Electric Hoist Single Girder Gantry Crane Specification 3 Ton-20 Ton

Electric hoist single girder gantry crane specifications 3 Ton, 5 ton, 10 ton, 16 ton, 20 Ton. MH type single girder gantry crane with cd/md wire rope hoist, economical gantry crane design for sale.

| Crane type | Electric hoist single girder gantry crane |

| Crane capacity | 1 ton -20 ton |

| Lifting Height | As your request |

| Crane Span | 7.5-31.5 m |

| Working class | A3,A4 |

Category: Hoist and Crane Specifications

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Electric Hoist Single Girder Gantry Crane Specifications

3 Ton, 5 ton, 10 ton, 16 ton, 20 Ton Gantry Crane for Sale

Electric hoist single girder gantry crane specifications 3 Ton, 5 ton, 10 ton, 16 ton, 20 Ton. MH type single girder gantry crane with cd/md wire rope hoist, economical gantry crane design for sale.

MH model rail mounted single girder gantry crane with electric hoist is applied outside warehouse or railway sideways to do common lifting and unloading works. This electric hoist gantry crane is composed of bridge, support legs, crane travelling organ, trolley, electric equipment,strong lifting electric hoist. Single girder gantry crane can be divided into box type and truss type.Our company produce single girder gantry crane series with electric hoist mainly with the lifting capacity of 3-16t, span 12-30m, the lifting height of 12-30m, and the light (A3/A4) working duty, also can design and manufacture non-standard series hoist according to your demands.

Main application of single girder gantry cranes

This electric hoist gantry crane is used in ambient temperature of -25℃~+40℃,humidity≤85%,elevation under 1000m; the average temperature does not exceed +35℃ within 24 hours, when the average temperature exceeds +25℃, relative humidity allowed temporarily up to 100% within 24 hours, in the temperature of +40℃, relative humidity not more than 50%.suitable power supply is 3-ph, 380V, 50HZ (can change as user demand).

- The standard mh type single girder gantry crane is equipped with CD1 MD1 electric wire rope hoist, with electric traveling hoist

- The electric hoist gantry cranes are widely used in docks, freight yards, warehouses, construction sites and other open space

- The general use single beam gantry crane is prohibited to use in the flammable, explosive, corrosive media environment

Box type signle girder gantry crane with electric hoist

The box type single girder gantry crane is usually equipped with standard CD MD electric hoist as the lifting mechanism, and the electric hoist traversing along the lower flange of the I- steel of the main girder, which is made of high quality steel plates, such as, C-steel and I-steel.

Truss type single girder gantry crane with electric hoist

The truss single girder gantry crane are different from the box type crane . The truss single girder gantry is made of steel bars, and the latter is made of steel plates. The truss gantry crane have many good advantages,it is much lighter than that of the box type gantry crane and it has high wind resistance.

Technical Specifications of Electric Hoist Gantry Crane 3 Ton -20 Ton

Capacity |

t |

3 |

5 |

10 |

16 |

20 |

Span |

S(m) |

8~35 |

8~35 |

8~35 |

8~35 |

8~35 |

Lifting height |

m |

6~18 |

6~18 |

6~18 |

6~18 |

6~18 |

Lifting speed |

m/min |

8(0.8/8) |

8(0.8/8) |

7(0.7/7) |

3.5(0.35/3.5) |

3.3(0.33/3.3) |

Trolley speed |

m/min |

20(30) |

20(30) |

20(30) |

18 |

14 |

Crane speed |

m/min |

20(30) |

20(30) |

20(30) |

20(30) |

20(30) |

Work duty |

A3~A4 |

A3~A4 |

A3~A4 |

A3~A4 |

A3~A4 |

|

Track type |

P24 |

P24 P30 |

P30 P38 |

|

MH type electric hoist signle girder overhead crane specification 3 ton

MH type single girder gantry crane with electric hoist(box type) 3t |

||||||

Span (S) |

m |

12 |

16 |

20 |

24 |

|

Lifting height |

m |

6/9 |

||||

Lifting speed |

m/min |

8 |

||||

Hoist traveling speed |

m/min |

20 |

||||

Crane traveling speed |

m/min |

20(ground control);30、40(cabin control) |

||||

Whole weight(ground control) |

t |

7.4/8.7 |

8.6/9.9 |

11.3/12.6 |

13/14.3 |

|

Whole weight(cabin control) |

t |

8.2/9.9 |

9.4/11.1 |

12.1/13.8 |

13.8/15.5 |

|

Max wheel load |

KN |

37/42 |

40/46 |

44/50 |

48/54 |

|

Wheel diameter |

φ270 |

φ400 |

||||

Main dimension |

mm |

12 |

16 |

20 |

24 |

|

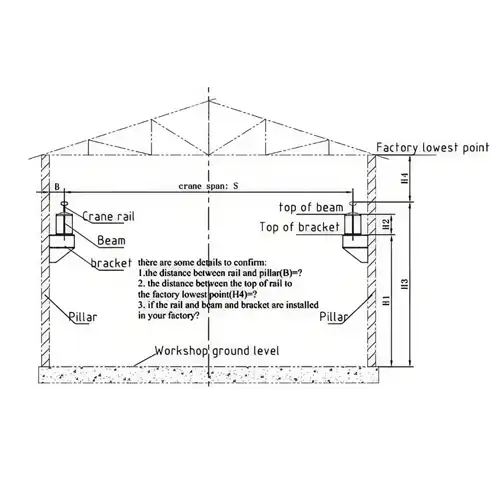

Crane total height |

H3 |

7635/10635 |

7685/10685 |

7785/10785 |

7885/10885 |

|

Wheel tread |

B1 |

50000/6000 |

50000/6000 |

6000/7000 |

6000/7000 |

|

Crane total wide |

B2 |

5400/6400 |

5400/6400 |

6500/7500 |

6500/7500 |

|

Left cantilever |

L1 |

3000 |

4000 |

5000 |

6000 |

|

Right cantilever |

L2 |

3000 |

4000 |

5000 |

6000 |

|

MH type electric hoist signle girder overhead crane specification 5 ton

MH type single girder gantry crane with electric hoist(box type) 5t |

||||||

Span (S) |

m |

12 |

16 |

20 |

24 |

30 |

Lifting height |

m |

6/9 |

9 |

|||

Lifting speed |

m/min |

8 |

||||

Hoist traveling speed |

m/min |

20 |

||||

Crane traveling speed |

m/min |

20(ground control);30、40(cabin control) |

||||

Whole weight(ground control) |

t |

8.4/9.8 |

9.6/11.2 |

13.6/15.2 |

18.3/20.4 |

|

Whole weight(cabin control) |

t |

9.2/11 |

10.4/12.2 |

14.4/16.4 |

19.1/21.6 |

25.1 |

Max wheel load |

KN |

54/59 |

62/67 |

70/75 |

78/83 |

96 |

Wheel diameter |

φ270 |

φ400 |

||||

Main dimension |

mm |

12 |

16 |

20 |

24 |

30 |

Crane total height |

H3 |

7960/10960 |

8060/11060 |

8160/11160 |

8310/11310 |

11460 |

Wheel tread |

B1 |

5500/6500 |

5500/6500 |

6500/7500 |

6500/7500 |

6500/7500 |

Crane total wide |

B2 |

6000/7000 |

6000/7000 |

7100/8100 |

7100/8100 |

7100/8100 |

Left cantilever |

L1 |

3000 |

4000 |

5000 |

6000 |

7500 |

Right cantilever |

L2 |

3000 |

4000 |

5000 |

6000 |

7500 |

MH type electric hoist signle girder overhead crane specification 10 ton

MH type single girder gantry crane with electric hoist(box type) 10t |

||||||

Span (S) |

m |

12 |

16 |

20 |

24 |

30 |

Lifting height |

m |

6/9 |

9 |

|||

Lifting speed |

m/min |

7 |

||||

Hoist traveling speed |

m/min |

20 |

||||

Crane traveling speed |

m/min |

20(ground control);30、40(cabin control) |

||||

Whole weight(ground control) |

t |

14.8/16.1 |

16.7/18.7 |

19.6/21.6 |

24.4/26.6 |

30.1 |

Whole weight(cabin control) |

t |

16/17.3 |

17.5/19.9 |

20.4/22.9 |

25.2/27.9 |

31.4 |

Max wheel load |

KN |

97/102 |

105/110 |

113/118 |

121/126 |

149 |

Wheel diameter |

φ400 |

φ500 |

||||

Main dimension |

mm |

12 |

16 |

20 |

24 |

30 |

Crane total height |

H3 |

8350/11350 |

8450/11450 |

8550/11550 |

8650/11650 |

12250 |

Wheel tread |

B1 |

5500/6500 |

5500/6500 |

6500/7500 |

6500/7500 |

6500/7500 |

Crane total wide |

B2 |

6000/7100 |

6000/7100 |

7100/8100 |

7100/8100 |

7100/8100 |

Left cantilever |

L1 |

3000 |

4000 |

5000 |

6000 |

7500 |

Right cantilever |

L2 |

3000 |

4000 |

5000 |

6000 |

7500 |

MH type electric hoist signle girder overhead crane specification 16 ton

MH type single girder gantry crane with electric hoist(box type) 16t |

||||||

Span (S) |

m |

12 |

16 |

20 |

24 |

30 |

Lifting height |

m |

6/9 |

9 |

|||

Lifting speed |

m/min |

3.5 |

||||

Hoist traveling speed |

m/min |

20 |

||||

Crane traveling speed |

m/min |

20(ground control);30、40(cabin control) |

||||

Whole weight(ground control) |

t |

16.2/18.2 |

18.6/20.7 |

23.3/25.5 |

25.9/28.1 |

35 |

Whole weight(cabin control) |

t |

17.1/19.5 |

19.5/22 |

24.2/26.8 |

26.8/29.4 |

33.7 |

Max wheel load |

KN |

143/150 |

152/159 |

165/174 |

169/176 |

190 |

Wheel diameter |

φ400 |

φ500 |

||||

Main dimension |

mm |

12 |

16 |

20 |

24 |

30 |

Crane total height |

H3 |

9500/12500 |

9600/12600 |

9700/12700 |

9800/12800 |

9950 |

Wheel tread |

B1 |

6500/7000 |

6500/7000 |

7500/8500 |

7500/8500 |

7500/8500 |

Crane total wide |

B2 |

7000/7500 |

7000/7500 |

8200/9200 |

8200/9200 |

8200/9200 |

Left cantilever |

L1 |

3000 |

4000 |

5000 |

6000 |

7500 |

Right cantilever |

L2 |

3000 |

4000 |

5000 |

6000 |

7500 |

Standardsof single girder gantry crane design and processing

Our company carry out the contract equipment design, manufacturing, testing according to the following standards, procedures and corresponding provisions. In the following standards, we give priority to the national standard and (former) Ministry of Machinery Standard.

- 1. GB / T 3811-2008 "Design R ules for C ranes "

- 2. GB of 6067-1985 " C rane S afety R egulations "

- 3. JB / T 5663-2008 " E lectric H oist G antry C rane "

- 4. JB / T 9008-2004 " W ire R ope E lectric H oist "

- 5. GB 5905-1986 "Crane Electric Control Equipment "

Main structure and characters

The single girder gantry crane is mainly consisted of steel gantry structure, lifting mechanism(electric hoist ), crane traveling mechanism, electric equipment and other accessories. Normally when working outside, the gantry crane and electric traveling and lifting mechanism should equipped with rainproof cover.

- With box type structure , the single girder electric hoist gantry crane is with a simple manufacturing process, which is easy to transport and install. Box girder single beam gantry crane is rigidity,but with a large dead weight.

- With trussed structure, the single beam gantry crantry with electric hoist is light weight, strong wind resistance, but poor manufacturing processes,inconvenience transportation and installation .

Whole structure box type and trussed type

- Gantry frame of the electric hoist gantry crane is mainly composed of main girder, ground beam, landing legs, outrigger, ladders, platforms, driver's room, etc.

- Main girder of electric hoist gantry crane, single girder design

- Main bearing structure, traveling rail of electric hoist

- Material Q235B or Q345B ( similar as Fe37 or Fe52)

- U-type groove, inclined plate, rib plate made by cold bending suppress steel plate weld solid web girder with i beam, or truss girder welded by steel plate group

- Arched main beam according to request, the arch degree F should be (1/1000~1.4/1000) S, max. Arch degree be in the scope of middle span S/10

- There are saddle seat jointed with legs in the two sides of span position, and there are square steel plate connect with flange

- Buffers at the girder ends ensure trolley's safe traveling along the main girder.

Gantry Frame

- Ground beams support the main girder and load, and also connect main girder and traveling mechanism, one of the main loading metal structures.

- Box structure girder welded by U-type groove and steel plate group or only steel plates, with features of light structure, good rigidity, appearance and welding technology

- Buffers settled at the ends of ground beam

- Isosceles trapezoid or right or left trapezoid box pillar welded by steel plate. Wide flanges welded at the upside and narrow flanges at the downside of the pillar increase the rigidity and stability of the gantry frame

- Two flexible legs designed for improve crane traveling effect when span ≥ 30m

- Bolts connect two flanges to become an "A" structure, increasing the crane's stability

- Bolts connect steel plate flange between legs and ground beam, simple structure, easy to install, transport and store

Ground beam of single beam gantry crane with cd/md hoist

Legs of single girder goliath crane

- generally adopted the closed type, top of the cabin can stand 2.5KN dead load at least.

- The head room height inside the cabin ≥ 1.8m.

Cabin room for single beam goliath crane

- Lifting Mechanism (see electric hoist specifications)

- Crane Traveling Mechanism

Drive separately, composed of traveling motor, traveling reducer, wheel group, etc.

- Motor -ZDY series motor with brake inside used for crane traveling, reliable brake.

- Reducer -LDAC or LDHC type vertical trinity reducer, open gear drive, small width, without coupling.

- Wheel -LDA type wheels, double wheel edges, efficiently avoid failures

- Baffles at the end of ground beam connected by bolts, easy to dismantle, install and maintain

- Rail sweeper -The rail sweeper sweep the barriers on the rail to ensure the safe travel

- Rail clamp -Rail clamp installed outdoor avoid crane moving due to force; The switch on the clamp avoid the damage due to driving crane when clamped

- Reducer -LDA or LDH type trinity reducer, open gear drive, small width, without coupling

A Structure Mode

B Structure Mode ( the others like A mode except reducer)

C Structure Mode

Drive device simple structure, low noise, safe and reliable, easy to install and maintain.

- Motor -YZR series wound rotor type motor for hoist and metallurgy used for crane traveling mechanism

- Strong overload capacity, large output torque

- Reducer -Separately drive, ZSC or ZSC(A) type vertical reducer

- Saving space, large ratio

- High transmission efficiency, smooth travel, low noise, easy to install and dismantle

- Brake -YWZ type electric hydraulic block brake installed between traveling motor and reducer, smooth braking, high operating frequency, safe and reliable

- Self-lubricating bearing in main swing hinge points, High transmission efficiency, long service life. Card plug-in brake rim or brake tile without asbestos, safe, easy to replace and green initiative

- Coupling -Couplings connect brake, reducer and motor together.

- Wheel -Double edges cylindrical tread wheel, seldom offset and slip, 45 degree division structure, easy to dismantle, install and maintain

- Buffer -JHQ series polyurethane buffer at the ends of ground beam, can transform impact kinetic energy to elastic potential energy quickly

- Reliable hardness and impact elasticity, good restorability

- Both high and low temperature resistance, insulation, ensure the crane's safe travel

- Rail sweeper (same as A)

- Rail clamp (same as A)

Electrics

- Pressured type load lifting limiter, set alarm point, sensor settled on wire rope directly remaining original rope structure, control instrument could be installed together with sensor, or installed in electrical cabinet or other parts separately

- Easy to install and debug, steady quality, intelligent, small size, etc.

Crane power feeder:

- (1) safety slide wire,(2) soft cable,(3) cable drum,Trolley feeder:,

- (1) cable pulley

The slideway of soft cable and cable pulley could be wire rope slideway, I beam slideway, or deformed steel slideway.

Wire and cable

- Wire and cable with Copper, multistrand and insulating sheath used allover the crane

- Multistrand single cable, whose cross area of control wire≥1.5mm2 and 1.0mm2 multistrand multicore cable, cross area of power line≥2.5mm2

- The cables set in trunkings or tubes with thickness of 1.5mm~2mm

- Protection devices at the parts of mechanical injury, chemical corrosion or oil erosion

Control mode

- Pendant: control the actions of all mechanisms by pressing the buttons

- Remote control: control the actions of all mechanisms with industrial remote control

- Cabin control: control the actions of all mechanisms with the buttons, master switches, cam controller or linkage in the cabin

- The crane could also have two sets control devices, such as: pendant + remote control or cabin + remote control. Two control modes could not be used together for safety.

Electric protection system of electric hoist gantry crane

Short circuit protection

Automatic air-breaker switch in main power circuit as short circuit protection of the crane control circuit.

Voltage-loss protection

Circuit structure has Voltage-loss protect function, the start button must be repressed to restart the crane when power restoration after break in case of the crane automatic operating.

Emergency power switch

- Rotating reset type emergency power switch like a red mushroom used for switching off power quickly in emergency condition

- Emergency power switch set in convenient place

Overload limiter

- Overload limiter will send hint alarm signal when the load reach 90% rated capacity

- The power for lifting will be cut together with prohibitive alarm signal when reach 110% rated capacity

- The sensor linked with control box, moisture proof and anti-seismic, anti-interference.

Position limiter

- Fire limiter in lifting mechanism as the switch to limit the lifting height, at the same time, protect the controller

- Traveling limiter in crane traveling mechanism, composed of traveling limit switch on the crane and safety rule at the place get out of the crane travel, ensure safe travel of crane

- Wind-proof rail clamp is installed at one end of ground beam when used outside. Limit switch on rail clamp interlocks with main power switch, that is to say crane could not start when it is locked on the rail by rail clamp.

Zero position and interlock protection

- Cabin control crane has zero position and interlock protect function

- Zero position protection prevent the motor automatic operating when restore power after power off, avoid accidents

- Interlocking of door and switches avoid accidents like people or objects fall down from the door when the crane start suddenly as the door open.

Three-phase fault & voltage fault protection

- Comprehensive protection in circuit system will cut off main power automatically when three phase fault or voltage fault in case of damaging people and equipment.

Ground protection of electric hoist gantry crane

- Metacor of crane and metal shell, raceway, low side of transformer of electric equipment all have grounding. Total grounding resistance≤4Ω, and the crane rails could be as ground wire. Insulation resistance to ground≥1MΩ at normal temperature (it is measure value of 500V megger at normal temperature).

Paint coating & appearance of electric hoist gantry crane

- Surface derusting processing for steel plate before welded;

- The derusting quality level of main girder, legs, upper beam and lower beam should reach Sa2 1/2 or St3 level of GB/T8923 at least, other parts should reach Sa2 or St2 level;

- Painting the crane color as customer requirement before leaving factory. Coating thickness of mechanisms≥50μm after drying; paint film thickness of metal structure part: 25μm~35μm per layer, total: 75μm~105μm. Exposed surface without coating should take antirust measures.

Hot Sale Single Girder Gantry Cranes & General Crane Specifications

Gantry cranes are a type of overhead crane with legs that support the crane structure. Unlike bridge cranes, gantry cranes can be used outdoors, making them suitable for various applications in open yards, construction sites, and port facilities.

Gantry cranes are commonly used in settings where outdoor lifting is required. They excel in tasks like loading and unloading shipping containers, handling construction materials, and moving heavy equipment.

single girder gantry crane 1 ton to 20 ton with economical price

semi gantry crane, good price for sale

single girder gantry crane with European style electric hoist

semi gantry crane with European style electric hoist

Hot Sale Single Girder Gantry Crane Specifications

MH Single Girder Gantry Crane

MH single girder gantry crane is a typical gantry lifting equipment used for light duty to moderate services. It is adaptable to a variety of fields and sectors, such as workshop, freight yard, construction site, railroad, port and shipyard. The single beam gantry crane is generally outfitted with CD1 and MD1 electric hoist, and the capacity is in a range of 3 tons to 20 tons.

MH single girder gantry crane for sale in China:

- Load capacity: 3-20t

- Span: 8-35m

- Lifting height: 6-18m

- Lifting speed: 0.33-8m/min

- Trolley running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A3, A4

NMH European Single Girder Gantry Crane

- Load capacity: 3.2-20t

- Span: 8-35m

- Lifting height: 6-12m

- Lifting speed: 0.66-5m/min

- Trolley running speed: 2-20m/min

- Crane running speed: 3-30m/min

- Work duty: A5

| Technical Parameter of MH Electric Hoist Single Girder Gantry Crane | ||||||

| Capacity | t | 3 | 5 | 10 | 16 | 20 |

| Span | S(m) | 8~35 | 8~35 | 8~35 | 8~35 | 8~35 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 | 6~18 |

| Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) | 3.5(0.35/3.5) | 3.3(0.33/3.3) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 18 | 14 |

| Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Track type | P24 | P24 P30 | P30 P38 | P38 | P38 P43 |

| Technical Parameter of NMH European Electric Hoist Gantry Crane | ||||||

| Capacity | t | 3.2 | 5 | 10 | 16 | 20 |

| Span | S(m) | 8~35 | 8~35 | 8~35 | 8~35 | 8~35 |

| Lifting height | m | 6~12 | 6~12 | 6~12 | 6~12 | 6~12 |

| Lifting speed | m/min | 0.8/5 | 0.8/5 | 0.8/5 | 0.66/4 | 0.66/4 |

| Trolley speed | m/min | 2~20 | 2~20 | 2~20 | 2~20 | 2~20 |

| Crane speed | m/min | 3~30 | 3~30 | 3~30 | 3~30 | 3~30 |

| Work duty | A5 | A5 | A5 | A5 | A5 | |

| Track type | P24 | P24 P30 | P30 P38 | P30 P38 | P38 P43 |

Single Leg Semi Gantry Crane with Single Girder For Sale

Semi gantry crane is a piece of gantry lifting equipment used indoors and outdoors, such as machine shop, warehouse and freight yard. It is also regarded as a combination of half overhead crane and half gantry crane in that it is mounted to a carriage that travels on an overhead runway on one side and supported by a leg that travels along rails on the ground on the other side.

Designed for general purpose, this type of crane can be used for small to heavy duty lifting work in manufacturing and material handling industries. The cranes supplied by our company are also available in custom design to meet your special requirements.

BMH single girder semi gantry crane parameters:

- Load capacity: 3-20t

- Span: 8-30m

- Lifting height: 6-18m

- Lifting speed: 0.33-8m/min

- Trolley running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A3-A4

| Technical Parameter of BMH Electric Hoist Semi Gantry Crane | ||||||

| Capacity | t | 3 | 5 | 10 | 16 | 20 |

| Span | S(m) | 8~30 | 8~30 | 8~30 | 8~30 | 8~30 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 | 6~18 |

| Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) | 3.5(0.35/3.5) | 3.3(0.33/3.3) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 18 | 14 |

| Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Track type | P24 | P24 P30 | P30 P38 | P30 P38 | P38 P43 |

Truss Gantry Crane

Truss gantry crane can be extensively found in a variety of fields and sectors to accomplish small to heavy duty lifting work. It is distinguished by the fact that it is built with truss girder so as to prevent the attack of strong winds and storms. According to the girder construction, the crane can be classified into single girder and double girder. Each type has its own advantages and disadvantages with respect to the crane capacity, lifting speed and working efficiency.

Single girder truss gantry crane parameters:

- Load capacity: 3-20t

- Span: 8-35m

- Lifting height: 6-18m

- Lifting speed: 0.33-8m/min

- Trolley running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A3, A4

| Technical Parameter of MHH Electric Hoist Truss Gantry Crane | ||||||

| Capacity | t | 3 | 5 | 10 | 16 | 20 |

| Span | S(m) | 8~35 | 8~35 | 8~35 | 8~35 | 8~35 |

| Lifting height | m | 6~18 | 6~18 | 6~18 | 6~18 | 6~18 |

| Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) | 3.5(0.35/3.5) | 3.3(0.33/3.3) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 18 | 14 |

| Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

| Track type | P24 | P24 P30 | P30 P38 | P30 P38 | P38 P43 |

L Type Single Beam Gantry Crane 5 Ton to 50 Ton for Sale

L type single beam gantry crane is distinguished by its unique structure, L-shaped support legs, which makes it perfect for handling long pieces of items. The L-type gantry crane is capable of lifting and moving heavy loads in a range of 5 tons to 50 tons, widely used in open freight yard, railroad terminals, factories and warehouses. This type of single girder gantry crane is an essential tool for increasing working efficiency, safety and productivity of lifting operations.

Single girder L type gantry crane parameters:

- Load capacity: 5-50t

- Span: 18-35m

- Lifting height: 6-12m

- Lifting speed: 5.9-11.2m/min

- Trolley running speed: 36.6-39.7m/min

- Crane running speed: 39.7-46.2m/min

- Work duty: A3-A5

| Technical Parameter of MDG Single Girder Gantry Crane | |||||||

| Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 |

| Span | S(m) | 18~35 | 18~35 | 18~35 | 18~35 | 18~35 | 18~35 |

| Lifting height | m | 6~12 | 6~12 | 6~12 | 6~12 | 6~12 | 6~12 |

| Lifting speed | m/min | 11.2 | 9.6 | 9.6 | 7.2 | 7.6 | 5.9 |

| Trolley speed | m/min | 36.6 | 39.7 | 39.5 | 39.3 | 38.6 | 38.5 |

| Crane speed | m/min | 46.2 | 40.1 | 40.1 | 40.1 | 48.2 | 39.7 |

| Work duty | A3-A5 | A3-A5 | A3-A5 | A3-A5 | A3-A5 | A3-A5 | |

| Track type | P43 | P43 | P43 | P43 | QU80 | QU80 |

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch