Mg Double Girder Gantry Crane with Box Girder Design

5 -500 ton gantry cranes with A frame gantry, double beam box girder & hook crane design for heavy lifting. Reliable box girder crane & hook crane for sale.

| Crane Type | Double girder gantry crane with open winch trolley |

| Crane capacity | 5-500ton |

| Crane span | 18-35m |

| Lifting height | 6-30m |

| Working class | A3, A4, A5, A6, A7, A8 |

Category: Gantry Crane

Your Trusted Gantry Crane Manufacturer & Supplier

Mg Double Girder Gantry Crane Box Girder Design

Double Beam Gantry Crane & Hook Crane Design for Heavy Lifting

MG double girder gantry crane is a typical A frame gantry crane, with double box girder design, equipped with single crane hook or double crane hooks for general material handling. The MG type A frame gantry crane is the most frequently used overhead travelling crane equipment for its high utilization, wide crane application, high adaptability and great versatility. The rated lifting capacity of the double girder gantry crane is from 5 tons to 500 tons.

Crane parameters of box girder double beam gantry crane

Due to the box girder design & double beam design, the A frame gantry crane is very strong and robust, which makes the hook gantry crane have almost unlimited capability of 5 ton to 500 ton and long crane span of 18-35 meters. And the main parameters and specifications of standard box girder double beam gantry crane are as following:

- Gantry crane type: MG A frame gantry crane, with double box girder & hook crane design

- Load capacity of double box girder gantry crane : 5-500ton , 20ton /5ton, 32ton /8ton, 40ton /10ton, 50ton /10ton, 75ton /20ton

- Span of double box girder gantry crane : 18-35m, 13m, 15m, 17m, 18m, 19m, 20m, 22m, 23m, 30m

- Lifting height of double box girder gantry crane : 6-30m, 6m, 9m, 12m, 16m, 24m, 30m

- Lifting speed of double box girder gantry crane : 1.5-11.5m/min

- Trolley running speed of double box girder gantry crane : 10-40.1m/min

- Crane running speed of double box girder gantry crane : 16-50m/min

- Work duty of double box girder gantry crane : A3, A4, A5, A6, A7, A8

Structure & components

The MG double girder gantry crane adopts box girder crane design, which includes a four sided box welded of steel plates, with the hoisting trolley mechanism running on rails attached on the top of both box girders, supported on the typical A frame leg, which has a side profile of "A" shape.

The MG box girder gantry crane is mainly consisted of upper main beam,end beam, trolley, crane travelling mechanism, electrical system, supporting legs, the lower end carriages, safety devices, and control system, like crane cabin, etc.In respect of crane cantilever design, the metal gantry structure can be processed with two cantilevers, one cantilever or no cantilever at the both end of main beam girder.

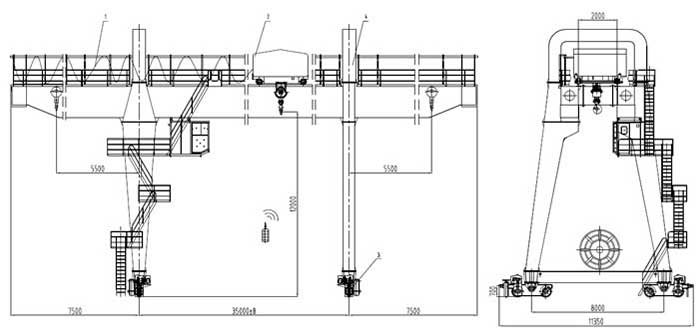

Box girder double beam gantry crane drawing

Features of double girder gantry crane design

- Gantry frame – Paired box girders supported on A frame legs, the most stable and reliable crane frame, which is consisted of upper main beam,end beam, trolley, crane travelling mechanism, electrical system, supporting legs, the lower end carriages, safety devices, and control system, and crane cabin, etc. The design of two cantilevers, one cantilever or no cantilever are selected based on application and requirements.

- Hoist trolley – The hoist trolley of the double girder crane consists of hoisting mechanism which lifts loads up and down rapidly and smoothly and a trolley which takes the hoist mechanism to move along the main girders horizontally .A hoisting mechanism of an overhead travelling crane is designed and determined largely by the rated loading capacity, crane duty, lifting height and speed and application conditions, etc. When the rated crane capacity is more than 10 tons, the double girder gantry crane is usually equipped with two sets of hoisting mechanisms,which includes, the main hook for the main lifting work,and the auxiliary hook.for lighter loads handling or auxiliary work to improve efficiency.

- Crane travelling mechanism – The MG double box girder gantry crane is a rail mounted A frame crane which is limited to move on rails, which can be designed to accommodate a variety of configurations. The steel wheels are adopted to support a substantial amount of weight.

- Electrical system – The cable reel, diesel generator or bare copper slip line are selected and adopted to power the double girder crane

- Control system –A permanent cabin control or remote crane control are offered for selection. .Both of the two types of crane controls has their own merits and demerits in terms of capacity, working environment, ease of use and safety.You can select either way to control the movement of the box girder crane or the combination of the two types.

Open winch trolley- Box girder gantry crane parts and components

Main girder- Box girder gantry crane parts and components

Gantry cabin - Box girder gantry crane parts and components

Siemens contol-unit- Box girder gantry crane parts and components

Benefits of Employing A Double Girder Gantry Crane

- Large capacity and high utilization- The A frame double girder crane has much larger capacity and covering larger working area than its counterpart in single girder crane design

- High efficiency and environment friendly- By adopting the powerful rail mounted A frame box girder crane, the heavy duty material handling will be effortless and convenient, which will improve your working efficiency and save your time. For be powered by electricity, they are much more friendly to environment.

- Reliable safety and durability - Paired box girders supported on strong A frame legs are the most stable and reliable crane structure and a number of safety devices are used to make sure the double girder gantry crane with high safety and stability,long working life and reliable performance.

- High versatility and custom design - The double girder gantry crane are available with various crane designs and configurations which offers a high flexibility in design to accommodate a wide range of working occasions. What's more, the custom design are available to meet the special requirements of clients.

Open winch gantry crane with double girder design and with no cantilever

Open winch gantry crane with box girder design and 2 cantilevers

Double Girder Gantry Crane Application

As a heavy duty crane solution, the A frame double girder gantry cranes have an extremely wide application both indoor and outdoor occasions due to its high utilization, wide crane application, high adaptability and great versatility.

- As a regular overhead travelling gantry crane, the box girder gantry crane is designed for moderate and heavy duty material handling , which is frequently used at open yard, ports, granite pit, cement pipe yard, open yard, container depots and shipyards,

- The double girder gantry cranes are also widely used indoor applications such as any workshop where a material handling solution is needed but a bridge overhead crane is not practical or a crane equipment is needed to work together with the existing overhead bridge crane, etc.

- However,the A frame box girder double beam crane is forbidden to handle melt metal, inflammable, or explosive loads or to be used in hazardous applications.

Metal Processing Industrial

Iron, steel, aluminum & basic metal processing industry cranes. Industry cranes for metal process- EAF charging & ladle crane, forging crane, finished product crane & scrap crane - for metallurgy harsh conditions, safe overhead travelling crane.

General Manufacturing

Types of industrial hoist & cranes for general manufacturing- Various types of industrial overhead crane systems for multiple sectors of manufacturing, integrated solution, maximum productivity, cost-effective price.

Mining Industry

Mining industry cranes, Coal mine crane systems - Safe industrial overhead crane & industrial gantry crane system for ore, limestone, coke, coal, slag, loose clay handling, explosion proof and durable.

Energy Industry

Energy generation|Industrial cranes for types of power plants - Industrial cranes & hoists systematic solutions for various power plants,i.e, traditional fuel power & waste renewable energy, wind power, hydroelectric, biomass energy, etc.

Machinery and Equipment

Industrial material handling cranes for mechanical engineering- Material handling cranes for mechanical engineering industry - overhead industrial crane solution for manufacturing of light & heavy machinery & equipment.

Pulp & Paper Industry

Pulp & paper| Industrial crane systems for paper making - Industrial overhead crane system for pulp & paper industry , full overhead travelling crane services, cost-effective paper making cranes for your paper mills.

Waste Management Industry

Waste management|Waste recycle & sorting industry cranes - Industrial overhead cranes for waste sorting&recycling. Types of industrial cranes in incinerator for mixing, stacking, handling and stirring of the waste materials, etc.

Wood , Timber & Furniture

Industrial cranes and hoists systems for timber & wood processing. Diverse overhead crane & hoists designs for material handling in sawmills or furniture plants, etc.

Shipbuilding & Boat Making

Industry crane systems for shipyard material handling, i.e, components assembly, boats & yachts lifting, etc. Reliable & safety industry crane system.

Plastic & Rubber

Industrial hoist and crane solution for plastic & rubber industry- Injection mould installation & Die exchanging- Efficient & Accurate heavy lifting systems.

Construction and Infrastructure

Industrial material lift for construction & infrastructure- types of industry overhead travelling cranes, gantry & hoist crane system- Reliable & cost-effective.

Chemical Industry

Industry cranes for chemical & petrochemical material handling, explosion proof overhead crane & hoist system for hazardous environment.

Automobile Industry

Automotive | Industrial overhead crane & hoist for automobile - Industrial cranes for automotive industry from press & assembly lines to workstations & warehouses, i.e., open winch crane & Light kbk, jib crane & chain hoists,etc.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch