Ease of Installation

Quick and Hassle-Free Installation Process Tailored to the Infrastructure in Bangladesh

The installation process for the 5-ton electric hoist is straightforward, designed to fit seamlessly with Bangladesh’s existing industrial infrastructure.

- Adaptable to Local Infrastructure: The hoist’s power requirements (415V, 50Hz, 3-phase) align with Bangladesh’s standard electrical systems, ensuring a smooth installation without the need for complex power system modifications. This makes it easier for businesses to integrate the hoist into their operations quickly and without significant additional costs.

- Simplified Setup: The hoist is designed to be installed with minimal hassle. With clear installation instructions and a simple setup process, the hoist can be up and running in a short time frame, reducing any project delays. This is particularly beneficial for industries with tight project schedules.

- Support and Expertise: Installation is often accompanied by local support and expertise from the hoist supplier, ensuring that businesses can get the necessary assistance during setup. Whether it's training, troubleshooting, or hands-on help with assembly, this support ensures hassle-free installation in any location in Bangladesh.

By offering a quick and efficient installation process, the 5-ton electric hoist helps businesses in Bangladesh save time and resources, getting their operations up and running without unnecessary delays.

Conclusion

The 5-ton electric hoist with 90-meter lifting capacity is perfectly suited to the demands of industrial projects in Bangladesh. With its high lifting height, energy-efficient power specifications, durable and low-maintenance design, and easy installation process, it offers a reliable and cost-effective solution for large-scale and vertical projects. Whether you’re working in construction, ports, or manufacturing, this hoist is tailored to meet the specific needs of Bangladesh's growing industries, providing exceptional value and performance over time.

Conclusion

The 5 Ton Electric Hoist with 90 Meter Lifting Height offers exceptional value for industrial projects in Bangladesh, with features tailored to meet the demands of large-scale and high-rise operations. Here’s a quick recap of its key attributes:

Hoist Features:

- CD Series Wire Rope Electric Hoist with single-speed design for simplicity, reliability, and low maintenance.

- 5-ton capacity ideal for medium-duty lifting applications in various industries, from construction to shipping.

- 90-meter lifting height, perfect for high-rise construction and vertical projects.

- Powered by 415V, 50Hz, 3-phase power supply, ensuring compatibility with local electrical systems and energy efficiency.

Technical Specifications:

- Wire rope mechanism that allows for smooth, efficient lifting over long distances.

- Safety features like overload protection and limit switches ensure safe operation, while its robust build ensures durability in harsh environments.

Advantages:

- Cost-effective with lower maintenance and energy consumption compared to variable-speed models.

- High reliability in diverse environmental conditions, particularly in construction, ports, and energy sectors.

- Quick and easy installation aligned with Bangladesh's electrical infrastructure and industrial needs.

Call to Action for Purchasing

If you’re looking for a reliable, efficient, and cost-effective solution for your industrial lifting needs, the 5 Ton Electric Hoist with 90 Meter Lifting Height is the ideal choice for your project in Bangladesh. Don’t miss the opportunity to enhance your lifting operations with a hoist designed for durability, high performance, and ease of use.

Contact us today to get a quote or to place your order. Our team is ready to assist you with any inquiries or specific project requirements.We look forward to helping you elevate your project’s success with our reliable lifting solutions.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch