Light KBK Rail Crane Inspection & Maintenance to Ensure Safety

How to inspect & maintain your kbk crane system to prolong your rail crane working life & enhance safety? Make the best out of your kbk crane system.

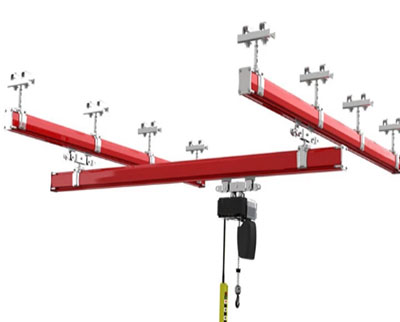

Flexible combined KBK crane system is a new type overhead travelling crane system with modular crane deigning concept. Crane parts and components of various functions are separated into different modular and the modular with same function are easy to interchange.

Ceiling mounted single girder kbk crane

Ceiling mounted double girder girder kbk crane

Freestanding single girder kbk crane

Freestanding single girder kbk crane

KBK crane inspection before commissioning

- A. The work area must have striking marks.

- B. It must be checked whether the voltage and frequency of the power supply are consistent with the conditions specified on the label.

- C. All safety distances should be checked.

- D. It must be checked that the kbk crane and trolley can be moved by hand over the entire length of the track without resistance.

- E. The function of control devices (such as flashlights), wireless control devices, limit switches, brakes, buffers and safety devices must be checked.

Main types of daily inspection for KBK cranes

- A. Visual inspection: determine the damage, wear and corrosion of parts.

- B. Functional inspection: determine the working condition of the parts and the working condition of the safety device.

Doing the inspection of the equipment is more conducive to the safety of our work and the progress of the project. Every KBK rail crane is like us, and daily maintenance and regular inspection are very necessary. KBK cranes that are suitable for normal single-shift operation at the specified inspection cycle. For KBK cranes operating in multiple shifts or under severe working conditions, the inspection period must be shortened, and the table does not include regular inspections and some inspections that are carried out on a daily basis.

Inspect and maintain of kbk light crane

KBK light crane is one of the more common lifting equipment on the market. It is often used in the working environment without any support above the workshop. It is a crane that can run freely suspended above the workshop or workshop. The walking track and span can be set freely. It is an essential lifting equipment for efficient production lines. So what are the inspection and maintenance requirements for KBK light cranes?

- Check and adjust the pulley, wire rope, hook and winch of the KBK light crane for wear and tear.

- Check and adjust the uniformity and uniformity of the gap between the brake and the brake wheel of the KBK light crane. To ensure stability and reliability.

- Check whether the signal lights of KBK light cranes are safe and reliable.

- Check the transmission oil level and oil quality of the KBK light crane, and add new lubricating oil according to the specified requirements.

- Check whether the adjustment of the KBK light crane brake is flexible and reliable.

The above is a brief introduction to the inspection and maintenance requirements of KBK light cranes. KBK light cranes are often used in many industrial workshops, warehouses, freight yards and modern industrial production lines for logistics handling operations. Safe and efficient operation has been trusted and supported by the majority of users.

Requirements for metal structure of kbk cranes

Metal structural are important structures that make up KBK cranes. The inspection of KBK cranes before leaving the factory must meet the following requirements:

- The metal structure of the KBK crane shall have the strength, rigidity and stability to meet the requirements of safe use, and shall meet the relevant requirements of GB/T3811 "Code for Design of Cranes".

- The design of the structure must take into account the convenience and possibility of manufacturing, inspection, transportation, installation and maintenance. For structures that work in the open air, water accumulation must be avoided.

- The selection of the base metal thickness of the main force-bearing components should consider the corrosion effect of the structure according to the actual working environment of the crane.

- When the main stress components of the KBK crane lose their overall stability, they should not be repaired and should be scrapped.

- When the main stress-bearing components are obviously corroded, inspection, measurement and calculation should be carried out. When the calculated bearing capacity cannot meet the rated bearing capacity, maintenance should be carried out to meet the requirements for use, or modification should be carried out to reduce the rated lifting capacity. scrapped.

- When cracks occur in the main stress-bearing components, measures to prevent the cracks from continuing to expand should be taken according to the stress and crack conditions, and measures to strengthen or change the stress distribution should be taken, otherwise stop using.

- When the main force-bearing components cannot operate normally and safely due to plastic deformation, they should be scrapped if they cannot be repaired.

- When the structural parts need to be welded and repaired, the welding materials used should meet the requirements of the original structural parts, and the welding quality should meet the corresponding requirements.

Inspection of key structural connecting bolts in key positions such as KBK crane jib, tower body of tower crane, rotary center bearing seat of portal KBK crane, base of crawler KBK crane, etc. The comprehensive effect of shear force and torsion force, if the root rupture occurs, the consequences will be very serious.

Metal structure inspection of KBK rail cranes

The KBK track is composed of suspension equipment, rails, turnouts, walking trolleys, electric hoists, mobile power supply equipment (slide lines) and control equipment. It only needs to be simply hung on the roof or beam frame of the workshop to realize the material transfer. Direct air transportation is therefore widely used in material transportation links or systems in all walks of life. What inspections need to be done on the metal structure of KBK rail cranes?

- Brake Brake is an important part of KBK crane, which directly affects the accuracy and reliability of the movement of each mechanism. Therefore, it is necessary to carefully check the brakes of the hoisting mechanism and luffing mechanism, and observe the opening of the brake shoes and the friction elements. wear condition. The belt brake should pay attention to check whether the steel backing of the brake belt is cracked, whether the transmission of the brake is flexible, whether the brake frame is in good condition, and whether the elasticity of the main spring and auxiliary spring meets the requirements.

- Reducer Check whether the reducer has oil leakage and whether there is abnormal noise in the box during operation. Abnormal noise is generally caused by bearing problems or excessive gear meshing backlash, serious tooth surface wear and other reasons.

- Wire ropes and pulleys are inspected for broken wires, abrasions, kinks and rust, etc. For the locations where wear and tear are more serious but have not exceeded the standard, mark them for key re-inspection; check the safety of wire ropes in the reel Whether the limiter is effective, and whether the wire rope pressure plate on the drum has been compressed.

- The inspection focus of the pulley is whether the wear amount of the groove bottom exceeds the standard and whether there is any crack in the cast iron pulley. The balance wheel of the pulley block of the pitching mechanism is easy to be overlooked. Be sure to check the flexibility of its rotation before installation. If the balance wheel rotates inflexibly, the length and tension of the left and right wire ropes cannot be adjusted by the balance wheel during installation, which will increase the speed at high altitudes. Adjust the difficulty and operational danger of the lowering wire rope.

- Couplings Check whether the couplings are loose or even "rolling keys". Focus on checking the elastic rubber ring of the elastic pin coupling for abnormal wear, and pay special attention to the wear of the gear ring of the toothed coupling. In the case of poor installation accuracy and large offset between the two shafts, the entire ring gear will quickly wear out. If this situation occurs in the hoisting mechanism, it is prone to serious accidents.

Routine maintenance of combined kbk crane rail systems

Routine maintenance is very important for combined kbk rail cranes, which not only helps the operation of the rail crane, but also effectively prolongs its service life and improves work efficiency. So how to maintain and maintain the kbk rail crane?

- The combined rail crane should be cleaned daily. After each use, it should be cleaned up, and the dust and grease on the surface should be wiped clean to keep the surface clean and tidy.

- Carefully inspect the kbk rail crane, check whether the parts are damaged, and fasten the screws to ensure that it can be used safely next time.

- Coat the crane with lubricating grease and anti-rust grease to prevent the crane parts from rusting.

- The crane should be stored in a dry and ventilated place, and the anti-corrosion work of the crane should be done to prolong the service life of the crane.

The above is the daily maintenance method of the combined crane. If you have other questions, you can call for consultation.

What are main types of KBK rail crane system

KBK light crane system includes KBK monorail suspension crane, KBK single girder suspension crane, KBK double girder suspension crane, KBK telescopic girder suspension crane, KBK stacker crane, rigid kbk crane system, and combined-type KBK cranes, and other forms, etc.

How to maintain the KBK track after frequent use to avoid "derailment"?

As a member of the lifting industry, the KBK track is widely used for its excellent performance. Due to frequent use, there will be some small problems with the KBK track. In order to solve this problem, attention should be paid to regular maintenance. maintain:

The reason why the KBK track is widely used is that it has an important role in preventing the occurrence of "derailment". Only by using this kind of track to limit the operation of the hoisting trolley to a certain track range can the operation of the lifting equipment be guaranteed to be within the controllable range. Therefore, we must pay attention to regular inspections when using the KBK track, so as to prevent problems before they occur, and make the work solid and practical. Only by finding and solving the problem in time can the major safety hazard such as "derailment" of the lifting trolley be avoided.

Even the best lifting equipment has a certain lifespan, and it is easier to do so when the equipment is overloaded. The same is true for the KBK track. Although the track has a certain space reserved for the bearing weight, be careful not to "eat" it during use. Strictly abide by the operating rules and reduce overdrafts can make the track live longer and use it more powerfully.

Due to the heavy load for a long time, the wear rate of the KBK track is often very high. Therefore, the key to maintenance is to reduce its wear and tear, and this requires good lubrication. Too much lubrication will make the trolley slip, but if the lubrication is not enough, the trolley will rub the track excessively, which will aggravate the damage of the track. Therefore, we must conscientiously equalize the lubrication work, and do it just right, so that the track can be maintained with high quality.

Do you know how to maintain the KBK track through the above introduction? To make things perfect and meticulous, you can contact us if you have any questions or other needs that you don't understand!

How to prevent kbk rail crane from rusting ?

The rusting of the kbk track will affect the normal use of the crane, reduce the safety of the operation, and affect the normal lifting work. So how to prevent the rust of the kbk track?

- The track cannot be installed in a humid environment. The installation environment should be dry and ventilated to avoid rusting of the track.

- The kbk track is cleaned regularly. If it is not cleaned for a long time, the sundries will erode the track and cause the track to rust.

- Apply lubricating grease and anti-rust grease to the track to prevent the track from oxidizing and rusting.

- There should be no chemical corrosive substances in the working environment, keep away from fire sources, and prevent the rust of the track.

The above is the method to prevent the rust of the kbk track. Doing a good job in the anti-rust work of the track can effectively prolong its service life and improve the work efficiency.

How to remove rust of kbk crane ?

The kbk rail crane is a very practical and convenient crane, and it is an indispensable lifting equipment in many industries. How to deal with the rust of the rail crane during use?

When the kbk rail crane is rusted, do not use it in a hurry, but do the rust removal first. Clean the rust spots and apply grease to prevent the parts from oxidizing and rusting again. The amount of grease applied should not be too much, just apply a thin layer. After the rail crane has done the rust removal work, check the connection parts of each mechanism, and pay special attention to the stability of the bolts.

Kbk rail cranes pay attention to daily cleaning and maintenance work to avoid rust, reduce damage to parts, and make them more durable.

How to prevent failure of kbk rail crane systems ?

In order to reduce the failure frequency of kbk rail cranes, what preventive measures should be taken in daily use of cranes? Let's read on.

- The staff who operate the kbk single-girder suspension crane must undergo pre-job training, be certified, and be proficient in the operation skills of the crane, standardize the operation, and avoid accidents.

- Carry out a comprehensive inspection of the kbk crane before operation, check whether the parts are damaged, whether the model is suitable, and whether the equipment is running smoothly, so as to ensure that the crane can carry out the lifting operation safely.

- Check whether the hoisted heavy objects are firmly tied to prevent the heavy objects from falling during the lifting operation.