Stage Chain Hoist, Tailored Stage Hoist Specifications

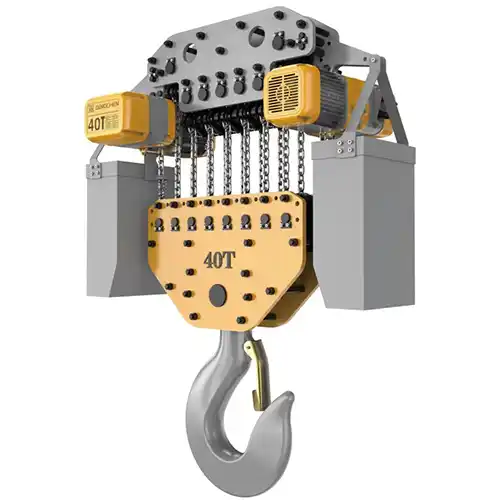

Stage chain hoists for theater lighting equipment & other equipment hoisting. Customized stage chain hoist specifications 500kg, 1000kg, 2000kg for sale.

Category: Hoist and Crane Specifications

Your Trusted Stage Hoist Manufacturer & Supplier

Stage Chain Hoist, Tailored Stage Hoist Specifications

500kg, 1000kg, 2000kg for sale

Stage chain hoists for theater lighting equipment & other equipment hoisting. Customized stage chain hoist specifications 500kg, 1000kg, 2000kg for sale.

What is a stage hoist ?

A stage hoist is a light-duty electric chain hoist used for installing lights and other stage equipment on top of stages and other event venues. It enables you to prepare and set up your equipment on the ground before lifting it up when you're ready. By not climbing too far off the ground to install stage applications, it saves time and helps workers avoid dangers. The stage hoist is simple to use and install. Additionally, you can alter the cable's length to meet your requirements. Based on your lifting requirements and applications the stage lighting chain hoist is available with capacity from 250 kg to 500 kg, 1000kg, 2000kg, depending on your demands and requirements.

Application of electric Stage Hoist

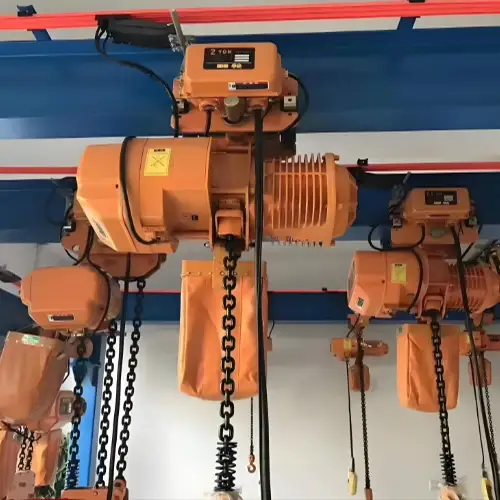

The entertainment industry frequently uses stage hoists and lighting hoists to lift lighting and audio equipment and attach it to the top of the stage or truss systems in the event space.

For large-scale performance occasions, speaker sets, ceiling lighting stands, and large-scale scenic setups, an electric stage hoist was specifically created. It is also referred to as the theater hoist, lighting hoist, or chandelier hoist because it is frequently used to lift these objects or item.

It is also appropriate for lifting in other temporary mobile situations, like the installation of neon sign advertising and small building sites. You will notice them in the sporting events, fashion shows or concerts where it's used to secure the lighting on top of the stage or the stadium.

Main types of electric stage hoists

Electric Stage Hoist SU D8+ 220V-440V 3 Phase Double Brake

Electric Stage Hoist SU2 D8+ 220V 1 Phase Double Brake

Electric Stage Hoist SU BGVC1 220V-440V 3Phase Double Brake

Electric Stage Hoist SU D8 220V-440V 3 Phase

Electric Stage Hoist HGA8 D8 220V-440V 3 Phase

Electric Stage Hoist HGA9 D8 220V- 440V 3 Phase

Electric Stage Hoist SU D8+ 220V-440V 3 Phase Double Brake 250kg, 500kg, 1000kg,

The electric stage hoist SU D8+ meets all Standard D8+ requirements. The stage hoist SU D8+ is designed and produced in accordance with the VPLT Code of Practice

Advantages

- chain guide made of high-strength nylon fiber.

- Free-from-maintenance overload clutch.

- Sprocket lifting wheels increase lifting efficiency and save chain wear.

- fuselage shell made of a high-strength aluminum alloy.

- Double AC Electro mechanical brake has undergone testing.

- Class 6 Gearboxes operate quietly and safely.

- IP66 is rain-proof and still functional.

- Standard G100 chain per EN 818-7.

- F class High-performance motor that is tough and robust and has CE and TUV overheat protection.

General Specifications of Electric Stage Hoist

SWL acc DGUV V54 (D8+) | 500kg/ |

1000Kg/2000kg | |

Direct Control : | 220-440V, 3ph, 50/60Hz |

Cable | 1m Cable with CEE-16/4 |

Chain | EN818-7 |

Dynamic safety factor for chain | min 101 |

Grade of steel | 100 |

Chain surface | galvanized |

Chain Guide | Precise chain guide with |

5-pocket chain wheel | |

Clutch | Patented friction clutch |

for overload protection | |

Full load noise level(db) | ≤60 |

Brake· | 2 DC brake |

Load hook | 1-fall / turnable |

Suspension | suspension loop |

Mounting position: | climbing & stationary |

Plastic handles | without |

Protection level | IP 66 |

Mechanism class /FEMS 9.511 | 1Arn/ 25% ED |

Color | black, RAL 9005 matt |

DC Brake Size | 10 |

DC Brake Operating Voltage | 180VDC |

DC Brake Rated Torque | 16Nm |

DC Brake gaps | 0.2mm |

Model | Capacity | Chain Fall | Speed (m/min) | Power (kw) | Chain (mm) | |

SU-0.25 | 250KG | 1 | 4 | 1.5 | 5*15 | |

SU-0.5 | 500KG | 1 | 4 | 8 | 1.5 | 7.1*21 |

SU-1.0-1 | 1000KG | 1 | 4 | 2.2 | 9*27 | |

SU-1.0-2 | 1000KG | 2 | 2 | 4 | 1.5 | 7.1*21 |

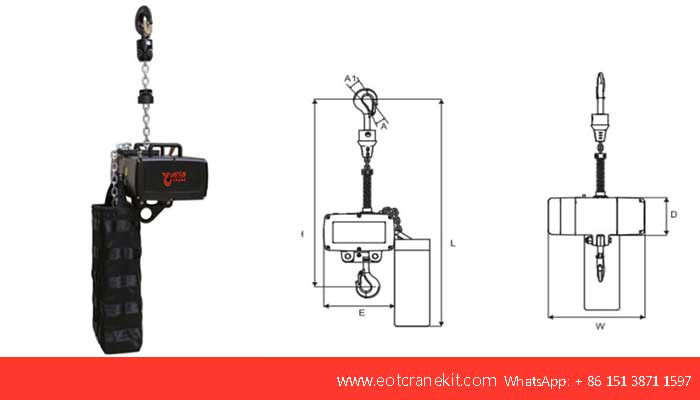

Model | Hoist Dimension/mm | |||||

L | W | H | D | A | A1 | |

SU-0.25 | 820 | 365 | 480 | 200 | 23 | 32 |

SU-0.5 | 820 | 365 | 480 | 200 | 26 | 38 |

SU-1.0-1 | 960 | 500 | 630 | 200 | 32 | 47 |

SU-1.0-2 | 820 | 365 | 680 | 200 | 32 | 47 |

Model | No Chain Self | Chain | Flight Case | |

Weight(kg) | Weight(kg) | Weight(KG) | Size(mm) | |

SU-0.25 | 38 | 0.7 | 22 | 500*550*500 |

SU-0.5 | 40 | 1.1 | 22 | 500*550*500 |

SU-1.0-1 | 52 | 1.7 | 22 | 520*570*500 |

SU-1.0-2 | 45 | 2.2 | 22 | 500*550*500 |

Electric Stage Hoist SU2 D8+ 220V 1 Phase Double Brake 250kg, 500kg, 1000kg

The SU D8+ stage hoist fulfills all Standard D8+ requirements. The clutch acts as a precise overload device outside the load path, and the design factor is 10:1 with a double brake installed. The SU D8+ stage hoist complies with the VPLT Code of Practice.

The theater hoist operates in a single phase.

General Specifications of Electric Stage Hoist

SWL acc DGUV V54 (D8+) : | 500kg/ |

1000Kg/2000kg | |

Direct Control : | 220-440V, 1ph, 50/60Hz |

Cable | 1m Cable with CEE-16/4 |

Chain | EN818-7 |

Dynamic safety factor for chain | min. 10:1 |

Grade of steel | 100 |

Chain surface | galvanized |

Chain Guide | Precise chain guide with 5-pocket chain wheel |

Clutch | Patented friction clutch for overload protection |

Full load noise level(db) | ≤60 |

Brake· | 2 DC brake |

Load hook | 1-fall / turnable |

Suspension | suspension loop |

Mounting position: | climbing & stationary |

Plastic handles | without |

Protection level | IP 66 |

Mechanism class /FEMS 9.511 | 1Am/ 25% ED |

Color | black, RAL 9005 matt |

DC Brake Size | 10 |

DC Brake Operating Voltage | 180VDC |

DC Brake Rated Torque | 16Nm |

DC Brake gaps | 0.2mm |

Model | Capacity | Chain Fall | Speed(m/min) | Power(kw) | Chain(mm) | |

SU-0.25 | 250KG | 1 | 4 | 1.5 | 5*15 | |

SU-0.5 | 500KG | 1 | 4 | 8 | 1.5 | 7.1*21 |

SU-1.0-1 | 1000KG | 1 | 4 | 2.2 | 9*27 | |

SU-1.0-2 | 1000KG | 2 | 2 | 4 | 1.5 | 7.1*21 |

Model | Hoist Dimension/mm | |||||

L | W | H | D | A | A1 | |

SU-0.25 | 900 | 500 | 640 | 200 | 23 | 38 |

SU-0.5 | 900 | 500 | 640 | 200 | 26 | 38 |

SU-1.0-1 | 990 | 500 | 630 | 200 | 32 | 48 |

SU-1.0-2 | 900 | 500 | 700 | 200 | 32 | 48 |

Model | No Chain Self | Chain | Flight Case | |

Weight(kg) | Weight(kg) | Weight(KG) | Size(mm) | |

SU-0.25 | 56 | 1.1 | 22 | 600*450*500 |

SU-0.5 | 56 | 1.1 | 22 | 600*450*500 |

SU-1.0-1 | 65 | 1.9 | 22 | 680*450*650 |

SU-1.0-2 | 61 | 2.2 | 22 | 680*450*650 |

Electric Stage Hoist SU BGVC1 220V-440V 3Phase Double Brake 500kg, 1000kg, 2000kg,

All prerequisites for the Stage Hoist SU D8+ have been met. Outside of the load path, the clutch serves as a precise overload mechanism. With a double brake installed, the design factor is 10:1. The SU D8+ stage hoist complies with the VPLT Code of Practice.

The theater hoist is single phase.

General Specifications of Electric Stage Hoist

SWL acC DGUV V54 (D8+) | 500kg/ |

1000Kg/2000kg | |

Direct Control : | 220-440V, 3ph, 50/60Hz |

Cable | 1m Cable with CEE-16/4 |

Chain | EN818-7 |

Dynamic safety factor for chain | min 101 |

Grade of steel | 100 |

Chain surface | galvanized |

Chain Guide | Precise chain guide with |

5-pocket chain wheel | |

Clutch | Patented friction clutch |

for overload protection | |

Full load noise level(db) | ≤60 |

Brake· | 2 DC brake |

Load hook | 1-fall / turnable |

Suspension | suspension loop |

Mounting position: | climbing & stationary |

Plastic handles | without |

Protection level | IP 66 |

Mechanism class /FEMS 9.511 | 1Am/ 25% ED |

Color | black, RAL 9005 matt |

DC Brake Size | 10 |

DC Brake Operating Voltage | 180VDC |

DC Brake Rated Torque | 16Nm |

DC Brake gaps | 0.2mm |

Model | Capacity | Chain Fall | Speed(m/min) | Power(kw) | Chain(mm) | |

SU-G0.5 | 500KG | 1 | 4 | 1.5 | 5*15 | |

SU-GP0.5 | 500KG | 1 | 16 | 1.9 | 7.1*21 | |

SU-G1.0 | 1000KG | 1 | 4 | 8 | 1.9 | 7.1*21 |

SU-G2.0-1 | 2000KG | 1 | 4 | 2.2 | 9*27 | |

SU-G2.0-2 | 2000k g | 2 | 2 | 4 | 1.9 | 7.1*21 |

Model | Hoist Dimension/mm | ||||||

L | W | H | D | E | A | A1 | |

SU-G0.5 | 900 | 500 | 640 | 200 | 330 | 26 | 38 |

SU-GP0.5 | 900 | 500 | 640 | 200 | 330 | 26 | 38 |

SU-G1.0 | 900 | 500 | 640 | 200 | 330 | 26 | 38 |

SU-G2.0-1 | 990 | 500 | 630 | 200 | 330 | - | 48 |

SU-G2.0-2 | 900 | 500 | 700 | 200 | 330 | - | 48 |

Model | No Chain Self | Chain | Flight Case | |

Weight(kg) | Weight(kg) | Weight(KG) | Size(mm) | |

SU-G0.5 | 56 | 1.1 | 22 | 600*450*500 |

SU-GP0.5 | 56 | 1.1 | 22 | 600*450*500 |

SU-G1.0 | 56 | 1.1 | 22 | 600*450*500 |

SU-G2.0-1 | 65 | 1.9 | 22 | 680*450*650 |

SU-G2.0-2 | 61 | 2.2 | 22 | 680*450*650 |

Electric Stage Hoist SU D8 220V-440V 3 Phase 500kg, 1000kg, 2000kg

The stage hoist SU D8 is built for the particular rigging requirements found in small venues and is compact, quiet, and portable. With an overload device that guards against dangerous overloads for the hoist, operator, and structure.

Option: Double brake,customized logo.

General Specifications of Electric Stage Hoist

SWL acc DGUV V54 (D8+): | 500kg/ |

1000Kg/2000kg | |

Direct Control : | 220-440V, 3ph, 50/60Hz |

Cable | 1m Cable with CEE-16/4 |

Chain | EN818-7 |

Dy_namic safety_ factor for chain | min. 10:1 |

Grade of steel | 100 |

Chain surface | galvanized |

Chain Guide | Precise chain guide with 5-pocket chain wheel |

Clutch | Patented friction clutch for overload protection |

Full load noise level(db) | ≤60 |

Brake· | 1 DC brake |

Load hook | 1-fall / turnable |

Suspension | suspension loop |

Mounting position: | climbing & stationary |

Plastic handles | without |

Protection level | IP 66 |

Mechanism class /FEM9.511 | 1Am/25% ED |

Color | black, RAL 9005 matt |

DC Brake Size | 10 |

DC Brake Operating Voltage | 180VDC |

DC Brake Rated Torque | 16Nm |

DC Brake gaps | 0.2mm |

Model | Capacity | Chain Fall | Speed (m/min) | Power(kw) | Chain (min) |

SU-05 | 500 | 1 | 4 | 1.5 | 5*15 |

SU-1.0 | 1000 | 1 | 4 8 | 1.5 | 7.1*21 |

SU-2.0-1 | 2000 | 1 | 4 | 2.2 | 9*27 |

SU-2.0-2 | 2000 | 2 | 2 4 | 1.5 | 7.1*21 |

Model | Hoist Dimension/mm | |||||

L | W | H | D | A | A1 | |

SU-05 | 820 | 365 | 480 | 200 | 23 | 32 |

SU-1.0 | 820 | 365 | 480 | 200 | 26 | 38 |

SU-2.0-1 | 960 | 500 | 630 | 200 | 32 | 47 |

SU-2.0-2 | 820 | 365 | 680 | 200 | 32 | 47 |

Model | No Chain Self | Chain | Flight Case | |

Weight(kg) | Weight(kg) | Weight(KG) | Size(mm) | |

SU-05 | 38 | 0.7 | 19.5 | 500*550*500 |

SU-1.0 | 40 | 1.1 | 19.5 | 500*550*500 |

SU-2.0-1 | 52 | 1.7 | 19.5 | 520*570*500 |

SU-2.0-2 | 45 | 2.2 | 19.5 | 500*550*500 |

Electric Stage Hoist HGA8 D8 220V-440V 3 Phase 500kg, 1000kg, 2000kg

For more than a decade, the stage hoist has been at the forefront of the entertainment industry, providing best-in-class performance, safety, and reliability. The stage hoist and lighting hoist is widely used by rigging professionals worldwide and is ideal for touring concerts and productions both indoors and outdoors.

General Specifications of Electric Stage Hoist

SWL acc DGUV V54 (D8): | 500kg/ |

1000Kg/2000kg | |

Direct Control : | 220-440V, 3ph, 50/60Hz |

Cable | 1m Cable with CEE-16/4 |

Chain | EN818-7 |

Dynamic safety factor for chain | min. 8:1 |

Grade of steel | 80 |

Chain surface | galvanized |

Chain Guide | Precise chain guide with 5-pocket chain wheel |

Clutch | Patented friction clutch for overload protection |

Full load noise level(db) | ≤65 |

Brake· | 1 mechanical brake |

Load hook | 1-fall / turnable |

Suspension | suspension loop |

Mounting position: | climbing & stationary |

Plastic handles | without |

Protection level | IP 55 |

Mechanism class /FEM9.511 | 1Bm/25% ED |

Color | black, RAL 9005 matt |

Capacity | Chain Fall | Speed (m/min) | Power(kw) | Chain (min) |

500 | 1 | 4 | 0.75 | 6.3*18 |

1000 | 1 | 4 | 1.5 | 7.1*21 |

2000 | 1 | 4 | 3 | 10*30 |

2000 | 2 | 2 | 1.5 | 7.1*21 |

Capacity | Hoist Dimension/mm | |||||

L | W | H | D | A | A1 | |

500 | 480 | 470 | 530 | 200 | 23 | 32 |

1000 | 960 | 470 | 650 | 240 | 26 | 38 |

2000 | 1200 | 630 | 800 | 280 | 33 | 47 |

2000 | 960 | 470 | 750 | 240 | 32 | 47 |

Capacity | No Chain Self | Chain | Flight Case | |

Weight(kg) | Weight(kg) | Weight(KG) | Size(mm) | |

500 | 27 | 0.86 | 19.5 | 580*390*490 |

1000 | 37.5 | 1.1 | 20 | 600*450*500 |

2000 | 76 | 2.0 | 21 | 680*450*650 |

2000 | 37.5 | 2.2 | 19.5 | 680*450*650 |

Electric Stage Hoist HGA9 D8 220V- 440V 3 Phase 500kg, 1000kg, 2000kg

The stage hoist offers best-in-class performance, safety, and dependability. The stage hoist Hoist is universally trusted by rigging professionals all over the world and is ideal for touring concerts and productions both indoors and outdoor use.Single phase is available.

General Specifications of Electric Stage Hoist

SWL acc DGUV V54 (D8): | 500kg/ |

1000Kg/2000kg | |

Direct Control : | 220-440V, 3ph, 50/60Hz |

Cable | 1m Cable with CEE-16/4 |

Chain | EN818-7 |

Dynamic safety factor for chain | min. 8:1 |

Grade of steel | 80 |

Chain surface | galvanized |

Chain Guide | Precise chain guide with 5-pocket chain wheel |

Clutch | Patented friction clutch for overload protection |

Full load noise level(db) | ≤65 |

Brake· | 1 mechanical brake |

Load hook | 1-fall / turnable |

Suspension | suspension loop |

Mounting position: | climbing & stationary |

Plastic handles | without |

Protection level | IP 55 |

Mechanism class /FEM9.511 | 1Bm/25% ED |

Color | black, RAL 9005 matt |

Capacity (kg) | Chain Fall | Speed (m/min) | Power(kw) | Chain (min) |

500 | 1 | 6.8 | 0.75 | 6.3*18 |

1000 | 1 | 7/5 | 1.5 | 7.1*21 |

2000 | 1 | 6 | 3 | 10*30 |

Capacity (kg) | Hoist Dimension/mm | |||||

L | W | H | D | A | A1 | |

500 | 560 | 490 | 400 | 160 | 24 | 33 |

1000 | 800 | 560 | 520 | 240 | 26 | 43 |

2000 | 920 | 630 | 720 | 300 | 32 | 47 |

Capacity (kg) | No Chain Self | Chain | Flight Case | |

Weight(kg) | Weight(kg) | Weight(KG) | Size(mm) | |

500 | 30 | 0.79 | 19.5 | 540*325*450 |

1000 | 41 | 1.1 | 20 | 595*430*460 |

2000 | 80 | 2.1 | 21 | 690*400*590 |

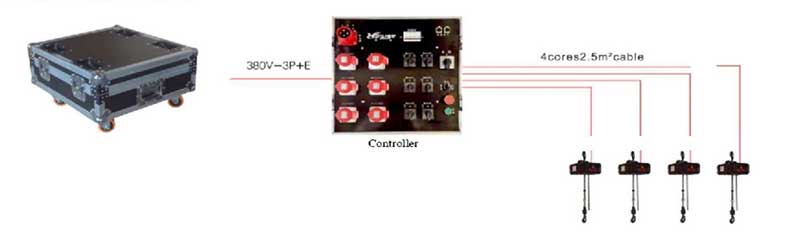

Types of stege hoist controlling system for your selection

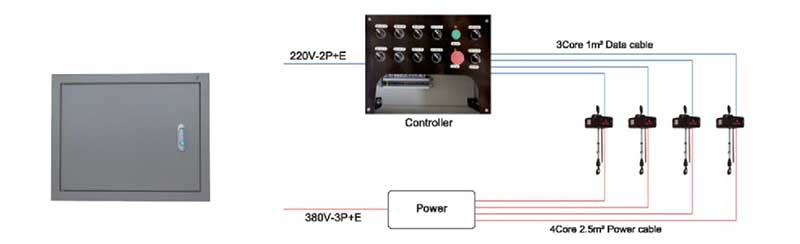

The direct hoist controllers are built to withstand the rigors of touring, with stand-alone or multiple-unit control systems for maximum flexibility. Tailor-made options are available upon request.

Each controller briefcase comes with a water-resistant hard case. Lightweight and compact, they take up less storage space. For maximum flexibility, a switching power supply with multiple inputs ranging from 220V to 440V is used. The controller includes an individual up/down rotary switch for each motor for easy operation, as well as overall system protection and a control circuit breaker to ensure operational stability.

We can provide various upgraded versions of HGK with various new features in addition to the standard model of controller. There is also a Programmable Synchronous Controller available. Please contact us for more information.

Model | Voltage | Power(kw) | Currency (A) | Size |

HGK04 | 220-440v | 6 | 12 | 460*380*180mm |

HGK06 | 9 | 18 | 580*560*350mm | |

HGK08 | 12 | 24 | 580*560*350mm | |

HGK012 | 18 | 40 | 720*640*440mm |

HGK-G system controller

Specification of stage hoist control system

The HGK-G controller is a group controller that has been specifically designed for specific areas of mobile performance.

- A maximum of 46 electric synchronous controllers can be used.

- All synchronous controller electrical appliances have been aging tested, and the main components are imported brands.

- The controller is a heavy knob reversing switch that supplies power to each electric hoist separately to increase controllability. A fast serial interface allows multiple controllers to be linked together.

- The aviation box shell design meets the market demand for mobile performance, and it is easy to cany and transport.

- A wireless remote control is optional.

- To ensure construction safety, the power supply is 380V and is connected with a ground wire.

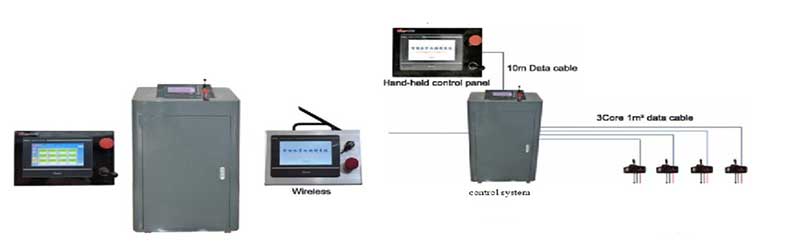

KGK-C-G Series

Product features:

- The touch screen controller is a high-end digital control system, and all control options for digital display are centralized on the LCD touch screen.

- The controller can control the lifting of one or more electric hoists independently, and it can mark the grouping name for each point to save the time-consuming task of finding the layout drawing.

- The ergonomically designed LCD console has a beautiful appearance and is easy to use.

- Because the console and integrated circuit cabinet are designed separately, only one signal line is required to connect in the middle, increasing operational convenience and flexibility (the longest theoretical distance of signal line is 200m).

- The hand-held console has a rocker-style operating lever. Only when it is pushed up or pulled down can the electric hoist be turned on. When the rocker is not moved, it resets in the middle and stops sending action signals to the operating system, making the operation more controllable and safe.

- The console has an emergency stop button that, in an emergency, can turn off the control system and power supply to prevent accidents.

- The wireless dual screen touch screen control cabinet is customizable, and the wireless operation distance is up to 200m.

- Cabinet power supply: the operating system is 220v-l + N + PE (weak current). A single three-wire system is used.

HGK-D series

- The Hgk-D series controller is a synchronous controller that is specifically designed for fixed installation in specific locations. The synchronous controller system's control voltage is 36V.

- Wall-mounted cabinet with a small volume and an unlimited number of custom electric hoist points

- All synchronous controller electrical appliances have been aging tested, and the main components are imported brands.

- Set jog and continue knobs for added convenience.Optional wireless remote control.

- The power supply is 220V and is grounded to ensure the safety of the construction.

HGK-PLC programming control system

Product features of PLC programming control system:

- The electric hoist control power line and signal line are centralized - controlled by a single cabinet, making maintenance and commissioning easier. It is appropriate for the construction of a bar, banquet hall, and theater studio.

- A high-performance vector frequency converter that is built into the device that can smoothly and steadily adjust speed to achieve the stability of rise and fall.

- For each electric hoist, the touch screen console can perform grouping control, fixed-point positioning, and real-time lifting height display.

- Accurate positioning and Repeated actions to an accuracy of 5mm.

- PLC programming cabinet can realize the electric hoist's load-bearing detection function and monitor the load of each lifting point in real time. If it exceeds 120% of the total load-bearing capacity of operation, it will automatically cut power, stop the entire lifting point, and send an alarm to remind the operator to change the operation mode.

- A touch screen operation console with an emergency stop button and an operation rocker is linked to the PLC cabinet.

- To achieve the effect actions required by each dance beauty, the programmable control system can store multiple individual scenes and complete continuous actions of multiple shapes.

- The split design of the console and main cabinet allows the operator to see the action scene of the electric hoist more intuitively and monitor it in real time to ensure safety.

HGK-C-D Series

Product features:

- The touch screen controller is a high-end digital control system, with all control options centralized on the digital display LCD touch screen.

- The controller can control the lifting of one or more electric hoists independently, and it can mark the grouping name for each point to save the time-consuming task of finding the layout drawing.

- The ergonomically designed LCD console has a beautiful appearance and is easy to use.

- Because the console and integrated circuit cabinet are designed separately, only one signal line is required to connect in the middle, increasing operational convenience and flexibility (the longest theoretical distance of signal line is 200m).

- The hand-held console has a rocker-style operating lever. Only when it is pushed up or pulled down can the electric hoist be turned on. When the rocker is not moved, it resets in the middle and stops sending action signals to the operating system, making the operation more controllable and safe.

- The console has an emergency stop button that, in an emergency, can turn off the control system and power supply to prevent accidents.

- The wireless dual screen touch screen control cabinet is customizable, and the wireless operation distance is up to 200m.

- Cabinet power supply: the operating system is 220v-l + N + PE (weak current). A single three-wire system is used.

HGK-LMS Load Monitoring system

Features of load monitoring and control system:

- Dual screen control, screen 1 displays load monitoring, which can display the weight of each lifting point and serve as a safety monitor. Customers can better understand the dynamics of lifting points thanks to the embedded operation panel.

- Screen 2 is the electric hoist control display. All control options are centralized and digitally displayed on the LCD touch screen. The controller can control the lifting of one or more electric hoists independently, and it can group the use name and remarks of each point to save the time-consuming operation of finding the layout drawing.

- Ergonomic LCD console with a beautiful appearance and simple operation.

- Cabinet power supply is a 220V three-wire system.

Main type of manual stage hoists

HM-A Manual Chain Hoist

HM-B Manual Chain Hoist

HM-D Manual Chain Hoist

HM-A Manual Chain Hoist of 1000kg & 2000kg Specification

- All components are made of high-quality materials, and additional galvanization and spraying processes are used to improve corrosion resistance.

- Even in harsh environments, the strong shell can effectively protect the internal mechanism from damage.

- Both the chain guide and the gear transmission mechanism have protection devices, allowing the theather hoist to be used successfully in a variety of environments. The lifting sprocket is made of hardened materials and finely finished to ensure smooth and accurate operation.

- Low headroom increases the effective lifting distance dramatically.

- The galvanized alloy lifting chain matches the hoist perfectly and runs smoothly and accurately.

- Both hooks are made of high-quality alloy steel, ensuring user safety.

- The hoist can rotate 360 degrees, making it easier to use.

Capacity | Chain /G80 | Lifting Height(M) | Test Load (KG) | N.W (KG) |

1000kg | 6*18MM | 3 | 1500kg | 11 |

2000kg | 8*24MM | 3 | 3000kg | 17 |

Capacity | Hoist Dimension/mm | ||||

A | B | C | E | F | |

1000kg | 221 | 40 | 279 | 145 | 79 |

2000kg | 245 | 52 | 304 | 157 | 81 |

Capacity | No Chain Self | Chain | Flight Case | |

Weight(kg) | Weight(kg) | Weight(KG) | Size(mm) | |

1000kg | 9.5 | 1.67 | 13kg | 550*500*300 |

2000kg | 14 | 2.26 | 15kg | 620*590*310 |

HM-B Manual Chain Hoist of 500kg, 1000kg, 1500kg, 2000kg, 3000kg, 5000kg Specifications

- External shock-resistant gear case and hand wheel cover

- Double enclosure to keep rain and dust out.

- Reliable and secure braking functions (mechanical break).

- Double pawl spring mechanism for added security.

- Hook for simple work.

- Gear with hang precision and tenacity characteristics.

- Load chain guide mechanism made of finely wrought iron.

- Extremely strong load chain.

- Comes with a long-lasting chain bag.

Capacity | Chain | Lifting Height(M) | Test Load | N.W (KG) |

500kg | 5MM*1 | 2.5 | 750kg | 8.4 |

1000kg | 6.3MM1 | 2.5 | 1500kg | 12 |

1500kg | 7.1MM*1 | 2.5 | 2250kg | 16.2 |

2000kg | 8MM*1 | 3 | 3000kg | 20 |

3000kg | 7.1MM*1 | 3 | 4500kg | 24 |

5000kg | 9MM1 | 3 | 7500kg | 41 |

Capacity | Hoist Dimension/mm | ||

A | B | C | |

500kg | 129 | 136 | 270 |

1000kg | 151 | 145 | 317 |

1500kg | 151 | 165 | 399 |

2000kg | 162 | 187 | 414 |

3000kg | 151 | 165 | 465 |

5000kg | 162 | 211 | 636 |

Capacity | No Chain Self | Chain | Flight Case | |

Weight(kg) | Weight(kg) | Weight(KG) | Size(mm) | |

500kg | 4.8 | 1.44 | 13kg | 550*500*300 |

1000kg | 7.8 | 1.69 | 13kg | 550*500*300 |

1500kg | 11.3 | 1.97 | 15kg | 620*590*310cm |

2000kg | 13.2 | 2.28 | 15kg | 620*590*310cm |

3000kg | 15 | 3.04 | - | - |

5000kg | 27.8 | 4.4 | - | - |

HM-D Manual Chain Hoist of 500kg, 1000kg & 2000kg Specifications

- External shock-resistant gear case and hand wheel cover.

- Double Enclosure to keep out dust and precipitation.

- Functions for safe and dependable braking (mechanical break).

- A double pawl spring system to boost certainty.

- A hook for simple work.

- Equipment with hang precision and toughness qualities.

- A well crafted load chain guide mechanism made of wrought iron.

- Extremely sturdy load chain.

- Has a strong chain bag.

Capacity | Chain | Lifting Height(M) | Test Load | N.W (KG) |

500kg | 5MM*1 | 2.5 | 750kg | 8.4 |

1000kg | 6.3MM1 | 2.5 | 1500kg | 12 |

2000kg | 8MM*1 | 3 | 3000kg | 20 |

Capacity | Hoist Dimension/mm | ||

A | B | C | |

500kg | 129 | 136 | 300 |

1000kg | 151 | 145 | 300 |

2000kg | 162 | 187 | 350 |

Capacity | No Chain Self | Chain | Flight Case | |

Weight(kg) | Weight(kg) | Weight(KG) | Size(mm) | |

500kg | 4.8 | 1.44 | 13kg | 550*500*300 |

1000kg | 7.8 | 1.69 | 13kg | 550*500*300 |

2000kg | 13.2 | 2.28 | 15kg | 620*590*310cm |

Hoist Trolley

- constructed using a high-strength, low-alloy material to assure four times the SWL.

- Lightweight, highly secure, and accurate positioning allow for easy movement of heavy loads.

- Excellent mechanical qualities are found in sealed bearings with predetermined lubrication oil.

- Adaptable to various widths and angles of inclination.

- The anti-corrosion of the pulling chain is superb.

- After positioning, a shrinking device can be inserted to achieve locking.

Capacity | Width of Beam/mm | Min Radius of Curve/M | Test Load | N.W /KG |

1000kg | 64-203 | 1 | 1500kg | 12 |

2000kg | 88-203 | 1.1 | 3000kg | 20 |

3000kg | 100-203 | 1.3 | 4500kg | 24 |

Stage hoist sling

Made in accordance with EN1492-2, STAGE HOIST SLING complies with CE safety regulations. It is an unending synthetic sling covered in a woven tubular jacket and produced from a skein of polyester core yarn. The round sling is perfect for quickly and discretely suspending stage lighting and sound equipment.

Stage sling | SS-1 | SS-2 |

Capacity | 200kg | 2000kg |

Ring length | 2m | 3m |

N.W. | 0.9kg | 1.35kg |

Beam Clamp

The BEAM CLAMP is a rapid and adaptable rigging point for lifting loads, pulley blocks, and other objects. Installation can be done quickly and simply by hand without the use of any tools. With only a small amount of headroom lost, units can incorporate load blocks or hook-mounted hoists. The load is applied inside of the flange edge by the clamp jaws, which are designed to reduce beam stress.

Beam Clamp | BC-1 | BC-2 | BC-3 | BC-5 |

Capacity | 1000KG | 2000KG | 3000KG | 5000KG |

I Beam Size | 75-230MM | 75-230MM | 80-320MM | 90-320MM |

N.W. | 4KG | 5KG | 9KG | 11KG |

Shackles

SHACKLES are made of forged carbon steel and have an alloy pin. Each shackle has its size and working load limit permanently displayed. All shackles have batch codes that connect to the test certificate and quality traceability. Detection of 100% mega flux cracks during manufacturing. The fatigue rating is 20,000 cycles at 1.5 times the working load limit. The working load limit is 6 times the minimum ultimate load.

Shackles | Capacity | 3.25t | n.w. | 0.57kg |

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch