Case Study: Customized Double-Speed Hoist with 65m Lifting Height

A 3-ton double-speed electric hoist with 65m lift customized for Bangladesh’s industrial needs, enhancing efficiency and safety.

Category: Wire Rope Hoist Crane

Your Trusted Overhead Wire Rope Hoist Crane Manufacturer & Supplier

Case Study: Customized Double-Speed Hoist with 65m Lifting Height

A 3-ton double-speed electric hoist with 65m lift customized for Bangladesh’s industrial needs, enhancing efficiency and safety.

Case Study of Double Speed Hoists: Customized Electric Hoist 3 Ton with 65 M Lifting Height

Overview of the Project

The installation of a 3-ton MD Series Double Speed Wire Rope Electric Hoist in Bangladesh represents a significant enhancement to the facility’s material handling operations. Designed to lift loads up to 3 tons with a height of 65 meters, this hoist provides the precision and efficiency required for demanding industrial tasks.

Key features of the hoist include:

- Load capacity: 3 tons for handling medium to heavy-duty materials.

- Lifting height: 65 meters, tailored for specific operational needs.

- Double-speed operation: Ensures both fast and precise lifting.

This project showcases how modern, customized equipment can transform workflows in industrial settings by increasing productivity and ensuring safer operations.

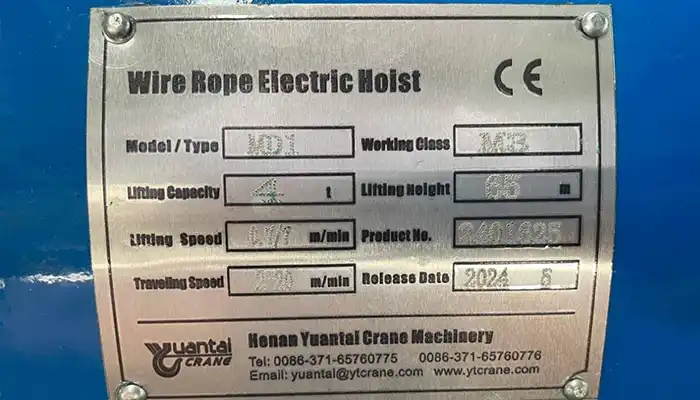

Namplate of Electric Hoist 3 Ton with 65 M Lifting Height

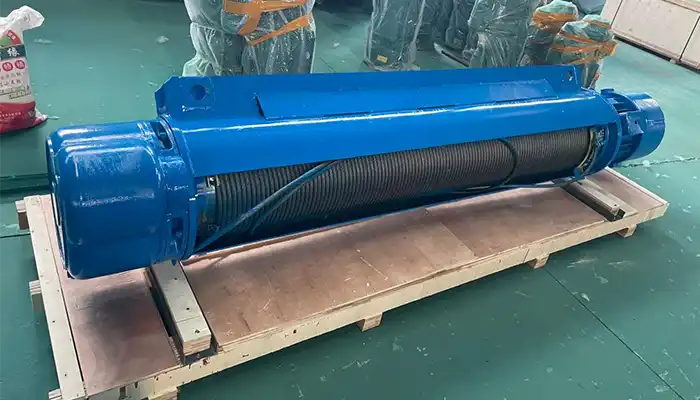

Electric Hoist 3 Ton with large lifting height of 65 M

3 Ton Wire Rope Electric Hoist with 65 M Lifting Height

Project Background

Location and Industrial Needs

Bangladesh’s industrial sector has experienced rapid growth in recent years, particularly in areas such as manufacturing, construction, and infrastructure development. With a growing demand for advanced machinery and reliable material handling systems, there is an increasing need for efficient lifting solutions that can keep pace with the evolving industry landscape.

Key Factors Driving the Demand for Efficient Lifting Equipment:

- Expanding Industrial Sector: Bangladesh is home to a fast-developing manufacturing and construction industry, with an emphasis on heavy-duty operations such as steel, textiles, and infrastructure projects.

- Lifting Needs: Many industrial operations require specialized equipment to handle heavy loads at significant heights. The demand for equipment capable of high lifts and precise handling has increased, especially in factories and construction sites with multi-level operations.

- Environmental Conditions: The region's humid climate and high temperatures call for lifting equipment that is durable, reliable, and resistant to wear, ensuring long-term performance in challenging conditions.

As industries in Bangladesh continue to expand, efficient lifting systems like electric hoists are essential to improving productivity and safety standards in various sectors.

Client Requirements

The client in this project needed a hoist that could efficiently handle heavy loads in high-lifting environments. Their requirements were clear:

Specific Needs:

- Load Capacity: A 3-ton electric hoist to safely lift and move medium to heavy loads.

- Lifting Height: A critical requirement was the 65-meter lifting height, necessary for operations in facilities with significant vertical space. The hoist had to be capable of moving loads up to such heights with precision and reliability.

- Dual-Speed Operation: To accommodate both fast lifting for large materials and slow speeds for delicate or precise operations, the client requested a double-speed hoist for versatile performance across a variety of tasks.

- Power Supply: The hoist needed to be compatible with local power specifications, requiring a 400V, 50Hz, 3-phase power supply to ensure efficient operation in the client's facility.

In essence, the client sought a high-performance, reliable hoist that could handle specific load and height requirements while providing long-lasting performance in a demanding industrial environment.

Main Specifications of the Hoist

Hoist Type: MD Series Wire Rope Electric Hoist with Double-Speed Functionality

The MD Series Wire Rope Electric Hoist is specifically designed for reliable and efficient material handling in industrial environments. This hoist is equipped with double-speed functionality, which allows it to operate at two distinct speeds:

- Fast Speed: For quick lifting and lowering of loads, optimizing overall operation speed and throughput.

- Slow Speed: For precise and controlled lifting, ensuring safety and accuracy when handling sensitive or heavy materials.

The MD Series is known for its robust build and high-quality components, making it suitable for demanding applications in industries such as manufacturing, construction, and heavy lifting. The wire rope system enhances durability and lifting capacity, ensuring a smooth operation over the long term.

Load Capacity: Rated for a Maximum Load of 3 Tons

This hoist is rated for 3 tons, making it ideal for medium-duty lifting tasks in various industrial applications. The load capacity ensures that it can handle typical material handling jobs in construction sites, factories, and other industrial settings where moderate to heavy loads are common. The hoist’s reliable load rating offers peace of mind, knowing that it is built to safely lift up to 3 tons without compromising performance or safety.

Lifting Height: Customized for a Lifting Height of 65 Meters

One of the standout features of this hoist is its customized lifting height of 65 meters, designed to meet the specific operational requirements of the client. This extended lifting height is crucial in applications where materials need to be raised or lowered over large vertical spaces, such as in multi-story warehouses, high-rise construction sites, or large-scale manufacturing facilities. The hoist is engineered for smooth and stable operation even at such significant heights, ensuring both safety and efficiency throughout the lifting process.

Electrical Specifications: Power Supply and Motor Efficiency

The MD Series hoist is designed to operate on a 400V, 50Hz, 3-phase power supply, which is the standard electrical configuration used in industrial settings across Bangladesh and similar regions. This ensures compatibility with the local power grid, allowing for seamless integration into the client's existing infrastructure.

- Power Supply: 400V, 50Hz, 3-phase, ideal for industrial environments where reliable, high-efficiency power is required.

- Motor Type and Efficiency: The hoist is equipped with a high-performance electric motor designed for durability and energy efficiency. This motor is engineered to minimize power consumption while delivering the necessary torque and lifting speed. The combination of a powerful motor and an efficient power system contributes to the hoist’s ability to handle heavy loads over long periods without overheating or excessive wear.

In summary, the MD Series Wire Rope Electric Hoist is a highly capable, customizable solution that meets the demanding lifting requirements of industrial operations, with reliable load capacity, impressive lifting height, and efficient electrical specifications tailored for optimal performance.

Features and Benefits of the Double Speed Hoist

Double-Speed Operation: Smooth Transition for Precise and Efficient Handling

The double-speed functionality of the MD Series Wire Rope Electric Hoist ensures that the lifting process is both efficient and precise. This feature allows the operator to switch between two speeds, making the hoist versatile for different types of loads and tasks:

- Fast Speed: Ideal for quickly lifting or lowering heavy loads when time is critical, improving overall operational efficiency.

- Slow Speed: Perfect for delicate or precise tasks, such as positioning or aligning materials, where accuracy is essential.

The ability to smoothly transition between these two speeds gives operators full control over the lifting process, ensuring that each lift is completed with the right balance of speed and precision. This contributes to enhanced productivity, as the hoist can be adapted to various working conditions, reducing downtime and increasing efficiency.

Wire Rope System: High-Quality Wire Rope for Durability and Reliability

The wire rope system used in this hoist is designed for durability and long-lasting performance, even under heavy use. Wire ropes are known for their high tensile strength, making them ideal for handling the significant loads that this hoist is rated for. Some key advantages of the wire rope system include:

- Durability: Wire rope is resistant to wear and tear, ensuring a long service life even in demanding industrial environments.

- Reliability: The robust design of the wire rope ensures smooth operation, reducing the risk of failure or maintenance issues during critical operations.

- High Load Capacity: The wire rope is capable of safely handling heavy loads, making it perfect for tasks that involve lifting up to 3 tons.

The choice of wire rope as the primary lifting mechanism ensures that the hoist is both tough and reliable, capable of withstanding the stresses associated with frequent, high-capacity lifting.

Compact Design: Optimized for Installation in Facilities with Space Constraints

The compact design of the MD Series hoist is specifically engineered to fit into environments where space is limited. This makes it an ideal solution for facilities with narrow aisles or smaller work areas, such as warehouses, manufacturing plants, and construction sites. The space-saving design offers several benefits:

- Ease of Installation: The hoist can be quickly and easily installed in facilities where other, bulkier equipment might not fit.

- Space Efficiency: By utilizing a more compact design, the hoist allows for more efficient use of the available workspace, without compromising its lifting capabilities.

- Flexibility: Its smaller footprint allows for greater flexibility in facility layout and storage.

This feature is particularly useful in facilities with height constraints or areas where maximizing floor space is critical for operations.

Enhanced Safety Mechanisms: Overload Protection, Emergency Stop, and Advanced Braking Systems

Safety is a top priority in industrial applications, and the MD Series hoist incorporates several key features to ensure the safe operation of the equipment:

- Overload Protection: Prevents the hoist from operating beyond its maximum load capacity (3 tons), protecting both the hoist and the operator from damage or injury.

- Emergency Stop: In case of unforeseen issues, the emergency stop function allows the operator to immediately halt the hoist, preventing accidents and minimizing potential damage.

- Advanced Braking Systems: The hoist is equipped with highly responsive brakes that ensure smooth and controlled stopping, even when handling heavy loads or when operating at high speeds. This reduces the risk of load slippage and enhances overall safety during lifts.

These safety features work together to create a secure and controlled environment for operators, ensuring that the hoist functions safely and reliably in demanding conditions.

The double-speed hoist offers a range of features that enhance its performance, safety, and suitability for various industrial applications. From the versatility of dual-speed operation to the reliability of the wire rope system and the compact design for space efficiency, the MD Series hoist is an excellent choice for operations requiring both high performance and safety. The built-in safety mechanisms provide additional peace of mind, making it a trustworthy solution for even the most demanding lifting tasks.

Customization Highlights

Adaptation for the Lifting Height: Design Modifications to Achieve 65 Meters of Lifting Height

One of the key customizations for this project was adapting the hoist to handle a 65-meter lifting height, a critical requirement for the client’s industrial operation. Achieving such a high lifting height while ensuring both stability and performance involved several design modifications:

- Extended Lift Mechanism: The hoist was equipped with an extended drum and longer wire rope to accommodate the 65-meter lift. This modification ensures that the hoist can raise loads to the required height without compromising on safety or reliability.

- Reinforced Structure: To support the increased lifting height, the hoist's structural components, including the frame and support systems, were reinforced. This helps to maintain the hoist’s stability, even when lifting at extreme heights.

- Precision Control: Special attention was given to ensure that the hoist maintained its precision and smooth operation at this height. The double-speed functionality became even more critical for precise load handling at higher altitudes, allowing for both fast and controlled movements.

These design adaptations ensure that the hoist operates efficiently and safely at the desired height, making it perfect for large-scale industrial environments with significant vertical space.

Durability in Challenging Environments: Features Tailored for the Local Conditions in Bangladesh

Bangladesh’s industrial environments can be particularly challenging due to factors such as high temperatures, humidity, and the potential for corrosive exposure. To address these conditions, the hoist was customized with several features to ensure its durability and reliable performance:

- Corrosion-Resistant Components: The hoist's key parts, including the wire rope, hooks, and frame, were treated with anti-corrosion coatings to prevent degradation due to the humid and coastal climate in Bangladesh. This helps to extend the service life of the hoist, reducing the need for frequent maintenance.

- Heat-Resistant Materials: The motor and electrical components were designed with heat-resistant materials to ensure the hoist could function effectively in high-temperature conditions. This is particularly important in industrial settings where machinery can become overheated due to continuous use.

- Sealed Electrical Systems: The hoist’s electrical components were sealed to protect them from dust, moisture, and other environmental factors that could cause wear or malfunctions. This contributes to the hoist's ability to perform consistently even in the most demanding conditions.

- Heavy-Duty Lubrication: To combat the effects of high humidity, a specialized heavy-duty lubrication system was implemented. This ensures that moving parts, such as the hoist’s motor and gears, remain well-lubricated and free from corrosion or wear, even when exposed to moisture-rich environments.

These custom features ensure that the hoist is built to withstand the harsh conditions in Bangladesh, enhancing its longevity and reducing the need for costly repairs or downtime. The combination of anti-corrosion treatments and heat-resistant materials makes this hoist highly suitable for the local climate, ensuring that it performs reliably and efficiently over time.

The customization of this hoist for the specific demands of the 65-meter lift, as well as its adaptation to the environmental conditions of Bangladesh, ensures that it delivers both high performance and durability. By incorporating design modifications for stability at extreme heights and tailoring the hoist for the local climate, this customized electric hoist offers a robust and reliable solution for the client’s industrial needs.

Challenges and Solutions

Technical Challenges: Adapting the Hoist Design for Extended Lifting Height and Ensuring Compliance with Power Supply Standards

The project involved several technical challenges that had to be overcome to meet the client’s specific requirements, including:

- Extended Lifting Height: Achieving a 65-meter lifting height presented challenges related to both the hoist's physical design and operational stability. The added height required significant adjustments to the hoist’s drum and cable system to ensure smooth, safe operation without compromising the overall performance.

- Power Supply Compliance: Another challenge was ensuring the hoist's electrical system was fully compatible with the 400V, 50Hz, 3-phase power supply available at the client’s facility in Bangladesh. This meant ensuring that the motor and electrical components were designed to operate efficiently and safely within the local power specifications, while also handling the increased load and stress caused by the high lifting height.

- Space and Design Constraints: Given the limited space in the client’s facility, the hoist needed to be compact while still achieving the necessary lifting height. Integrating such a large lifting system into a smaller workspace required careful planning and precise measurements.

Problem-Solving Approaches: Innovations and Solutions Implemented to Overcome These Challenges

To overcome the challenges associated with the project, several innovative solutions and design adaptations were implemented:

- Reinforced Structure and Extended Lifting Mechanism: To address the challenge of the extended lifting height, the hoist was equipped with an extended drum system and reinforced structural components. This ensured that the hoist could maintain stability during operation, even at the required height. The use of high-strength wire rope further minimized the risks of wear and tear, providing durability and safety in extreme lifting scenarios.

- Electrical System Customization: The electrical components of the hoist were specifically designed to meet the 400V, 50Hz, 3-phase power requirements of the local infrastructure. This involved adjusting the motor specifications to ensure efficiency while maintaining the power output necessary for lifting at great heights. Specialized transformers and controllers were used to guarantee smooth power delivery, preventing potential electrical issues during operation.

- Space-Efficient Design: The hoist’s compact design was achieved by customizing its frame, motor housing, and drum system to fit within the facility’s spatial constraints. This allowed for easy integration without sacrificing lifting capacity or performance. The installation also included a detailed space analysis to ensure that the hoist would operate efficiently within the available area.

These problem-solving approaches helped create a hoist solution that was perfectly aligned with the project’s needs while overcoming the technical hurdles associated with high-lifting height, power supply compatibility, and space limitations.

Outcomes and Client Satisfaction

Performance Results: How the Customized Double-Speed Hoist Met or Exceeded Expectations

The performance of the 3-ton MD Series Double Speed Wire Rope Electric Hoist far exceeded the client’s expectations. Key results include:

- Seamless High-Lift Operation: The hoist successfully achieved the required 65-meter lifting height with smooth operation and precise control. Both fast and slow-speed modes were used effectively in varying work conditions, ensuring that the lifting process was efficient without compromising on accuracy.

- Load Handling and Durability: The hoist's ability to lift 3 tons reliably, even at such a height, demonstrated the robustness of the design. The wire rope system performed flawlessly under load, providing the necessary strength and reliability for heavy-duty applications.

- Energy Efficiency: The customized electrical system operated seamlessly with the local power supply, ensuring energy efficiency and minimizing operational costs.

Overall, the hoist performed optimally across all specified metrics, proving its suitability for the demanding environment of the client’s facility.

Impact on Operations: Enhanced Efficiency and Safety in the Client’s Industrial Processes

The installation of the customized hoist had a significant impact on the client’s operations:

- Increased Productivity: The dual-speed functionality allowed operators to lift materials quickly while maintaining control for more delicate tasks, enhancing overall efficiency. This resulted in faster turnaround times for lifting tasks and minimized downtime during production.

- Improved Safety: The overload protection and emergency stop features enhanced safety, reducing the risk of accidents and equipment damage. The advanced braking system ensured smooth and controlled movements, further contributing to a safer work environment.

- Cost-Effective Operation: The hoist’s durability and energy-efficient design also contributed to long-term cost savings, as the client saw reduced maintenance needs and lower energy consumption.

Feedback: Client’s Testimonial on the Delivered Solution

The client expressed complete satisfaction with the performance of the hoist, highlighting its high performance and the tailored solution that met their specific needs:

"We are extremely pleased with the installation of the 3-ton MD Series Double-Speed Wire Rope Electric Hoist. The customized lifting height of 65 meters has been invaluable to our operations, and the hoist’s dual-speed functionality allows us to manage loads with greater efficiency and precision. The team did an excellent job ensuring that the hoist met all our requirements and the local environmental conditions, and it has made a significant difference in our daily operations. The safety features give us peace of mind, and we look forward to using this hoist for many years to come."

This feedback underscores the success of the project and the effectiveness of the customized hoist in meeting both operational and safety goals.

Conclusion

The installation of the 3-ton MD Series Double-Speed Wire Rope Electric Hoist with a 65-meter lifting height in Bangladesh was a resounding success. Key takeaways from the project include:

- Customized Design: The hoist was tailored to meet the specific requirements of the client, including the extended lifting height and the need for reliable, high-performance equipment in demanding industrial environments.

- Enhanced Performance: The hoist's dual-speed functionality allowed for efficient and precise lifting, while the reinforced design ensured smooth operation even at maximum height and load capacity.

- Adaptability to Local Conditions: Custom features, such as corrosion-resistant components and heat-resistant materials, were incorporated to ensure the hoist could withstand Bangladesh’s challenging environmental conditions, including high humidity and heat.

- Operational Efficiency and Safety: The hoist significantly improved the client’s operational efficiency, reducing downtime and increasing lifting speed, while its safety mechanisms ensured a secure working environment for operators.

- Client Satisfaction: The client’s testimonial highlighted the successful integration of the hoist into their facility, emphasizing the overall performance and reliability of the equipment.

In conclusion, this project demonstrated the critical importance of customized solutions in meeting specific industrial needs, delivering outstanding results in terms of both performance and client satisfaction.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch