Gantry Crane PDF & Types of Gantry Crane Design PDF

Overviews of gantry cranes pdf, including types of gantry crane designs pdf, and types of gantry crane spcifications pdf for you to download to select the right type of gantry crane for your application. More information, please feel free to contact us. WhatsApp/ WeChat: + 86 151 3871 1597.

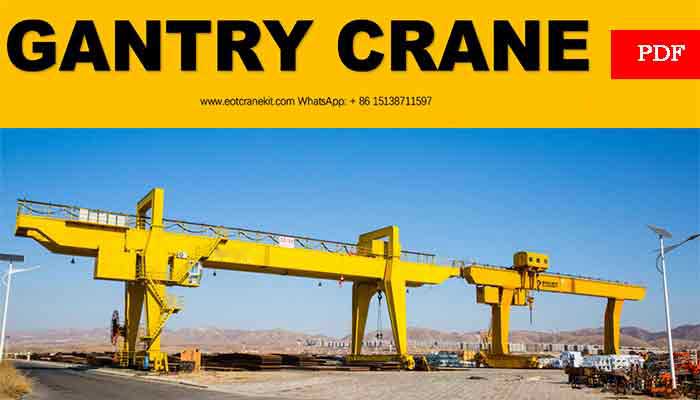

Overview of gantry crane

- Gantry crane concept- The structure of gantry crane is similar to a door frame, with legs under the main beam to support it, and it travels on rail with wheels on the ground. Cantilever is he extension of gantry span which enables the hoisting trolley runs beyond the legs of the beam.

- Application of gantry cranes- Storage, station, port, and other outdoor yards are examples of Gantry crane applications.

- Gantry crane loading capacity- Rated capacity from 1 to 900 tons

- Advantages of gantry cranes: high space utilization, vast range of operation, wide adaption, strong commonality, and are frequently employed in port yards.

- Gantry crane structure: Gantry cranes have its own legs and wheels, move on rails, and the rails are fixed to the ground.

Main crane specifications of standard gantry cranes

The main overhead crane specifications andparameters of the general use gantry cranes in terms of crane capacity, span, crane services duty and crane applications are presented for your reference. As for the process crane, please feel free to contact us directly to get your customized gantry cranes.

Main crane specifications and parameters of general use gantry cranes :

- Lifting capacity of gantry cranes : 5 ton-550 ton.

- Span of electric gantry cranes:3 to 35m,

- Lifting height of electric gantry cranes:Customized according to your applications,

- Working duty of electric gantry cranes: (A3, A4, A5, A6).

- Working ambient -25℃~+40℃, moisture ≤85%, altitude below 1000 meters,

- Power supply: 380V, 50Hz, 3phases, (Adjustable according to customer's different requirement).

Note:1. A5-Applied in working with not so much frequently, such as in the workshops of general machining and assembly or for maintaince .A6 -Applied in much more frequency work, such as auxiliary hoisting crane in metallurgy and casting workshop. A7-Applied in busy working and the hoisting of melted hot metal.

Non-standardgantry cranes with process crane designs are available for your specific applications.

Main types of gantry cranes

Gantry cranes can be grouped into various types based on different terms, can provide a complete range of gantry cranes, i.e. full gantry cranes, semi-gantry cranes and portable gantry cranes, including, single girder, double girder, single leg, double leg, and cantilever styles for indoor or outdoor service. The capacities, spans, heights can be customized. The main types of gantry cranes are presented for your reference.

- Single girder gantry crane - Single girder gantry crane is usually adopted box shaped gantry girder design with the features of simple structure easy manufacturing and installation, and light self-weight. Compared with double-girder gantry cranes, the overall stiffness of single girder gantry crane is weaker and usually used when the loads Q≤50 ton and the span S≤35m.

- Double girder gantry crane Double girder gantry cranes is the most frequently used structure design, with the features of strong bearing capacity, large span, good overall stability, and coming in many varieties, but the self-weight of the double girder gantry crane is larger and their processing cost is higher compared with single-girder gantry cranes .

- According to gantry girder design, double girder gantry cranes can be grouped into - box shaped girder design gantry crane and truss girder design gantry crane . At present, box-shaped girder design gantry crane is more frequently used.

- Box girder gantry crane -The box shaped gantry girder is welded with steel plates , with features of high safety, stiffness and other, etc. Box gantry girder design is usually used for gantry cranes with large and super large tonnages.The box gantry girder design also has the drawbacks of high production cost, heavy self weight and poor wind resistance.

- Truss gantry crane -The truss gantry girder is welded with angle steel or I-beam, featured as low manufacturing cost, light self-weight, and good wind resistance. However, due to the large amount of welding points and the inborn defects of the trusses structure, the truss gantry girder has the disadvantages of large deflection, low rigidity, low reliability, and frequent welding spots detection. Truss cranes are suitable for application with low requirements on safety and lifting capacity.

Single girder gantry crane

Single girder gantry crane specifications: Capacity: 1ton-20ton, Span Length: 8~30m, Working Class: A3, A4. Ask for single girder gantry crane price.

L leg single girder gantry crane

L types gantry crane specifications: Capacity 5ton -32ton, Span Length: 18~35m, Working Class: A5, A6.Ask for l leg single beam gantry crane price.

Truss girder gantry crane

Truss gantry crane specifications: Capacity: 1 ton -50 ton, Span Length: 12~35m, Working Class: A5, A6. Ask for truss gantry crane price.

Double girder gantry crane

Double girder gantry crane specifications: Capacity: 5 ton - 500 ton, Span Length: 12~35m, Working Class: A5, A6.Ask for double girder gantry crane price.

Semi gantry crane

Semi-gantry crane specifications: Capacity: 2 ton- 10 ton, Span Length: 8~20m, Working Class: A3, A4.Ask for semi-gantry crane price.

Portable gantry crane

Portable gantry crane specifications: Capacity:0.25 ton -10ton, Span length: 2~16m,Lifting height : 2~12m, Working class : A2.Ask for small gantry crane price.

Applications of gantry cranes

This gantry crane is working by traveling rails on the ground, mainly used in open-air storage yard, docks, power plants, ports and railway stations and other places for cargo handling and installation operations.

Gantry crane hoisting mechanism, trolley traveling mechanism and bridge construction, are basically same with bridge crane. Because of long span, gantry crane are usually used by respective driven way to prevent the crane producing skewed running and increasing the resistance, and even accidents.

It is mainly used for the loading and unloading operations of freight yards, yard goods, and bulk cargoes. Its metal structure is like a gantry frame, bearing two feet under the main beam, and can directly walk on the track of the ground. Both ends of the main beam can have an outrigger cantilever beam. The gantry crane has the characteristics of high site utilization rate, large operating range, wide adaptability and strong versatility and is widely used in the port cargo yard.