Full Gantry Cranes 3 Ton to 100 Ton: Design, Applications & Operation

Full gantry cranes 3t, 5t, 10t up100 ton efficiently lift and transport heavy loads with robust design, versatile applications & precise control.

Category: Full& Half Gantry

Your Trusted Full Gantry Crane& Goliath Crane Manufacturer & Supplier

Full Gantry Cranes 3 Ton to 100 Ton: Design, Applications & Operation

Full gantry cranes efficiently lift and transport heavy loads with robust design, versatile applications, and precise operational control.

Overview of Full Gantry Cranes

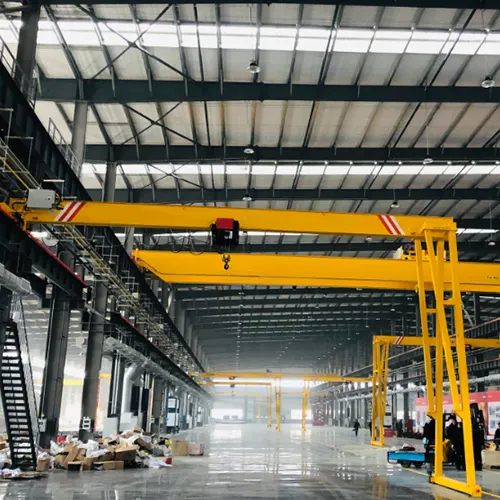

Full gantry cranes are robust lifting systems used to handle heavy loads in various industrial settings. These cranes feature a structure supported by two or more legs that move on tracks, with a bridge spanning between them. The main components include the gantry legs, a beam or bridge, and a hoist or trolley for lifting and moving materials. Their design allows them to operate both indoors and outdoors, making them versatile for different applications.

Full gantry cranes play a crucial role in several industries due to their capacity and flexibility. In manufacturing, they facilitate the movement of heavy machinery and components, improving workflow and efficiency. In construction, they are used to lift and transport building materials, significantly speeding up project timelines. Ports and shipping facilities rely on them for container handling and loading, ensuring smooth operations in busy logistics hubs. The aerospace industry benefits from their precision and strength when handling delicate and heavy aerospace parts.

What is a Full Gantry Crane?

Basic Structure

A full gantry crane is a type of overhead crane where the lifting mechanism is supported by a gantry structure, which consists of two or more vertical legs that travel on tracks or rails. This design allows the crane to straddle a workspace or load area, providing a large and unobstructed lifting zone. The crane typically includes a horizontal beam or bridge spanning between the legs, which supports the hoist or trolley that performs the lifting and moving operations.

Comparison with Other Crane Types

- Bridge Cranes: Unlike full gantry cranes, bridge cranes are supported by overhead rails and do not have legs that move on tracks. They are typically fixed in place and used for tasks within a defined space. Bridge cranes are often found in buildings with pre-installed tracks and are used for tasks that do not require mobility.

- Jib Cranes: Jib cranes consist of a horizontal arm (the jib) that extends from a fixed vertical column. They provide a limited range of motion compared to gantry cranes and are more suitable for tasks within a confined area. Jib cranes are ideal for repetitive lifting tasks in smaller spaces but do not offer the broad coverage and mobility of full gantry cranes.

Key Components

- Gantry Legs: These are the vertical supports of the crane that bear the load and allow the crane to move along tracks. They are often equipped with wheels or rollers to facilitate smooth movement.

- Beam (or Bridge): The horizontal structure that spans between the gantry legs. It supports the hoist or trolley and provides the path along which the lifting equipment moves. The beam's design can vary, including single or double girder configurations, depending on the load capacity and application.

- Wheels: Mounted on the bottom of the gantry legs, these allow the crane to travel along the tracks or rails. They are designed to support the crane's weight and facilitate smooth movement across the workspace.

- Hoist or Trolley: The lifting mechanism attached to the beam or bridge. It can move horizontally along the beam and is equipped with a hoist to lift and lower loads. The hoist can be operated manually or powered electrically, depending on the crane's design and requirements.

These components and how they interact helps in appreciating the versatility and functionality of full gantry cranes in various industrial applications.

Types of Full Gantry Cranes

Single Girder Full Gantry Cranes

Design and Applications

Single girder full gantry cranes are characterized by their straightforward yet effective design. They feature a single horizontal beam, known as the girder, supported by two or more vertical gantry legs that run on tracks or wheels. This girder supports the hoist and trolley system, which travels along its length to lift and move loads. The single girder design is particularly advantageous for applications requiring lighter loads and shorter spans, offering a cost-effective solution for various industries.

Design Characteristics:

- Beam Structure: The single horizontal beam is typically made of robust steel, designed to carry the load with minimal deflection. The beam's design supports the hoist and trolley system, allowing for smooth and efficient load handling.

- Gantry Legs: The vertical gantry legs provide stability and support for the beam, ensuring the crane can handle the specified load capacities. The legs are mounted on wheels or tracks for mobility across the workspace.

- Hoist and Trolley System: The hoist, mounted on the trolley, moves along the beam to lift and lower loads. The trolley can be equipped with different hoisting mechanisms based on the specific lifting requirements.

10 ton single girder full gantry crane for sale Mongolia

Common Applications:

- Manufacturing: In manufacturing settings, single girder full gantry cranes are used to handle various components, machinery, and materials along assembly lines. Their ability to lift and transport items efficiently helps streamline production processes and improve workflow.

- Warehousing: These cranes are ideal for use in warehousing environments, where they facilitate the movement of goods and materials within storage facilities. Their compact design makes them suitable for confined spaces and narrow aisles, enhancing storage efficiency.

- Construction: Single girder full gantry cranes are employed on construction sites to lift and position building materials and equipment. Their mobility and ability to operate in tight spaces make them valuable tools for managing construction tasks and ensuring timely project completion.

In summary, single girder full gantry cranes offer a practical solution for various applications where lighter loads and space constraints are a consideration. Their design ensures efficient load handling while remaining cost-effective and versatile for different operational needs.

Advantages and Limitations

Advantages:

- Cost-Effective: Single girder full gantry cranes have a lower initial cost compared to double girder models, due to reduced material and manufacturing expenses.

- Simplicity: Fewer components result in easier installation and maintenance, reducing overall operational complexity.

- Suitable for Smaller Spans: Ideal for environments with limited space or lower clearance needs, providing effective lifting capabilities in compact areas.

- Efficient for Lighter Loads: Well-suited for lifting lighter and moderate loads, offering practical solutions for many standard industrial tasks.

Limitations:

- Limited Load Capacity: Single girder full gantry cranes are not designed for extremely heavy loads or very long spans, which can limit their application in high-load scenarios.

- Less Stability: Compared to double girder full gantry cranes, single girder models may offer less stability when handling heavy loads, necessitating careful planning and usage.

- Reduced Lifting Height: Generally provides a lower lifting height compared to double girder cranes, which may be a limitation in some applications requiring greater vertical reach.

Single girder full gantry cranes provide an efficient and cost-effective solution for many industrial needs, though their design constraints should be considered when selecting the appropriate crane for specific lifting tasks and environments.

Typical Capacity of Single Girder Full Gantry Cranes (1 Ton to 20 Tons)

1 Ton to 5 Tons: Single girder full gantry cranes in this capacity range are designed for light-duty tasks, including:

- Small Workshops: Perfect for handling small, precise components such as tools, parts, and small machinery. Ideal for workshops with limited space.

- Maintenance Areas: Efficient for lifting and positioning equipment in tight or restricted areas, making routine maintenance and repairs easier.

- Laboratories: Safely transporting delicate instruments and materials without risk of damage, ensuring precise handling for sensitive tasks.

6 Tons to 10 Tons: Cranes within this range are suited for moderate industrial applications, such as:

- Manufacturing Facilities: Capable of lifting medium-sized machinery, production equipment, and components, aiding in assembly and production processes.

- Warehousing: Effective for moving larger inventory items, including pallets and bulk materials, optimizing warehouse operations.

- Assembly Lines: Supporting operations that require handling moderate loads, such as moving parts and materials along assembly lines.

11 Tons to 15 Tons: Single girder full gantry cranes with these capacities address heavier lifting needs, including:

- Heavy Equipment Maintenance: Facilitating the movement of large machinery parts and components, essential for equipment upkeep and repair.

- Construction Sites: Lifting substantial construction materials like steel beams, concrete panels, and prefabricated structures, crucial for building projects.

- Industrial Plants: Handling significant components and machinery in various processing tasks, enhancing productivity and efficiency in industrial environments.

16 Tons to 20 Tons: These cranes are designed for substantial and critical applications, including:

- Large Production Facilities: Managing large quantities of raw materials and heavy machinery, ensuring smooth operation in high-demand production settings.

- Automotive Industry: Moving heavy engine parts, assembly line components, and large automotive components, supporting automotive manufacturing processes.

- Metal Fabrication: Lifting and positioning large metal sheets, structural beams, and heavy fabrication components, essential for metalworking and fabrication tasks.

Single girder full gantry cranes in these capacities offer robust and precise lifting solutions, catering to a wide range of industrial needs based on load requirements and application specifics. Their design ensures durability and efficiency across various tasks, from light-duty to heavy-duty operations.

Double Girder Full Gantry Cranes

Design and Applications

Double girder full gantry cranes feature two parallel horizontal beams (or girders) supported by vertical gantry legs. This design enhances the crane's strength and stability, allowing it to handle heavier loads and cover larger spans compared to single girder cranes. The hoist or trolley system is mounted on top of the girders and can move along their length, providing increased versatility in load handling and positioning.

Common applications include:

- Heavy Manufacturing: Ideal for lifting and moving large and heavy machinery, components, and equipment in manufacturing plants.

- Construction Projects: Used for handling substantial construction materials, such as steel beams and prefabricated elements on construction sites.

- Ports and Shipping: Effective for lifting and transporting shipping containers and other heavy cargo in port facilities.

- Aerospace and Engineering: Suitable for handling large aerospace parts or heavy engineering components where precision and load capacity are critical.

10 ton gantry crane with grab bucket for sugercane handling in Thailand

Advantages and Limitations

Advantages:

- Increased Load Capacity: Double girder full gantry cranes offer higher load capacities compared to single girder models, making them suitable for very heavy and oversized loads.

- Greater Span and Height: They can cover larger spans and provide higher lifting heights, which is beneficial for extensive work areas and tall structures.

- Enhanced Stability: The dual girder design provides superior stability and balance when lifting heavy loads, reducing the risk of crane instability or tipping.

- Customizable: Allows for a variety of customization options, including different girder lengths and hoist configurations, to meet specific industrial needs.

Limitations:

- Higher Cost: Double girder full gantry cranes generally have a higher initial cost due to the additional materials and complexity of the design.

- More Space Required: Their larger size and structure require more space for installation and operation, which may not be suitable for smaller or constrained environments.

- Complex Maintenance: More components and a more complex structure can lead to higher maintenance requirements and potentially increased downtime if issues arise.

Double girder full gantry cranes are highly effective for demanding industrial applications, offering robust performance and versatility. However, their higher costs and space requirements should be considered when planning their use in various operational settings.

Hot Sale Capacity of Double Girder Full Gantry Cranes (3 Ton to 100 Ton)

3 Ton to 10 Tons: Double girder full gantry cranes in this capacity range are versatile for moderate industrial applications:

- Manufacturing Facilities: These cranes efficiently manage medium-sized machinery and production equipment, such as CNC machines, assembly line components, and moderate-sized presses, enhancing workflow and productivity.

- Warehousing: Ideal for moving larger bulk items like heavy pallets, sizable storage containers, and substantial inventory, optimizing warehouse operations and storage management.

- Maintenance Areas: Suitable for lifting and positioning equipment and components in maintenance areas where higher capacity and stability are required compared to single girder cranes, improving safety and efficiency.

11 Ton to 20 Tons: Full gantry cranes with capacities in this range cater to heavier industrial tasks:

- Heavy Equipment Handling: Designed for lifting and moving large machinery parts, including industrial motors, generators, and complex assemblies, crucial for both maintenance and operational efficiency in industrial settings.

- Construction Sites: Effective for transporting heavy construction materials such as steel beams, concrete panels, and prefabricated structures, supporting large-scale construction projects and enhancing site productivity.

- Ports and Shipping: These cranes are instrumental in handling and moving substantial cargo, including shipping containers, bulk materials, and heavy equipment, crucial for efficient port and dock operations.

21 Ton to 50 Tons: Double girder full gantry cranes in this range address more demanding industrial and commercial needs:

- Large Production Facilities: Capable of managing significant quantities of raw materials and large machinery, such as heavy-duty fabrication equipment and large-scale production lines, increasing manufacturing efficiency and throughput.

- Automotive Industry: Suitable for handling heavy automotive components like engine blocks, chassis parts, and large assembly line components, supporting various stages of automotive production and assembly.

- Energy Sector: Designed for lifting and positioning large and heavy equipment such as turbines, generators, and complex assemblies used in power plants and energy production facilities, facilitating major maintenance and installation tasks.

51 Ton to 100 Tons: Cranes with these capacities are engineered for high-demand and heavy-duty applications:

- Heavy Construction: Ideal for lifting large structural components, including precast concrete sections, massive steel beams, and complex structural elements in major construction projects, ensuring safe and efficient handling of large materials.

- Steel Mills: Essential for handling and moving large metal products like steel sheets, billets, and heavy slabs in steel processing plants, aiding in the steel production and fabrication process.

- Shipyards: These cranes are crucial for moving large maritime components such as ship hull sections, heavy equipment for shipbuilding, and oversized marine components, supporting efficient and effective ship construction and repair.

Double girder full gantry cranes with capacities from 3 tons to 100 tons are designed for durability and robustness, offering reliable and versatile solutions for a wide range of industrial tasks. Their dual girder configuration provides enhanced stability and load-bearing capabilities, making them suitable for both indoor and outdoor applications across diverse sectors.

Comparison: Full Gantry Cranes vs. Semi-Gantry Cranes

Design and Applications

Full Gantry Cranes: Full gantry cranes are supported entirely by gantry legs on tracks or rails, allowing them to straddle the full width of the workspace or load area. They consist of a horizontal beam (or girder) that spans between the legs and supports the hoist or trolley system. This design provides complete coverage of the area below and allows the crane to operate independently of existing building structures. Full gantry cranes are ideal for extensive lifting tasks and can be used both indoors and outdoors. Typical applications include heavy-duty manufacturing, large-scale construction projects, port facilities for container handling, and aerospace industries where wide spans and high lifting capacities are required.

Semi-Gantry Cranes: Semi-gantry cranes feature a design where one side of the crane is supported by a gantry structure with legs and wheels, while the other side is supported by an existing building structure or rail system. This setup provides partial coverage of the workspace and is suitable for applications where full gantry coverage is unnecessary or where space constraints limit installation options. Semi-gantry cranes are commonly used in indoor warehouses, manufacturing facilities with existing overhead structures, and sites where only partial gantry coverage is needed.

Advantages and Limitations

Full Gantry Cranes:

Advantages:

- Complete Mobility: Fully independent of existing building structures, allowing flexibility in positioning and extensive coverage of large areas. This independence enables the crane to be used in environments where no existing overhead support is available.

- High Load Capacity: Capable of handling very heavy loads and spanning large distances due to the robust design of gantry legs and the option of dual-girder or single-girder configurations. This makes them suitable for tasks requiring significant lifting power.

- Versatility: Can be deployed in a variety of settings, including outdoor areas, where no support structures are present. Their design accommodates a wide range of industrial and commercial applications.

Limitations:

- Higher Cost: Generally more expensive due to the need for a complete gantry structure, extensive materials, and installation requirements. The cost is often higher compared to semi-gantry cranes due to these factors.

- Space Requirements: Requires a significant amount of space for installation and operation, which may be impractical in smaller facilities or areas with limited space. The need for extensive clearance around the crane can limit its use in constrained environments.

Semi-Gantry Cranes:

Advantages:

- Cost-Effective: Typically less expensive than full gantry cranes due to the use of existing building structures or rail systems for partial support. This can reduce the overall cost of the crane system.

- Space Efficiency: Requires less installation space compared to full gantry cranes, making it suitable for environments where space is limited or where only partial coverage is needed.

Limitations:

- Limited Coverage: Provides only partial coverage of the workspace, which may not be suitable for applications requiring full access or extensive range.

- Dependence on Existing Structures: Relies on existing building structures or rail systems for support, which may limit flexibility in placement and usage. This dependence can also affect the crane's versatility in different operational environments.

Overall, the choice between full gantry cranes and semi-gantry cranes depends on the specific requirements of the application, including load capacity, coverage area, budget, and available space.

Design Considerations of Full Gantry Cranes

Capacity and Load Handling

- Typical Capacities (1 Ton to 500 Tons): Full gantry cranes are designed to handle a wide range of loads. Smaller cranes may have capacities starting at 1 ton, suitable for light industrial applications. In contrast, heavy-duty models can lift up to 500 tons, making them ideal for demanding tasks in large manufacturing plants, ports, and construction sites. The specific capacity required depends on the nature of the loads and the operational needs of the facility.

- Load Distribution and Stability: Effective load distribution is critical for maintaining crane stability and preventing accidents. Full gantry cranes are designed to evenly distribute the load across the gantry legs and beam. Proper engineering ensures that the crane can handle the maximum rated load without compromising stability. Features like reinforced girders and adjustable supports help manage heavy loads and maintain balance during operation.

Dimensions and Space Requirements

- Headroom and Lifting Height: The headroom refers to the vertical distance between the crane's beam and the highest point of the load. Full gantry cranes can be designed with varying headroom and lifting heights to accommodate different types of loads and operational requirements. Taller headroom is necessary for lifting larger items or for applications that require significant vertical clearance.

- Workshop and Outdoor Space Considerations: The dimensions of the crane must fit within the available workspace, whether indoors or outdoors. Full gantry cranes require ample space for installation, operation, and movement of loads. For indoor installations, ensure that the crane's size does not obstruct other machinery or workflows. Outdoor installations must consider environmental factors such as weather conditions and space for crane movement.

Material and Durability

- Structural Materials (Steel): Full gantry cranes are primarily constructed from steel due to its strength and durability. Steel provides the necessary support for the crane's structure and load-bearing components. It is chosen for its ability to withstand heavy loads and resist deformation over time. The choice of steel grade and thickness can be adjusted based on the crane's capacity and operational environment.

- Anti-Corrosion Measures and Coatings: Given that full gantry cranes are often used in harsh environments, such as ports or outdoor construction sites, anti-corrosion measures are essential. Steel components are typically coated with anti-corrosion paints or treated with galvanization to prevent rust and degradation. Regular maintenance and inspections ensure that coatings remain intact and that any signs of corrosion are addressed promptly.

These design considerations ensure that full gantry cranes operate efficiently and safely, meeting the specific needs of various industrial applications while maintaining durability and performance.

Customization and Features of Full Gantry Cranes

Special Features

Remote Control Systems: Full gantry cranes can be fitted with remote control systems, which allow operators to manage crane operations from a safe distance. This feature is crucial for enhancing safety and providing greater flexibility, particularly in environments where precise control over crane movements is necessary or where operators need to avoid hazardous conditions.

Variable Speed Drives: Full gantry cranes equipped with variable speed drives offer improved control over lifting and movement operations. These drives enable the crane to operate at varying speeds, which is essential for tasks that require precise load positioning and smooth operation. This capability enhances efficiency and reduces mechanical wear, leading to better overall performance.

Automated Systems and Integration: Advanced full gantry cranes can be integrated with automated systems, such as sensors and programmable logic controllers (PLCs). These automated features can include load monitoring, automatic positioning, and data logging. Such integration streamlines crane operations, improves accuracy, and enhances overall operational efficiency.

Customization Options

Custom Beam Lengths and Widths: Full gantry cranes can be tailored with custom beam lengths and widths to suit specific operational requirements. Adjusting these dimensions allows the crane to span larger areas or fit within constrained spaces, providing versatility for various industrial applications and ensuring optimal coverage for different load handling needs.

Specialized Hooks and Attachments: To cater to different types of loads, full gantry cranes can be equipped with specialized hooks and attachments. Custom attachments such as magnetic chucks, lifting beams, or spreader bars are designed to handle a wide range of materials and loads efficiently. This customization ensures that the crane can adapt to specific lifting tasks, from handling heavy machinery to delicate components.

These advanced features and customization options enhance the functionality and adaptability of full gantry cranes, making them suitable for a diverse array of industrial applications and operational needs.

Typical Applications of Full Gantry Cranes in Different Industries

Indoor Applications

Manufacturing Plants: Full gantry cranes play a crucial role in manufacturing facilities by efficiently handling heavy machinery, production components, and raw materials. Typical objects managed by these cranes include:

- CNC Machines: High-precision computer-controlled machines used for cutting and shaping metal, plastic, and other materials.

- Assembly Line Equipment: Components and machinery used in assembly lines, including heavy presses and conveyor systems.

- Raw Materials: Large quantities of materials like steel beams, metal sheets, and heavy tooling.

The capacities of these cranes generally range from 5 tons to 50 tons, tailored to meet the specific demands of the manufacturing process. This range ensures that the cranes can handle the substantial weights associated with industrial production.

Warehousing and Distribution: In warehouse environments, full gantry cranes streamline the movement of bulk materials, pallets, and stored goods. They are commonly used to handle:

- Large Pallets of Inventory: Bulk storage of products ready for distribution.

- Drums of Chemicals: Containers holding hazardous or bulk chemicals.

- Heavy Storage Containers: Large, heavy-duty containers used for bulk storage of various items.

For warehousing applications, cranes typically have capacities ranging from 10 tons to 30 tons, suitable for managing substantial inventory and materials efficiently.

Aerospace Industry: Full gantry cranes are integral to aerospace manufacturing and assembly processes, where they are used to lift and position oversized and heavy aircraft components. Commonly handled items include:

- Fuselages: The central body of an aircraft, which houses passengers and cargo.

- Wing Sections: Large sections of an aircraft's wings, crucial for aerodynamic performance.

- Engine Parts: Heavy and complex components that are critical to aircraft propulsion systems.

In the aerospace industry, full gantry cranes are equipped with capacities ranging from 20 tons to 100 tons. This range accommodates the considerable weight and size of aerospace components, ensuring precise handling and assembly.

In summary, full gantry cranes are versatile tools in various indoor applications, providing essential support in manufacturing, warehousing, and aerospace industries. Their capacity and design are tailored to meet the specific needs of each sector, enhancing operational efficiency and safety.

Outdoor Applications

Construction Sites: Full gantry cranes are indispensable on construction sites where they facilitate the lifting and transportation of substantial materials. Typical objects managed by these cranes include:

- Steel Beams: Heavy structural components essential for building frameworks and supports.

- Concrete Panels: Large precast concrete elements used in building facades and structural walls.

- Prefabricated Structures: Pre-assembled sections of buildings, such as modular units and heavy components.

Full gantry cranes in construction typically have capacities ranging from 50 tons to 200 tons. This strength is necessary to handle the large and bulky materials commonly used in construction projects.

Ports and Shipping: At ports and shipping facilities, full gantry cranes are critical for efficient cargo handling and container management. They are used to move:

- Shipping Containers: Standardized large containers that hold various goods for international transport.

- Bulk Cargo: Loose, unpackaged cargo like grains, coal, or ores.

- Heavy Equipment: Large machinery and equipment being shipped or received.

These cranes are designed with capacities from 100 tons to 500 tons, allowing them to handle the massive weight and size of maritime cargo effectively and efficiently.

Energy Sector: In the energy sector, full gantry cranes support the handling of heavy equipment essential for energy production. They are used to manage:

- Turbines: Large and heavy machinery used in power generation, such as wind turbines or gas turbines.

- Generators: Massive units that convert mechanical energy into electrical power.

- Drill Rigs: Equipment used for drilling in oil and gas extraction, requiring substantial lifting capabilities.

For energy sector applications, full gantry cranes usually have capacities ranging from 50 tons to 200 tons. This range is adequate to manage the heavy and large components crucial to energy production operations.

In conclusion, full gantry cranes are essential in outdoor applications across diverse industries, providing robust solutions for lifting and transporting heavy and large items. Their capacities are tailored to meet the specific demands of construction, port operations, and energy sectors, ensuring efficient and safe handling of substantial loads.

Safety and Maintenance

Safety Standards and Regulations

Compliance with OSHA and Other Standards: Full gantry cranes must adhere to safety standards and regulations to ensure safe operation and protect workers. In the U.S., compliance with Occupational Safety and Health Administration (OSHA) standards is mandatory. OSHA regulations cover aspects such as crane design, load capacities, operator training, and maintenance procedures. International standards, such as those from the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI), also provide guidelines to ensure safety in crane operations. Adhering to these standards helps prevent accidents and ensures that cranes operate efficiently and safely.

Routine Maintenance

Inspection Procedures: Regular inspections are crucial for maintaining the safety and functionality of full gantry cranes. Inspections typically include checking structural components for signs of wear and damage, verifying the integrity of welding and bolts, and ensuring that safety features, such as limit switches and emergency stops, are functioning correctly. Routine inspections should be conducted daily, weekly, and annually, with detailed records kept to track the condition and maintenance history of the crane.

Lubrication and Parts Replacement: Proper lubrication is essential for the smooth operation of moving parts in full gantry cranes. Regular lubrication of bearings, gears, and other mechanical components helps reduce friction and prevent premature wear. Additionally, worn or damaged parts should be promptly replaced to avoid operational issues. Scheduled maintenance should include checking and replenishing lubricants, as well as replacing parts like ropes, pulleys, and bearings as needed.

Troubleshooting Common Issues

Mechanical Failures: Mechanical issues in full gantry cranes can include problems with the hoist mechanism, gantry wheels, or the beam structure. Common mechanical failures might involve gear malfunctions, brake issues, or misalignment of the gantry tracks. To troubleshoot these problems, operators should perform a visual inspection, listen for unusual noises, and check for any signs of mechanical stress or damage. Maintenance personnel should address any identified issues promptly to prevent further damage or unsafe conditions.

Electrical and Control System Issues: Electrical problems can affect the crane's control systems, affecting its operation and safety. Common issues include faulty wiring, malfunctioning control panels, or issues with the crane's motor or electrical connections. Troubleshooting electrical problems involves checking circuit connections, testing components for continuity, and verifying that control systems are responding correctly. Regular testing and inspection of electrical components are essential to ensure the crane's reliable operation.

Maintaining full gantry cranes involves adhering to safety regulations, performing routine maintenance tasks, and promptly addressing common issues. By following these practices, facilities can ensure the safe and efficient operation of their cranes, reducing the risk of accidents and extending the equipment's lifespan.

Installation and Setup

Pre-Installation Requirements

Site Preparation and Foundation: Before installing a full gantry crane, it's crucial to prepare the site properly. This involves assessing the ground conditions to ensure they can support the crane's weight and operation. A solid foundation is required to anchor the crane's gantry legs securely. The foundation must be designed to handle the loads imposed by the crane and should include detailed planning for leveling, alignment, and stability. Site preparation also includes clearing the area of obstacles and ensuring adequate space for crane movement and maintenance access.

Crane Assembly and Erection: The assembly and erection of a full gantry crane involve several key steps. First, the individual components, including the gantry legs, beam, and wheels, are transported to the site. The crane is then assembled according to the manufacturer's specifications, with careful attention to alignment and secure connections. Erection procedures may require cranes or other lifting equipment to position and install large sections of the gantry structure. Proper assembly is crucial to ensure the crane's structural integrity and safe operation.

Operational Testing

Load Testing and Calibration: Once the crane is assembled, operational testing is essential to verify its performance and safety. Load testing involves applying weights to the crane to ensure it can handle its rated capacity without issues. This test checks for stability, structural integrity, and accurate load handling. Calibration of the crane's control systems is also performed to ensure precise operation and response. Load testing and calibration are typically conducted by qualified personnel to confirm that the crane meets all operational and safety standards.

Operator Training and Certification: Proper training is essential for safe and effective crane operation. Operators must be trained to understand the crane's controls, safety features, and operational procedures. Training programs should cover topics such as load handling, emergency protocols, and routine maintenance tasks. Certification is often required to verify that operators have the necessary skills and knowledge to operate the crane safely. Ongoing training and recertification may be needed to ensure operators stay current with best practices and safety regulations.

By carefully addressing pre-installation requirements, assembling and erecting the crane correctly, and conducting thorough operational testing, facilities can ensure that their full gantry cranes are installed and set up for optimal performance and safety. Proper training and certification of operators further contribute to the crane's efficient and secure operation.

Cost and Investment Considerations

Initial Costs

Cost Factors (Capacity, Customization): The initial cost of a full gantry crane varies based on several factors, including its capacity and customization requirements. Higher-capacity cranes, which can handle more substantial loads, generally cost more due to the increased strength and materials required for their construction. Customization options, such as specialized beam lengths, custom attachments, or advanced features like remote control systems, also contribute to higher costs. The complexity of the crane's design and the specific requirements of the installation site can further impact the initial investment. It's essential to evaluate these factors carefully to align the crane's specifications with your operational needs and budget.

Operational Costs

Energy Consumption and Maintenance: Operating a full gantry crane involves ongoing costs related to energy consumption and maintenance. Energy consumption depends on the crane's size, load capacity, and frequency of use. Larger cranes and those with higher capacities generally consume more power, which can affect overall operational costs. Maintenance is another significant expense, including routine inspections, lubrication, parts replacement, and potential repairs. Regular maintenance is crucial to prevent breakdowns and ensure the crane operates efficiently. Budgeting for these operational costs helps manage the long-term expenses associated with owning and operating a full gantry crane.

Return on Investment

Efficiency Gains and Productivity Improvements: Investing in a full gantry crane can lead to substantial returns on investment through increased efficiency and productivity. Full gantry cranes enhance material handling capabilities, allowing for faster and more precise movement of heavy loads. This efficiency reduces downtime and improves workflow, contributing to higher production rates and operational throughput. Additionally, the ability to handle larger and more complex loads can open new business opportunities and expand operational capabilities. By improving overall operational efficiency and reducing manual labor, a full gantry crane can provide a significant return on investment over its lifespan.

Evaluating the cost and investment considerations for full gantry cranes involves assessing both the initial purchase costs and ongoing operational expenses. By understanding these factors and the potential for increased efficiency and productivity, businesses can make informed decisions and maximize the benefits of their crane investment.

Case Studies

Successful Implementations

Real-World Examples of Full Gantry Cranes in Use: Examining successful implementations of full gantry cranes provides valuable insights into their practical applications and benefits across various industries. For example:

- Automotive Manufacturing: A leading automotive manufacturer implemented a full gantry crane system to streamline the assembly process of large vehicle components. The crane's high load capacity and adjustable beam length allowed for efficient handling of heavy engine parts and chassis. This setup significantly reduced assembly time and improved operational efficiency.

- Aerospace Industry: An aerospace company utilized a full gantry crane for assembling and positioning large aircraft components. The crane's precise control and high lifting capacity facilitated the handling of complex and heavy parts, such as fuselages and wing sections. This solution helped enhance the accuracy of assembly and maintain stringent quality standards.

- Port Operations: A major shipping port deployed full gantry cranes for container handling and cargo movement. The cranes' robust design and high load capacities enabled efficient management of shipping containers and bulk cargo, leading to improved throughput and reduced turnaround times for vessels.

Lessons Learned and Best Practices

Lessons Learned: Through these real-world examples, several key lessons have emerged:

- Importance of Customization: Tailoring the crane's design to specific operational needs can significantly enhance performance and efficiency. Custom features such as specialized hooks or adjustable beam lengths ensure that the crane meets the unique demands of different applications.

- Regular Maintenance is Crucial: Consistent maintenance and inspections are essential to prevent downtime and extend the crane's lifespan. Implementing a proactive maintenance schedule helps identify and address potential issues before they escalate into major problems.

- Operator Training Enhances Safety and Efficiency: Comprehensive training programs for crane operators improve safety and operational efficiency. Well-trained operators are better equipped to handle the crane's controls, manage loads effectively, and respond to emergencies.

Best Practices:

- Conduct Detailed Needs Assessments: Before purchasing a full gantry crane, conduct a thorough assessment of your operational requirements, including load capacities, space constraints, and potential customization needs. This ensures that the crane selected is well-suited to your specific application.

- Invest in Quality and Reliability: Choose cranes from reputable manufacturers known for quality and reliability. High-quality equipment is more likely to perform consistently and require fewer repairs, contributing to a better return on investment.

- Implement Safety Protocols: Establish and enforce strict safety protocols for crane operation and maintenance. This includes regular safety inspections, adherence to industry standards, and providing adequate training for all personnel involved in crane operations.

These case studies and best practices offer valuable insights into the effective use of full gantry cranes and highlight the importance of thoughtful planning, maintenance, and operator training in achieving successful outcomes.

Conclusion

Summary of Key Points: Full gantry cranes are versatile and powerful solutions for handling heavy loads across various industries, both indoors and outdoors. They come in different configurations, including single and double girder designs, each with its own set of advantages and limitations. Key design considerations include capacity, dimensions, and material durability, while operational safety and routine maintenance are crucial for ensuring efficient and safe performance. Customization options and understanding cost factors further enhance the crane's value and utility in specific applications.

Final Recommendations: For businesses considering the investment in full gantry cranes, it's essential to carefully evaluate your operational needs and select a crane that meets those requirements efficiently. Prioritize safety by adhering to industry standards, invest in comprehensive training for operators, and establish a proactive maintenance program to ensure long-term reliability. By focusing on these areas, you can maximize the benefits of your full gantry crane and achieve optimal performance and return on investment.

Appendices

Glossary of Terms:

- Gantry Crane: A type of crane that has a beam supported by two or more legs, which run on wheels or tracks, allowing it to span across a workspace and lift heavy loads.

- Single Girder Gantry Crane: A crane with one main horizontal beam supported by two gantry legs, designed for lighter loads and shorter spans.

- Double Girder Gantry Crane: A crane with two horizontal beams (girders) providing greater strength and capacity for lifting heavier loads and longer spans.

- Load Capacity: The maximum weight a crane can safely lift and handle.

- Headroom: The vertical distance from the crane's hook to the highest point of the crane's supporting structure, crucial for determining lifting height.

- Customization: Modifications made to the crane to fit specific operational needs, such as adjusting beam length or adding special attachments.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch