Low Headroom Hoist Overhead Crane 3, 5, 10 Ton, Save Space & Cost

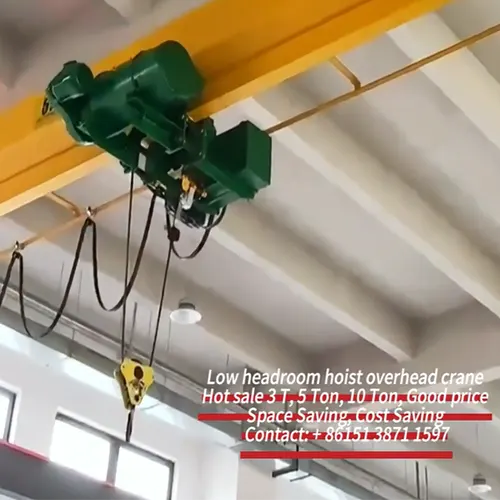

Low headroom hoist overhead crane offers 3, 5, and 10-ton for sale, maximizing space efficiency & providing cost-effective lifting solutions.

Category: Low Built Cranes & Hoists

Your Trusted Top Running Low Headroom Crane Manufacturer & Supplier

Low Headroom Hoist Overhead Crane 3, 5, 10 Ton, Save Space & Cost

Low Headroom Hoist Overhead Crane: Hot Sale 3 Ton, 5 Ton, 10 Ton, Good Price, Save Space & Save Cost

The low headroom hoist overhead crane offers 3, 5, and 10-ton capacities, maximizing space efficiency and providing cost-effective lifting solutions.

Low headroom hoist overhead cranes are designed to efficiently lift and move heavy loads in facilities with height constraints. Their compact design allows for optimal use of vertical space, making them ideal for environments like warehouses, manufacturing plants, and workshops where ceiling height is limited.

In many industrial settings, height limitations can restrict the type of equipment that can be used. Low headroom cranes address this challenge by providing substantial lifting capacity without requiring excessive overhead space. This feature is crucial for maximizing operational efficiency while ensuring safe material handling.

The available product offerings in this category include cranes with load capacities of 3 tons, 5 tons, and 10 tons. Each option caters to different lifting needs, allowing businesses to choose a model that best fits their specific requirements and operational constraints. These cranes are engineered for reliability and practicality, ensuring they meet the demands of various applications.

Features of Low Headroom Hoist Overhead Crane

Low Headroom Design

The low headroom design of these overhead cranes is a key feature that allows for effective operation in facilities with limited ceiling height. By positioning the hoist closer to the main girder, the crane minimizes the overall height required for operation. This design not only maximizes vertical space but also increases the usable area beneath the crane, allowing for efficient workflow and better access to materials.

Load Capacities

These cranes are available in three load capacities: 3 tons, 5 tons, and 10 tons. Each capacity is suited for specific applications:

- 3 Ton: Ideal for light to moderate lifting tasks, such as moving smaller components in assembly lines or warehouses.

- 5 Ton: Suitable for medium-duty applications, including handling heavier machinery parts and materials in manufacturing settings.

- 10 Ton: Designed for heavy lifting, this capacity is often used in large-scale operations, such as construction sites or heavy equipment maintenance.

Selecting the appropriate load capacity ensures that the crane meets the specific demands of the task at hand, promoting efficiency and safety.

Durability and Construction

The cranes are constructed from high-quality materials designed to withstand rigorous industrial use. Common materials include robust steel components that provide strength and stability. This construction enhances the long-term reliability and performance of the crane, reducing the likelihood of wear and tear. Regular maintenance practices can further extend the lifespan of the equipment, making it a practical investment for any business.

The low headroom hoist overhead crane combines advanced engineering with practical design, making it an ideal solution for facilities facing height limitations. Key features include:

Box Girder Design

- Structural Integrity: The box girder design provides exceptional strength and stability, allowing the crane to handle heavy loads safely. This configuration minimizes deflection under load, ensuring consistent performance over time.

- Weight Efficiency: The box shape optimizes material usage, providing a lightweight yet robust structure. This efficiency contributes to lower energy consumption during operation.

- Compact Profile: The design allows for a lower overall height, making it suitable for environments with limited headroom, maximizing the available vertical space.

H-Beam Construction

- Enhanced Load Capacity: H-beams are designed to carry heavy loads effectively, offering superior strength compared to traditional beams. This enhances the crane's lifting capabilities, accommodating a range of applications.

- Durability: The robust nature of H-beams ensures long-lasting performance even in demanding industrial settings, reducing the frequency of maintenance and replacement.

- Versatility: The combination of box girders and H-beams allows for flexible configurations, making it adaptable to various operational requirements and layout designs.

Equipped with Low Headroom Hoist

- Optimized Clearance: The low headroom hoist is positioned close to the girder, significantly reducing the height required for lifting operations. This feature is crucial in maximizing available space in facilities with overhead constraints.

- High Efficiency: Designed for quick and effective lifting, the low headroom hoist enhances productivity by allowing for smooth and rapid material handling.

- Safety Features: Integrated safety features, such as overload protection and limit switches, ensure safe operation and prevent accidents, providing peace of mind to operators.

The combination of box girder and H-beam designs, along with a low headroom hoist, results in a highly efficient, safe, and versatile overhead crane solution. This crane not only addresses the challenges of height limitations but also enhances operational efficiency, making it a valuable addition to any facility.

Economic Benefits

Competitive Pricing

One of the significant advantages of low headroom hoist overhead cranes is their competitive pricing. These cranes are offered at attractive price points, making them accessible for businesses looking to enhance their material handling capabilities without incurring substantial costs. When compared to traditional overhead cranes, which often require more installation space and may come with higher operational costs, low headroom cranes represent a cost-effective alternative. This affordability enables businesses to allocate resources more efficiently while still achieving high productivity levels.

Space and Cost Savings

The low headroom design inherently saves physical space by allowing cranes to operate in areas with limited overhead clearance. This optimized design maximizes the usable area in warehouses and workshops, facilitating better organization and movement of materials.

Additionally, by reducing the need for extensive structural modifications or taller facilities, businesses can avoid significant renovation costs. The space-saving benefits contribute to a more efficient layout, enhancing workflow and productivity.

The low headroom hoist overhead crane offers significant advantages in both cost-effectiveness and lifting height, making it an ideal choice for various industrial applications.

Lower Cost

- Reduced Structural Modifications: The compact design of low headroom cranes minimizes the need for extensive building renovations or alterations, resulting in lower installation costs. This is particularly beneficial for facilities with existing height constraints.

- Energy Efficiency: The lightweight construction, often utilizing box girders and H-beams, contributes to lower energy consumption during operation. Efficient lifting mechanisms reduce power usage, translating to lower operational expenses over time.

- Minimal Maintenance Requirements: The robust design and quality materials used in construction ensure durability, leading to fewer maintenance interventions. This reliability reduces long-term costs associated with repairs and replacements.

Increased Lifting Height

- Optimized Hoist Placement: The low headroom design positions the hoist closer to the girder, maximizing lifting height within the available space. This allows for higher loads to be lifted safely and efficiently, expanding the operational capabilities of the crane.

- Enhanced Usability: By increasing the lifting height, the crane can accommodate a wider range of applications, from moving large machinery to handling tall stacks of materials. This versatility enhances the overall functionality of the crane in various settings.

- Improved Workflow Efficiency: The ability to lift higher means less need for additional equipment or cranes to handle oversized loads, streamlining operations and improving overall workflow efficiency in the facility.

By offering lower costs through reduced structural modifications and energy efficiency, alongside increased lifting height for enhanced usability, the low headroom hoist overhead crane stands out as a practical investment for businesses looking to optimize their material handling capabilities.

Operationally, these cranes can also lead to reduced costs over time. With their efficient lifting capabilities and lower maintenance requirements, businesses can save on energy consumption and upkeep expenses. Overall, the economic benefits of investing in low headroom hoist overhead cranes extend beyond initial costs, offering long-term savings and improved operational efficiency.

Safety Features

Overload Protection

Safety is paramount in lifting operations, and the low headroom hoist overhead cranes are equipped with essential safety features, including overload protection. This system prevents the crane from lifting loads that exceed its specified capacity, significantly reducing the risk of accidents and equipment damage. By ensuring that the crane operates within safe limits, overload protection enhances the safety of operators and surrounding personnel, fostering a secure working environment.

Emergency Stop Functions

Emergency stop functions are another critical safety feature integrated into these cranes. This function allows operators to quickly halt crane operations in the event of an emergency, minimizing potential hazards and injuries. The ability to immediately stop the crane enhances operational security, giving operators confidence in their ability to manage unforeseen circumstances effectively. Together, these safety features contribute to safer lifting operations, ensuring that businesses can focus on productivity without compromising worker safety.

Installation and Maintenance

Easy Installation Process

The installation of low headroom hoist overhead cranes is designed to be straightforward, minimizing disruption to existing operations. The process typically involves the following steps:

- Site Assessment: Evaluate the installation area to ensure it meets space and structural requirements.

- Preparation: Clear the installation site and assemble necessary tools and components.

- Mounting the Main Girder: Securely install the main girder to the support structure, ensuring it is level and stable.

- Hoist Installation: Position and attach the hoist mechanism to the girder, verifying alignment and functionality.

- Electrical Connections: Complete any electrical wiring required for the hoist operation, adhering to safety standards.

- Testing: Conduct a thorough test of the crane's functionality, including lifting and safety features, before putting it into service.

This streamlined process helps ensure a quick and efficient setup, allowing businesses to start utilizing the crane promptly.

Maintenance Considerations

Regular maintenance is crucial for ensuring the longevity and reliable performance of low headroom cranes. Best practices include:

- Routine Inspections: Conduct regular checks on all mechanical and electrical components to identify potential issues early.

- Lubrication: Keep moving parts well-lubricated to reduce wear and friction, enhancing operational efficiency.

- Cleaning: Maintain cleanliness by removing debris and contaminants from the crane and surrounding areas, which can affect performance.

- Load Testing: Periodically perform load tests to verify that the crane operates safely within its capacity limits.

- Documentation: Keep detailed records of maintenance activities and inspections to track the crane's condition over time.

Following these maintenance practices helps ensure the crane remains safe and efficient, providing a reliable solution for lifting operations.

Customer Testimonials and Case Studies

Success Stories

Numerous businesses have successfully integrated low headroom hoist overhead cranes into their operations, experiencing significant benefits. For instance, a manufacturing plant that faced space constraints was able to optimize its workflow by using a 5-ton low headroom crane. This allowed them to efficiently handle heavy components without the need for extensive renovations, resulting in increased productivity and reduced operational downtime.

Another example is a warehouse that implemented a 10-ton crane to facilitate the movement of bulk materials. The low headroom design enabled the warehouse to utilize previously underused vertical space, enhancing their overall storage capacity while maintaining safe lifting practices.

Feedback on Performance and Efficiency

Customers consistently report high levels of satisfaction with the performance and efficiency of these cranes. Many operators highlight the ease of use and reliable lifting capabilities, allowing them to complete tasks quickly and safely. Feedback often mentions the cranes' robust construction, which contributes to long-term reliability even in demanding environments.

Additionally, businesses appreciate the cost savings associated with reduced maintenance needs and operational efficiency. Overall, user testimonials underscore the value of low headroom hoist overhead cranes as effective solutions for handling heavy loads in space-constrained settings, confirming their role in improving operational effectiveness and safety in various industries.

Conclusion

In summary, low headroom hoist overhead cranes offer a practical solution for businesses operating in environments with height limitations. Their efficient design maximizes vertical space, while available capacities of 3 tons, 5 tons, and 10 tons cater to diverse lifting needs. The competitive pricing, combined with significant space and cost savings, makes these cranes an attractive option for various industrial applications.

Additionally, safety features such as overload protection and emergency stop functions ensure secure operations, while easy installation and maintenance practices promote long-term reliability. Customer testimonials further reinforce the benefits of these cranes, highlighting their positive impact on productivity and efficiency.

For potential buyers, considering a low headroom hoist overhead crane is a strategic investment that can enhance operational capabilities while addressing space constraints. Explore your options today to improve your material handling processes and ensure a safer, more efficient workplace.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch