Vertical Coil Lifting Equipment | Overhead Crane & Coil Tongs

Vertical coil lifting equipment, all types of overhead cranes & gantry cranes with vertical coil lifter, i.e, coil tong, automatic coil clamps, magnets, etc.

Category: Coil Handling

Your Trusted Overhead Crane Manufacturer & Supplier

Vertical coil lifting equipment

Overhead cranes & gantry cranes with different vertical coil lifers

Vertical coil lifting equipment, all types of overhead cranes & gantry cranes with vertical coil lifter, i.e, coil tong, automatic coil clamps, magnets, etc.

Vertical coil lifting equipment offered are mainly overhead cranes and gantry cranes that are specifically designed for lifting and transporting steel coils in a vertical position with various types of coil lifting devices or spreaders such as, coil tong, clamp, magnets, and customized coil slings, etc. These coil handling cranes are commonly used in steel processing facilities, shipping yards, and other industrial applications where steel coils need to be lifted and transported overhead.

Types of coil handling overhead cranes based on crane structures

single girder overhead crane for vertical coil lifting with capacity up to 20 ton

double girder overhead crane for vertical coil handling with capacity of 5 ton and up to 80 ton

Heavy duty open winch overhead crane with processed design with capacity up to 320 ton

single girder overhead crane for vertical coil lifting with capacity up to 20 ton

double girder overhead crane for vertical coil lifting with capacity up to 80 ton

double girder gantry crane for vertical coil lifting with capacity up to 320 ton

Based on your coil sizes, weights and your coil lifting requirements, the vertical coil lifting equipment can be equipped with different coil lifters, such as, coil tongs, magnets, slings, and other, etc. The choice of which type of vertical coil handling crane to use depends on the size, weight, and shape of the steel coil, as well as the specific needs of the application. Usually, the magnetic coil cranes and clamp coil cranes are better suited for smaller coils. Coil tong cranes are typically used for very steel coils or in situations where other types of vertical coil lifting equipment cannot be used.

Vertical Coil lifters-Coil tongs & Magnets

What are the vertical coil lifters? These devices are designed to lift and transport steel coils in a vertical position without the use of an overhead crane. They typically consist of a frame with arms that grip the outer diameter of the coil. The advantages of vertical coil lifters are that they are portable and can be used in areas where overhead cranes cannot reach. The disadvantage is that they have a lower weight capacity than vertical coil handling cranes.

Vertical coil lifters are devices used to lift and transport steel coils in a vertical position. They are designed to grip the outer diameter of a steel coil and lift it from the top, allowing for easy and efficient transport of the coil in a vertical position.

Vertical coil lifters are typically used for smaller coils that are not too heavy or too large to be lifted in a vertical position. They are commonly used in steel processing facilities, where coils need to be transported from one location to another for further processing or storage.

Advantages of vertical eye steel coils

One of the advantages of vertical coil lifters is that they allow for efficient use of space. By lifting coils in a vertical position, they take up less floor space than when they are transported in a horizontal position. This can be especially beneficial in facilities where space is limited.

Vertical coil lifters also offer precision control for positioning heavy loads, which is critical when working with steel coils. They are equipped with safety features such as overload protection, which helps prevent accidents and injuries.

The choice of whether to use a vertical coil lifter depends on the size and weight of the coil, as well as the specific needs of the application. While they are not suitable for lifting larger or heavier coils, they can be an efficient and effective solution for lifting and transporting smaller coils in a vertical position.

Magnetic lifter for vertical coil lifting equipment

Magnetic vertical coil lifter

These cranes use magnets to grip the outer diameter of the coil and lift it in a vertical position. They are typically used for lighter coils and have a lower weight capacity than C-hook cranes. The advantages of magnetic lifters are that they can handle a variety of coil sizes, shapes, and materials, and they do not require physical contact with the coil. The disadvantage is that they require a clean surface to work effectively and can be affected by temperature changes.

Magnetic lifters are a popular choice for vertical coil handling due to their ability to securely grip and transport heavy loads. Here are some advantages and disadvantages:

Advantages of magentic coil lifter

- Magnetic lifters can handle a variety of coil sizes and shapes, making them versatile.

- They can lift and transport coils vertically, which is useful for storage and loading onto machinery.

- Magnetic lifters are easy to operate and require minimal training.

- They are a safer alternative to traditional lifting methods, as they reduce the risk of injury or damage to the coil.

Disadvantages of magentic coil lifter

- Magnetic lifters require a power source, which can increase operating costs.

- They can only be used on ferromagnetic materials, so they may not be suitable for all types of coils.

- Magnetic lifters may not be suitable for outdoor use or in harsh environments where they could become damaged.

- They have weight limits, so large or heavy coils may require multiple lifters or alternative lifting methods.

Vertical coil tongs & clamps

These vertical coil handling cranes are equipment with coil tongs and clamps to grip the outer diameter of the coil or one side of coils and lift it in a vertical position. They are commonly used for smaller coils and have a lower weight capacity than C-hook cranes. The advantages of clamp lifters are that they can handle a variety of coil sizes and shapes, and they can be used in tight spaces. The disadvantage is that they require more skill to operate than C-hook cranes.

Classification of vertical coil tongs

Coil spreaders are divided into horizontal roll spreaders and vertical roll spreaders according to the direction in which the rolls are placed.According to the different manufacturing forms, vertical coil tongs are divided into: no-joint rope vertical coil tongs, support rod vertical coil tongs, automatic opening and closing vertical coil tongs, double-arm vertical coil tongs.

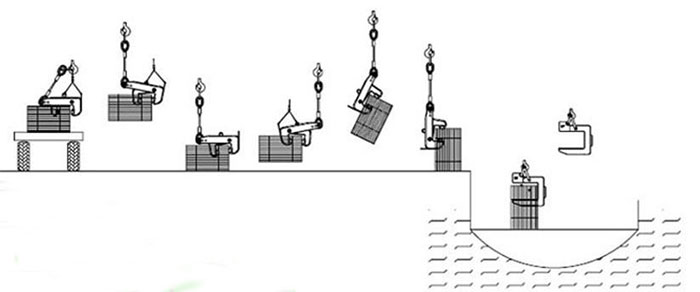

Vertical coil lifting & flipping tong/ clamp

Double-rope vertical coil clamp (no joint rope loop type) is a clamp used for hoisting and flipping vertical coils into horizontal positions. . It adopts double-rope vertical lifting to ensure the stability and safety of the coil during hoisting. The rope loop of the clamp adopts a jointless design, which can avoid clamp failure caused by wear at the joint. At the same time, the clamp also has a self-locking function, which can be automatically locked during hoisting to ensure that the coil will not slip. The fixture is suitable for coils of various specifications, which can effectively improve hoisting efficiency and safety.

Double-rope vertical hanging coil clamp (no joint rope loop type) is suitable for hoisting vertical coils, and the opening and closing of the sling is completed by changing the lifting position. There is a certain inclination of the steel coil in the hoisting state.

Vertical coil lifter for vertical eye steel coil handling 30 ton

Vertical coil lifting & flipping tong

The vertical coil flipping coil tongs is used to load and unload the vertically placed coiled steel. During the handling of steel coils, the coil clamps grip one side of the coil rolls , and with the changing the lifting point to flip the the steel coils from vertical to horizontal positions, and also the coil clamps also can be used to handle the steel coil vertically. They are, suitable for handling steel coils with capacity from 1 ton to 40 tons.

Features of Rolled steel flipping tongs

- It is mainly used for turning the steel coil. The lifting and turning process does not require external force (clamping the coil by its own gravity), and the pinching is safe and reliable. The appropriate model can be selected according to the lifting frequency and lifting requirements.

- The two legs of the coil tong work separately, and they clamp the steel coil respectively.

- During operation, there is no relative sliding between the clamp and the steel coil, and the steel coil will not be damaged during operation.

- The clamping force of the jaws of the coil flipping tongs on the steel coil is twice that of a jaw clamp, the contact stress is small, and the stress damage of the clamp to the steel coil is small.

- The vertical coil tong is easy to manufacture and require small working space, but the operation is cumbersome, and the coil crane driver must have a good view, otherwise the ground personnel must cooperate with the operation, and the coil tong hook must be hooked to the bottom during operation. The position needs to be adjusted for steel coils of different widths.

Steel coil lifter for turning vertical steel coil into horizontal position drawing

Steel coil lifter for turning vertical steel coil into horizontal position

Strut type vertical coil lifter

The vertical coil lifter is only suitable for vertical coil lifting. The fixture adopts the working principle of automatic opening and closing lever, its structure is simple and reasonable, flexible in action, and the lifting is safe and reliable. It does not need to provide any power source, relying on self-weight locking, open and close device positioning, automatically realize the opening and closing action of the jaws.

Strut type vertical coil lifter 32 ton

Strut type vertical coil lifter with truss girder gantry crane for outdoor vertical coil lifting

Self-closing vertical coil clamp is a special hoisting spreader for loading, unloading and transporting vertical steel coils. Hanging on a single-hook crane, relying on the shutter to open the clamp or grab the steel coil, no external power is required, and it is safe and reliable.

The vertical coil tong is mainly composed of seven parts: hanging beam, connecting rod, opening and closing mechanism, synchronizer, clamp arm, support plate and clamp teeth.

- Hanging beam - The hanging beam is the part connected with the crane hook, and has three structures: ring shackle type connection, sling type connection and lug type connection.

- Linkage - The link is the link between the boom and the tong arm.

- Opening and closing mechanism - The opening and closing mechanism has manual lifting rod type, (automatic) double hook type, (automatic) single hook type, (automatic) turn lock type and other forms.

- Synchronizer - A synchronizer is a device that ensures that the arms of the gripper move synchronously.

- Clamp Arm - The clamp arm is the main force-increasing part of the clamp, through which the billet is clamped.

- Support Plate - The support plate is the support for the billet fixture. The support plate is supported on the upper surface of the billet to ensure the smooth operation of the opening and closing mechanism of the billet fixture.

- Claw teeth - Claw teeth have pin shaft connection type, dovetail connection type and groove plug-in type and other structures. The jaws are the main parts that are in direct contact with the billet, and determine the reliability of the billet clamps to hold the billet.

Automatic vertical coil tong

Vertical coil tongs are designed to hold single, dry and oily coils in vertical or up position and are robustly designed for normal use under the harsh conditions encountered in steel mills.

The crane operator controls the entire lifting process from the coil crane cabin by placing the cone in the center of the coil. By lifting the tong, the cone and outer clutch shoe automatically clamp the coil. The suspension assembly is designed to accommodate standard crane hooks. The suspension is fixed with tow pins.

Automatic vertical coil tong

Automatic vertical coil tong double grips for steel coil handling with rated capacity of 25 ton

Features of automatic vertical coil tong

- Operated entirely from the steel coil crane cab without the assistance

- Easy access to gripping pads and grease points for all bearings

- All vertical coil lifter are individually designed and calculated

- Manufactured in accordance with worldwide recognised norms and safety standards

Benefits of automatic vertical coil tong

- No assistance of personnel on the floor required

- Increased operational safety

- Quick handling time

- Easy to maintain and ex-change of wear parts

- Minimum inherent weight

- Long working life

- Produced in line with the latest international machine guidelines

Automatic vertical coil tong single grip type

The Automatic Vertical Coil Tong (VCT) is intended to hoist coils vertically (eye-to-sky).

To satisfy the severe needs of steel and aluminum rolling mills, the coil tongs are robustly constructed for heavy duty application. By inserting the cone into the middle of the coil, the crane operator controls the entire lifting operation from the crane cabin. By lifting the tong, the cone and the outer gripping shoe immediately clamp onto the coil. The suspension assembly is made to fit conventional crane hooks. Pull pins secure the suspension. Customized suspensions are available upon request.

The Automatic Vertical Coil Tong (VCT) Double Grip Type is made for lifting coils vertically (eye-to-sky).

To satisfy the severe needs of steel and aluminum rolling mills, the tong is robustly constructed for high duty application. By inserting the cone into the middle of the coil, the crane operator controls the entire lifting operation from the crane cabin. By elevating the tong, the cone and both gripping shoes immediately clamp the coil. The suspension assembly is made to fit conventional crane hooks. Pull pins secure the suspension. Customized suspensions are available upon request.

Precautions for the use of vertical coil lifting tongs

- The hanging operation must be carried out by a qualified person for the hanging operation.

- Model selection is qualified to the operation conditions and lifting requirements.

- Use within the allowable loading capacity.

- Use within the allowable thickness range of steel coils.

- Do not enter the area where hanging objects fall or turn over

- Do not hit or collide with hanging objects and spreaders

- Do not make the hanging object move or stop suddenly

- Inspect before operation. It is not allowed to use when abnormal phenomena occurs such as, bite head, gasket, blockage between teeth, wear state and other s, etc.

- It is strictly forbidden to overload the device.

Inspection of vertical coil lifter

If the rotation of the twist lock is not flexible or in place while using the vertical coil tongs, check and adjust the adjusting nut, and then check the following parts:

- If the pawl's tension spring is damaged, it should be replaced;

- Check to see if the transmission mechanism has become jammed. If it is stuck, it is inadequately lubricated, and lubricating oil (or grease) should be applied to the transmission mechanism's moveable connection.

- If the guide pin is excessively tight, adjust the nut accordingly. If the connection is loose, or if the transmission pipe or other rods are distorted, they must be repaired.

- If the tension of the buffer spring is too low, the length of the wire rope connecting the buffer spring should be reduced.

Daily maintenance of vertical coil tongs

- The used vertical coil lifter must be placed on a special shelf, stored in a ventilated, dry and clean factory building, and kept by a special person.

- The surface of the vertical coil clamp should be protected against rust frequently, and it is not allowed to be stored in acid, alkali, salt, chemical gas and humid environment.

- Vertical coil tongs are prohibited from being stored in high temperature areas.

- Regularly clean the rotating parts and lubricate regularly to prevent dry friction and jamming

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch