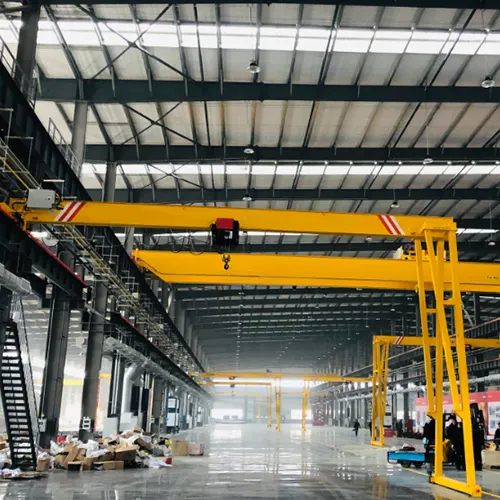

Semi-Portal Crane for Sale, Customization for Your Usage

Explore semi-portal cranes for sale with tailored customization options to fit your specific needs and enhance operational efficiency.

Category: Featured

Your Trusted Semi Portal Cranes Manufacturer & Supplier

Semi-Portal Crane for Sale, Customization for Your Usage

Explore semi-portal cranes for sale with tailored customization options to fit your specific needs and enhance operational efficiency.

A semi-portal crane is a versatile and efficient type of overhead crane used in various industrial applications. Unlike a full portal crane, which has two legs that run on rails, a semi-portal crane features one fixed leg and one or more movable legs. This design allows for greater flexibility in handling loads and navigating obstacles, making it suitable for a range of tasks.

What is a Semi-Portal Crane?

A semi-portal crane combines elements of both overhead bridge cranes and gantry cranes. It typically consists of a single or double girder system supported by one fixed leg that remains stationary on a rail, and one or more movable legs that can travel along a track. This configuration allows the crane to span over obstacles while providing stable support and ease of maneuverability.

Key Characteristics

- Load Capacity: Semi-portal cranes are designed to handle a wide range of loads, from light to heavy. The load capacity varies based on the crane's design, but they are generally capable of lifting and moving substantial weights with precision.

- Span and Height: The span of a semi-portal crane refers to the distance between the two legs, while the height is the vertical clearance available for lifting. These dimensions can be customized to fit specific needs, such as accommodating large machinery or providing extra clearance in warehouses.

- Mobility: The movable leg(s) of a semi-portal crane can travel along tracks, allowing the crane to cover a large area. This feature is particularly useful in environments where space is limited or where the crane needs to navigate around obstacles.

- Structural Design: The crane's structure is typically composed of steel or other strong materials to ensure durability and stability. The fixed leg is anchored firmly, while the movable leg(s) are designed for smooth travel and precise positioning.

- Control Systems: Semi-portal cranes can be equipped with various control systems, including manual, electric, or automated options, to enhance ease of use and operational efficiency.

Differences Between Portal and Semi-Portal Cranes

While both portal and semi-portal cranes are used for lifting and moving loads, they differ in their design and application:

Leg Configuration:

- Portal Cranes: These cranes have two legs that run on rails, creating a full portal structure. They are often used in environments where the crane needs to operate over large areas or navigate complex layouts.

- Semi-Portal Cranes: These cranes have one fixed leg and one or more movable legs. This design provides greater flexibility in areas with restricted space or where the crane needs to span over obstacles.

Mobility and Coverage:

- Portal Cranes: The full portal design allows for a large operating area, but the fixed rails can limit mobility.

- Semi-Portal Cranes: The movable leg(s) enable the crane to cover a larger area and navigate around obstacles more easily.

Applications:

- Portal Cranes: Commonly used in construction sites, large warehouses, and manufacturing plants where a wide span is needed.

- Semi-Portal Cranes: Ideal for applications requiring a mix of fixed and movable support, such as in indoor facilities with restricted space or when handling large items over obstacles.

These characteristics and differences can help in selecting the right type of crane for specific industrial needs and optimizing its performance in various applications.

Basics of Semi-Portal Cranes

Design and Structure

Semi-portal cranes are designed to offer flexibility and efficiency in various lifting applications. Their structure typically includes:

- Fixed Leg: Positioned on a stable foundation or rail, this leg provides consistent support and anchors the crane's structure.

- Movable Leg(s): These are equipped with wheels or tracks and can move along a rail or track, allowing the crane to cover a larger area and adapt to different spatial constraints.

- Girder System: The horizontal beam(s) that span across the work area. This can be a single girder or double girder, depending on the crane's design and load requirements.

This combination of fixed and movable elements allows semi-portal cranes to efficiently handle loads in environments where full portal cranes may not be practical.

Key Components

- Girder(s): The horizontal beam(s) that support the load. Single girder cranes use one beam, while double girder cranes use two beams for added strength.

- Hoist: The lifting mechanism mounted on the girder. It can be electric, manual, or hydraulic, depending on the crane's specifications and the operational requirements.

- End Trucks: Mounted on both the fixed and movable legs, end trucks support the girder system and include wheels or bearings for smooth movement along the rails.

- Legs: The vertical supports of the crane. The fixed leg is stationary, while the movable leg(s) travel along the rail or track, providing flexibility in operation.

- Control System: This can be manual, electric, or automated, controlling the crane's movements and operations to ensure precision and ease of use.

Load-Bearing Capacity

The load-bearing capacity of semi-portal cranes varies based on several factors:

- Girder Strength: The design and material of the girder affect its load-carrying capacity. Double girder cranes typically handle heavier loads compared to single girder models.

- Leg Design: The fixed and movable legs' structural integrity influences the crane's overall load capacity.

- Operational Environment: Factors such as temperature, humidity, and frequency of use can impact the crane's load-bearing capability.

Typical load capacities can range from a few tons to several dozen tons, depending on the crane's design and application.

Typical Configurations and Dimensions

Semi-portal cranes come in various configurations to meet different operational needs:

- Span: The distance between the fixed and movable legs, which can range from a few meters to over 20 meters.

- Height: The vertical clearance available for lifting operations, customized to accommodate different load sizes.

- Rail Length: The length of the track on which the movable leg(s) travel, determining the crane's coverage area.

These dimensions can be adjusted based on specific requirements, such as the size of the workspace or the type of loads being handled.

Types of Semi-Portal Cranes

Single Girder vs. Double Girder

semi portal crane with single girder design

semi portal crane with double girder design

Single Girder Semi-Portal Cranes

- Design and Features: Single girder semi-portal cranes feature a single horizontal beam that supports the crane's load. This simpler design makes them more cost-effective compared to double girder models.

- Load Capacity: Typically suited for lighter loads, these cranes are ideal for applications where the weight of the materials being handled is within a moderate range.

- Span and Height: Best used for shorter spans and lower lifting heights. They offer flexibility in smaller spaces where extensive coverage isn't required.

- Cost and Maintenance: More economical due to their simpler structure and lower material costs. Maintenance is generally less complex and less frequent, reducing overall operational costs.

- Applications: Commonly used in smaller manufacturing facilities, workshops, and warehouses where load requirements are moderate and space is limited.

Double Girder Semi-Portal Cranes

- Design and Features: Double girder semi-portal cranes utilize two parallel beams to support the load. This design provides enhanced strength and stability, allowing the crane to handle heavier and more demanding loads.

- Load Capacity: Capable of lifting heavier loads and covering longer spans. The additional girder provides better distribution of weight and improves overall load handling capacity.

- Span and Height: Suitable for longer spans and higher lifting heights. Their robust design allows them to cover larger areas and handle larger materials more effectively.

- Cost and Maintenance: Generally more expensive due to the additional materials and complexity of the design. Maintenance can be more involved, but the durability and performance often justify the higher investment.

- Applications: Ideal for larger industrial applications, such as heavy equipment assembly, large-scale manufacturing facilities, and extensive warehouse operations where greater load capacity and span are required.

Choosing between single girder and double girder semi-portal cranes depends on your specific operational needs, including load requirements, span, height, and budget considerations. Single girder cranes offer a cost-effective solution for lighter loads and smaller spaces, while double girder cranes provide the strength and capacity needed for heavier and larger-scale applications.

European Style vs. Traditional Style

European style semi portal crane

traditional semi portal crane

European Style

- Design and Features: European style semi-portal cranes are known for their compact and streamlined design. They often utilize advanced materials and engineering techniques to enhance efficiency while minimizing the crane's footprint.

- Materials and Construction: These cranes commonly employ lightweight yet high-strength materials such as high-grade steel or aluminum alloys. This approach reduces the overall weight and allows for more flexible design options.

- Efficiency and Performance: European style cranes are engineered for higher efficiency, featuring optimized load distribution and reduced energy consumption. Their modern design often includes advanced control systems and automation options to improve operational performance.

- Aesthetics: With a focus on modern aesthetics, these cranes often have a sleek, contemporary look that integrates well with modern industrial facilities. Their design can also enhance the overall appearance of the workspace.

- Applications: Suitable for environments where space is at a premium and where advanced performance and aesthetics are important. Common in high-tech manufacturing plants, logistics centers, and industries with a focus on innovation.

Traditional Style

- Design and Features: Traditional style semi-portal cranes are characterized by their robust and straightforward design. They use heavier materials and conventional construction methods, focusing on durability and reliability.

- Materials and Construction: Typically constructed with thicker, heavier steel, these cranes are built to withstand harsh conditions and heavy loads. The design emphasizes proven engineering solutions and ruggedness.

- Efficiency and Performance: While not as optimized as European style cranes, traditional cranes are highly reliable and capable of handling significant loads. They may not feature the latest automation or control technologies but are known for their longevity and dependability.

- Aesthetics: The design of traditional style cranes is generally less focused on modern aesthetics. They often have a more industrial appearance, reflecting their robust construction and functional purpose.

- Applications: Ideal for industries where durability and strength are paramount, and where the latest design innovations are less critical. Common in heavy manufacturing, construction sites, and environments where reliability under tough conditions is crucial.

Both European style and traditional style semi-portal cranes have their unique advantages. The choice between the two depends on factors such as space constraints, efficiency needs, aesthetic preferences, and the specific demands of your operational environment. European style cranes offer modern performance and sleek design, while traditional style cranes provide proven durability and robustness.

Indoor vs. Outdoor Semi-Portal Cranes

indoor semi portal crane

outdoor semi portal crane

Indoor Semi-Portal Cranes

- Design and Features: Indoor semi-portal cranes are specifically engineered for use within enclosed environments like warehouses, manufacturing facilities, and workshops. Their design focuses on optimizing performance in controlled conditions.

- Space Optimization: These cranes are tailored for limited space and lower heights typical of indoor settings. They often feature compact designs to maximize usable space and efficiency within confined areas.

- Weather Resistance: While not required to handle extreme weather, indoor cranes may still include some basic weather-resistant features to address issues like dust or occasional moisture exposure. However, these features are usually minimal compared to outdoor models.

- Efficiency and Performance: Indoor cranes are designed to operate smoothly within the controlled climate of an indoor environment. They may include advanced control systems and automation features to enhance operational efficiency.

- Applications: Ideal for use in warehouses, factories, and assembly lines where space is limited, and environmental conditions are stable. They are suited for handling materials and products within a protected area.

Outdoor Semi-Portal Cranes

- Design and Features: Outdoor semi-portal cranes are built to endure various environmental conditions such as rain, wind, and temperature fluctuations. They are designed with durability and reliability in mind for outdoor applications.

- Weatherproofing and Corrosion Resistance: These cranes are equipped with robust weatherproofing and corrosion-resistant features to withstand exposure to the elements. This includes special coatings, sealed components, and rust-resistant materials to ensure long-term durability.

- Structural Reinforcements: To handle the stresses of outdoor conditions, outdoor semi-portal cranes often have reinforced structures and additional safety features. This includes enhanced stability to cope with wind and uneven ground conditions.

- Efficiency and Performance: Designed to operate efficiently in varying weather conditions, outdoor cranes are built to provide consistent performance regardless of environmental changes. They may include features to manage temperature extremes and maintain functionality.

- Applications: Suitable for use in open storage yards, construction sites, shipping docks, and other outdoor environments where exposure to weather elements is a factor. They are ideal for handling materials and equipment in unprotected areas.

Choosing between indoor and outdoor semi-portal cranes depends on your specific operational environment. Indoor cranes offer optimized performance for enclosed spaces with stable conditions, while outdoor cranes are built to endure the challenges of environmental exposure, ensuring reliable operation and durability in open settings.

Key Industrial Applications of Semi-Portal Cranes

Semi-portal cranes are highly adaptable and play a vital role in multiple industrial settings due to their versatility and efficiency. Here's an overview of their prominent applications:

Industrial Manufacturing

Heavy Equipment Assembly

- Function: In the assembly of large and heavy machinery, semi-portal cranes are indispensable. Their robust design enables them to lift and position heavy components with ease, making them essential for industries that require handling substantial weights and navigating around various obstacles.

- Advantages: These cranes offer exceptional control over load movements, which is crucial when dealing with large and bulky parts. Their stable construction ensures that even the heaviest loads are managed safely and accurately, which is vital for assembling complex machinery and equipment.

Production Lines and Assembly Stations

- Function: Within manufacturing facilities, semi-portal cranes are employed to move materials and components along production lines. They are instrumental in ensuring a smooth flow of items between different stages of the assembly process.

- Advantages: The adaptability of semi-portal cranes allows for efficient management of workflow by accommodating changes and covering extensive areas. Their ability to transport materials effectively reduces downtime and enhances overall productivity, making them a key component in optimizing manufacturing operations.

Semi-portal cranes are crucial in industrial manufacturing due to their ability to manage heavy loads and support efficient production workflows. They are particularly valuable in the assembly of large machinery, where their precise control and stability are essential. Additionally, their role in production lines boosts productivity by streamlining material handling. Their flexibility and effectiveness make them a vital tool in various industrial applications.

Construction Sites

Building Erection

- Function: Semi-portal cranes are crucial for the assembly of large-scale structures like buildings and bridges. They play a key role in lifting and accurately placing heavy materials and structural components during construction.

- Advantages: Their design allows them to reach over obstacles and cover broad areas, making them well-suited for intricate construction projects. This capability helps ensure that materials and components are positioned precisely, facilitating complex building tasks efficiently.

Material Handling

- Function: On construction sites, semi-portal cranes are used to manage various materials, such as steel beams, concrete panels, and construction machinery. They aid in the effective relocation of these materials across the site.

- Advantages: By enhancing the speed and safety of material handling, semi-portal cranes reduce the reliance on manual labor and decrease the risk of accidents. Their efficient operation streamlines material movement, which helps in maintaining a smooth workflow and preventing delays.

Warehousing and Distribution

Storage Facilities

- Function: Within warehouses, semi-portal cranes are employed to handle and organize inventory. They are instrumental in lifting goods into storage areas and retrieving them as required, which streamlines the overall warehouse operations.

- Advantages: These cranes make optimal use of vertical space, allowing for efficient storage and retrieval of items. They enhance inventory management by providing easy access to stored goods, thereby improving organization and reducing the time spent locating and handling inventory.

Distribution Centers

- Function: In distribution centers, semi-portal cranes are vital for moving goods from storage areas to shipping zones. They assist in sorting and preparing orders for dispatch, playing a key role in the distribution process.

- Advantages: By facilitating efficient sorting and packing, semi-portal cranes boost the effectiveness of the distribution process. Their capability to handle large volumes of goods ensures timely and accurate order fulfillment, which is essential for meeting customer demands and maintaining smooth logistics operations.

Specialized Uses

Outdoor Storage Yards

- Function: In outdoor storage environments such as ports or large material yards, semi-portal cranes are essential for managing and organizing bulky and heavy items. They are specifically designed to operate reliably in diverse weather conditions and withstand the rigors of outdoor use.

- Advantages: Their sturdy construction and weather-resistant features ensure long-term durability and consistent performance, even in challenging environmental conditions. This makes them highly effective for organizing and moving large materials in exposed areas.

Maintenance and Repair Facilities

- Function: Within maintenance and repair workshops, semi-portal cranes are employed to lift and position large machinery or components for servicing. They are crucial for providing the support needed for heavy and complex maintenance tasks.

- Advantages: The flexibility and substantial load capacity of semi-portal cranes make them well-suited for a wide range of repair and maintenance activities. Their ability to handle various types of equipment efficiently improves operational productivity and facilitates more effective servicing of machinery.

These specialized applications underscore the adaptability and efficiency of semi-portal cranes across different sectors, highlighting their capability to handle a variety of tasks with precision and reliability.

Customizing Your Semi-Portal Crane

Customizing a semi-portal crane to fit specific needs involves a thorough assessment of operational requirements and selecting appropriate modifications. Here's a guide to help you tailor a crane to your exact specifications:

Assessing Your Needs

Load Capacity Requirements

- Identify Load Types: Begin by categorizing the types of loads your crane will be handling. Different loads, such as heavy machinery, construction materials, or large industrial components, each have distinct requirements. Understanding the nature of these loads will guide you in choosing a crane that is equipped to handle specific weight distributions and dimensions effectively.

- Calculate Maximum Load: Determine the maximum weight the crane needs to lift and maneuver. This involves calculating both static loads (weights that remain constant) and dynamic loads (weights that may change or move). Ensure the crane's specifications align with these requirements to guarantee safety and operational efficiency. For dynamic loads, consider additional factors like acceleration and deceleration that may impact the crane's performance.

Span and Height Specifications

- Measure Workspace Dimensions: Carefully measure the dimensions of the area where the crane will be operated. The span refers to the distance between the crane's fixed and movable legs, and the height pertains to the vertical clearance available. Accurate measurements are crucial to ensure that the crane fits within the workspace and can reach all necessary areas without obstruction.

- Plan for Future Changes: Anticipate any potential changes in your workspace or operational needs that might necessitate adjustments in the crane's span and height. For example, if future expansions are planned or if the types of loads are expected to vary, a crane with adjustable span and height settings might be beneficial. This flexibility will allow the crane to adapt to evolving needs, ensuring long-term utility and efficiency.

Environmental Considerations

- Indoor vs. Outdoor Use: Assess whether the crane will be used indoors or outdoors. Indoor cranes generally require fewer protective features compared to outdoor models. For outdoor use, ensure the crane is equipped with weatherproofing, such as sealed electrical components and weather-resistant materials, to withstand exposure to rain, sun, and dust.

- Temperature and Humidity: Evaluate the typical temperature and humidity levels in the crane's operating environment. Extreme temperatures and high humidity can affect the crane's materials and components. Choose cranes made from materials and coatings designed to resist corrosion, rust, and degradation. For example, cranes operating in very cold environments may need specialized lubricants and heating elements to maintain performance, while those in humid areas may require additional rust-proofing treatments.

By carefully assessing these factors, you can ensure that your crane is well-suited to your specific operational needs and environmental conditions, ultimately enhancing performance and longevity.

Customization Options

Structural Modifications

- Adjustable Components: Tailor the crane to your specific needs by incorporating adjustable features such as extendable beams or height-adjustable legs. These modifications allow the crane to adapt to different operational requirements and spatial constraints, enhancing its versatility and functionality across various tasks and environments.

- Reinforced Structures: If the crane will handle unusually heavy loads or operate in demanding conditions, consider reinforcing its structural components. Strengthening the crane's framework ensures it can support heavier weights safely and withstand harsh environments, thereby extending its operational life and maintaining safety standards.

Control Systems and Automation

- Manual vs. Automated Controls: Choose between manual operation, electric controls, or fully automated systems depending on your operational needs and user preferences. Automated systems can provide greater precision, reduce the physical demands on operators, and streamline complex tasks, while manual controls may be preferred for simpler operations or in situations where direct operator input is essential.

- Advanced Features: Enhance the crane's functionality with advanced features such as remote control capabilities, load monitoring systems, and integrated safety alarms. These additions can improve efficiency by allowing for more precise control and real-time monitoring, and they enhance safety by alerting operators to potential issues before they become critical.

Material Choices and Finishes

- Durable Materials: Opt for high-quality materials like steel or alloy metals for the crane's construction to ensure robust performance and long-term reliability. The choice of materials should reflect the crane's expected load capacity and environmental conditions, ensuring it can handle the demands placed upon it.

- Protective Coatings: Apply protective coatings to safeguard the crane against environmental damage and corrosion. For outdoor cranes, use weather-resistant finishes to protect against rain, UV exposure, and temperature extremes. Anti-corrosion coatings are essential for extending the crane's lifespan and maintaining its structural integrity, especially in harsh or coastal environments.

Case Studies

Example 1: Heavy Equipment Assembly in Manufacturing

- Custom Features: For a manufacturing facility focused on heavy machinery assembly, a semi-portal crane was customized with a double girder system to accommodate high load capacities. The crane's span was extended to cover the entire assembly line, and it was equipped with a sophisticated automated control system for enhanced precision and ease of use.

- Outcome: The customized crane greatly increased assembly efficiency by allowing smooth handling of large equipment. The advanced automation reduced assembly time and improved overall productivity on the assembly line, ensuring quicker and more accurate completion of machinery assembly tasks.

Example 2: Construction Site in Urban Development

- Custom Features: For a high-rise building project in a densely populated urban area, a semi-portal crane was adapted with adjustable legs to maneuver through tight spaces and varying heights. The crane was reinforced to handle the heavy steel beams and construction materials required for the project.

- Outcome: The crane's flexibility and reinforced structure facilitated the rapid assembly of building components despite the constrained working environment. This adaptability helped accelerate the construction process, making it possible to meet project deadlines and manage the complexities of urban construction efficiently.

Example 3: Outdoor Storage Yard in Port Operations

- Custom Features: A semi-portal crane was specially designed for outdoor use at a busy port, featuring heavy-duty weatherproofing and anti-corrosion coatings. The crane was equipped with an extended rail length and high lift capacity to handle large shipping containers and heavy materials.

- Outcome: The crane's robust construction and weather-resistant features ensured reliable performance even under harsh environmental conditions. This durability improved the efficiency of cargo handling operations at the port, contributing to smoother logistics and better management of shipping and storage activities.

By carefully evaluating your specific needs and exploring these customization options, you can ensure that your semi-portal crane is tailored to deliver exceptional performance in your unique operational context.

How to Buy a Semi-Portal Crane

Purchasing a semi-portal crane involves a strategic approach to ensure that the crane meets your specific operational requirements and delivers excellent value for your investment. Here's a comprehensive guide to help you navigate the buying process:

Selecting the Right Supplier

Evaluating Manufacturer Reputation

- Research and Reviews: Start by investigating the reputation of potential suppliers of semi-portal cranes. Check customer reviews, case studies, and industry ratings to assess the quality and reliability of their products. A manufacturer with positive feedback and a solid reputation is more likely to provide a dependable semi-portal crane and reliable support.

- Industry Experience: Choose suppliers with extensive experience in manufacturing semi-portal cranes. Experienced manufacturers will have a better understanding of specific industry needs and can offer solutions that are tailored to meet your operational requirements.

Comparing Quotes and Specifications

- Request Multiple Quotes: Obtain quotes from several suppliers for semi-portal cranes to compare pricing and terms. Ensure that each quote includes detailed specifications, such as load capacities, dimensions, and customization options, allowing for a clear comparison of costs and features.

- Review Specifications: Carefully review the technical specifications of each semi-portal crane in the quotes you receive. Make sure that the crane meets your specific needs by comparing factors like load capacity, span, height, and any additional features. Ensure that the specifications align with your operational requirements.

Key Considerations

- Compliance with Safety Standards: Confirm that the semi-portal crane adheres to relevant safety regulations and industry standards. Compliance with safety standards is crucial for maintaining a safe working environment and avoiding potential legal issues.

- Warranty and Support Services: Check the warranty terms provided by the manufacturer and the availability of support services for the semi-portal crane. A robust warranty and responsive support services are essential for addressing any issues and ensuring long-term reliability.

- Delivery and Installation Services: Ensure that the purchase includes comprehensive delivery and installation services. Proper delivery and installation are crucial for the crane's performance and safety. Confirm that the supplier offers support for these aspects to facilitate a smooth setup.

Negotiation Tips

- Pricing and Payment Terms: Engage in negotiations to achieve the best possible price and favorable payment terms for your semi-portal crane. Discuss potential discounts, financing options, and any additional costs associated with the purchase.

- Additional Features and Add-ons: Negotiate for additional features or add-ons that could enhance the functionality of your semi-portal crane. Consider options like advanced control systems, customization features, or extended warranties that can provide additional value.

By thoroughly evaluating these factors and working with reputable suppliers, you can make an informed decision and acquire a semi-portal crane that meets your specific operational needs while ensuring long-term performance and value.

Send Us Your Inquiry to Get Your Customized Semi-Portal Crane Design

When you're ready to acquire a semi-portal crane tailored to your specific needs, reaching out to a reputable supplier with a detailed inquiry is a crucial step. Here's how you can effectively communicate your requirements and get a customized design that meets your operational needs:

Crafting Your Inquiry

Provide Detailed Operational Requirements

- Load Specifications: Clearly state the types of loads you need the crane to handle, including maximum load weight and dimensions. This will help the supplier design a crane with the appropriate load-bearing capacity.

- Operational Environment: Describe the environment in which the crane will operate, such as indoor or outdoor, and any environmental factors like temperature extremes or exposure to corrosive elements.

Specify Dimensions and Configuration Needs

- Span and Height: Provide the required span (distance between the fixed and movable legs) and height (vertical clearance) to ensure the crane fits your workspace and operational requirements.

- Configuration Preferences: Indicate whether you prefer a single girder or double girder design, and specify any adjustments or features you need, such as adjustable spans or custom leg configurations.

Customization Requirements

- Additional Features: Outline any additional features or enhancements you need, such as advanced control systems, automated functions, or specialized coatings.

- Aesthetic and Structural Modifications: If applicable, mention any specific aesthetic preferences or structural modifications required for your crane.

Submitting Your Inquiry

Contact Information

- Include Your Details: Ensure that your inquiry includes complete contact information, such as your name, company, phone number, and email address. This allows the supplier to respond promptly and accurately.

- Preferred Communication Method: Indicate your preferred method of communication (e.g., email, phone) for follow-up discussions and clarifications.

Attachments and Documentation

- Site Layouts and Drawings: Attach any relevant site layouts, blueprints, or drawings that illustrate your workspace and the intended crane location. This helps the supplier understand your spatial constraints and design requirements.

- Technical Specifications: Provide any existing technical specifications or requirements that will aid in the design process.

Request for Proposal (RFP)

- Formal Request: If your inquiry is part of a formal procurement process, consider preparing a Request for Proposal (RFP) that includes all detailed specifications and requirements. This allows for a more structured and comprehensive response from the supplier.

Receiving and Reviewing Proposals

Evaluate Design Proposals

- Review Designs: Once you receive design proposals from suppliers, carefully review each one to ensure it meets your specifications and requirements.

- Assess Compliance: Check if the proposed designs comply with safety standards, industry regulations, and any specific customization needs you outlined.

Discuss and Refine

- Consultation: Engage in discussions with the supplier to refine the design based on your feedback. Address any concerns or adjustments needed to achieve the optimal crane design for your application.

- Finalization: Finalize the design and agree on the terms of purchase, including delivery, installation, and support services.

By sending a well-detailed inquiry, you set the stage for receiving a customized semi-portal crane design that aligns perfectly with your needs. This approach ensures you get a solution that enhances your operational efficiency and meets all your specifications.

Conclusion

Semi-portal cranes are versatile and efficient solutions for various industrial applications. They offer a balance between the functionality of full portal cranes and the cost-effectiveness of simpler designs. Key features include their ability to span large areas and support heavy loads, making them suitable for manufacturing, construction, warehousing, and specialized uses. Customizing a semi-portal crane ensures it meets specific operational needs, whether through load capacity adjustments, environmental considerations, or additional features.

Benefits of Semi-Portal Cranes

- Flexibility: Semi-portal cranes can adapt to different workspace configurations and operational requirements, offering flexibility in design and application.

- Cost-Effectiveness: They provide a more economical solution compared to full portal cranes, especially when covering large spans or heavy loads.

- Enhanced Performance: Custom features and configurations can improve efficiency and safety, tailored to specific tasks and environments.

- Durability: With the right materials and protective coatings, semi-portal cranes offer long-term reliability and minimal maintenance.

Importance of Customization and Proper Selection

Customization ensures that the crane meets your precise needs, enhancing its effectiveness and longevity. Proper selection based on detailed requirements—such as load capacity, span, and environmental conditions—prevents operational issues and ensures the crane performs optimally. Evaluating suppliers, comparing designs, and negotiating terms are crucial steps in securing a crane that aligns with your operational goals and safety standards.

Final Recommendations

Choosing the Right Crane for Your Application

- Assess Needs Thoroughly: Evaluate your operational requirements, including load capacity, dimensions, and environmental conditions, to select the appropriate crane design.

- Consult with Experts: Engage with suppliers and industry experts to ensure you receive a crane that meets your needs and complies with safety standards.

Ensuring Long-Term Performance and Safety

- Regular Maintenance: Implement a maintenance schedule to keep the crane in good working condition and address any potential issues before they affect performance.

- Training and Safety Protocols: Provide adequate training for operators and establish safety protocols to ensure safe and efficient crane operation.

Appendix

Glossary of Terms

- Load Capacity: The maximum weight a crane can safely lift and move.

- Span: The distance between the supports or legs of a crane.

- Girder: A main horizontal beam in a crane structure that supports the load.

- Automated Controls: Systems that use technology to control crane operations, enhancing precision and reducing manual input.

FAQs

What is the difference between a single girder and a double girder semi-portal crane?

- A single girder crane has one main beam, making it more cost-effective and suitable for lighter loads. A double girder crane has two beams, providing greater load capacity and stability for heavier applications.

Can semi-portal cranes be used outdoors?

- Yes, semi-portal cranes can be designed for outdoor use with weatherproofing and corrosion-resistant materials to withstand environmental conditions.

How do I determine the right span and height for my crane?

- Measure your workspace and consider the maximum reach and clearance needed for your specific tasks. Consult with suppliers to ensure the crane fits within your operational area and meets your requirements.

Resources and Further Reading

- Industry Standards and Guidelines: Review relevant industry standards for crane design and safety, such as those from OSHA or local safety authorities.

- Case Studies and Success Stories: Explore case studies of semi-portal cranes used in various industries to understand real-world applications and benefits.

- Supplier and Manufacturer Websites: Visit supplier websites for detailed product information, customization options, and customer reviews.

This comprehensive guide should help you navigate the process of selecting, customizing, and purchasing a semi-portal crane, ensuring it meets your operational needs and provides reliable performance.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch