Assessing Quality: What to Look for in a 10 Ton Overhead Crane Manufacturer

10 ton overhead crane buying tips:How to assess quality of 10 ton overhead bridge crane ? What to Look for in a 10 ton overhead crane manufacturer? Check!

Category: 10 Ton Overhead Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Assessing Quality: What to Look for in a 10 Ton Overhead Crane Manufacturer

10 ton overhead crane buying tips:How to assess quality of 10 ton overhead bridge crane ? What to Look for in a 10 ton overhead crane manufacturer? Check!

Assessing Quality: What to Look for in a 10 Ton Overhead Crane Manufacturer

When it comes to industrial equipment like overhead cranes, ensuring top-notch quality is paramount. However, navigating the myriad of manufacturers can be daunting. How do you separate the reliable from the subpar? This is where understanding what to look for in a 10-ton overhead crane manufacturer becomes essential.

In a practical situation like a construction project or warehouse management, the reliability of the overhead crane is crucial for ensuring the efficiency and safety of daily operations. Any breakdown or malfunction caused by poor quality not only disrupts workflow but also poses significant safety risks to workers and property.

In this guide, we'll break down the key factors to consider when assessing the quality of a 10-ton overhead crane manufacturer. From structural integrity to safety features, we'll explore the critical elements that ensure you're investing in equipment that not only meets but exceeds your expectations.

So, whether you're a seasoned industrial operator or new to the scene, join us as we unravel the complexities of assessing quality in 10-ton overhead crane manufacturers, empowering you to make informed decisions that drive efficiency, safety, and success in your operations.

Intelligent Crane with Advanced Crane Design with Smart Features

Types of 10 Ton Overhead Cranes Designs for Sale

Double girder overhead crane with rotary trolley for sale

Double girder gantry cranes with intelligent hoists including main hoist and auxialiry

Importance of Quality in Overhead Crane Manufacturing

- Safety Considerations in Industrial Environments In any industrial setting, safety reigns supreme. Overhead cranes play a pivotal role in the movement of heavy materials, and ensuring their safe operation is paramount to protecting both personnel and property. Low-quality cranes can pose significant safety risks, leading to accidents, injuries, and even fatalities. By prioritizing quality in crane manufacturing, you not only mitigate these risks but also foster a safer working environment for all.

- Impact of Crane Reliability on Productivity and Efficiency Reliability is the cornerstone of productivity in industrial operations. A breakdown or malfunction of an overhead crane can bring operations to a grinding halt, resulting in costly downtime and disruptions to workflow. High-quality cranes, built to withstand the rigors of heavy-duty use, offer greater reliability, minimizing the likelihood of unplanned maintenance and repairs. This translates to enhanced operational efficiency, smoother workflows, and ultimately, greater output.

- Long-Term Cost Implications of Investing in High-Quality Equipment While the upfront cost of investing in high-quality overhead cranes may seem daunting, the long-term cost implications tell a different story. Quality equipment is built to last, with durable construction and robust components that withstand the test of time. By opting for a reputable manufacturer known for their commitment to quality, you're not just purchasing a crane; you're making an investment in the future of your operations. The reduced need for repairs and replacements, coupled with increased uptime and productivity, ultimately leads to lower total cost of ownership over the lifespan of the equipment. In this way, prioritizing quality upfront yields significant cost savings and delivers lasting value.

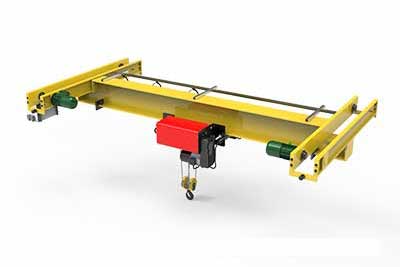

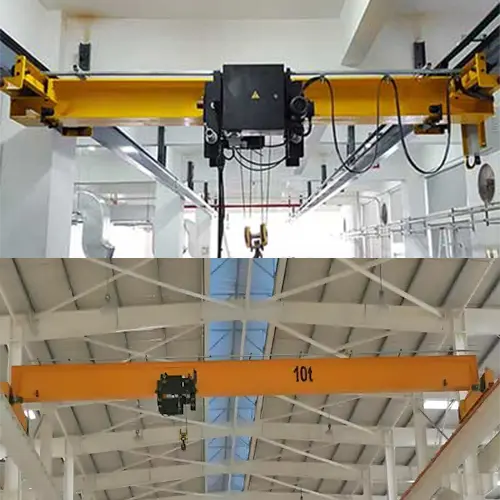

single girder overhead crane 10 ton

double girder overhead crane 10 ton

Key Factors to Consider in Assessing Manufacturer Quality

Reputation and Experience

- Track Record of the Manufacturer in the Industry When assessing a manufacturer's quality, their track record speaks volumes. Look for manufacturers with a proven history of delivering reliable, high-quality overhead cranes to satisfied customers. A track record of success indicates a manufacturer's ability to consistently meet or exceed industry standards and customer expectations.

- Reviews and Testimonials from Previous Clients Customer feedback is an invaluable resource when evaluating manufacturer quality. Seek out reviews and testimonials from previous clients to gain insight into their experiences with the manufacturer. Positive reviews and glowing testimonials are indicative of a manufacturer's commitment to customer satisfaction and the quality of their products and services.

- Years of Experience in Crane Manufacturing Experience is a key indicator of a manufacturer's expertise and competence in crane manufacturing. A manufacturer with years of experience under their belt has likely encountered and overcome various challenges, honing their skills and refining their processes along the way. Prioritize manufacturers with a lengthy tenure in the industry, as their longevity is often a testament to their reliability and trustworthiness.

Compliance with Standards and Regulations

- Adherence to Safety Standards such as OSHA, ANSI, and ISO Safety standards serve as essential benchmarks for ensuring the safe design, manufacture, and operation of overhead cranes. A reputable manufacturer prioritizes compliance with key safety standards set forth by organizations such as the Occupational Safety and Health Administration (OSHA), the American National Standards Institute (ANSI), and the International Organization for Standardization (ISO). By adhering to these standards, manufacturers demonstrate their commitment to producing cranes that meet stringent safety requirements, thereby reducing the risk of accidents and injuries in industrial environments.

- Certification and Compliance with Industry-Specific Regulations In addition to overarching safety standards, different industries may have their own specific regulations governing the use of overhead cranes. Whether it's the automotive, aerospace, construction, or manufacturing sector, each industry has unique safety and operational requirements that manufacturers must adhere to. Look for manufacturers that possess relevant certifications and demonstrate compliance with industry-specific regulations pertinent to your sector. This ensures that the cranes you invest in not only meet general safety standards but also align with the specific needs and regulations of your industry, enhancing safety and operational efficiency.

Engineering and Design Capabilities

- Expertise in Designing Cranes Tailored to Specific Industrial Needs A manufacturer's ability to tailor their crane designs to meet the unique requirements of different industries is a crucial indicator of their engineering and design capabilities. Look for manufacturers with a proven track record of developing custom solutions that address specific challenges and operational needs within your industry. Whether it's adapting crane dimensions, capacities, or functionalities, a manufacturer that can customize their designs demonstrates versatility and an understanding of diverse industrial applications.

- Utilization of Advanced Engineering Software and Technologies In today's rapidly evolving technological landscape, the use of advanced engineering software and technologies is essential for optimizing crane design and performance. Seek out manufacturers that leverage cutting-edge software tools such as computer-aided design (CAD), finite element analysis (FEA), and simulation software to model, analyze, and refine crane designs. By harnessing the power of technology, manufacturers can enhance the accuracy, efficiency, and reliability of their engineering processes, resulting in superior crane performance and durability.

Focus on Innovation and Continuous Improvement Innovation is the lifeblood of progress in crane manufacturing. Look for manufacturers that prioritize innovation and demonstrate a commitment to continuous improvement in their engineering and design practices. This includes investing in research and development initiatives, exploring new materials and technologies, and soliciting feedback from customers and industry experts to drive innovation. Manufacturers that embrace a culture of innovation are better positioned to anticipate and adapt to changing market demands, resulting in cranes that push the boundaries of performance, efficiency, and safety.

Quality of Materials and Components

- Use of High-Grade Materials for Construction The quality of materials used in the construction of overhead cranes directly impacts their durability, reliability, and longevity. Look for manufacturers that prioritize the use of high-grade materials known for their strength, durability, and resistance to wear and corrosion. Materials such as high-strength steel for structural components, premium-grade electrical components, and durable surface coatings contribute to the overall quality and performance of the crane. By opting for cranes constructed from high-grade materials, you can ensure superior reliability and longevity, minimizing the risk of premature failure or deterioration.

- Source of Components and Parts (In-House Manufacturing vs. Outsourcing) Another key consideration in assessing manufacturer quality is the source of components and parts used in the construction of overhead cranes. Manufacturers may choose to either manufacture components in-house or outsource them from third-party suppliers. While both approaches have their merits, in-house manufacturing often allows for greater control over quality, consistency, and customization. Manufacturers with in-house manufacturing capabilities can closely monitor the production process, ensuring that components meet stringent quality standards and specifications. On the other hand, outsourcing may offer cost savings and access to specialized expertise but can introduce variability in quality and lead times. Evaluate manufacturers based on their approach to sourcing components and prioritize those with a robust in-house manufacturing capability or established partnerships with reputable suppliers.

- Quality Control Measures in Place for Material Inspection Quality control is paramount in ensuring that materials and components meet the necessary standards and specifications for overhead crane construction. Look for manufacturers that have rigorous quality control measures in place throughout the manufacturing process, with a particular emphasis on material inspection. This includes thorough testing and inspection of raw materials upon receipt to verify their quality and suitability for use in crane construction. Additionally, manufacturers should employ quality control procedures at each stage of production to identify and rectify any defects or discrepancies before they impact the final product. By adhering to strict quality control protocols, manufacturers can maintain consistency and reliability in the materials and components used in their cranes, ultimately delivering a product of superior quality and performance.

Manufacturing Process and Quality Assurance

- Overview of the Manufacturing Process from Design to Assembly The manufacturing process is crucial in assessing the quality of overhead cranes. Look for manufacturers that follow a comprehensive process from design conception to final assembly. This typically involves several stages, including design engineering, material procurement, fabrication, assembly, testing, and quality assurance. Manufacturers should have well-defined processes and workflows in place, with clear communication channels to ensure seamless coordination between different departments and stakeholders. A transparent overview of the manufacturing process demonstrates the manufacturer's commitment to efficiency, precision, and quality throughout every stage of crane production.

- Implementation of Rigorous Quality Control Protocols Quality control is a cornerstone of manufacturing excellence. Reputable manufacturers prioritize the implementation of rigorous quality control protocols to maintain consistency and reliability in their products. This includes comprehensive inspection and testing procedures at various stages of the manufacturing process to identify and rectify any defects or deviations from specifications. Quality control measures may encompass visual inspections, dimensional checks, material testing, weld inspections, and functional testing to ensure that each component and assembly meets the required standards of quality and performance. By adhering to strict quality control protocols, manufacturers can uphold the integrity of their products and deliver cranes of uncompromising quality and reliability.

- Testing Procedures for Ensuring Crane Performance and Safety Testing is a critical phase in the manufacturing process to verify the performance, functionality, and safety of overhead cranes. Manufacturers should conduct a series of comprehensive tests to validate crane operation under various conditions and loads. This may include load testing to assess lifting capacity, endurance testing to evaluate long-term performance, and functional testing to verify proper operation of controls and safety features. Additionally, manufacturers may subject cranes to simulated operational scenarios to identify any potential issues or weaknesses and ensure compliance with safety standards and regulations. By conducting thorough testing procedures, manufacturers can instill confidence in the reliability, safety, and performance of their cranes, providing customers with assurance of quality and peace of mind in their investment.

After-Sales Support and Service

- Availability of Maintenance and Repair Services The availability of reliable maintenance and repair services is essential for ensuring the long-term performance and longevity of overhead cranes. Look for manufacturers that offer comprehensive maintenance and repair programs tailored to your specific needs. These services may include preventive maintenance inspections, routine servicing, emergency repairs, and component replacements. Manufacturers should have a dedicated team of trained technicians and service personnel equipped with the necessary expertise and resources to address any maintenance or repair needs promptly and efficiently. By partnering with a manufacturer that prioritizes after-sales support, you can minimize downtime, extend the lifespan of your crane, and maximize operational productivity.

- Warranty Coverage and Support Options Warranty coverage is a critical consideration when evaluating manufacturer quality and reliability. Reputable manufacturers stand behind their products with comprehensive warranty coverage that provides protection against defects in materials and workmanship. Assess the warranty terms and duration offered by different manufacturers, paying attention to coverage details, exclusions, and support options. Look for manufacturers that offer flexible warranty options and responsive customer support to address any issues or concerns that may arise during the warranty period. Additionally, manufacturers may provide extended warranty plans or service contracts to further enhance coverage and peace of mind for customers. By choosing a manufacturer with robust warranty coverage and support options, you can safeguard your investment and mitigate potential risks associated with crane ownership.

- Responsiveness to Customer Inquiries and Concerns Effective communication and responsiveness are key indicators of a manufacturer's commitment to customer satisfaction. Evaluate manufacturers based on their responsiveness to customer inquiries, concerns, and service requests. Look for manufacturers that prioritize customer engagement and offer multiple channels of communication, such as phone support, email correspondence, and online portals. A responsive customer support team should be readily available to address technical questions, provide assistance with troubleshooting, and offer guidance on maintenance and service issues. Additionally, manufacturers should proactively seek feedback from customers to identify areas for improvement and enhance the overall customer experience. By partnering with a manufacturer that values open communication and responsiveness, you can feel confident that your needs will be promptly addressed and your concerns will be effectively resolved, fostering a positive and productive relationship for years to come.

Conclusion

Throughout this discussion, we have delved into the crucial aspects of quality assessment in the manufacturing of 10-ton overhead cranes. We explored the importance of structural integrity, material quality, safety features, and operational efficiency in ensuring the reliability and longevity of these industrial machines.

Selecting the right manufacturer for your overhead crane needs is a decision that warrants thorough evaluation and research. It is imperative to assess not only the technical specifications and capabilities of the manufacturer but also their reputation, track record, and commitment to quality and safety standards. By conducting due diligence in this process, you can mitigate risks and ensure that you partner with a reliable and reputable manufacturer who can meet your specific requirements and deliver superior-quality equipment.

Investing in quality overhead crane equipment is not just a short-term expense but a strategic investment with long-term benefits for industrial operations. By prioritizing quality and reliability in your equipment procurement decisions, you can enhance operational efficiency, minimize downtime, improve workplace safety, and ultimately, optimize productivity and profitability. Quality overhead cranes not only perform better and last longer but also contribute to a safer and more productive work environment, thereby delivering significant value and ROI over their lifespan.

In conclusion, by adhering to rigorous quality assessment standards, conducting comprehensive research in manufacturer selection, and prioritizing investment in quality equipment, industrial enterprises can ensure the seamless and successful integration of 10-ton overhead cranes into their operations, unlocking unparalleled efficiency, safety, and performance.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch