Single Girder Semi Goliath Crane 1 Ton, 2 Ton, 3 Ton, 5 Ton, 10 Ton

Single Girder Semi Goliath Cranes provide efficient, versatile lifting for indoor and outdoor applications with partial rail-mounted support. Design for you!

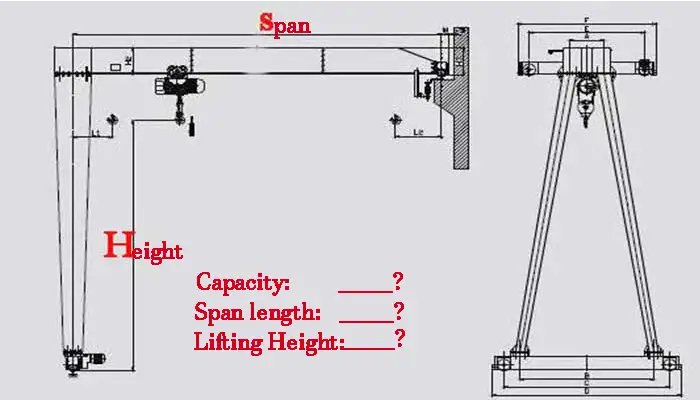

| Semi Goliath Crane | Single girder semi gantry crane |

| Crane capacity | 1 ton to 16 ton |

| Lifting height | As your request |

| Note | Customized semi goliath crane with singlle girder design are available. |

Category: Single Girder Goliath Crane

Your Trusted Semi Goliath Crane Manufacturer & Supplier

Single Girder Semi Goliath Cranes 1 Ton, 2 Ton, 3 Ton, 5 Ton, 10 Ton

Single Girder Semi Goliath Cranes provide efficient, versatile lifting for indoor and outdoor applications with partial rail-mounted support

2 ton semi gantry crane for sale

2 ton semi gantry crane for saleSingle girder semi goliath cranes, also known as half gantry cranes, are a type of overhead crane characterized by their asymmetric design. These cranes are supported by a single end truck that travels along a runway beam, while the opposite end is supported by a leg or column on the ground. This configuration allows the crane to operate efficiently in areas where one side of the workspace is accessible and the other side requires support from the ground.

The primary distinction between full gantry and semi gantry cranes lies in their structural support. Full gantry cranes are entirely supported by legs or columns on both sides of the runway, providing symmetrical lifting capabilities across the entire span. In contrast, semi goliath cranes are supported by a combination of an end truck on one side and a ground-mounted leg or column on the opposite side. This asymmetrical design allows for greater flexibility in deployment, especially in environments where space or access is limited.

Industries and Applications Where Single Girder Semi Goliath Cranes Are Commonly Used

Single girder semi goliath cranes find wide application across various industries and environments, including:

- Manufacturing and Assembly: Used in production facilities to lift and move materials and components during assembly processes. They are particularly useful in workshops where overhead clearance may be limited.

- Warehousing and Logistics: Employed in warehouses for loading and unloading cargo from trucks and containers. Their mobility and moderate lifting capacity make them suitable for handling goods in storage yards with limited space.

- Construction Sites: Ideal for outdoor construction projects where the crane can be positioned alongside a building or structure to facilitate material handling, equipment installation, and assembly tasks.

- Maintenance Depots: Utilized in maintenance facilities to lift and maneuver heavy machinery and components for repair and servicing operations.

Single girder semi goliath cranes are valued for their versatility, operational flexibility, and cost-effectiveness in environments where the full infrastructure of a double girder or full gantry crane may not be necessary or feasible. Their ability to combine the benefits of an overhead crane with ground-level support makes them a practical choice in various industrial applications.

Design and Structure

Explanation of the Single Girder Configuration

Single girder semi goliath cranes feature a single beam or girder that spans the length of the crane's operational area. This girder is typically supported by an end carriage on one side, which travels along a runway beam or rail mounted on the ground. The opposite end of the girder is supported by a leg or column firmly anchored to the ground, providing stability and support for lifting operations.

Components:

- Main Girder: The main girder forms the backbone of the crane structure, supporting the hoisting mechanism and facilitating the movement of loads along its length. It is designed to withstand the specified load capacity and operational stresses.

- End Carriages: End carriages are mounted on wheels or tracks and support the main girder while allowing it to travel along the ground-mounted runway beam. They typically house the drive motors and gearing mechanisms necessary for horizontal movement.

- Hoisting Mechanism: Single girder semi goliath cranes are equipped with a hoisting mechanism that lifts and lowers loads. This mechanism can be a wire rope hoist or a chain hoist, depending on the crane's capacity and application requirements. It is mounted on the main girder and controlled via pendant or remote controls.

- Trolley System (Optional): Some single girder semi goliath cranes may feature a trolley system mounted on the main girder. The trolley allows for lateral movement of the hoisting mechanism along the length of the girder, expanding the crane's operational flexibility and range.

- Electrical Components and Controls: Electrical components include motors for drive and hoisting operations, as well as control systems for precise maneuvering and load handling. These components are integrated into the crane's structure to ensure safe and efficient operation. Control panels, pendant stations, and remote control systems enable operators to manage crane movements and load handling operations effectively.

Single girder semi goliath cranes are designed to optimize space utilization while providing reliable lifting and maneuvering capabilities. The configuration and components of these cranes are tailored to meet specific operational needs, from light to moderate lifting applications across various industrial sectors.

Types of Single Girder Semi Goalith Gantry Cranes

Indoor Single Girder Semi Goliath Cranes

Outdoor Single Girder Semi Goliath Cranes

Indoor Single Girder Semi Goliath Cranes

These are designed for use inside facilities such as factories and warehouses. They usually have one side running on a rail mounted on the ground while the other side runs on an elevated rail or a wall-mounted track.

Design and Construction:

- Rail Configuration: One side of the crane runs on a rail mounted on the ground, while the other side runs on an elevated rail or a wall-mounted track. This design maximizes the use of vertical space and ensures efficient load handling within confined indoor environments.

- Single Girder: The single girder supports the hoist and trolley, providing a streamlined and efficient lifting mechanism. The girder is typically made of high-strength steel to ensure durability and longevity.

- Compact Design: Designed to fit within the spatial constraints of indoor facilities, these cranes have a compact footprint, making them ideal for use in factories and warehouses.

- Electric Hoist: Equipped with an electric hoist for smooth, precise lifting operations. The hoist is controlled via a pendant or remote control for ease of use and safety.

- Customization: Can be tailored to specific height, span, and load capacity requirements, ensuring they meet the unique needs of different indoor applications.

Typical Applications:

- Factories: Used for transporting raw materials, components, and finished products within manufacturing facilities. They are essential for assembly lines, production processes, and material storage.

- Warehouses: Ideal for loading and unloading goods, organizing inventory, and managing storage operations. They improve efficiency by enabling quick and precise material handling.

- Maintenance Workshops: Used for lifting and moving heavy machinery and components during maintenance and repair operations. They enhance safety and efficiency by reducing manual handling.

- Assembly Lines: Integral to the movement and positioning of parts and materials along production lines, ensuring a smooth and continuous workflow.

Outdoor Single Girder Semi Goliath Cranes

These cranes are used in outdoor environments like storage yards, construction sites, and shipyards. They are built to withstand weather conditions and typically have robust construction for heavy-duty operations.

Design and Construction:

- Rail Configuration: Similar to indoor cranes, these have one side running on a ground rail and the other on an elevated rail or wall-mounted track. However, they are built to withstand outdoor conditions.

- Weather Resistance: Constructed with materials and finishes that resist corrosion, rust, and other weather-related wear and tear. This ensures long-term durability and reliable performance in various environmental conditions.

- Robust Construction: Designed for heavy-duty operations, these cranes feature reinforced structures to handle large and heavy loads. The robust design ensures stability and safety during operation.

- Electric Hoist: Equipped with an electric hoist, often with additional weatherproofing and protective features to ensure reliable performance in outdoor environments.

- Customization: Can be adapted to specific site requirements, including height, span, and load capacity, to suit various outdoor applications.

Typical Applications:

- Storage Yards: Used for moving and organizing heavy materials, such as steel beams, containers, and other large items. They enhance operational efficiency by enabling quick and precise handling.

- Construction Sites: Essential for lifting and placing construction materials, such as steel structures, concrete components, and heavy equipment. They improve productivity and safety by reducing manual lifting and transport.

- Shipyards: Used for handling ship components, cargo, and other heavy items. They facilitate efficient loading and unloading operations, contributing to smoother logistics processes.

- Logistics and Freight Terminals: Integral to the movement and storage of goods in freight yards and logistics centers. They enable efficient loading, unloading, and organization of cargo.

Both indoor and outdoor Single Girder Semi Goliath Cranes offer versatile and efficient material handling solutions tailored to their respective environments. Indoor cranes focus on maximizing space efficiency and providing precise lifting within confined spaces, while outdoor cranes are built to withstand harsh weather conditions and handle heavy-duty operations. Customization options ensure that these cranes can be adapted to meet specific operational requirements, enhancing productivity and safety across various industries.

Comparison: Indoor vs. Outdoor Single Girder Semi Goliath Cranes

Design and Construction:

- Indoor Single Girder Semi Goliath Cranes: Compact design for confined spaces; suitable for factories and warehouses.

- Outdoor Single Girder Semi Goliath Cranes: Robust construction to withstand harsh weather; suitable for outdoor environments.

Rail Configuration:

- Indoor Single Girder Semi Goliath Cranes: One side on a ground rail, the other on an elevated rail or wall-mounted track.

- Outdoor Single Girder Semi Goliath Cranes: Similar rail configuration, with additional weatherproofing for outdoor use.

Material and Finish:

- Indoor Single Girder Semi Goliath Cranes: Standard industrial-grade materials.

- Outdoor Single Girder Semi Goliath Cranes: Corrosion-resistant, weatherproof materials to prevent rust and degradation.

Electric Hoist:

- Indoor Single Girder Semi Goliath Cranes: Electric hoist designed for precise lifting in controlled indoor environments.

- Outdoor Single Girder Semi Goliath Cranes: Electric hoist with weatherproof features for reliable performance outdoors.

Customization:

- Indoor Single Girder Semi Goliath Cranes: Customizable height, span, and load capacity for various indoor applications.

- Outdoor Single Girder Semi Goliath Cranes: Customizable for specific site requirements, including height, span, and load capacity.

Durability:

- Indoor Single Girder Semi Goliath Cranes: Durable construction with high-quality steel.

- Outdoor Single Girder Semi Goliath Cranes: Reinforced for heavy-duty operations and outdoor durability.

Environmental Resistance:

- Indoor Single Girder Semi Goliath Cranes: Designed for controlled indoor environments.

- Outdoor Single Girder Semi Goliath Cranes: Built to resist weather conditions, including rain, wind, and temperature fluctuations.

Space Requirements:

- Indoor Single Girder Semi Goliath Cranes: Designed to maximize vertical space and fit within confined indoor spaces.

- Outdoor Single Girder Semi Goliath Cranes: Requires adequate outdoor space, with design focusing on stability and robustness.

Typical Applications:

- Indoor Single Girder Semi Goliath Cranes: Factories, warehouses, maintenance workshops, assembly lines.

- Outdoor Single Girder Semi Goliath Cranes: Storage yards, construction sites, shipyards, logistics and freight terminals.

Operational Efficiency:

- Indoor Single Girder Semi Goliath Cranes: Enhances indoor operational efficiency by enabling quick and precise material handling.

- Outdoor Single Girder Semi Goliath Cranes: Improves outdoor operational efficiency by facilitating heavy-duty lifting and transport.

Portability:

- Indoor Single Girder Semi Goliath Cranes: Generally less portable due to indoor fixed installations.

- Outdoor Single Girder Semi Goliath Cranes: More portable and flexible within outdoor settings, but typically installed permanently.

Cost:

- Indoor Single Girder Semi Goliath Cranes: Potentially lower due to standard indoor construction requirements.

- Outdoor Single Girder Semi Goliath Cranes: Potentially higher due to the need for weatherproof materials and robust design.

All in all, the pros an cons of indoor and outdoor semi goliath cranes are as following

Indoor Single Girder Semi Goliath Cranes:

- Pros: Compact design, efficient use of vertical space, ideal for controlled environments, typically lower cost.

- Cons: Less robust against environmental conditions, generally less portable.

Outdoor Single Girder Semi Goliath Cranes:

- Pros: Built to withstand harsh weather, robust construction for heavy-duty use, flexible within outdoor settings.

- Cons: Requires more space, potentially higher cost due to weatherproofing and reinforced materials.

Both types of cranes are essential for their respective environments, providing tailored solutions to meet the specific needs of indoor and outdoor material handling operations.

Single Girder Semi Goliath Crane with A-Frame Gantry Design

Single Girder Semi Goliath Crane with L-Frame Gantry Design

Single Girder Semi Goliath Crane with A-Frame Gantry Design

Typical Features:

- A-Frame Legs: The A-frame design offers stability and strength, with legs forming an 'A' shape to provide a wide base for load distribution.

- Single Girder: The single girder supports the hoist and trolley, allowing for efficient material handling.

- Half-Gantry Configuration: One side of the crane runs on a ground rail while the other side runs on an elevated rail or wall-mounted track.

- Adjustable Height and Span: Can be customized to fit specific operational requirements and space constraints.

- Durable Construction: Made with high-quality steel to ensure longevity and resistance to wear and tear.

- Electric Hoist: Equipped with an electric hoist for smooth and precise lifting operations.

- Safety Features: Includes emergency stop buttons, overload protection, and limit switches for safe operation.

Typical Applications:

- Warehouses: Ideal for indoor material handling where stability and strength are essential.

- Manufacturing Plants: Used for transporting raw materials and finished products efficiently.

- Construction Sites: Suitable for lifting and moving heavy materials within confined spaces.

- Maintenance Workshops: Used for repairing and assembling heavy machinery and components.

Single Girder Semi Goliath Crane with L-Frame Gantry Design

Typical Features:

- L-Frame Legs: The L-frame design offers a compact footprint and efficient use of space, with legs forming an 'L' shape for optimal load support.

- Single Girder: The single girder supports the hoist and trolley, facilitating efficient material handling.

- Half-Gantry Configuration: One side of the crane runs on a ground rail while the other side runs on an elevated rail or wall-mounted track.

- Compact Design: The L-frame design is suitable for areas with limited space, providing maximum lifting capacity without taking up much room.

- Electric Hoist: Equipped with an electric hoist for smooth and precise lifting operations.

- Customizable: Can be tailored to fit specific height, span, and load capacity requirements.

- Safety Features: Includes emergency stop buttons, overload protection, and limit switches for safe operation.

Typical Applications:

- Indoor Facilities: Perfect for warehouses, workshops, and production lines with space constraints.

- Material Handling: Used in logistics and storage facilities for efficient loading and unloading of materials.

- Small-Scale Manufacturing: Ideal for small factories and assembly lines where space and efficiency are crucial.

- Automotive Industry: Used for handling components and parts during assembly and maintenance operations.

Both types of Single Girder Semi Goliath Cranes offer versatility and efficiency in material handling, with specific designs tailored to meet various operational needs and space constraints.

Comparison: Single Girder Semi Goliath Crane with A-Frame Gantry Design vs. Single Girder Semi Goliath Crane with L-Frame Gantry Design

Leg Design:

- A-Frame Gantry Design: A-shaped legs provide a wide base for load distribution, enhancing stability and strength.

- L-Frame Gantry Design: L-shaped legs offer a compact footprint, optimizing space usage while maintaining load support.

Typical Applications:

- A-Frame Gantry Design: Warehouses, manufacturing plants, construction sites, maintenance workshops.

- L-Frame Gantry Design: Indoor facilities with space constraints, material handling, small-scale manufacturing, automotive industry.

Stability:

- A-Frame Gantry Design: High stability due to the wider base, suitable for heavy-duty applications.

- L-Frame Gantry Design: Sufficient stability with a more compact design, ideal for confined spaces and lighter loads.

Space Requirements:

- A-Frame Gantry Design: Requires more floor space due to the wide base of the A-frame legs.

- L-Frame Gantry Design: Requires less floor space, making it suitable for areas with limited space.

Customizability:

- A-Frame Gantry Design: Adjustable height and span, suitable for various operational requirements.

- L-Frame Gantry Design: Highly customizable for height, span, and load capacity to fit specific needs.

Durability:

- A-Frame Gantry Design: Durable construction with high-quality steel, resistant to wear and tear.

- L-Frame Gantry Design: Also durable, with a focus on efficient use of materials and space.

Lifting Mechanism:

- A-Frame Gantry Design: Electric hoist for smooth and precise lifting operations.

- L-Frame Gantry Design: Electric hoist for smooth and precise lifting operations.

Safety Features:

- A-Frame Gantry Design: Includes emergency stop buttons, overload protection, and limit switches.

- L-Frame Gantry Design: Includes emergency stop buttons, overload protection, and limit switches.

Portability:

- A-Frame Gantry Design: Less portable due to the larger footprint.

- L-Frame Gantry Design: More portable and easier to relocate within a workspace.

Cost:

- A-Frame Gantry Design: Potentially higher due to the larger structure and materials used.

- L-Frame Gantry Design: Potentially lower due to the compact design and efficient material use.

All in all, the pros an cons of A Frame and L Frame semi goliath cranes are as following

A-Frame Gantry Design:

- Pros: Higher stability, ideal for heavy-duty applications, wide base for load distribution.

- Cons: Requires more floor space, potentially higher cost.

L-Frame Gantry Design:

- Pros: Compact footprint, suitable for confined spaces, more portable, potentially lower cost.

- Cons: Slightly less stability compared to A-frame, better for lighter loads and applications with space constraints.

Both designs offer unique advantages and are suitable for different applications based on specific operational needs and spatial constraints. The choice between an A-frame or L-frame gantry design should be guided by the particular requirements of the workspace and the nature of the material handling tasks.

Advantages of Single Girder Semi Goliath Cranes

- Lower Overall Height Compared to Double Girder Cranes:Single girder semi goliath cranes typically have a lower overall height compared to double girder cranes. This characteristic makes them suitable for facilities with limited vertical clearance or where overhead space is constrained. By minimizing height requirements, these cranes can operate effectively in workshops, warehouses, and manufacturing plants without extensive modifications to existing structures.

- Cost-Effective Solution for Moderate Lifting Capacities:One of the primary advantages of single girder semi goliath cranes is their cost-effectiveness, especially for applications requiring moderate lifting capacities. Compared to double girder cranes, which may involve higher initial costs due to additional structural components and increased load-bearing capacity, single girder cranes offer a more economical alternative. They provide adequate lifting capabilities for handling materials and components without exceeding operational requirements or budget constraints.

- Flexibility in Handling Loads Along a Defined Path:Single girder semi goliath cranes offer flexibility in handling loads along a defined path within their operational area. The combination of a ground-mounted leg or column and an end carriage traveling along a runway beam allows these cranes to maneuver efficiently in designated work zones. This capability is advantageous in environments where precise load positioning and movement are essential, such as assembly lines, maintenance depots, and construction sites.

Overall, single girder semi goliath cranes are valued for their compact design, cost efficiency, and operational flexibility in various industrial settings. They provide a reliable solution for lifting and transporting materials while optimizing space utilization and minimizing overhead costs associated with crane installation and maintenance.

Typical Applications

Industry-Specific Uses:

- Small to Medium-Sized Manufacturing Facilities: Single girder semi goliath cranes are well-suited for manufacturing environments where space is at a premium. They facilitate efficient material handling during production processes, such as moving raw materials, work-in-progress, and finished goods within the facility.

- Workshops and Maintenance Depots: These cranes play a crucial role in workshops and maintenance depots by assisting in the assembly, repair, and maintenance of machinery and equipment. Their maneuverability and moderate lifting capacity make them ideal for lifting heavy components and tools safely and efficiently.

- Outdoor Construction Sites with Limited Space: In outdoor construction sites where space constraints limit the use of full gantry cranes, single girder semi goliath cranes provide a practical solution. They can be positioned alongside buildings or structures to support construction activities, such as lifting construction materials, prefabricated components, and equipment installation.

Specific Tasks:

- Loading and Unloading Trucks and Trailers: Single girder semi goliath cranes are used for loading and unloading trucks and trailers in warehouses, distribution centers, and logistics hubs. They facilitate the efficient transfer of goods between vehicles and storage areas, optimizing logistics operations.

- Assembly and Maintenance of Machinery and Equipment: These cranes are instrumental in assembly lines and maintenance operations, where they help position heavy machinery and equipment for installation, adjustment, and repair. Their ability to handle precise load movements enhances productivity and operational efficiency.

- Handling Materials in Confined Spaces: Due to their compact design and flexibility, single girder semi goliath cranes are suitable for handling materials in confined spaces such as narrow aisles or congested work areas. They can navigate tight corners and maneuver around obstacles while maintaining safe and controlled load handling.

Single girder semi goliath cranes are versatile tools that support a wide range of industrial applications, from manufacturing and assembly to construction and maintenance tasks. Their ability to operate effectively in diverse environments makes them a preferred choice for facilities seeking reliable and efficient material handling solutions.

Key Features and Customization Options

Safety Features:

- Limit Switches: Limit switches are installed to prevent the crane from traveling beyond predetermined positions along the runway beam. They ensure safe operation by automatically halting crane movement when the end of the travel path is reached.

- Emergency Stop Systems: Emergency stop systems provide immediate shutdown of crane operations in critical situations. They are activated manually or automatically in response to emergencies, safeguarding personnel and preventing equipment damage.

- Overload Protection Devices: Overload protection devices monitor the load being lifted and intervene to prevent the crane from lifting weights beyond its rated capacity. These devices enhance safety by reducing the risk of structural damage and accidents due to overloading.

Environmental Considerations:

- Weatherproofing for Outdoor Use: Cranes intended for outdoor applications are equipped with weatherproofing measures to withstand exposure to elements such as rain, humidity, and extreme temperatures. This includes protective coatings, seals, and enclosures for critical components.

- Corrosion-Resistant Materials: Components exposed to corrosive environments, such as coastal areas or chemical processing plants, are constructed from corrosion-resistant materials. Stainless steel, galvanized steel, and specialized coatings extend the crane's lifespan and maintain operational reliability.

Customization Options:

- Span Length and Height Adjustments: Single girder semi goliath cranes can be customized to accommodate specific span lengths and heights to suit the operational requirements of the facility. This flexibility ensures optimal coverage and accessibility within the workspace.

- Integration with Existing Facility Infrastructure: Cranes can be integrated with existing infrastructure, such as overhead beams or support structures, to maximize space utilization and operational efficiency. Custom mounting options and structural adaptations facilitate seamless integration into diverse facility layouts.

- Choice of Hoisting Mechanisms and Control Systems: Operators can select from a range of hoisting mechanisms, including wire rope hoists or chain hoists, based on load capacity and operational preferences. Control systems, such as pendant controls or radio remote controls, offer flexibility in crane operation and enhance operator safety and convenience.

These key features and customization options enhance the versatility, safety, and performance of single girder semi goliath cranes in various industrial applications. By addressing specific safety requirements, environmental challenges, and operational needs, customized cranes optimize productivity and contribute to a safe and efficient working environment.

Maintenance and Service Considerations

Recommended Maintenance Intervals and Procedures:

- Scheduled Inspections: Regular inspections are crucial for ensuring the safe and efficient operation of single girder semi goliath cranes. Recommended intervals typically include daily visual checks by operators, weekly/monthly detailed inspections by trained personnel, and annual comprehensive inspections conducted by qualified service technicians.

- Routine Maintenance Tasks: Maintenance tasks should include:

- Checking and tightening fasteners and connections.

- Inspecting electrical components and wiring for signs of wear or damage.

- Lubricating moving parts, such as wheels, bearings, and hoisting mechanisms, according to manufacturer recommendations.

- Testing and calibrating safety devices and control systems.

- Verifying alignment and condition of runway beams and support structures.

Importance of Regular Inspections and Lubrication:

- Enhanced Safety and Reliability: Regular inspections identify potential issues before they escalate, reducing the risk of equipment failure and accidents. Lubrication of moving parts minimizes friction and wear, prolonging component lifespan and ensuring smooth crane operation.

- Compliance with Safety Standards: Adherence to recommended maintenance schedules and procedures helps maintain compliance with safety regulations and industry standards. It demonstrates a commitment to workplace safety and minimizes liability risks associated with equipment malfunction.

Availability of Spare Parts and Service Support:

- Access to Genuine Parts: Ensure availability of genuine spare parts that meet manufacturer specifications. This guarantees compatibility, performance, and reliability of replacement components.

- Responsive Service Support: Partnering with a reputable crane manufacturer or service provider ensures access to prompt technical support, troubleshooting assistance, and emergency repair services. Service agreements may include priority response times and scheduled maintenance visits to optimize crane performance and minimize downtime.

- Training and Certification: Operators and maintenance personnel should receive adequate training and certification to perform inspections, maintenance, and repairs safely and effectively. Training programs ensure proficiency in crane operation, maintenance practices, and compliance with regulatory requirements.

Effective maintenance and service practices maximize the operational lifespan and performance of single girder semi goliath cranes. By prioritizing regular inspections, proactive maintenance, and responsive service support, facilities can optimize crane reliability, safety, and productivity throughout their operational lifecycle.

Regulatory Standards and Compliance

- International Standards (e.g., ISO, CMAA):Single girder semi goliath cranes are designed and manufactured to comply with international standards set by organizations such as the International Organization for Standardization (ISO) and the Crane Manufacturers Association of America (CMAA). These standards establish guidelines for crane design, manufacturing, testing, and safety requirements to ensure reliability and performance consistency across global markets.

- Local Safety Regulations and Guidelines: Compliance with local safety regulations and guidelines is essential for the installation and operation of single girder semi goliath cranes. These regulations vary by region and may include requirements related to crane design, structural integrity, electrical safety, and operator training. Adhering to local standards helps mitigate risks, ensure workplace safety, and maintain legal compliance.

- Certification Requirements for Installation and Operation:Prior to installation and commissioning, single girder semi goliath cranes often require certification from regulatory authorities or third-party organizations. Certification verifies that the crane meets specified safety and performance criteria outlined in applicable standards. It typically involves thorough inspections, load testing, and documentation to confirm compliance with regulatory requirements and ensure safe operation within the intended environment.

Adhering to international and local regulatory standards is crucial for ensuring the safe and compliant operation of single girder semi goliath cranes in industrial settings. By staying updated on standards and certification requirements, facilities can uphold operational safety, mitigate risks, and maintain compliance with legal obligations.

What specific aspects of regulatory compliance are most critical for your current projects or applications involving overhead cranes?

Cost Considerations

Initial Investment Costs vs. Long-Term Operational Savings:

- Initial Investment Costs: The initial investment in a single girder semi goliath crane includes procurement, installation, and commissioning expenses. These costs depend on factors such as crane size, capacity, customization options, and local market conditions. Higher capacity cranes or specialized configurations may involve higher upfront expenditures.

- Long-Term Operational Savings: Despite initial costs, single girder semi goliath cranes offer potential long-term savings through improved operational efficiency and reduced labor costs. Efficient material handling, minimized downtime, and extended equipment lifespan contribute to overall operational savings over the crane's lifecycle.

Factors Influencing Costs:

- Size and Capacity of the Crane: The size and lifting capacity of the crane significantly influence costs. Larger cranes with higher load capacities require more robust structural components, increased power ratings, and specialized engineering, resulting in higher initial investments.

- Customization Requirements: Customization options such as span length adjustments, specific hoisting mechanisms, control systems, and environmental protections can impact costs. Tailoring the crane to meet unique operational needs may involve additional engineering and manufacturing expenses.

- Maintenance and Service Agreements: Budgeting for ongoing maintenance and service agreements is essential for optimizing crane performance and longevity. Costs associated with routine inspections, preventive maintenance, spare parts, and emergency repairs should be considered to ensure reliable operation and minimize unplanned downtime.

Cost-Benefit Analysis:

- Conducting a comprehensive cost-benefit analysis helps assess the economic feasibility of investing in a single girder semi goliath crane. Evaluating upfront costs against projected operational savings, productivity improvements, and safety enhancements provides clarity on the crane's return on investment (ROI) over time.

- ROI Calculation: Calculating ROI involves comparing total investment costs with anticipated savings and operational efficiencies achieved through the crane's utilization. Factors such as increased throughput, reduced labor requirements, and improved workplace safety contribute to ROI considerations.

Careful consideration of initial investment costs, ongoing operational expenses, and potential savings is essential for making informed decisions regarding the procurement and deployment of single girder semi goliath cranes. By balancing cost considerations with performance requirements and long-term benefits, facilities can optimize resource allocation and enhance operational efficiency effectively.

Case Studies and Projects for Your Reference

Applications in Different Industries:

- Manufacturing Industry: A single girder semi goliath crane is installed in a medium-sized manufacturing facility to facilitate the movement of raw materials and finished products across production lines. The crane's compact design and moderate lifting capacity optimize space utilization and streamline material handling processes, improving overall operational efficiency.

- Construction Sector: In outdoor construction sites with limited space, single girder semi goliath cranes support construction activities by lifting and positioning heavy construction materials, prefabricated components, and equipment. Their mobility and flexibility enable precise load handling, contributing to project timelines and operational productivity.

- Maintenance and Repair Workshops: Maintenance depots and repair workshops utilize single girder semi goliath cranes for lifting and maneuvering heavy machinery and equipment during maintenance and repair operations. The crane's ability to operate in confined spaces and its cost-effective solution for moderate lifting capacities enhance workshop efficiency and service delivery.

Success Stories and Operational Efficiencies Achieved:

- Improved Workflow Efficiency: Case studies demonstrate significant improvements in workflow efficiency and productivity achieved through the deployment of single girder semi goliath cranes. Enhanced material handling capabilities reduce turnaround times, minimize manual labor requirements, and optimize operational throughput.

- Cost Savings and ROI: Successful implementations highlight cost savings derived from reduced downtime, enhanced equipment utilization, and minimized operational disruptions. The ROI from investing in single girder semi goliath cranes is realized through long-term operational savings, improved safety compliance, and increased profitability.

Challenges Encountered and Solutions Implemented:

- Space Constraints: Challenges related to limited workspace availability are addressed through custom design solutions, including adjustable span lengths and compact crane configurations. Innovative engineering solutions optimize crane placement and operational flexibility without compromising performance or safety.

- Environmental Factors: Adverse environmental conditions, such as exposure to weather elements or corrosive atmospheres, necessitate the integration of weatherproofing measures and corrosion-resistant materials. Implementing protective coatings, seals, and robust maintenance practices mitigate environmental impacts and extend crane lifespan.

- Operational Safety: Ensuring compliance with stringent safety regulations and guidelines requires comprehensive training programs for crane operators and maintenance personnel. Safety enhancements, including advanced control systems, emergency stop mechanisms, and regular safety audits, minimize risks and promote a safe working environment.

Case studies and practical examples illustrate the diverse applications, operational efficiencies, and challenges addressed through the deployment of single girder semi goliath cranes across different industries. By leveraging these insights, organizations can make informed decisions regarding crane selection, customization, and operational strategies to optimize performance, enhance safety, and achieve sustainable business outcomes.

Conclusion

Single girder semi goliath cranes offer a versatile and cost-effective solution for material handling across various industries. Key benefits include:

- Compact Design: Suitable for facilities with limited overhead space or where full gantry cranes are impractical.

- Moderate Lifting Capacity: Efficiently handles loads within specified weight limits, enhancing operational efficiency without overinvestment.

- Flexibility: Maneuvers in confined spaces and navigates around obstacles, optimizing workflow and productivity.

- Cost Efficiency: Lower initial investment and maintenance costs compared to double girder cranes, with potential long-term savings through improved operational efficiency.

Future Trends in Semi Goliath Crane Technology

The future of semi goliath crane technology is evolving with advancements aimed at enhancing performance, safety, and sustainability:

- Smart Crane Technology: Integration of IoT (Internet of Things) for real-time monitoring, predictive maintenance, and remote operation.

- Automation and Robotics: Incorporation of automated features for precise load handling, autonomous operations, and increased productivity.

- Environmental Sustainability: Adoption of eco-friendly materials, energy-efficient components, and technologies to reduce environmental impact.

Final Considerations for Selecting and Implementing a Single Girder Semi Goliath Crane

When selecting and implementing a single girder semi goliath crane, consider the following factors:

- Operational Requirements: Assess specific lifting capacities, span lengths, and customization needs tailored to operational workflows and facility constraints.

- Safety and Compliance: Ensure compliance with international and local safety standards, prioritize operator training, and implement robust safety protocols.

- Lifecycle Cost Analysis: Conduct a comprehensive cost-benefit analysis to evaluate initial investment costs against projected operational savings and ROI over the crane's lifespan.

- Supplier and Support: Partner with a reputable crane manufacturer or supplier offering reliable service support, spare parts availability, and maintenance agreements to maximize crane performance and longevity.

Single girder semi goliath cranes continue to play a pivotal role in enhancing material handling efficiency and operational productivity across diverse industrial sectors. By embracing technological advancements and strategic planning, organizations can leverage these cranes to achieve sustainable growth, operational excellence, and competitive advantage in the evolving industrial landscape.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch