How Overhead Cranes Are Manufactured & Fabricated?

How to make an overhead crane? What are procedures of overhead crane manufacturing & machining parts processing? Read crane manufacturing & fabrication.

Steel material for overhead crane manufacturing

During our interactions with clients, we've found that some of them have specific preferences for crane steel materials. Here's a quick rundown of the two types of steel that will be utilized in our cranes.

Steel materials Q235 and Q355 are commonly employed in the production of our cranes.

The difference of the 2 kinds materials:

The yield strength: | alloy content | |

Q235 steel | 235MPa | Carbon structural steel |

Q355 steel | 355MPa | Low alloy structural steel |

- Q235—Metal structural parts, low-core-strength carbonized or cyanide parts, tie rods, connecting rods, hooks, couplings, bolts and nuts, sleeves, shafts, and welded parts.

- Q345—Good overall mechanical properties, good low-temperature performance, good plasticity and weldability, as metal structural parts for medium and low-pressure containers, oil tanks, vehicles, cranes, mining machinery, power plants, bridges and other structures, mechanical parts, and building structures that bear dynamic loads, hot-rolled or normalized use, can be used for various structures in cold areas below -40 °C.

Customer can choose the steel material they want according to the working demands:

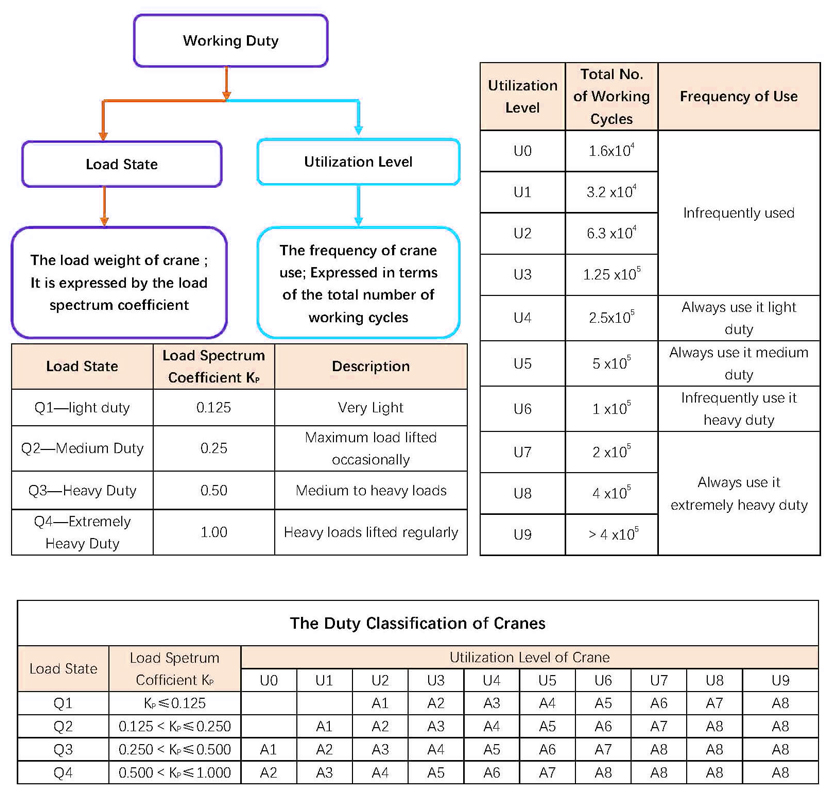

- The Q355 steel plate will be the ideal choice for the client if the material handling cranes are working in low-temperature areas, or if the overhead crane's working class is very high (such as A6 or A7, A8 in ISO standard ), or if the crane structure is rigidly controlled.

- If the customer has no special needs, they can opt for Q235 steel plate, which is likewise extremely good in application and costs less than Q355.

If you have any special requests on crane steel, please feel free to contact us. We have extensive expertise in crane design, production, and supply to customers in China and abroad, and we will provide the best solution for each customer!

Steel materials for overhead crane, gantry crane, jib crane fabrication

Overhead crane production process

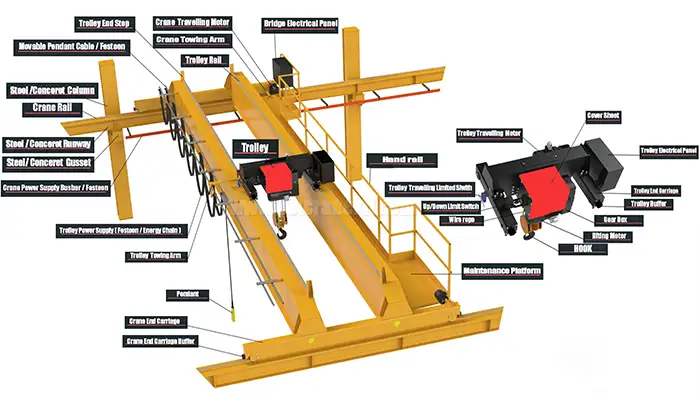

Our overhead cranes are primarily made up of metal structure (which includes main beams, side beams, platform, ladder, railings, and trolley frame, among other components), machining parts, purchased parts (such as bearings, fasteners, standard parts, and other components), cooperation parts (such as the hook), and electrical spare parts, among other components.

Main overhead crane processing procedures

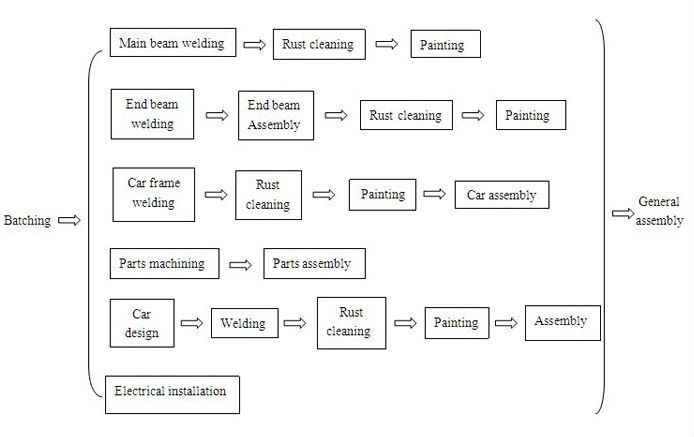

The production process is showed as the following diagram:

Overhead crane production process diagram

Steel structure production process

- Incoming material inspection: Incoming materials such as steel and welding materials will be inspected for quality, chemical composition, mechanical strength, and other factors in accordance with applicable national requirements.Steel for overhead crane fabrication is sourced from Anyang Iron and Steel, Handan Iron and Steel, and other significant steel mills, which may provide the user with a material book and certificate if required.

- Steel surface pretreatment: The pretreatment of steel structures includes shot blasting and ball blasting to eliminate rust, bringing the surface of essential parts up to GB8923 degree Sa2.5.

- Primer painting: To prevent rusting, primer will be painted immediately after shot and ball blasting.

- Marking off: Using a sample plate, handrail, or diagram, mark the shape and processing lines on the plate.

- Plate cutting: Plates will be cut using CNC, semi-automatic, shearing, and sawing techniques.

- Plate welding: Using a semi-automated cutter and automatic submerged-arc welding, plates will be welded together according to specifications.

- Detection of flaws: The butt weld seams will be discovered using ray and ultrasonic technology.

- Leveling: After joining the plates, level them.

- Secondary mark, cutting: After connecting, detecting, and leveling the plate, draw cutting lines according to the desired shape and size and cut them using the semi-automatic cutting machine.

- Assemble: Weld the plates and profiles together to form the overhead crane's metal structure.

- Flaw detection: The major sections' butt weld seams will be discovered once more.

- Assembly (assemblage): Assemble each part according to specifications, paying particular attention to the distance between the centers of two tracks and the length tolerance of the overhead crane bridge diagonal line when the overhead crane's main girder and end carriage are connected into the overhead crane bridge.

Income Material Testing - Crane Manufacturing & Crane Fabrication Procetures

Stee Material Pretreatment - Crane Manufacturing & Crane Fabrication Procetures

Steel Sheet Cutting- Crane Manufacturing & Crane Fabrication Procetures

Welding Stifferner - Crane Manufacturing & Crane Fabrication Procetures

Flaw Detection - Crane Manufacturing & Crane Fabrication Procetures

QC Testing - Crane Manufacturing & Crane Fabrication Procetures

Machining parts production process

- Rough components: cast steel (ZG270-500, ZG340-640, etc. ), iron casting (HT, QT), welding parts (steel plate and welding parts), and round steel parts are the most common (cut by saw machine).

- Machining: Milling, planning, grinding, boring, drilling, insertion, and other processes will be used to change the shape, size, and surface roughness of the mechanical components in order to turn them into certified ones.

- Electric assembly: An electrician assembles the system.

- Bought items: Items such as motors, reducers, bearings, standard fasteners, electrics, and other standard parts will be brought in according to the configuration table prepared by the design department and the schedule prepared by the process department, and will be assembled according to the drawing.

- Cooperation components: These are parts created and produced by other Overhead crane spare parts manufacturers, such as cast steel, iron casting, forging, and overall spare parts, which will be examined when they are carried into the processing workshop.

- General overhead crane assembly: Assemble each portion of the Overhead crane according to the general drawing, such as the hoisting mechanism on the trolley, the pulley and support stand, the traveling mechanism, and so on. Some sections must be dismantled for shipment and reassembled on site, however they must first be trial constructed at the manufacturer's site, where a welding positioning block must be placed in the proper spot for the second assembly to be positioned.

- General overhead crane inspection: After general assembly, a complete quality inspection will be carried out in accordance with the applicable standard and technical requirements, and the qualified one will be awarded an ex-work certificate.

- Painting: Paints will be chosen based on the overhead crane's working environment.

- Paint inspection: This is the last step in the overhead crane production process, and it includes tests for film thickness, sag, and crinkle, among other things.

- Overhead crane delivery: Deliver the merchandise to the customer.

- Site erection

- Acceptance

As a well know crane manufacturer, types of overhead cranes, gantry crane and jib cranes can be fabricated to meet all the needs of customers from various countries and regions, including South Africa, Malaysia, United Arab Emirates, Singapore, Canada, Saudi Arabia, Philippines , Pakistan, Australia , United States, Thailand, United Kingdom, Indonesia, Egypt, India, Brazil, Sweden, and Taiwan, etc. If you have any quesiton, please feel free to contact us by leaving a message below.