What Are Types of Cranes for Construction?

What are the types of cranes for construction? Overhead crane, Telescopic Crane, Mobile Cranes , Truck Crane,Tower Crane ,Rough Terrain Crane , Overhead Travelling Crane, etc. A look at the different types of crane equipment used in construction and industrial applications.

Different Types of Cranes for Construction

It's incredible to watch all of the different sorts of heavy equipment and machinery being used on a construction site. A crane with its boom or mast up in the air hauling or lifting a load is frequently the first thing you see.

Whether you're new to the profession or a seasoned pro, there's a high chance you've come across crane equipment you've never seen before or heard a crane phrase you've never heard before.

We've teamed with customers employing practically every type of crane throughout our 34 years of delivering lifting and rigging solutions, rigging inspection services, and lifting and rigging training for many types of businesses.

Static Cranes vs. Mobile Cranes

Cranes are divided into two types: static cranes and mobile cranes. A static crane is a permanent/semi-permanent structure that lifts and transports items along a fixed path and is fixed to the ground or building. A mobile crane is a crane that can be transported from job site to job site and is mounted on treads or wheels.

Mobile cranes, unlike static cranes, are not bound to a defined path. Some mobile cranes can perform a "pick and carry" operation, in which they literally pick up a cargo and transport it to a new site using their treads or wheels. Outriggers, counterweights, and even on-site assembly are required by some mobile cranes.

Types of Static Cranes

A static crane is a fixed-path structure that is permanently or semi-permanently attached to the ground or a building.

The main components of an overhead crane are an overhead bridge that swings back and forth along a runway while the hoist moves side to side along the bridge beam.

The vertical foundation (the tower) and a rotating horizontal jib along which the trolley and hoist travel are the essential components of a tower crane. The movement of an overhead crane is limited to a rectangular bay, but the movement of a tower crane is limited to the radius of the jib.

A level-luffing crane is similar to a tower crane in that it has a vertical base with a connected jib, but it has more jib movement and hook leveling capabilities.

Overhead Cranes

A horizontal beam known as the bridge runs up and down a runway on a track or rail on an overhead crane. To lift and lower cargo throughout a rectangular bay, a trolley and hoist move side to side along the bridge. These cranes are intended to improve warehouse or facility safety and efficiency, and their load limitations range from.25 to 400 tons.

An overhead crane may be identified by the fact that it does exactly what it says on the tin: it moves horizontally up and down a runway over a facility or building site along a predetermined course.

Overhead cranes are usually permanent constructions that are constructed for repetitive workflow use in facilities or building sites. Overhead cranes are most frequently associated with bridge cranes, but there are other types of overhead cranes, including:

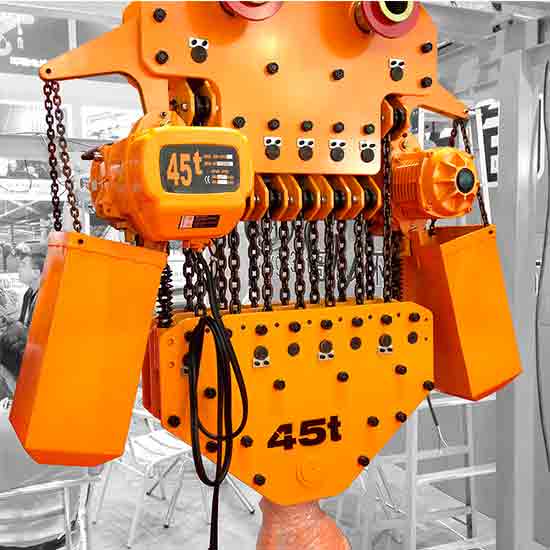

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

Safe & fast air operated hoists. Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs,wide specification, good price.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

Tower Cranes

The cranes you see along city skylines are tower cranes, which are used to construct big structures like skyscrapers. A vertical tower, sometimes known as a mast, and an outstretched jib are the essential components of a tower crane.

The trolley and hook block travel around the mast on the jib, which can spin 360 degrees (this motion is called slewing). Smaller, mobile cranes are frequently used to erect these cranes.

Tower cranes are classified into three categories:

- Hammerhead cranes

- Luffing tower cranes

- Self-erecting tower cranes

Hammerhead Tower Crane

Hammerhead Tower Crane with A-Frame is one of the many types of cranes used in construction.

The jib on a hammerhead tower crane revolves horizontally 360 degrees around the mast at a fixed level, like an upside-down "L."

Racking is a function peculiar to this type of tower crane, in which the trolley transfers the load horizontally along the jib without changing its level.

Hammerhead tower cranes are also known as "A-frame" tower cranes and, in some situations, topless/flat top tower cranes. The presence of metal work (in the shape of a "A") above the crane linking the jib to the counter jib distinguishes an A-frame from a topless tower crane.

A flat top crane is designed to be utilized in circumstances where there is limited headroom or where numerous cranes may slew beneath or over one another. The disadvantage of flat top cranes in the past was their inability to lift capacities equivalent to those of an A-frame crane. Flat-top cranes are beginning to take over the market, according to Cranes Today, with equivalent lifting capacity of 32, 40, or even 50 tons.

Luffing Tower Cranes

A luffing-jib crane is another name for a luffing tower crane. Its design is similar to that of a hammerhead tower crane, except that the jib is latticed and can be raised and lowered in a motion known as "luffing."

These cranes can do more with their enhanced jib mobility:

- Lifting capacity greater than hammerhead cranes

- Are they more costly?

- Because of its smaller slewing radius, they're ideal for working in congested situations and/or with several cranes.

Self-Erecting Tower Cranes (SETC)

Construction Cranes: There Are Several Types of Cranes: Tower Cranes That Self-Erect

Self-erecting tower cranes have a horizontal jib and mast connected to a ballast that can fold and unfold for on-site dismantling and erection. SETCs have the following advantages over hammerhead or luffing tower cranes:

- Have a slender build.

- Are they transportable?

- Have a significantly reduced maximum load capacity

SETCs are particularly useful in situations where:

- Construction necessitates a close fit between structures.

- Extremely heavy lifting isn't necessary.

- The equipment is frequently erected, dismantled, and transported.

Level-Luffing Cranes

Level Luffing Cranes are one of the many types of cranes used in construction.

A vertical mast is attached to a rotating, latticed jib that slews and moves inward and outward from the base of a level-luffing crane.

The inner and outward jib movement, which is unique to these cranes, provides a method for maintaining the hook leveled while moving the jib up and down at the same time. This makes these cranes very helpful for lifting and transferring items close to the ground.

Instead of a trolley and hook block moving along the jib, the jib moves inward and outward to lift and lower the cargo. Cranes like these are frequently employed in shipbuilding, freight loading, and construction.

Types of Mobile Cranes

Movable cranes are made up of an outstretched boom, also known as a lattice or telescopic boom, that is attached to a vehicle or other mobile structure and drives on treads or tires. The crane's boom can spin 360 degrees and extend to different lengths depending on the crane's kind and size. Cranes of this sort do not have to follow a set path and can travel around a construction site and/or between sites.

The crane may or may not be road legal, depending on the type of mobile crane. Some sources define a mobile crane as this, whereas others define a mobile crane as any crane mounted to a movable vehicle with an engine. The latter explanation is referred to as a mobile crane for the sake of this article.

Crawler Cranes

Crawler cranes are the largest of the mobile cranes. They are also known as lattice cranes, boom lattice cranes, lattice crawlers, telescopic crawlers, and so on. These are large cranes that move around a construction site on "tank-like" treads and can lift more than 2500 tons.

Crawler cranes, out of all the mobile cranes, can hoist the biggest weights and require the most on-site setup. Depending on the crane's size and the weight of the cargo it will hoist, onsite assembly may include:

- Attaching the tracks

- Assembling the lattice boom

- Addition of counterweights

Outriggers aren't needed with crawler cranes because the treads give enough stability. Crawler cranes are not road legal due to their considerable on-site installation, enormous size, and treads.

A lattice boom or a telescopic boom can be used by crawler cranes. Those who use a lattice boom can raise bigger loads at higher heights and over greater distances than those who use a telescopic boom.

Rough Terrain Cranes

Rough terrain cranes, often known as "RT" cranes, are a type of mobile crane built for "off-roading" in difficult settings such as mud, snow, and other obstacles.

Rough terrain cranes are four-wheeled and have a telescoping boom for picking and carrying up to 165 tons. They are ideal for maneuvering and lifting in limited spaces because to their tiny design. When a crawler crane would be more appropriate, but a smaller load capacity or navigation in limited locations is required, RT cranes are frequently used.

RT cranes are easy to set up and carry from site to site because they are mounted on an undercarriage with tires, but they are not road legal. These cranes are controlled by a cab that swivels over the undercarriage in sync with the movement of the boom. Their on-site assembly needs include using outriggers to stabilize the crane for hoisting.

All-Terrain Cranes

An all-terrain crane is a type of mobile truck crane that can go on both the road and most off-road surfaces (at high speeds on the highway). These cranes, like large trucks, have anywhere from 4 to 18 tires, depending on the crane's size.

To lift and transfer cargo, a telescoping boom installed on the truck's bed is employed. All terrain cranes can lift far more than rough terrain cranes (up to 1200 tons), but they are less adept of traveling in harsh situations or limited spaces.

All-terrain cranes are controlled from a cab that swivels over the truck bed to follow the movement of the boom. Because it is stabilized by outriggers and balanced by counterweights, the crane requires some on-site assembly.

Truck Cranes

Truck crane, boom truck, and truck mounted crane (TMC) are all phrases that are interchangeable. Truck cranes are a form of mobile crane with a boom mounted to the bed of a truck and are thus road legal. Truck cranes are less adaptable, smaller, and used to hoist lighter weights (load capacity limit of about 45 tons).

Carry Deck Cranes

A carry deck crane is made up of a spinning, telescopic boom that is attached to a compact, flat platform with four wheels. These cranes have outriggers and can lift loads weighing between 4 and 10 tons. These cranes, as the name implies, transport items throughout a construction site by lifting and loading them onto the deck.

Lifting & rigging

A full range of lifting and rigging services are available, including:

- Wire rope and spooling skills that are high-performance

- Assemblies of wire rope, alloy chain, and synthetic slings

- Hardware rigging

- Inspection and repair of rigging

- Hook blocks, hoists, and hoist parts

- Lifting devices that are below the hook

- Training in lifting and rigging

Contact one of our Lifting Specialists to schedule a consultation if you'd like to learn more about how we can assist you with your next project or employee training.