Below The Hook Lifting Devices- All About Below-the-hook Devices

Find your below-the-hook lifting devices. Below-the-hook lifting devices are useful under hook crane attachments that allow for the efficient and safe material handling of various types of loads. There are several types of below hook devices available for your consideration, including coil hooks, coil grabs,magnetic below-the-hook lifting device, mechanical below-the-hook lifting devices, and spreader bars, which are used in conjunction with overhead travelling cranes and hoists.

What is a below-the-hook lifting device?

A below-the-hook lifting device, also known as a below-the-hook device, is a type of lifting device "a device used to secure a load to a hoist , which may consist of slings, hooks, and rigging hardware ."

Below-the-hook devices are tools or mechanical devices that secure a load to an overhead crane or hoist for safe transport from one working-site to another.

Identifying the Service Class of Below-the-hook devices

The under hook below-the-hook lifting device must be rated for a Service Class once the design is finalized. The Service Class is determized by many factors such as the number of load cycles a below-the-hook lifting device will experience over its lifetime.

A under hook below-the-hook lifting device flexes every time it is used, and if it flexes enough times, it will fracture - this is known as Fatigue. To maintain the below-the-hook lifting device's safety and longevity, fatigue must be taken into account.

Three questions will aid the engineer in determining the below-the-hook device's Fatigue and Service Class:

- How long do you plan on using this below-the-hook lifting device?

- How often will the below-the-hook lifting device be utilized per day?

- How heavy of a weight do you expect to lift?

The most typical Service Class is 2, which assigns a rating of 100,001 to 500,000 load cycles to the below-the-hook lifting device.

Single girder grab bucket crane, clamshell bucket - Crane below hook devices

Four rope grab bucket, grab bucket overhead crane

Selecting Materials and a Design

The engineer can choose the material and construct a below-the-hook lifting device that meets both the standards and the 3:1 design factor once the Design Category and Service Class have been defined. The material must be strong enough to withstand design forces and meet safety regulations while still being cost-effective for the customer's needs.

Welds are a crucial part of the design of a below-the-hook lifting mechanism. On a below-the-hook lifting device, all welds must adhere to industry and national standards.

Tagging the below-the-hook lifting device

The below-the-hook lifting device must be marked when it has been designed and produced. If the weight of a below-the-hook lifting device exceeds 100 pounds, the weight of the device must be listed on the tag. A tag is an essential component of any below-the-hook lifting mechanism. It identifies who built it, its working load limit (WLL), and the design criteria employed.

Motors may be used in several below-the-hook lifting systems. If this is the case, the tag must additionally include electrical information such as amps and voltage requirements. The tag is typically positioned near the hook attachment or bail, where it is least likely to be damaged. The tag can also be placed behind the counterweight on various C-Hook or coil below-the-hook lifting mechanisms. The placement was chosen to avoid causing damage to the tags.

Biomass grab - Biomass crane for straw bale handling

Steel scrap magnet, Magnetic overhead crane - magnetic blow hook device

Below-the-hook lifting devices standards

A lifting device, for example, lifting basket, spreader bar, or lift fixture must carry its own rated capacity. At the very least, it should have a name tag or plate, or some other permanent marker with the following information:

- It must bear the contractor's or manufacturer's name if it is fabricated on-site.

- If the lifting equipment weighs more than 100 pounds,

- Serial number

- The below-the-hook devices that have been re-rated must be labeled with the new rated capacity.

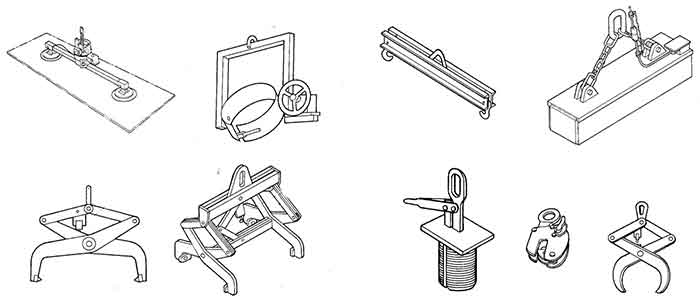

Types of below-the-hook devices and their uses

Types of below-the-hook lifting devices

Before offering the best below-the-hook devices and solving your most complex difficulties, our technical and sales staff will take the time to completely understand your application.

- Coil hook: A coil hook has an inner diameter that allows it to lift and carry steel and other types of coil materials.

- Motorized Coil Grabs: With this rack and pinion style grab, you can handle a wide range of coil sizes with very little effort. The crane operator can locate the coil with precision thanks to the option of motorized rotation.

- Mechanical lifter : A mechanical lifter is made up of two or more rigid parts that move in unison to secure a load to a hoisting device.

- Sheet lifters: A sheet lifter is a machine that grabs loads of wood or sheet metal using two claw-like actuators.

- Pallet lifters : Pallet lifters have a fork that allows them to raise pallets from underneath.

- Gripping lifters: To grasp a load, these lifters use indentation or friction-causing pressure.

- Beams: Beams are strung from a hoist that provides one or more load lifting points to efficiently secure and control load movement. They are often composed of manufactured metal or structural shapes. Lifting beams, spreader bars, and spreader beams are the three main types of beams.

- Vacuum lifters: These use an electrical extraction pump and sealed pads to create a vacuum to attach the lifter to an object.

- Die turners: A die turner is a machine that uses a crane and rigging equipment to turn or spin (rather than flip) enormous dies.

- Drum turners: As their name implies, drum turners are used to turn a drum over in order to empty or fill it.

- Magnet lifts: With or without the use of electricity, magnet lifts are used to release or transport flat or round ferrous items.

Magnetic beam spreader, magentic beam spreader below hook device

Magnetic chuck gantry crane for steel scrap handling - Gantry crane designs

Advantages of Below-the-Hook Lifting Devices

Below-the-hook lifting devices are the ideal option to provide the safest and most reliable load handling. Traditional wire rope, alloyed metal chains, or robust synthetic materials slings are easy to create, but they are not the safest means to transport loads and frequently change or shift abruptly. Unpredictable load bearing endangers both equipment and workers, particularly when transferring items of unique shape, size, or weight.

Below-the-hook lifters are designed to provide you the most control over your load. They not only improve worksite safety, but they also save you time and money by eliminating the need to come up with a creative workaround using a sling or other existing equipment.

Below-the-hook lifers are excellent for even the most challenging loads since they are very adaptable. For example, if your project necessitates the flexibility to raise weights with varied centers of gravity, a custom designed below-the-hook lift with an adjustable bail may readily accommodate them. A lifting device can be developed to transfer your items more efficiently and safely, no matter what your project requires.

Using below-the-hook lifting devices Safely & Correctly

What is your responsibility as an owner now since you have a below-the-hook lifting device constructed to all applicable standards and specifications? The individual who will use the below-the-hook lifting equipment must be appropriately trained. They must know how to utilize a below-the-hook lifting equipment safely and correctly. They must also know how to conduct a frequent inspection of the below-the-hook lifting device at the beginning of each shift. Although frequent inspections are not required before using a below-the-hook lifting device, they are an important step to take.

Before and during each lift, the operator must inspect for damage. Any debris must be removed from the load's surface. If the below-the-hook lifting device is powered, the operating controls should be in good working order, as should any indicators fitted to monitor the power component of the below-the-hook lifting device.

A more complete inspection should be performed at least once a year — this is a periodic inspection. The severity of use of the below-the-hook lifting device influences the frequency of the periodic inspection. Simply said, the more you use something, the more inspections it will require. We must also take into account the context in which the below-the-hook lifting device is operated. A periodic check could be required as often as quarterly, depending on the severity of use and the environment. Periodic inspection records must be retained.

You can fairly presume that any below-the-hook lifting device that does not have tags or calculations to back up its design is unsafe to use the next time you encounter one. A reliable manufacturer must produce your below-the-hook lifting devices. If you opt to create them yourself, remember to adhere to all of the safety precautions set in place to protect you and/or your coworkers.

Overhead crane with vacuum lifting for steel plate, glass handling - Overhead travelling crane series

Jib crane with vacuum lifting for steel plate, glass handling -jib crane series

Below the Hook Lifting Device Inspection Requirements

Three inspection frequencies are necessary for below-the-hook lifting devices:

- Immediately before and throughout each lift performed by the below-the-hook lifting device

- Inspections are carried out on a regular basis.

- Inspection on a regular basis

Prior to and during use -Before and during each lift, carefully inspect the below-the-hook lifting device for anything out of the ordinary, notably severe damage and wear.

Frequent Inspection - Visual inspections should be performed on a regular basis by the operator or another designated person (s). Frequent inspections of below-the-hook devices do not necessitate keeping written records.

- Normal Service – Monthly

- Heavy Service – Weekly to Monthly

- Severe Service – Daily to Weekly

- Special or Infrequent Service – Before and after each examination, a certified expert may prescribe special or infrequent service.

Periodic Inspection - A certified person must visually inspect all below-the-hook lifting devices on a regular basis, noting any exterior circumstances that may affect future inspections. An exterior code mark is appropriate identification instead of written records.

- Normal Service – Yearly

- Heavy Service – Semi-Annually

- Severe Service – Quarterly

- Special or Infrequent Service – Before the first such inspection, as suggested by a qualified person, and as directed by the qualified person for any subsequent inspections.

Get your customized below hook devices

We specialize in producing various sorts of overhead cranes and related components at EOTCRANEKIT. Please contact one of our industry experts if you require a bespoke below-the-hook lifting device or have questions about any of our products and services.

Many of our customers in the steel mill and foundry, steel service centers, manufacturing and fabrication, and paper mill industries work with us to improve the efficiency and safety of lifts and loads.

There are numerous applications for below-the-hook lifting devices, which is why there are various types of below-the-hook lifting devices. Most manufacturers make conventional lifting devices that can raise and move bars, pipes, coils, sheets, and plates, as well as pallets and various structural shapes.

Below-the-hook gadgets that are customized are also extremely common. These are specially constructed below-the-hook lifting devices for picking up and transporting specific goods. The load's size, shape, weight, and center of gravity can all influence how a custom-built below-the-hook device is made.