Semi Gantry Crane- Semi Gantry Frame, Single / Double Gantry Girder Design up to 32 Ton

Semi gantry crane designs, single leg gantry cranes, save half gantry crane cost with existing workshop.Semi gantry cranes & semi goliath cranes for sale.

| Crane Type | Semi-gantry crane with Chinese traditional sytel |

| Crane Capacity | 1t to 16t, 5 ton -32 ton |

| Crane Span | 5m to 20m, 18m to 35m |

| Lifting Height | 6m to 12m |

| Working Class | A3, A4 |

Category: Gantry Crane

Your Trusted Semi Gantry Crane Manufacturer & Supplier

Semi Gantry Crane & Single Leg Gantry Crane

Single Girder / Double Girder Gantry Crane Design up to 32 Ton

Semi gantry crane is a variant of regular gantry crane with one end supported on a leg running on the ground rail and the other end travelling overhead on wall mounted track, therefore also called Single Leg Gantry Cranes. The single leg semi gantry cranes offers a cost-effective solution for factory or applications with narrow, confined spaces or crowded machinery.

Basics of Semi Gantry Cranes for Sale

A semi gantry crane is a type of crane that features one side running on a rail attached to a wall or an elevated structure, while the other side moves on a track on the ground. This unique design allows for efficient space utilization, making it an excellent choice for environments where space is limited or where a full gantry crane is not feasible.

Semi gantry cranes are composed of several key components:

- Bridge: The horizontal beam that spans across the working area, supporting the hoist and allowing it to move laterally.

- Hoist: The lifting mechanism that raises and lowers the load. It can be electric or manual, depending on the specific needs of the application.

- Legs: One side has a leg that moves on a ground-level track, while the other side is supported by an elevated structure.

- End Trucks and Wheels: These allow the crane to move along the tracks, providing flexibility in material handling across different parts of a facility.

This configuration provides the lifting capability of a gantry crane but with one leg running on a track and the other side fixed to an overhead structure, offering a blend of flexibility and strength.

Applications and Industries

Semi gantry cranes are versatile and widely used across various industries due to their efficient design and adaptability. Here are some of the most common applications:

- Manufacturing: In manufacturing plants, semi gantry cranes are often used to move heavy machinery and equipment, handle raw materials, and assist in the assembly process. Their ability to operate in tight spaces makes them ideal for areas with limited headroom or floor space.

- Warehouses: In warehouse settings, semi gantry cranes facilitate the efficient movement of goods and materials. They are used for loading and unloading trucks, moving pallets, and organizing inventory, particularly in warehouses where a full gantry crane would be too large or cumbersome.

- Shipyards and Ports: Semi gantry cranes are employed in shipyards for lifting and transporting heavy ship components, machinery, and equipment. Their design allows them to work alongside other cranes and machinery, optimizing space usage and providing flexibility in handling large, heavy items in challenging environments.

- Automotive Industry: In the automotive sector, these cranes are used for handling large vehicle components such as engines and chassis. Their ability to cover large areas while maintaining a low profile makes them ideal for assembly lines and maintenance bays.

- Construction Sites: On construction sites, semi gantry cranes assist in lifting and moving building materials like steel beams, concrete blocks, and other heavy materials. Their mobility allows them to be easily relocated, providing flexibility in dynamic construction environments.

Overall, semi gantry cranes are a practical solution for various industrial sectors, combining the benefits of overhead cranes and gantry cranes. Their unique design makes them suitable for facilities where space and adaptability are critical.

Main Parameters of Semi-gantry Cranes

The semi gantry cranes is a small or middle scale gantry crane, which can maximize your space utilization. With single gantry girder design, the capacity of single girder semi-gantry crane is range from 1 ton to 16 ton, and with double gantry girder design, the capacity of the double girder semi-gantry crane is from 3 ton up to 32 tons.Due to the semi-gantry frame design and semi-overhead crane design, the single legged semi-gantry crane owns the advantages of full gantry crane and overhead cranes, widely used for material handling indoors and outdoors.

Main parameters of semi-gantry cranes

- Crane type: BMH semi-gantry crane with single leg gantry design

- Lifting capacity of semi gantry cranes: single girder design with capacity of 1 ton to 16ton, double girder design with capacity of 5 ton -32 ton

- Span of semi gantry cranes:5m to 20m, 18m to 35m

- Light Height of semi gantry cranes:6m to 12m,

- Working class of semi gantry cranes:A3, A4

- Ambient temperature of semi gantry cranes:-20℃ to 40℃

- Click to check more on semi gantry crane specification table to get your customized semi gantry crane solution for your industrial use.

Structures & Components of Semi-gantry Cranes

Semi gantry crane is a special form developed on the base of Gantry Crane. The semi gantry crane has one end of gantry girder,move on an overhead runway system elevated like an overhead crane supported on the building of factory workshop and at the other side of gantry girder is supported on one gantry girder moving on a rail like a standard rail mounted gantry crane.

Main Components of Semi-gantry Cranes

The semi-gantry crane is mainly consisted of the main crane parts and components such as,crane bridge girder , travelling mechanism, trolley part, electrical control system and other electric part,etc. The main crane parts and components such as , hoist, main girder, crane out-trigger or legs, and ground end beam, are presented for your reference. More information about parts and components of semi-gantry cranes, please feel free to contact us.

Electric Hoist :

Dual speed CD1,MD1 wire rope electric hoist, with single girder design & double girder design, can be mounted on single beam & double beam bridge crane, gantry crane and arm cranes.

Main Beam :

Main girder beam is de-rustd by sandblast and painted with zinc rich epoxy primer, and cut by plasma numerical control cutting machine with high precision.

Supporting gantry leg or Outrigger :

The rigid outrigger design and flexible outrigger,are all connected by high -tension bolt.

When the length of span is beyond 30m, a flexible leg is need to reduce the lateral thrust of the loaded trolley to the rail.

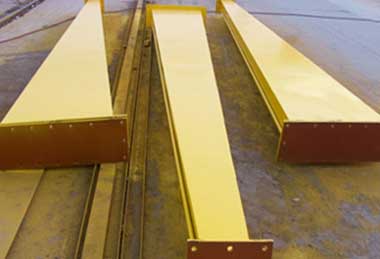

Ground End Beam :

End beam is de-rustd by sandblast and painted with zinc rich epoxy primer, equipted with wheels which is produced in special vacuum casting workshop with more elastic and durable hard-wearing outer surface.

electric chain hoist

Electric chain hoists are lifting devices designed for efficient, heavy-duty material handling. They feature durable chains, motorized lifting, and precise controls for smooth operation. Ideal for workshops and industrial settings, they provide reliable lifting of various loads with enhanced safety.

low headroom hoist with advanced hoist design with European style design

Low headroom hoists are compact lifting solutions designed for spaces with limited clearance, maximizing lifting height while ensuring efficient, safe operation.

- Electric Hoist :Dual speed CD1,MD1 wire rope electric hoist, with single girder design & double girder design, can be mounted on single beam & double beam bridge crane, gantry crane and arm cranes.

- Main Beam :Main girder beam is de-rustd by sandblast and painted with zinc rich epoxy primer, and cut by plasma numerical control cutting machine with high precision. The ultrasonic or x-ray flaw detection is used to ensure the quality of the butt welding of tension flange.

- Outrigger :The rigid outrigger design and flexible outrigger,are all connected by high -tension bolt. When the length of span is beyond 30m, a flexible leg is need to reduce the lateral thrust of the loaded trolley to the rail.

- Ground End Beam :End beam is de-rustd by sandblast and painted with zinc rich epoxy primer, equipped with wheels which is produced in special vacuum casting workshop with more elastic and durable hard-wearing outer surface.

Single Girder Semi Gantry Crane

A single girder semi gantry crane is a versatile and cost-effective material handling solution designed for light to medium-duty tasks. Featuring a single overhead beam supported on one side by a gantry leg and the other side by a fixed structure, this crane type is ideal for use in indoor environments such as warehouses, manufacturing facilities, and maintenance shops. It combines efficient space utilization with robust lifting capabilities, making it suitable for handling various loads up to 16 tons. With adjustable spans and lifting heights, the single girder semi gantry crane is adaptable to different operational needs and environments, providing reliable performance and ease of use.

single girder semi gantry crane for sale hot sale 3 ton, 5 ton, 10 ton

Specifications of Single Girder Semi Gantry Crane

- Loading Capacity: 0.5 to 16 tons

- Lifting Height: 6 to 12 meters

- Span: 5 to 20 meters

- Power Supply: 220 to 440V, 50/60Hz, 3 Phase

- Working Temperature: -20°C to 40°C

Product Parameters

- Loading Capacity: 0.5 to 16 tons. Typical Capacity: Common capacities are 1 ton, 2 tons, 5 tons, and 10 tons, suitable for light to medium-duty tasks.

- Lifting Height: 6 to 12 meters. Typical Height: Most applications will use heights around 6 to 10 meters, depending on the specific needs and clearance requirements.

- Span: 5 to 20 meters. Typical Span: Often ranges from 8 to 15 meters, accommodating various indoor and outdoor setups.

- Power Supply: 220 to 440V, 50/60Hz, 3 Phase. Typical Configuration: Standard power supplies include 380V, 50Hz in many regions, but can be customized based on local requirements.

- Working Temperature: -20°C to 40°C. Typical Range: Most cranes are designed to operate comfortably within this temperature range, suitable for a variety of climates.

Typical Capacities

Single girder semi gantry cranes are versatile and often come in various capacities to suit different applications. The most common capacities are:

- 1 Ton: Ideal for light-duty tasks, such as handling small components or materials in manufacturing and maintenance operations.

- 2 Tons: Suitable for moderate loads, such as small machinery parts and packaging materials.

- 5 Tons: Commonly used in warehouses and light industrial settings for moving heavier items like pallets and medium-sized equipment.

- 10 Tons: Appropriate for heavier lifting needs, such as large machine components or parts in assembly lines and light construction.

These specifications ensure that single girder semi gantry cranes can handle a range of lifting tasks efficiently, with flexibility in both capacity and operational conditions.

Design Features and Benefits

Design Features

Structure:

- Beam Configuration: The crane features a single overhead beam or girder that supports the load. One side of the beam is supported by an overhead track or rail, while the other side rests on a set of wheels or a rail system on the ground.

- Support Mechanism: The ground-supported side typically includes wheels or rollers, allowing the crane to move along a fixed track or rail, which enables efficient movement across the workspace.

Load Capacity:

- Typical Range: Single girder semi gantry cranes commonly handle loads ranging from 1 ton to 10 tons. This capacity makes them suitable for various light to medium-duty applications.

Construction:

- Design Complexity: The single girder design is generally lighter and less complex compared to double girder cranes. This simplicity in design reduces the overall cost of the crane.

- Material Efficiency: Constructed using fewer materials, single girder cranes are both cost-effective and efficient in terms of material usage.

Advantages

Cost-Effective:

- Affordability: Due to the simpler design and fewer components, single girder semi gantry cranes are more affordable compared to their double girder counterparts. This makes them an attractive option for businesses looking to manage budget constraints while still obtaining reliable lifting equipment.

Lightweight:

- Ease of Maneuvering: The reduced weight of single girder cranes makes them easier to maneuver and install, especially in areas where space is limited or where overhead lifting requirements need to be optimized.

- Installation: Lighter construction facilitates quicker and simpler installation, minimizing downtime and disruption to operations.

Lower Maintenance:

- Fewer Moving Parts: With a simpler structure and fewer components, single girder semi gantry cranes typically require less maintenance compared to more complex designs.

- Reduced Wear and Tear: The reduced number of parts means fewer opportunities for wear and tear, leading to lower maintenance costs and fewer operational interruptions.

Benefits

Efficiency:

- Productivity Enhancement: Single girder semi gantry cranes improve productivity by allowing for the quick and efficient handling of loads. Their design facilitates smooth movement of materials, which helps streamline workflow and operational processes.

Flexibility:

- Adaptability: These cranes are particularly suited for environments with space and height constraints. Their ability to operate in confined areas makes them ideal for applications in warehouses, small manufacturing facilities, and other tight spaces.

- Versatility: The ability to adjust spans and lifting heights allows for flexibility in various applications, accommodating different operational needs and configurations.

Single girder semi gantry cranes offer a blend of simplicity, cost-effectiveness, and efficiency, making them a practical choice for many industries. Their design features and benefits cater to a range of operational environments, ensuring reliable performance and enhanced productivity.

Double Girder Semi Gantry Crane

A double girder semi gantry crane is a heavy-duty lifting solution designed to handle more substantial loads with greater stability and span capabilities. Featuring two parallel overhead beams supported by gantry legs on one side and a fixed structure on the other, this crane type offers superior strength and durability compared to single girder models. It is commonly used in industrial settings such as steel mills, shipyards, and large warehouses, where it handles loads up to 20 tons or more. The double girder design allows for wider spans and higher lifting heights, making it ideal for demanding applications requiring robust performance and versatility.

double girder semi gantry crane for sale,hot sale 5 ton, 10 ton, 25 ton, up to 30 ton,

Specifications of Double Girder Semi Gantry Cranes

- Capacity : 3 Ton to 35 Ton

- Span:Range: 10.5 to 35 meters. Specific Spans: 10.5, 13.5, 15, 19.5, 25, 25, 25, 35 meters

- Lifting Height:Range: 16 to 18 meters

- Lifting Speed:Slow: 0.58 to 8 meters per minute. Fast: 07 to 10.7 meters per minute

- Trolley Travelling Speed:Range: 3.2 to 32 meters per minute

- Crane Travelling Speed:Range: 4 to 54 meters per minute

- Max. Wheel Load:Range: 135 to 193 kN. Specific Loads: 135, 144, 151, 161, 169, 177, 185, 193 kN

- Rail Recommended:Model: 43 kg/m

- Total Motor Power:Power: 43.2 kW

Typical Capacity of Double Girder Semi Gantry Cranes

Double girder semi gantry cranes are renowned for their ability to handle heavy loads with exceptional stability and precision. The typical capacities for these cranes generally range from:

- 10 Tons: Suitable for medium-heavy lifting tasks, such as moving large components in manufacturing facilities or handling substantial materials in warehouses.

- 20 Tons: Often used in more demanding industrial settings, including steel production, heavy equipment assembly, and large-scale maintenance operations.

- 30 Tons: Ideal for handling very heavy loads, such as large machinery parts, steel beams, or substantial construction materials in environments like shipyards or heavy-duty warehouses.

Design Features of Double Girder Semi Gantry :

- Structure: Features two parallel beams (girders) that provide support for the crane, with one end mounted on an overhead rail and the other end resting on wheels or a rail system on the ground.

- Load Capacity: Usually ranges from 10 tons to 20 tons and can be customized for higher capacities.

- Construction: Robust and heavy-duty, designed to handle larger and heavier loads.

Advantages:

- Higher Load Capacity: Capable of lifting heavier loads compared to single girder cranes.

- Enhanced Stability: Provides greater stability and can span wider areas.

- Better Performance: Suitable for heavy-duty tasks and applications requiring higher reliability and durability.

Typical Applications:

- Steel Production: Handles large metal coils, beams, and other heavy metal parts.

- Construction: Moves heavy construction materials, such as concrete beams and steel structures.

- Shipbuilding: Used for lifting and moving large ship components and marine equipment.

Benefits:

- Heavy-Duty Performance: Ideal for industries requiring high lifting capacities and extended spans.

- Operational Efficiency: Facilitates the handling of large and bulky items, improving workflow and productivity.

Both single and double girder semi gantry cranes offer distinct advantages depending on the specific needs of the application, load requirements, and workspace constraints. By selecting the appropriate type, businesses can optimize their material handling processes and enhance overall operational efficiency.

Customizations and Considerations:

- Load Distribution: Double girder design provides enhanced load distribution across the span, reducing the stress on individual components and improving stability.

- Span and Lift Height: The capacity of these cranes can be influenced by the span and lift height. Larger spans or higher lift heights typically require cranes with higher load capacities to ensure safe operation.

- Operational Conditions: Capacities can vary based on the specific operational environment and requirements. Custom features or modifications can be made to meet unique needs, such as extreme temperatures or corrosive environments.

Applications:

- Steel Mills: Handling large steel coils and beams.

- Shipyards: Moving massive sections of ships or heavy marine equipment.

- Construction Sites: Lifting large building components like concrete panels or steel structures.

- Heavy Manufacturing: Moving large machinery parts or assemblies.

The robust design and customizable features of double girder semi gantry cranes make them ideal for heavy-duty applications where reliability, performance, and safety are critical.

Semi-gantry Crane: Single girder design vs. Double girder design

In terms of gantry girder designs, the semi gantry cranes can be grouped into single girder semi-gantry crane and double girder semi-gantry cranes. With single gantry girder design, the capacity of single girder semi-gantry crane is range from 1 ton to 16 ton, and with double gantry girder design, the capacity of the double girder semi-gantry crane is from 3 ton up 32 ton. The main parameters of the single girder & double girder semi-gantry cranes are shown as following:

Single Girder Design

- Capacity Range: Single girder semi gantry cranes typically handle loads ranging from 1 ton to 10 tons. They are designed for light to medium-duty tasks, making them suitable for applications that do not require extremely high lifting capacities.

Typical Applications: These cranes are ideal for operations where space, cost, and ease of installation are crucial factors. Common applications include:

- Assembly Lines: Used for moving smaller components and parts during the assembly process.

- Maintenance Operations: Perfect for tasks that involve routine maintenance, where moderate lifting capabilities are sufficient.

- Warehouses: Effective for handling inventory and moving goods around, particularly in facilities with limited headroom or floor space.

Advantages: Single girder semi gantry cranes offer several benefits:

- Cost-Effective: Less material is required for construction, making them a more economical choice compared to double girder designs.

- Lightweight: The reduced weight simplifies installation and reduces stress on the building structure.

- Ease of Installation: Fewer components mean quicker and simpler installation, reducing downtime and labor costs.

- Low Maintenance: With fewer moving parts and less weight, these cranes generally require less maintenance, resulting in lower long-term operating costs.

Double Girder Design

Capacity Range: Double girder semi gantry cranes are built for heavier loads, typically ranging from 10 tons to 20 tons, and can be customized for even higher capacities. This makes them well-suited for more demanding applications where strength and stability are paramount.

Typical Applications: These cranes are designed for heavy-duty industrial environments that require robust lifting capabilities. Common applications include:

- Steel Mills: Used to handle large coils of steel, heavy equipment, and raw materials.

- Shipyards: Ideal for moving heavy ship components, engines, and other large parts during the shipbuilding and repair processes.

- Construction Sites: Employed for lifting heavy building materials, such as steel beams and concrete sections, where durability and strength are essential.

Advantages: Double girder semi gantry cranes provide several key benefits:

- Higher Load Capacity: Capable of handling much heavier loads than single girder designs, making them suitable for more intensive tasks.

- Better Stability: The additional girder offers enhanced stability, allowing the crane to handle larger and heavier items with greater precision.

- Wider Span Capabilities: Can cover a broader area, providing increased operational flexibility and efficiency in larger facilities.

Manual vs. Motorized

Semi gantry cranes can also be classified based on their operational mechanism:

- Manual: Operated by hand, these cranes are suitable for light-duty tasks where the load is not too heavy and precision control is required. Manual cranes are generally more affordable, with lower installation and operating costs, but they demand more physical effort from the operator and are slower in operation. They are best used in environments where the volume of lifting is low, and fine control is necessary, such as in maintenance workshops or small assembly lines.

- Motorized: Equipped with electric motors, motorized semi gantry cranes offer faster and more efficient lifting capabilities. They are suitable for medium to heavy-duty tasks where speed, automation, and high load capacity are needed. These cranes reduce the need for manual labor, increase productivity, and are ideal for continuous operations in larger industrial settings like manufacturing plants, shipyards, and warehouses. Although motorized cranes involve higher initial and maintenance costs, they provide significant advantages in terms of efficiency and safety.

Customized Options

Semi gantry cranes can be customized to meet specific operational needs, enhancing their versatility and adaptability across various industries:

- Height: Customization allows the crane to be tailored to specific lifting heights, ensuring it can safely and efficiently handle loads at the required elevations.

- Span: The crane's span, or the width it covers, can be adjusted to fit the operational area, optimizing the use of space and ensuring maximum coverage.

- Lifting Speed: Depending on the application, cranes can be customized with different lifting speeds to match the pace of operations, whether it's for rapid handling in a busy warehouse or precise, controlled movements in a manufacturing process.

By offering these customized options, semi gantry cranes can be perfectly tailored to the specific requirements of a facility, ensuring optimal performance, safety, and efficiency.

Indoor vs. Outdoor Semi Gantry Cranes

Semi gantry cranes are versatile and can be tailored for both indoor and outdoor environments. Each type has specific design features to accommodate the conditions and requirements of its operational setting. Here's a comparison of indoor and outdoor semi gantry cranes:

Indoor Semi Gantry Crane

Design Features:

- Structure and Materials: Typically built with materials that are suitable for controlled indoor environments. May use standard steel or aluminum construction with less emphasis on corrosion resistance.

- Space Considerations: Designed to operate in confined or limited spaces with consideration for indoor clearance and height restrictions.

- Power Supply: Generally powered by electric systems compatible with standard indoor power sources.

Advantages:

- Space Efficiency: Ideal for facilities where space is limited, such as warehouses, manufacturing plants, and assembly lines.

- Reduced Maintenance: Less exposure to environmental elements reduces wear and tear.

- Precision Handling: Often equipped with fine-tuned controls suitable for handling delicate or precise tasks.

Typical Applications:

- Manufacturing Plants: Handling parts and materials in assembly lines or production areas.

- Warehouses: Moving pallets, crates, and other goods within storage areas.

- Maintenance Facilities: Assisting with maintenance and repair tasks for machinery and equipment.

Benefits:

- Cost-Effective: Lower cost due to fewer requirements for weatherproofing and corrosion resistance.

- Improved Efficiency: Streamlined design tailored for indoor operations enhances productivity and handling efficiency.

Outdoor Semi Gantry Crane

Design Features:

- Durable Materials: Constructed with corrosion-resistant materials, such as galvanized steel or stainless steel, to withstand outdoor elements like rain, wind, and UV exposure.

- Weatherproofing: Includes features to protect mechanical and electrical components from environmental factors, such as waterproof controls and weather-resistant coatings.

- Robust Construction: Built to handle the additional stresses of outdoor environments, including varying temperatures and potential exposure to harsh conditions.

Advantages:

- Weather Resistance: Designed to operate reliably in outdoor conditions, including extreme weather scenarios.

- Enhanced Durability: Built to last with components specifically chosen for their resistance to rust and corrosion.

- Versatility: Can be used in a variety of outdoor settings, including construction sites, ports, and open-air warehouses.

Typical Applications:

- Construction Sites: Moving heavy construction materials, such as steel beams and concrete panels.

- Ports and Shipyards: Handling large cargo, shipping containers, and marine equipment.

- Outdoor Storage Areas: Managing bulk materials and equipment in open-air environments.

Benefits:

- Operational Reliability: Maintains performance and safety in varying outdoor conditions.

- Increased Lifespan: Longer service life due to durable construction and weatherproofing features.

Both indoor and outdoor semi gantry cranes are designed to meet the specific needs of their environments, ensuring efficient operation and longevity. By choosing the appropriate crane for the intended setting, businesses can optimize their material handling processes and adapt to their operational conditions effectively.

Hazardous Environment Semi Gantry Cranes

Semi gantry cranes designed for hazardous environments are built to handle specific safety and operational challenges posed by conditions such as flammable materials, corrosive substances, high temperatures, or explosive atmospheres. Here's an overview of the features and considerations for these specialized cranes:

Design Features

Explosion-Proof Components:

- Certification: Cranes are often built to comply with standards such as ATEX (for Europe) or NEC (for North America) for explosive atmospheres. Components are certified to prevent sparks or heat that could ignite hazardous substances.

- Sealed Enclosures: Electrical and control systems are housed in explosion-proof enclosures to prevent ignition of hazardous gases or dust.

Corrosion-Resistant Materials:

- Materials Used: Constructed from materials like stainless steel or specially coated metals to resist corrosion from chemicals or saltwater.

- Protective Coatings: Coatings such as epoxy or zinc-rich primers are applied to enhance durability in corrosive environments.

Temperature Control:

- Heat Resistance: Designed to operate in extreme temperatures, with heat-resistant materials and components.

- Cooling Systems: Some cranes include integrated cooling systems to prevent overheating in high-temperature environments.

Enhanced Safety Features:

- Overload Protection: Equipped with sensors and alarms to prevent lifting beyond the crane's capacity.

- Emergency Shutdown: Includes emergency stop buttons and automatic shutdown systems in case of system failure or safety breaches.

Applications

Chemical Processing Plants:

- Handling: Moving and transferring chemical drums, reactors, and other hazardous substances.

- Features Needed: Corrosion resistance, explosion-proof electrical systems, and temperature control.

Oil and Gas Industry:

- Handling: Lifting and moving heavy equipment, pipes, and other materials in explosive or high-temperature environments.

- Features Needed: Explosion-proof design, rugged construction, and high load capacities.

Mining Operations:

- Handling: Moving mining equipment and extracted materials in environments with dust or potentially explosive gases.

- Features Needed: Dust-tight enclosures, corrosion resistance, and high durability.

Pharmaceutical and Food Processing:

- Handling: Moving materials and equipment in sterile or high hygiene environments.

- Features Needed: Easy-to-clean surfaces, resistant to chemicals, and compliance with hygiene standards.

Safety Considerations

Compliance with Standards:

- Regulatory Standards: Ensure compliance with industry-specific regulations and standards for hazardous environments (e.g., ATEX, IECEx, NEC).

- Certification: Verify that the crane and its components are certified for use in hazardous areas.

Routine Maintenance:

- Inspection: Regular inspections for wear and tear, corrosion, and compliance with safety standards.

- Maintenance Procedures: Follow strict maintenance procedures to ensure ongoing safety and operational efficiency.

Training and Operation:

- Operator Training: Ensure that operators are trained in handling hazardous materials and operating the crane safely in a hazardous environment.

- Emergency Procedures: Develop and implement emergency procedures for dealing with potential incidents or malfunctions.

Benefits

Increased Safety:

- Reduced Risk: Minimizes the risk of accidents and incidents in hazardous environments through specialized safety features and design.

- Compliance: Meets stringent safety and regulatory requirements, ensuring safe operation in challenging conditions.

Enhanced Durability:

- Longevity: Extended lifespan of the crane due to robust construction and resistance to environmental factors.

- Reliability: Consistent performance in demanding environments, contributing to operational efficiency.

Operational Efficiency:

- Optimized Handling: Facilitates the handling of hazardous materials and equipment with specialized design features.

- Versatility: Adaptable to various hazardous environments, ensuring effective material handling across different applications.

Specialized semi gantry cranes for hazardous environments are essential for ensuring safety and efficiency in industries dealing with dangerous conditions. By incorporating advanced design features and adhering to strict safety standards, these cranes provide reliable solutions for challenging operational environments.

Key Features of Semi Gantry Cranes

Design and Structure

Semi gantry cranes differ from full gantry cranes primarily in their design and how they are supported. A full gantry crane typically has two legs that move on rails embedded in the floor, allowing it to span a large area completely and carry heavy loads across this space. In contrast, a semi gantry crane has only one leg that moves on a floor-level track, while the other side is fixed to a wall-mounted or overhead runway beam. This difference in structure provides several benefits:

- Space Efficiency: Semi gantry cranes take up less floor space than full gantry cranes because they only require a single track on the ground. This is ideal for facilities where space is limited or where keeping floor space clear is a priority.

- Cost-Effectiveness: The semi gantry design can be more economical to install and maintain, as it requires fewer structural components and less extensive groundwork compared to full gantry systems.

- Versatility: The unique design allows semi gantry cranes to operate effectively in environments where a full gantry crane would be impractical, such as areas with height restrictions or where one side must remain open or unobstructed.

Load Capacities and Sizes

Semi gantry cranes are available in a wide range of load capacities and sizes to accommodate various industrial needs:

- Single Girder Designs: These cranes typically support lighter loads, ranging from 1 ton to around 10 tons. They are suitable for applications where frequent, lighter lifting tasks are required, such as in assembly lines, small manufacturing plants, or warehouses handling smaller goods.

- Double Girder Designs: These cranes are designed for heavier lifting, with capacities ranging from 10 tons to 20 tons and even higher depending on the specific design and customization. Double girder semi gantry cranes are ideal for more demanding applications, such as handling heavy machinery, large containers, and bulky materials in industrial settings like steel mills, shipyards, and construction sites.

The choice between single and double girder designs allows businesses to select a crane that best matches their specific lifting needs, ensuring optimal performance and safety.

Mobility and Flexibility

One of the standout features of a semi gantry crane is its mobility and flexibility. Unlike stationary cranes, semi gantry cranes can cover a wide area thanks to their unique movement system:

- Fixed Track and Free Movement: With one side of the crane running on a fixed track (usually mounted to a wall or an overhead runway), the other side can move freely along the ground. This design allows the crane to navigate around obstacles and work in spaces where a full gantry or overhead crane might be too restrictive.

- Customizable Pathways: The floor track can be customized to suit specific operational needs, allowing the crane to operate along a designated path and making it adaptable to various layout requirements within a facility. This flexibility is particularly beneficial in dynamic environments where workflows may change or where different areas need to be accessed frequently.

Materials and Construction

The construction materials used for semi gantry cranes significantly impact their durability, performance, and suitability for different applications:

- Steel: Most semi gantry cranes are constructed from high-grade steel, providing excellent strength and durability. Steel cranes are ideal for heavy-duty applications and environments where robustness is crucial, such as in outdoor settings or facilities handling heavy and abrasive materials.

- Aluminum: For lighter applications or where corrosion resistance is a concern, aluminum cranes may be used. Aluminum is lighter than steel, which can reduce wear and tear on the crane's moving parts and track system, extending its lifespan. Additionally, aluminum's natural resistance to rust makes it suitable for environments with high moisture or corrosive elements, like food processing plants or chemical facilities.

By selecting the appropriate materials and construction methods, semi gantry cranes can be tailored to meet the specific demands of different industries, ensuring optimal performance and longevity.

Semi Gantry Crane, Your Economical Material Handling Solution

Semi gantry cranes, the special form of overhead gantry cranes combine the advantages of overhead travelling bridge cranes and gantry cranes, but with higher flexibility than overhead eot crane and lower cost than the standard regular rail gantry crane. Semi gantry crane is a good choice to save investment and space, especially when you are in the following conditions:

- Your plant needs an efficient solution to coordinate forklifts to handle heavy or very long loads to improve safety, efficiency and save time.

- Your lifting volume is moderate which does not need to install an expensive and permanent overhead travelling crane system.

- Your plant has existing overhead cranes, but need an economical and versatile lifting system to supplement the existing crane system.

Semi gantry crane has a widely application for various industrial applications, Generally, semi gantry cranes can be used in the following two typical applications:

- Indoors - Semi gantry cranes is used to cooperate with the the existing overhead bridge cranes to provide more hooks and to improve the productivity of your factory.

- Outdoors - The single leg gantry crane is used outside but near the building, , taking advantage of the existing runway structure, to improve the cost efficient of your building.

All in all, Semi Gantry Cranes offers your economical material handling solution with lifting capacity up to 32 ton and crane span up to 32 m, which is an excellent alternative solution to expensive overhead cranes. Single leg semi gantry crane is widely used for material handling in open warehouse,mechanical processing workshop, outdoor places, etc. However, standard semi gantry crane is not allowed to be in hazardous environments, such as, the environment of combustible, explosive, dusty and corrosive, etc.

Advantages of Single Leg Semi-gantry Crane

- Customized design, Compact crane structure, Durable gantry girder design, Great rigidity.

- Good crane performance,Smooth crane starting and stopping,Stable and reliable traveling, Strong ability of lateral load proof.

- Crane installation and operation with high flexibility, Excellent exchange ability for parts and components,.Convenient maintenance,

- Low noise, No pollution,Electricity saves,Less investment

Features of Semi-gantry Crane

- Dual speed electric hoist with CD,MD motor, travelling on rail of semi gantry crane.

- Three-in-one motor used on the semi gantry crane to save more working space.

- Best light crane equipped with hard tooth face reducer & three-in-one motor for outdoor or workshop use.

- Lowest space between the top of trolley crab and the trolley rail, 20-30 % less than the traditional type.

- Electric panel with more than 2 million times service life, are used on the semi gantry crane.

- Various protection devices and alarming devices are used to .ensure the security and stability of semi-gantry crane.

Case Studies and Customer Testimonials

Case Study 1: Automotive Parts ManufacturerA leading automotive parts manufacturer integrated a semi gantry crane into their assembly line to handle engine components and packaging materials. Prior to this, manual handling was labor-intensive and time-consuming. After installing a semi gantry crane with a 5-ton single girder design, the company reported a 30% increase in assembly line efficiency. The crane's ability to quickly and safely move parts significantly reduced manual labor and minimized the risk of injury. The increased efficiency also led to faster production cycles and improved overall productivity.

Case Study 2: Steel Production FacilityIn a steel production facility, a double girder semi gantry crane with a 15-ton capacity was installed to manage the movement of large metal coils and fabricated structures. This crane's robust design and high load capacity allowed the facility to handle heavier loads more effectively, leading to improved handling processes and reduced bottlenecks in production. The company noted that the crane's stability and ability to span wider areas were crucial in optimizing their workflow and enhancing their capacity to meet high-demand periods.Case Study 3: Port OperationsA major port installed a semi gantry crane with a 10-ton capacity to handle smaller vessels and light cargo. This crane, equipped for outdoor use, allowed the port to streamline its cargo handling operations and reduce turnaround times. The ability to operate effectively in a space-constrained environment with varying load sizes provided significant benefits. The port reported a noticeable improvement in operational efficiency and a reduction in the time required to load and unload ships.

5 Ton Semi Gantry Cranes Project Video for Your Reference

5 ton semi gantry crane for sale and half gantry crane installation for your reference

Frequently Asked Questions (FAQs)

Common Queries

How long does installation take?The installation time for a semi gantry crane varies depending on several factors, including the crane's design (single girder vs. double girder), the complexity of the installation site, and the experience of the installation team. On average, installation can take anywhere from a few days to a week. This includes site preparation, assembly, alignment, and initial testing. For a more accurate timeline, it's best to consult with your crane supplier or installation contractor.- Gantry girder design of semi-gantry crane: Single girder / double girder design? With 1 cantilever/ no cantilever?

- Capacity: ____ ,Span:____, Height of Lift:____,Travelling Length:___

- Power supply: 3 phase___Voltage___ Hz

- Operation: Through Pendant/Radio Remote/Cabin Control?

- Application: Industry type: _____, Indoor/Outdoor: ____. Loads: _______

- Size of Existing Rail: ___

What is the typical lifespan of a semi gantry crane?The lifespan of a semi gantry crane can vary based on usage, maintenance practices, and environmental conditions. Generally, a well-maintained semi gantry crane can last between 10 to 20 years. Regular maintenance and adherence to manufacturer guidelines play a crucial role in extending the crane's operational life. Cranes used in harsh environments or for heavy-duty applications may experience more wear and require more frequent servicing.

What factors affect the load capacity of a semi gantry crane?The load capacity of a semi gantry crane is influenced by several factors, including the crane's design (single girder vs. double girder), the quality of construction materials, and the crane's structural integrity. For single girder designs, capacities typically range from 1 ton to 10 tons, while double girder designs can handle capacities from 10 tons to over 20 tons. Additionally, the installation environment and load distribution practices can affect the crane's effective load capacity.

Can a semi gantry crane be customized to fit specific needs?Yes, semi gantry cranes can be customized to meet specific operational needs. Customization options may include adjustments to lifting height, span, load capacity, and control systems. You can also choose from various power supply options and additional features such as remote controls or specialized lifting equipment. Discuss your specific requirements with your crane supplier to explore available customization options.

What maintenance is required for a semi gantry crane?Routine maintenance for a semi gantry crane includes regular inspections of mechanical and electrical components, lubrication of moving parts, and checking for signs of wear or damage. Essential tasks include inspecting the hoist, trolley, and rail systems, as well as ensuring that safety features are functioning correctly. Establish a maintenance schedule based on the manufacturer's recommendations and the crane's usage to prevent unexpected issues and ensure smooth operation.

Are semi gantry cranes suitable for outdoor use?Semi gantry cranes can be designed for both indoor and outdoor use. When used outdoors, the crane must be equipped with weather-resistant features and coatings to protect against environmental factors such as moisture, temperature extremes, and corrosive elements. Ensure that the crane is specifically designed for outdoor conditions and discuss any additional requirements with your supplier to ensure its durability and reliability in various environments.

What safety features should I look for in a semi gantry crane?Important safety features to look for in a semi gantry crane include emergency stop functions, overload protection, anti-collision systems, and proper braking mechanisms. Safety features should also include regular safety inspections and adherence to industry standards and regulations. Ensure that the crane meets all relevant safety certifications and that the safety systems are tested and operational before use.

How can I ensure that my semi gantry crane is compliant with industry standards?To ensure compliance with industry standards, purchase your crane from a reputable supplier who adheres to relevant safety and quality regulations. Check that the crane meets local and international standards, such as those set by organizations like the American Society of Mechanical Engineers (ASME) or the European Standards (EN). Request documentation and certification from the supplier to verify compliance and ensure that the crane's design and construction meet industry requirements.

Get your customized semi-gantry crane

Drawing of Semi gantry cane: Span Length and Lifting Height

How to select a semi-gantry crane for your application? In order to give you suitable semi gantry crane solution and specific crane price promptly, please confirm the following with our gantry crane engineer as much as possible:

Free consultation of semi gantry crane is available.Any questions or problem are welcomed.Please just leave a message below and reply will be given within 24 hours. Click to learn more on semi gantry crane and your custom designed semi gantry crane.

Conclusion

When considering the purchase of a semi gantry crane, several key factors should be carefully evaluated. Understanding your specific lifting needs and the environment in which the crane will operate is crucial. This includes assessing the types of loads, required capacity, and space constraints. Researching reputable suppliers, comparing quotes, and ensuring the crane meets quality standards are essential steps in making an informed decision. Additionally, considering installation requirements, maintenance practices, and potential common issues will help ensure the crane remains efficient and reliable over its lifespan. Finally, exploring customer testimonials and case studies can provide valuable insights into the real-world benefits and performance of different crane models. If you are considering investing in a semi gantry crane, take the time to thoroughly assess your needs and reach out to suppliers for more detailed information. By understanding your specific requirements and evaluating the options available, you can make a well-informed decision that enhances your operational efficiency and meets your lifting needs. Contacting reputable suppliers to discuss your requirements, request quotes, and explore customization options will help you find the right crane for your application. Taking these steps will ensure that you invest in a crane that delivers optimal performance, reliability, and value for your business.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch