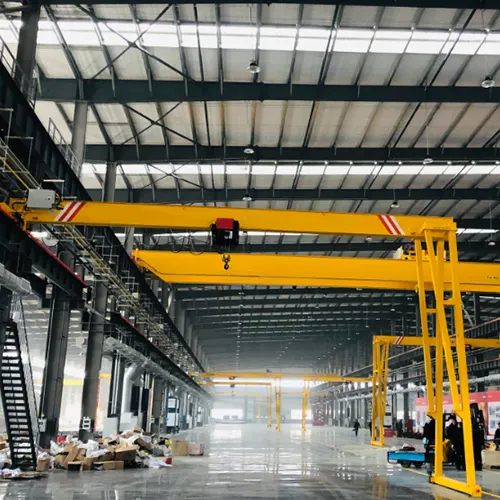

Double Hoist Goliath Gantry Crane Single Girder 1 to 20 Ton

A high-capacity goliath crane designed for tandem lifting of long, heavy loads, ensuring stability, precision, and enhanced lifting efficiency.

Category: Single Girder Goliath Crane

Your Trusted Overhead Crane Manufacturer & Supplier

Double Hoist Goliath Gantry Crane Single Girder 1 Ton to 20 Ton for

Tandem Lifting of Long and Heavy Loads

Overview of the MHE Type Electric Hoist Goliath Gantry Crane with Double Hoist Design

The MHE type electric hoist goliath gantry crane is designed to handle heavy and long loads with ease. It features a strong and stable frame that supports dual hoists, which work together to lift materials that are too large or heavy for single-hoist cranes. This crane is commonly used in industries such as construction, shipbuilding, and aerospace, where there is a need to lift oversized materials in a safe and controlled manner.

- Dual hoist system allows for better load distribution.

- Heavy-duty frame designed for stability during lifting.

- Versatile in handling various load types like beams, pipes, and machinery.

The MHE type gantry crane provides reliable lifting capabilities in demanding environments, improving efficiency and safety in operations.

Double hoist goliath gantry crane with doule hoists for long and heavy loads handling , types of double hoist cranes for sale

Significance of Tandem Lifting in Handling Long and Heavy Loads

Tandem lifting is a method where two hoists are used to lift a single load, ensuring better balance and control. This approach is particularly useful for long and heavy materials, as it helps to distribute the weight evenly, preventing the load from tilting or swaying during the lifting process.

- Increased load stability ensures safer handling of heavy or long materials.

- Prevents load sway and tipping, reducing the risk of accidents.

- Improved precision and control during lifting and moving materials.

Tandem lifting is essential in industries where materials are too large or heavy for traditional lifting methods, providing more stability and safety during the lifting process.

Double Electric Hoist Configuration for Enhanced Lifting Capacity

The double electric hoist configuration is key to enhancing the lifting capacity of the MHE type crane. By using two hoists, the crane can lift heavier loads and manage more complex lifting tasks. The two hoists can operate independently or synchronously, offering flexibility and adaptability for different lifting scenarios.

- Increased lifting capacity allows for handling larger, heavier loads.

- Flexibility in operation, with hoists working independently or together.

- Reduced strain on each hoist, improving crane longevity and performance.

This dual hoist setup enables the crane to handle a wider range of loads with improved efficiency, making it a valuable tool for industries requiring frequent heavy-duty lifting.

Key Features of the MHE Type Double Electric Hoist Goliath Gantry Crane

Dual Hoist System: Explanation of the Double Hoist Mechanism

The MHE type electric hoist goliath gantry crane is equipped with a dual hoist system, where two electric hoists are mounted on the crane structure. These hoists can either work independently or in tandem to lift a single load. When operating together, the hoists share the lifting weight, which reduces the strain on each hoist and enhances the stability of the lift. The hoists are synchronized to ensure that the load is lifted evenly, providing smoother, safer lifting operations.

- Dual hoist mechanism for better load management.

- Independent or synchronous operation for flexibility in lifting.

- Precision in lifting long or heavy loads, preventing uneven weight distribution.

This double hoist mechanism is crucial for handling large, heavy, or extended materials, improving the crane's overall performance.

Benefits of Using Two Electric Hoists for Tandem Lifting

Using two electric hoists for tandem lifting brings several key benefits, especially when handling long, heavy, or difficult-to-maneuver loads. The tandem system ensures that both hoists share the load, making the lifting process more stable and reducing the likelihood of tipping or tilting. This method also improves safety, as it provides better control and precision during lifts.

- Improved load control by distributing weight evenly across both hoists.

- Enhanced safety with less risk of load instability.

- Reduced wear and tear on individual hoists, extending their operational life.

- Increased lifting capacity by allowing the crane to handle more weight.

Tandem lifting with two hoists enables the crane to lift larger, more complex loads efficiently and safely, reducing the risk of accidents and improving productivity.

Lifting Capacity and Versatility: Options for Different Lifting Capacities

The MHE type electric hoist goliath gantry crane is designed to handle a variety of lifting tasks with different load requirements. Available in various lifting capacities, such as 10 tons, 20 tons, and even higher, this crane can be customized to meet specific lifting needs. Whether handling smaller loads or large, bulky items, the crane's versatile design ensures that it can accommodate different weight categories with ease.

- Lifting capacities ranging from 10 tons to 20 tons or more.

- Customizable options to meet specific operational needs.

- Versatility in handling different types of materials and load sizes.

This broad range of lifting capacities makes the MHE type crane suitable for a wide array of industries and applications, from construction to shipbuilding.

Adaptability for Handling Varying Load Sizes and Weights

The crane's dual hoist system offers high adaptability for handling various types of loads, including large, long, and heavy materials. It can handle different load shapes, sizes, and weights by adjusting the hoists to work independently or in tandem. The system is designed to accommodate loads with uneven weight distribution, ensuring that the crane can manage everything from heavy beams to oversized machinery with ease.

- Adaptable design for different load shapes and sizes.

- Flexible hoist configurations to handle various weights and dimensions.

- Efficiency in lifting long or bulky materials, with even weight distribution.

The MHE type gantry crane can be tailored to handle almost any load type, making it a highly adaptable solution for industries with diverse lifting requirements.

Enhanced Load Stability: How Tandem Lifting Improves Load Stability During Transportation

Tandem lifting with two electric hoists significantly enhances load stability during transportation. By sharing the lifting weight, both hoists work together to keep the load balanced and secure. This reduces the chance of load sway or tilting, which is a common risk when lifting large, long, or heavy items with a single hoist. The synchronized operation of the hoists ensures that the load remains level, improving the safety of both the workers and the equipment.

- Synchronized hoists maintain a level and balanced lift.

- Improved load stability reduces the risk of accidents during transportation.

- Precise control over long or heavy loads.

Tandem lifting not only makes the lifting process more efficient but also enhances the crane's ability to move loads safely across various distances within a facility or worksite.

Reduced Risk of Load Sway and Accidents

One of the main advantages of tandem lifting is the reduced risk of load sway and accidents. By using two hoists, the load is evenly supported, which helps prevent unwanted movements during the lift. The synchronized hoist operation ensures that both sides of the load are lifted simultaneously, maintaining balance and minimizing the chances of the load swinging or shifting unpredictably. This enhanced stability is crucial for maintaining a safe working environment.

- Reduced load sway improves safety and precision.

- Minimized risk of accidents by ensuring load stability.

- Increased worker confidence in handling complex lifting tasks.

Tandem lifting with the MHE type electric hoist goliath gantry crane provides a safer and more reliable solution for lifting and transporting long, heavy, or awkward loads.

Technical Specifications

- Model Information:MHE type, dual hoist gantry crane.

- Lifting Capacity:Available capacities and how dual hoists work in tandem (e.g., 20 tons, 32 tons).

- Span and Lifting Height:Customizable span (e.g., 12m, 21m). Lifting height as request.

- Operating Speed:Lifting speed, trolley speed, and crane movement speed.

- Power Supply:Electrical requirements and power specifications (three-phase AC, 380V, 50Hz).

Model Information: MHE Type, Dual Hoist Gantry Crane

The MHE type electric hoist goliath gantry crane is engineered to meet the demanding needs of industries requiring heavy-duty lifting. This crane is equipped with a dual hoist system, which allows two hoists to work independently or together to lift large and heavy loads. The crane's robust design and advanced lifting technology make it suitable for handling long, oversized, and bulky materials with precision and safety.

- Model Type: MHE (Electric Hoist Goliath Gantry Crane with Dual Hoist System).

- Dual Hoist: Features two hoists that can operate in tandem for increased lifting capacity.

- Heavy-duty design: Ensures reliability and stability during complex lifting operations.

This model provides the flexibility needed for a wide variety of lifting tasks in heavy industries such as construction, shipbuilding, and steel manufacturing.

Lifting Capacity: Available Capacities and How Dual Hoists Work in Tandem

The MHE type electric hoist goliath gantry crane is available in multiple lifting capacities, typically ranging from 10 tons to 50 tons or more. The dual hoist system enables the crane to lift larger loads by sharing the weight across both hoists, which helps distribute the load evenly. Depending on the configuration, the hoists can work synchronously for maximum lifting power or independently for more precise control.

Available Capacities:

- 20 tons (10+10 tons with dual hoists).

- 32 tons (16+16 tons with dual hoists).

- Custom capacities can be designed to meet specific lifting needs.

Tandem Lifting:

- Both hoists can lift the load together, sharing the weight for enhanced lifting power.

- Hoists can work independently for more controlled handling of uneven loads.

This system ensures the crane can handle a wide variety of lifting applications, from moving massive beams to lifting large equipment, while maintaining control and safety.

Span and Lifting Height: Customizable Span and Lifting Height

The MHE type gantry crane is designed with flexibility in mind, offering customizable span and lifting height options. The span refers to the width of the crane, and it can be adjusted to fit the specific dimensions of a facility or worksite. Similarly, the lifting height is adaptable to suit different lifting tasks, ensuring that the crane can handle a range of load sizes and heights, from standard lifting to high-clearance operations.

- Span Options:Available spans range from 12 meters to 29 meters.Customizable spans can be designed based on operational needs.

- Lifting Height:Standard lifting heights range from 6 meters to 30 meters.

These customizable features make the MHE type crane suitable for a broad range of applications, from construction sites to industrial manufacturing facilities.

Operating Speed: Lifting Speed, Trolley Speed, and Crane Movement Speed

The MHE type electric hoist goliath gantry crane offers adjustable operating speeds for lifting, trolley movement, and overall crane movement, ensuring that it can handle a variety of tasks efficiently. The operating speeds are designed to provide a balance between fast operation and precise control, allowing the crane to move loads quickly while minimizing the risk of accidents.

- Lifting Speed: Typically around 7 meters per minute (m/min), which is ideal for controlled and smooth lifting.

- Trolley Speed: Around 20 meters per minute (m/min), providing quick horizontal movement of the hoist.

- Crane Movement Speed: Typically around 30 meters per minute (m/min), allowing the crane to move quickly along its track to reposition for different lifting tasks.

These speed settings can be adjusted based on specific operational requirements, ensuring efficiency while maintaining safety.

Power Supply: Electrical Requirements and Power Specifications

The MHE type electric hoist goliath gantry crane requires a reliable power supply to operate its dual hoist system and other components. The crane is powered by three-phase alternating current (AC), providing the necessary voltage and current for heavy-duty lifting operations. The power supply specification is set to meet standard industrial electrical requirements for a range of applications.

- Power Supply: Three-phase AC (Alternating Current).Voltage: 380V.Frequency: 50Hz.

This power setup ensures that the crane operates efficiently and reliably under demanding conditions, offering the necessary force for heavy-duty lifting tasks across a wide range of industries.

Applications in Industry

Typical Loads or Objects Handled by Electric Hoist Goliath Gantry Cranes with Double Hoists

Electric hoist gantry cranes with double hoists are designed for lifting heavy and long loads that require additional stability and control. These cranes are commonly used to handle:

- Long Materials: Such as steel beams, structural components, and pipes.

- Heavy Equipment: Large machinery, engines, and industrial components.

- Oversized Loads: Items like prefabricated building elements, ship parts, and oversized containers.

- Construction Materials: Concrete blocks, steel girders, and large scaffolding components.

Typical Load Weights and Crane Capacity Ranges

The load weights and crane capacity ranges vary depending on the crane's specifications, but typically, the capacities for cranes with double hoists are in the following ranges:

Load Weight: Typically, these cranes handle weights ranging from 10 tons to 50 tons. However, they can also be customized to handle loads above 50 tons for specific applications.

Crane Capacity:

- Standard: 10 tons, 20 tons, common capacities for electric hoist goliath gantry cranes with double hoists.

- High Capacity Models: Can reach up to 100 tons or more, depending on the design and application needs.

Typical Application Conditions

Electric hoist gantry cranes with double hoists are used in a variety of conditions that demand high lifting capacity and precision. These conditions typically include:

- Heavy Duty Environments: High-stress industrial sites where heavy lifting is constant, like steel mills, shipyards, or construction sites.

- Outdoor and Indoor Use: Many cranes are designed to work in both indoor warehouses and outdoor facilities, providing versatility for various applications.

- Harsh Conditions: Environments with high temperature fluctuations, corrosive chemicals, or wet conditions, where cranes may need additional protection like anti-corrosion coatings and weatherproofing.

- Limited Space: Cranes that are designed for smaller facilities or spaces with limited headroom while still handling large loads.

Typical Industrial Sectors

Electric hoist gantry cranes with double hoists are used across several key industries where large, heavy, and long loads need to be lifted with precision and safety. Common sectors include:

- Steel Industry: For lifting steel beams, rolls, and large metal products.

- Construction: Handling large construction materials like concrete panels, pre-fabricated structures, and steel reinforcements.

- Shipbuilding: For lifting and moving large ship components, including hulls, engines, and machinery.

- Aerospace: Moving large and heavy aerospace parts, such as fuselages, wings, and engines.

- Automotive: Used in the transportation and assembly of heavy machinery and automotive parts.

- Heavy Equipment Manufacturing: Lifting large equipment or machinery used in industries such as mining, energy, and construction.

- Power Plants: For moving heavy components in the assembly, maintenance, and upgrading of plant equipment.

- Logistics and Warehousing: Handling oversized or heavy goods in storage and transit.

These cranes are designed to meet the demanding needs of industries that rely on heavy lifting, ensuring safety, efficiency, and reliability.

Tandem Lifting Scenarios: Real-World Case Studies

Tandem lifting, using two hoists in unison, offers significant benefits in various industries by improving load stability, increasing lifting capacity, and ensuring safer operations. Below are some case studies where tandem lifting has proven beneficial:

- Construction of Large Infrastructure: When constructing bridges or tunnels, oversized beams and structural elements need to be lifted simultaneously by two hoists to distribute the load evenly and avoid imbalance. The MHE dual hoist system excels in this scenario, providing the precise control required for such heavy-duty lifts.

- Shipbuilding Operations: In shipyards, lifting and positioning massive ship components like engine blocks, propellers, and large hull sections often require tandem lifting. The MHE gantry crane's tandem lifting capability ensures these components are moved without the risk of tipping or damage, especially when they are of irregular shapes and sizes.

- Automotive Manufacturing: In automotive production lines, the use of tandem lifting for heavy parts such as chassis or large subassemblies allows the load to be evenly distributed, reducing stress on the crane's structure and ensuring safer lifting operations.

In each of these real-world scenarios, tandem lifting improves load stability and efficiency, minimizing the risk of accidents while enhancing operational productivity.

Advantages of Tandem Lifting with Double Electric Hoists

Improved Load Distribution: Evenly Distributed Weight Across the Hoists for Safer Lifting

One of the primary benefits of tandem lifting with double electric hoists is the even distribution of the load between both hoists. By splitting the weight of heavy and long loads across two hoists, the crane ensures that the load is balanced, reducing the risk of instability. This evenly distributed weight minimizes the chances of tipping, tilting, or swinging, which can lead to accidents or damage to both the load and the crane.

- Balanced Load Handling: Tandem lifting ensures that no single hoist bears the full weight of the load, allowing for safer operations.

- Stable Load Movement: With both hoists working in sync, the load remains steady throughout the lifting and transportation process, improving the precision of the lift.

This level of control makes tandem lifting particularly useful in applications that involve oversized or delicate loads.

Reduced Stress on Equipment: Extending the Lifespan of Crane Components

The use of two hoists for lifting large loads also helps reduce the stress on individual crane components, such as the hoist motors, cables, and pulleys. By splitting the load between two hoists, the wear and tear on any single component is minimized, extending the lifespan of the crane and reducing the frequency of maintenance and repairs.

- Less Wear and Tear: With the load spread between two hoists, each hoist experiences less strain, leading to lower operational costs and reduced downtime.

- Enhanced Durability: Tandem lifting ensures that crane components work more efficiently and experience less overloading, which helps to prolong the life of key parts such as the lifting mechanism and structure.

This benefit is especially valuable in industries where the crane is used for frequent, high-capacity lifting tasks.

Enhanced Safety: Safety Features of Tandem Lifting

Safety is a critical concern when handling large and heavy loads, and tandem lifting with double electric hoists offers several safety advantages. The synchronized operation of the hoists ensures precise load control, reducing the risk of tipping, swinging, or shifting during the lift. Additionally, safety features such as load sensors, anti-sway systems, and synchronized lifting systems enhance operational safety.

- Reduced Risk of Tipping: By evenly distributing the load, tandem lifting minimizes the risk of the crane tipping over, particularly when dealing with long or unevenly shaped loads.

- Improved Load Control: The dual hoist system provides better control of the load, preventing dangerous swings or jerks that can occur when lifting very heavy or large items.

- Safety Systems: Integrated safety features, such as limit switches and overload sensors, help ensure that the load remains secure during the entire lifting process.

These safety features make tandem lifting a reliable choice for handling hazardous or delicate materials.

Increased Efficiency: Faster Handling of Long and Heavy Loads with Precise Control

Tandem lifting significantly increases operational efficiency by allowing for faster and more precise handling of long and heavy loads. With two hoists working together, the lifting and movement of bulky materials become quicker and more coordinated, reducing downtime and improving productivity.

- Faster Handling: By lifting heavy loads simultaneously, tandem lifting reduces the time needed to move large materials from one location to another, making the process faster than using a single hoist.

- Precise Control: The synchronized operation of the hoists ensures that the load is handled with precision, allowing for smoother and more accurate positioning of the load, especially in tight or complex spaces.

- Streamlined Operations: Tandem lifting allows for more efficient work processes by minimizing the need for multiple setups or re-positioning of loads.

This increased efficiency translates into higher throughput and more effective use of crane resources, particularly in industries that require high-volume lifting, such as steel manufacturing and shipbuilding.

Design and Construction Considerations

Structural Integrity: Importance of Robust Design for Supporting Heavy and Long Loads

The design and construction of the MHE type electric hoist goliath gantry crane must prioritize structural integrity to safely support and handle heavy and long loads. Given the demanding nature of lifting tasks, particularly in industries like steel, construction, and shipbuilding, the crane's framework must be designed to withstand significant forces without compromising stability.

- Strong Frame Construction: The crane's main frame, including the beams and girders, must be robust enough to handle the combined weight of the load and the crane components. This ensures that the crane remains stable even under maximum lifting capacity.

- Reinforced Support Structures: Structural supports, such as bracing and foundations, are crucial for maintaining balance and preventing deformation or failure during operation.

- Stress Distribution: Proper design ensures that weight is evenly distributed across the crane's structure, reducing localized stress that could lead to structural weaknesses or failures.

This structural integrity ensures safe operation, even when lifting extremely heavy or large materials, and provides long-term reliability in harsh industrial environments.

Materials Used: Durability and Anti-Corrosion Materials Used in Crane Construction

Durability is a key factor in crane design, particularly in environments where heavy lifting is frequent and challenging. The MHE type gantry crane is constructed with high-quality materials to ensure long-term performance and resistance to wear and tear.

- High-Strength Steel: The main structural components of the crane are made from high-strength steel, which provides the necessary strength and durability to support heavy loads.

- Anti-Corrosion Coatings: For cranes used in corrosive environments such as ports, shipyards, or coastal areas, the crane frame is often coated with anti-corrosion treatments or materials like galvanization. This prevents rust and extends the crane's operational lifespan.

- Weather-Resistant Materials: To handle the elements, materials are selected for their resistance to temperature extremes, moisture, and other environmental factors. This ensures the crane remains functional under varying weather conditions.

By using these durable, corrosion-resistant materials, the crane's operational life is extended, reducing maintenance and downtime costs over time.

Customization Options: Tailoring Span, Lifting Height, and Other Parameters Based on Project Needs

The MHE type electric hoist goliath gantry crane offers a range of customization options to ensure it meets the specific needs of different projects. Each industrial operation may require different span lengths, lifting heights, and other specifications, which can be tailored to the application.

- Customizable Span: The span of the crane, or the distance between its supports, can be adjusted to fit the layout of the facility or the requirements of the specific load. Whether handling long beams or large containers, the crane can be configured for optimal reach.

- Adjustable Lifting Height: Lifting height can be modified based on the clearance required for lifting materials at varying heights, allowing for maximum flexibility in handling different load sizes and working environments.

- Adaptable Load Capacity: The crane's lifting capacity can be adjusted with dual hoists, ensuring that the crane can handle a variety of weights and sizes without the need for additional equipment.

- Other Parameters: Factors such as lifting speed, hoist type, and operational controls can be customized to align with specific operational needs and improve overall efficiency.

These customization options ensure that the crane is perfectly suited to the unique requirements of the industry or project it is used for.

Integration with Other Equipment: How MHE Type Cranes Integrate with Other Lifting or Transport Systems in the Facility

The MHE type electric hoist goliath gantry crane is designed to seamlessly integrate with other equipment and systems in the facility to enhance workflow and operational efficiency. This integration is vital for industries where multiple lifting and transport systems are used simultaneously.

- Integration with Overhead Cranes: The MHE gantry crane can work in conjunction with overhead cranes, allowing for coordinated lifting and transport of materials across the facility. This collaboration streamlines operations and optimizes space utilization.

- Automation Systems: In modern facilities, the crane can be connected to automated transport systems, such as conveyors or automated guided vehicles (AGVs). This integration enables the crane to load and unload materials directly into transport systems, speeding up the material handling process.

- Control Systems: The crane's control systems can be integrated with facility-wide operations management systems, allowing for centralized control and monitoring. This integration improves real-time decision-making, troubleshooting, and system optimization.

By integrating with other lifting or transport equipment, the MHE gantry crane enhances productivity, reduces handling time, and ensures smooth, efficient operations throughout the facility.

Maintenance and Operational Tips

Routine Maintenance: Regular Checks for Hoists, Trolleys, and Crane Structure

To ensure that the MHE type electric hoist goliath gantry crane remains in optimal working condition, regular maintenance is essential. Routine checks help identify potential issues early, reducing the likelihood of costly repairs and downtime.

- Hoist and Trolley Maintenance: Regularly inspect the hoists and trolleys for signs of wear, such as excessive noise, friction, or misalignment. Ensure the lifting mechanism is operating smoothly and that cables or chains are free of kinks or damage.

- Lubrication: Apply lubrication to moving parts, such as wheels, bearings, and gears, to reduce friction and prevent wear. This helps extend the lifespan of crane components and ensures smooth operation.

- Structural Inspections: Periodically inspect the crane's frame, beams, and support structures for signs of cracks, corrosion, or other damage. Ensure that bolts and joints are tightened and free of rust to maintain structural integrity.

- Load Tests: Perform load testing as part of routine maintenance to verify the crane's lifting capacity and ensure all safety features are functioning as expected. This can help detect any hidden issues that could impact the crane's performance.

Routine maintenance, including these checks, ensures that the crane operates safely and efficiently, minimizing downtime and improving the overall lifespan of the equipment.

Safety Inspections: Ensuring Compliance with Safety Regulations for Heavy Load Lifting

Safety is paramount when using heavy lifting equipment, and conducting safety inspections is a crucial part of maintaining the MHE type electric hoist goliath gantry crane. These inspections help ensure that the crane complies with all relevant safety regulations and minimizes risks during operation.

- Load Handling Safety: Check that the crane is capable of handling the maximum rated load without strain or instability. Inspect the lifting mechanisms, such as the hoists and hooks, to ensure they are secure and properly calibrated for heavy load lifting.

- Control Systems: Test all safety features, including emergency stop buttons, overload protection, and limit switches. Make sure that all control systems, whether manual or automated, are functioning correctly and are easily accessible for the operator.

- Safety Features Check: Verify the operation of safety features like anti-sway systems, brakes, and warning signals. Ensure that the crane has proper signage indicating weight limits and operational hazards.

- Compliance with Standards: Ensure that the crane meets industry safety standards, including those set by organizations such as OSHA (Occupational Safety and Health Administration) or the European Union (EU) regulations. This includes compliance with lifting guidelines and crane operation safety protocols.

By performing regular safety inspections, you can ensure that the crane meets the highest safety standards, reducing the risk of accidents or injuries while maintaining compliance with industry regulations.

Troubleshooting Common Issues: Common Operational Issues and How to Address Them for Optimal Crane Performance

Despite routine maintenance and safety inspections, operational issues may occasionally arise. Identifying and addressing these problems promptly helps keep the crane running efficiently and reduces unplanned downtime.

- Unusual Noises: If the crane starts making grinding, squealing, or rattling noises, it may indicate problems with the hoist motor, trolley, or other moving parts. Inspect the motor for any debris, check the lubrication, and ensure all parts are aligned and free of obstructions.

- Slow or Uneven Movement: If the crane is operating slower than usual or if the movement is jerky or uneven, it may suggest issues with the trolley's movement or the hoist mechanism. Check the drive systems and motors for wear, and ensure the tracks or rails are clear of obstructions and properly aligned.

- Electrical Failures: Issues with the electrical system, such as inconsistent power supply, can cause the crane to malfunction. Check the power supply and connections to ensure there are no loose wires, electrical shorts, or blown fuses. Inspect the control panel and switchgear to ensure they are functioning properly.

- Overload Warnings: If the crane shows overload warnings or fails to lift the designated load, inspect the load sensors, overload protection system, and lifting components for damage or malfunction. Make sure the load is within the crane's rated capacity and adjust accordingly.

Addressing these common issues early helps maintain crane performance and reduces the chances of more severe damage. Regular troubleshooting ensures that the MHE type electric hoist goliath gantry crane operates at its full capacity with minimal disruptions.

Conclusion

The MHE type electric hoist goliath gantry crane is engineered for handling heavy and long loads with efficiency. With its dual hoist system, the crane ensures stable and reliable operation, even in challenging environments. Its lifting mechanisms are designed to provide flexibility across various industries, making it a versatile choice for operations that require both strength and precision.

The Role of Double Electric Hoist in Tandem Lifting

The double electric hoist feature is critical for the crane's ability to lift large and heavy loads efficiently. By using two hoists in tandem, the crane ensures:

- Even Load Distribution: The weight is evenly spread across both hoists, minimizing strain on the crane.

- Improved Stability: Tandem lifting helps reduce the risk of load sway, providing better control and safety.

This capability is essential for industries like construction, aerospace, and steel manufacturing, where lifting heavy and oversized materials is routine.

Why This Crane Model is Reliable and Versatile

The MHE type crane is highly adaptable to different industrial needs, offering:

- Customizable Features: The span and lifting height can be adjusted to meet specific requirements, allowing for greater flexibility in different environments.

- Proven Reliability: It is built to handle demanding lifting tasks, ensuring long-term durability and consistent performance.

- Versatility Across Industries: Whether used for steel manufacturing, heavy machinery, or large-scale construction projects, this crane offers the versatility to handle various types of loads efficiently and safely.

In conclusion, the MHE type electric hoist goliath gantry crane provides a reliable, safe, and versatile solution for industries that require heavy lifting capabilities. Its tandem lifting system enhances performance by improving stability and safety, making it an essential tool in modern industrial operations.

To get a customized single girder electric hoist goliath gantry crane with a double electric hoist, the main parameters required are:

Load Capacity

- Specify the total lifting capacity (e.g., 10 tons, 20 tons, 50 tons) or each hoist's individual capacity (e.g., 5 tons per hoist for a 10-ton total capacity).

- Consider the weight of the loads to be lifted and the need for tandem lifting with double hoists.

Span (Width of the Crane)

- The span refers to the distance between the crane's two supporting legs (or rails) which will affect the coverage area of the crane.

- Determine the appropriate span to match your workspace or facility dimensions (e.g., 12m, 21m).

Lifting Height

- Specify the lifting height from the ground to the highest point the crane needs to lift the load.

- This includes the height from the floor to the hook of the hoist and any additional clearance required in your facility (e.g., 6m, 12m).

Operating Speed

- Lifting speed: Speed at which the hoist can raise or lower the load (e.g., 7 m/min).

- Traveling speed: Speed at which the trolley and crane move along the rails (e.g., 20 m/min for the trolley, 30 m/min for the crane).

- Determine if you require variable speed control for precise movement.

Power Supply: Specify the power requirements (typically three-phase AC power) such as: Voltage (e.g., 380V, 415V, etc.)Frequency (e.g., 50Hz, 60Hz)Phase (e.g., 3-phase)

Hoist ConfigurationDouble Electric Hoist: Define if you need two separate hoists for tandem lifting, or if one hoist will handle the entire load.Specify if the hoists need to operate independently or in synchronized mode for tandem lifting.

Crane TypeSingle girder design: Confirm the need for a single girder configuration, where the hoist is mounted on a single beam (rather than a double girder design).The single girder design is typically used for lighter to medium-duty lifting but can still be customized for heavy-duty loads depending on the crane capacity and materials.

Environmental Conditions

Determine if the crane will be used in special environments such as:

- Outdoor or indoor use: Impacting factors like weatherproofing or corrosion resistance.

- Temperature extremes: Need for special coatings or materials.

- Explosion-proof requirements: If the crane will be used in hazardous areas (e.g., chemical plants).

Control System. Specify the type of control: Wireless control: For increased mobility and flexibility. or your special requirement ?

Safety Features: Safety features like overload protection, limit switches, emergency stop buttons, and brake systems should be considered based on your specific lifting needs and the environment.

Customization Options

- Customization of the hoist configuration, for example, adding adjustable lifting heights, trolley-mounted hoists, or specific hoist types (e.g., wire rope or chain hoists).

- Design for special lifting tasks, such as tandem lifting systems for larger or more delicate loads.

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch