Your Trusted Overhead Bridge Crane Manufacturer & Supplier

Custom Bridge Crane & Crane Kits for Your Needs

Bridge Crane for Sale 3 Ton, 5 Ton, 10 Ton 15 Ton up to 320 Ton

Bridge crane for sale. Types of bridge cranes & kits for sale, i.e, Single Girder | Double Girder | Top Running & Underhung bridge for wide industry use.

Standard bridge crane and customized industrial overhead bridge crane are available with capacity of 3 ton, 5 ton, 10 ton, 15 ton, 20 ton, 25 ton, 35 ton, up to 100 ton and above for sale around word, such as, South Africa, Canada, Australia, Singapore, United States, United Kingdom, Philippines, India, Indonesia, Italy, Russia, Vietnam, Brazil,and other countries and area, etc.

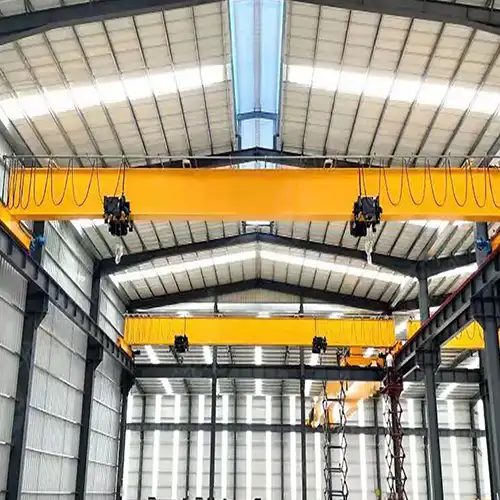

Bridge cranes are a type of lifting equipment that is commonly used for material lifting in the industrial workshop, workstation, warehouse, and material field. The operation coverage of an electric bridge crane is designed to be rectangular because the crane girder structure on a bridge crane can realize longitudinal operation along both sides of the rail laid on the elevated runway support frame, while the lifting trolley can realize horizontal operation along the rail laid on the crane span structure. Because of the unique structure, the overhead bridge crane can fully utilize the space beneath the crane span girder structure to lift material from the ground without being hindered. This type of crane is commonly used in a variety of fields such as indoor and outdoor warehouses, factories, wharfs, and outdoor material storage yards, and others, etc.

4 Main Types of Bridge Crane Designs

Depending on your crane application, you can select a single girder top running crane, a single girder under running crane / under hanging crane, a double girder top running crane / a double girder under running crane or custom crane for special use, etc.

One-source bridge crane services for all kinds of electric overhead traveling cranes and ceiling mounted bridge cranes are available, such as:

- Single girder bridge crane -A single beam that runs above or below the runway/end trucks is referred to as a single girder crane.

- Double girder bridge crane - A double girder crane is made up of two bridge beams that are mounted on top of the runway/end trucks.

- Top running bridge crane- An overhead eot crane mounted on the runway's top.

- Underhung bridge crane -Electric Bridge Crane with the end trucks attached and supported to the flanges on the bottom of the runway beams.

Our in-house overhead crane engineering team can provide a full package of column footing, crane runway, and bridge crane design. Our crane sales engineers have the knowledge to help you in selecting the right piece of overhead lifting equipment for your application. More information on types of overhead bridge cranes.

General industrial sectors such as steel fabrication, coil handling, construction, equipment repair, power, defense, and railroad, as well as specialized environments such as medical, semi-conductor, biotechnology, and food processing, are the major applications or uses of our crane and hoist equipment such as general use overhead bridge crane, gantry crane, jib crane and specially processed crane with the features of dust-free , spark resistant, or explosion proof, etc. Contact us to get your customized overhead crane based on your requirements and application conditions today.

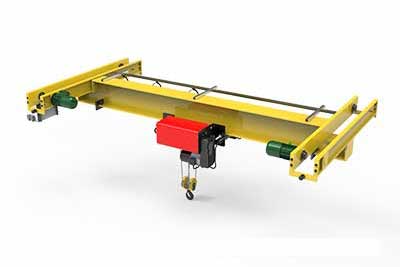

Top Running Single Girder Bridge Cranes 1 Ton -20 Ton

The standard bridge crane design is available with capacity from 500 kg to 20 ton. There are higher capacities and spans available. These single girder cranes are typically made of standard I-Beams or Wide flanges, but they can also be equipped with a custom fabricated monobox, patented track, or truss construction.

Advantages of Single Girder Top Running Bridge Cranes:

- Cost effective because there is less dead weight, which means less load on the runway, building structure, and foundations.

- Reduced freight costs to the job site.

- Easier installation means lower installation costs.

- Maintenance is simple.

Top Running Double Girder Bridge Cranes - 3 Ton to 320 Ton

Double girder top running cranes are built with wide flanges, reinforced wide flanges, or box girders. Trolleys are powered to travell along crane rail or square bar. End trucks can be supplied with four or eight wheels for greater spans and capacities.

Advantages of Double Girder Top Running Bridge Cranes

- Hook height is heigher.

- Ease of maintenance, particularly when controlling a catwalk.

- Designs with ultra-low headroom are possible.

- Durable construction for maximum uptime and minimal maintenance.

- Longer spans and capacities are also available.

- For ease of maintenance, modular components such as brakes, motors, and controls are used.

- Increased travel speeds.

- Longer spans. Increased duty cycle.

Single Girder Under Running Bridge Crane up to 10 Ton

Single girder under running bridge cranes are especially versatile when properly applied and can be provided in spans exceeding 75 feet and capacities up to 10 tons.

The design of these single girder overhead bridge cranes allows for interlocking systems in situations where the load must be transferred from one bay to the next, to a monorail, and then to another crane, or to a spur. These are typically provided as patented track designs, but they can also be made with wide flange or standard I-beam construction.

Underrunning bridge cranes are typically equipped with electric chain hoists or electric wire rope hoists, but they can also be equipped with a pneumatic hoist or a manual hand chain hoist.

Special construction is available for spark resistant, explosion proof, or food grade applications. Workstation bridge cranes are a type of underrunning bridge crane. These are in use and are typically used for lighter loads (up to 10 ton).

Advantages of a Single Girder Under Running Bridge Crane

- The bridge crane hoist trolley can travel beneath the runway, providing the best end approach.

- The system can be integrated into the building design to reduce the cost of the runway structure.

- Because of the connection of columns to headers and headers to the runway, freestanding workstation bridge crane systems are especially rigid.

- Interlocking to another crane or monorail can be provided.

- Low headroom design, particularly with notched bridge beams that take advantage of the runway's depth.

- Easier installation means lower installation costs.

Under Running Double Girder Bridge Cranes up to 25 Ton

Double girder under running bridge cranes are an excellent solution for extremely limited headroom. Because of the inherent design, the double girder hoist or crab hoist can be mounted in-between the girders, taking advantage of the girder headroom for maximum high hook. Under running girder cranes are typically supported by a runway structure built into the building's design.

These double girder overhead bridge cranes are typically built with Standard I-beam, Wide flange, Reinforced Wide Flange, or Box Girder construction. End trucks can be supplied with four or eight wheels (bogey construction) for greater spans and capacities.

Depending on the application and client demand, double girder cranes can also be equipped with electric chain hoists in addition to the standard electric wire rope trolley hoists. Double girder under running bridge cranes with top running trolley hoists are possible, despite the fact that they are uncommon.

In light to heavy industrial applications such as mining, steel processing, steel mills, railroad equipment, equipment repair, farm implement repair, coal, electricity, defense, and aerospace, double girder under running bridge cranes are frequently used. Environments used in clean rooms, food processing, and spark- or explosion-proof applications are examples of special applications.

Advantages of Double Girder Under Running Cranes

- Minimum headroom is necessary.

- Maintenance is very simple when using a catwalk.

- Designs with ultra-low headroom are feasible.

- Durable structure for long maintenance-free operation.

- Available longer spans and capacities.

- Brakes, motors, and controls are accessible as modular parts that are simple to fix for ease of maintenance.

- Faster moving forward.

- Longer stretches.

- increased duty cycle.

- Can be planned for an integrated system with your building.

Hot Sale Bridge Crane for Your Selection

Bridge Crane kits - a cost-effective solution for your needs

Our bridge crane kits ensure quality, efficiency, and reliability. Our overhead crane kit is designed to lift heavy loads. Bridge Crane Kit is appropriate for any situation. An industrial bridge crane is a lifting equipment that can lift and lower materials or loads as well as move them horizontally.

Single girder Suspension Crane Kit

Single Girder top running Bridge Crane Kit

Double Girder Bridge Crane Kit With Hoist

Double Girder Bridge Crane Kit With Winch

Your Trusted Overhead Bridge Crane Manufacturer & Supplier

Industrial Bridge Cranes for Sale, Custom Industrial Crane Design

General Use & Hazardous Use Brdige Cranes for Workshop, Warehouse & Workstations

Electric Bridge Crane is an important tool and equipment in the production process of modern industrial production and transportation. So the industrial bridge cranes have been widely used in the indoor and outdoor industrial and mining enterprise, iron and steel industry, railway transportation, port terminals, logistics, and other departments and places.

The overhead bridge cranes and widely used in various industrial sectors to Increase Safety,Improve Load Control,Avoid Floor Obstructions,Improve Ergonomics,and make the loads lifting easily, etc.

Industrial Bridge Crane For General Use

- Auto Industry -Overhead bridge cranes are used in the auto industry for a variety of tasks, including lifting and transport applications as well as material handling and supply chain applications.

- Steel- Steel mill cranes are customized for steel loads and material handling effectively and safely, such as, Ladle, tundish, slab, scrap, billet or ingot, coil,, etc.

- Plastics -The plastic industry requires high accurate bridge cranes for handlign different molding methods such as extrusion, injection molding, and rotation molding.

- Shipbuilding - An overhead crane is used for each of the steps of shipbuilding, which are processing, assembly, fieldwork, launch, rigging, and delivery.

- Biomass -Biomass bridge cranes are designed to handle waste, refuse, garbage, slag, sludge, and straw bales.

- Gas and Petroleum -Overhead cranes must be built with explosion-proof and spark-resistant components due to the flammability of gas and oil. This reduces the possibility of accidentally igniting the materials.

- Food and Drink -Sanitation and cleanliness are the primary requirements for material handling in the food and beverage business. Overhead cranes are used to transport rail-mounted containers for production or storage in the food processing industry.

- Semiconductor - To achieve the industry's high standards for quality, overhead cranes used in the semiconductor sector must be exact, accurate, spotless, and effective.

- Mining -Reliable and explosion proof bridge crane are widely used for mining industry which are made of heat, dust, and moisture resistant metals with heavy duty and large capacity.

- Paper -Paper rolls are frequently destroyed by even the slightest touch, hence the paper business needs high duty bridge cranes that can handle materials with great accuracy and care.

Industrial Bridge crane for Hazardous applications

This type of crane is primarily used to lift heavy materials in an explosive gas environment. The basic structure is similar to that of a standard bridge crane, but in the mechanical parts such as the motor and electrical parts, as well as the metal contact surface, explosion-proof measures are taken to ensure the safety of the user in an explosion-proof environment. According to the explosion-proof category, bridge cranes are classified into two types:

1.In a coal mine, an explosion-proof bridge crane is used.

The crane should have a coal mine security certificate because it is primarily used in coal mines, both aboveground and underground (MA).

2.In the factory, an explosion-proof bridge crane is used.

The crane should be issued by the national testing center of flame-proof certification if it is to be used in some dangerous places with combustible gas or combustible mixture.

More information on industrial bridge crane for your reference. Contact us to get your customized and processed bridge crane today.

What is Bridge Crane & its Advantages?

What exactly is a Bridge Crane? A Bridge Crane is a type of heavy duty lifting equipment that can move extremely heavy loads and equipment from one location to another in a safe and precise manner by utilizing the overhead space of a manufacturing facility. They are precision configured and designed to fit a specific type of loading application due to the nature of the work they perform.

Bridge Cranes are available in a variety of sizes, types, shapes, and configurations, as well as components and accessories. They are used to load and unload materials, move materials, lift dies from stamping machines, and feed raw materials.

Safety and effectiveness are the two basic justifications for deploying a bridge crane. Compared to floor- or land-based crane equipment, bridge cranes can operate at a far faster rate. Bridge cranes can safely transfer products without exposing employees in hazardous, risky, and challenging situations, such as when there are heated metals, chemicals, or toxic materials.

Advantages of Overhead Bridge Cranes:

- Workflow optimization in your facility.

- Reduced product damage.

- Improved load control and precision.

- Improvements to your facility's health and safety.

- There will be fewer lifting accidents.

- Lower operating costs than other floor mounted material handling systems.

- Overhead bridge cranes are environmentally friendly, with zero emissions and a long life cycle. They are custom engineered for your specific application and work area.

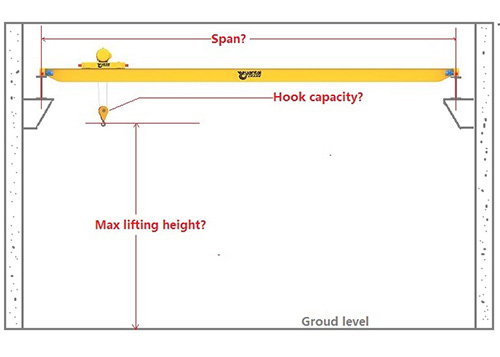

Main Factors Affecting Bridge Crane Design & Construction

crane span of bridge crane affect your crane design and price

crane lifting height of overhead bridge crane will affect your crane design

crane runway of electric travelling bridge crane

Span

One of the more expensive parts of the construction process is the span, which is the distance between the runway rails. The quantity of material needed to build the girders depends on how long and wide the span is, increasing the crane's weight and expense.

Load Capacity

The maximum load that may be applied to a crane under the necessary working circumstances is used to determine the crane's capacity. The size and weight of the material to be lifted are the first factors to consider when calculating the load capacity. The kind of hook and hoist can be chosen once the weight capacity has been established.

A double girder design may be required when the crane has a large span, capacity, and must withstand harsh conditions. Double girders are made of welded reinforced steel for added strength.

Runway

The installation of the runway may be difficult depending on the type of structure where the Bridge Crane will be mounted. Buildings have the runways positioned along the upper section of the walls, unlike gantry models that feature supporting legs. The length of the runway must be determined first since it affects how quickly the trolley and hoist go up and down the runway.

The Structure of the Building

The runways are planned as part of the construction and are included in the blueprints when a crane is installed in a new building. In this case, the contractor must pay special attention to crane tolerances because they are more stringent than standard construction codes.

Because several steps must be taken in the fabrication, design, and installation processes, adding a Bridge Crane to an existing structure can be costly. It is usually necessary to add extra support to the existing structure to ensure proper performance and safety.

Bridge Crane Working Duty

The Crane Manufacturers Association of America has established six classifications for bridge cranes (CMAA). The following criteria are used to determine a crane's classification:

- The frequency with which it is used.

- Material transfer speed.

- The number of lifts performed per hour.

- Maintenance cycle.

- Maintenance cycle.

- Average load.

- Number of full capacity lifts.

- Working conditions.

Working Environment Conditions

The severity, number of obstructions, and danger of the work environment all play a role in Bridge Crane design and construction. Heat, chemicals, fumes, steam, dust, or moisture all necessitate the use of special construction materials to keep the bridge crane from deteriorating. Various coatings may be required for protection and proper eletric bridge crane operation.

Explosion-prone operations, such as wastewater treatment, fertilizer plants, and oil and gas processing, require explosion-proof qualifications, which means the overhead crane must not generate sparks. This explosion proof bridge crane is powered by a pneumatic air system or a specially designed explosion proof electrical system.

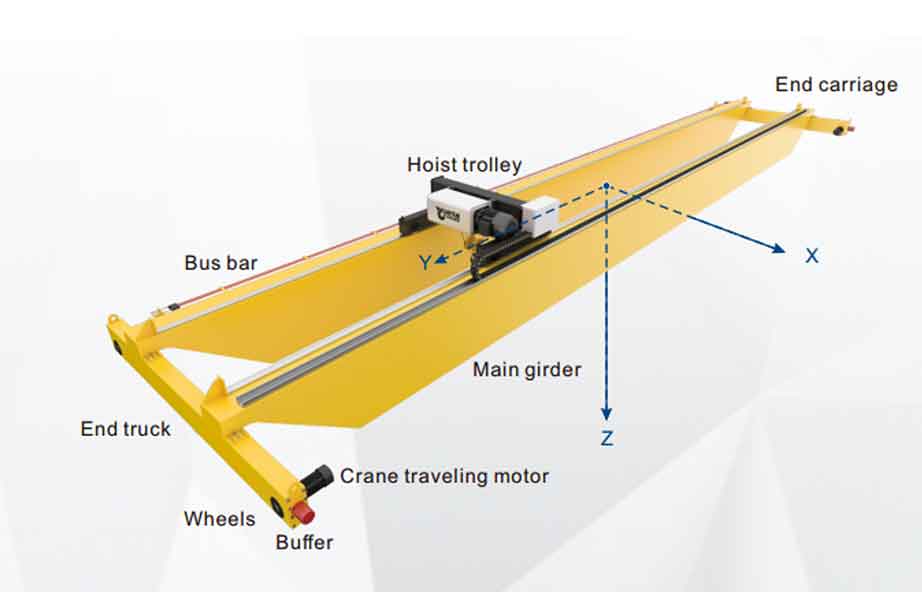

What are the Main Bridge Crane Parts & Components

Here is a list and explanation of the most common parts of overhead crane system to help you better understand workstation and bridge Crane components. Depending on the type of crane, not all components may be present or may differ from those shown here. Each crane is designed accordingly and specially. Leave a message below to get your customized bridge crane design with specialized bridge crane parts and components.

- Hook -The load is supported by a hook that connects to both the hoist and the end effector. According to our inspection experience, the latch kit is the most frequently replaced part.

- Bridge crane hoists -The hoist is responsible for creating the lift in lifting systems by holding, raising, or lowering the load with wire rope or chains. Hoists can be powered by hand, electricity, or compressed air (pnuematic). Choosing the right hoist for your lifting needs is critical to having a system that meets your lifting requirements.

- Trolley -Trolleys move along the crane's bridge and support the hoist. Trolleys can be top-running or bottom-running, and they can run on a track system or on a beam.

- Bridge -Bridges are the load-bearing components that span the crane system's width. This is the main structural component of a lift, connecting the runways and housing the hoists and trolleys. Bridges can have either a single or double beam. Depending on your needs and the load classifications of the work, they can be enclosed box style or beam/girder fabrication.

- Supporting Columns of overhead bridge crane -If the crane support system is not built into the structure, it will require columns to support it. The height of your bridge columns determines your headroom and the maximum height of your lift. Columns are all built to the size required by your environment in order to maximize lifting height.

- Bridge Crane Runway -The bridge travels along the runways, which move the crane up and down the bays. These can be built into the structure or supported by columns.

- Bridge Crane End Trucks -End trucks, located on either side of the bridge, move the bridge up and down the runways. End trucks have wheels that ride on the rail and can have up to eight wheels depending on the capacity of the crane.

- Electrification of electric motroized travelling bridge crane - The amount of power and the availability of power determine the electrification system required for a lifting system. Power is delivered to the lifting system via festooning systems (cables), insulated conductor bars, and power boxes from the building.

- Bridge crane controls - Controls can be mounted cabins, battery-powered remotes, or hanging pendants. The controls operate the drive and hoist motors, allowing the hoist and speed to be precisely controlled for precise load positioning. Remote pendants can be added to the majority of crane systems (remote operation is a safer alternative in many situations).

- Crane bumpers -Bumpers are designed to reduce crane impact and energy consumption. Bumpers bring the electric bridge crane to a controlled stop by reducing the force with which it reaches the end of travel. Bumpers can be attached to a variety of crane components. Crane stops are another name for bumpers. Replacing worn bumpers can help your crane last longer.

- End effectors of bridge crane attachment -The "lifting devices " of the bridge crane system is the end effector also called below hook device or crane attachment. End effectors can be as basic as cabling or strapping, and there are plenty of ready-made solutions for loads, but they work best when they are made to lift YOUR particular load. For your load lifting, a bespoke end effector is safer, quicker, and more accurate.

- Safety devices of bridge cranes - What are electric bridge crane safety devices? Overload limiter,Buffer,Stroke limiter,Interlock protection,Zero protection,Emergency switch,Conductive sliding wire protection board, and other bridge crane safety protection devices are available.

How to Get Your Custom Overhead Bridge Crane Price?

"How much is a 5 ton bridge crane?" "What is the cost of a 10 ton overhead bridge crane?" "Can you tell me the cost of a 15 ton double beam bridge crane?" and other similar inquiries.

Every day, so many customers ask the same queries! Yes, determining the price is always one of the most crucial factors you need to take into account, whether you are creating a budget or ordering cranes. Due to this, we have gathered the costs of a few bridge cranes solely for reference. First, let's discuss the variables that influence the cost of a bridge crane.

Each customer has different actual operating conditions, so a bridge crane with the same tonnage will cost a different amount. Lifting capacity, span, lifting height, power supply, the real working environment, and the specific needs of the customer are the primary elements that affect price. The pricing will vary depending on how one or more factors differ. Therefore, give us a thorough request that includes the following details if you'd like to find out the cost of an overhead bridge crane that suits your working requirements:

- - Lifting capacity

- - Span (S)

- - Lifting height (H)

- - Power supply(e.g. 380V 50Hz 3Phase)

- - Crane traveling length (L)

- - Detailed working conditions of the crane

- - How many hours does the crane need to work each day

- - Shall we provide you the crane traveling rails?

- - Other requirements

You can fill your crane needs in the contact form or by whatsapp : 0086 151 3871 1597. We will design the crane solution for you according to your actual needs, and then send you a detailed solution and Offer. Click to get more information on Bridge Crane Buy Guide to Get the Most Suitable Crane Solution or contact us by email.

What is Single Girder Bridge Crane Price?

Economial Chinese Single Girder Bridge Crane For Sale

IThe single girder bridges is a light small lift equipment with a capacity of 1 to 32 tons, and it is the most commonly used small material handling equipment in most factories, warehouses, and so on.

Main specifications of single girder top running bridge crane

- Lifting Capacity: 1~32t

- Lifting Height: 6-30m

- Span: 7.5~28.5m

- Working Duty: A3, A4

- Ambient Temperature: -20~40℃

Bridge Crane | Span(m) | Lifting Height(m) | Power Supply(V) | Price(USD) |

1 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $2200~40000 |

2 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $2500~40800 |

3 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $2600~41000 |

5 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $3000~41500 |

10 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $4000~45000 |

16 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5000~48000 |

20 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $6000~50000 |

25 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $8000~56000 |

The price of the above motorized travelling bridge cranes will change with the market, without further notice, for reference only. If you need an accurate overhead crane price in the near future, please contact us. Ask for single girder bridge crane price.

What is Double Girder Bridge Crane Price ?

Reliable Chinese Double Girder Bridge Crane For Sale

TThe double girder bridge crane can lift loads ranging from 5 to 63 tons and is commonly used in machinery fabrication, metallurgical plant auxiliary workshop, storage, stock ground, and power station, textile and food industries..

Main specification of double girder top running bridge crane

- Lifting Capacity: 1~63t

- Lifting Height: 6-30m

- Span: 7.5~28.5m

- Working Duty: A3, A4, A5

- Ambient Temperature: -20~40℃

Bridge Crane | Span(m) | Lifting Height(m) | Power Supply(V) | Price(USD) |

1 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $4000-60000 |

2 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $4500-62000 |

3 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5000-66000 |

5 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5800-72000 |

10 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $6500-79000 |

16 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $7800-86000 |

20 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $8600-95000 |

25 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $9800-110000 |

The price of the above double beam bridge cranes will change with the market, without further notice, for reference only. If you need an accurate double girder crane price in the near future, please contact us. Ask double girder bridge crane price .

Your Trusted Bridge Crane Manufacturer & Supplier

Customized Bridge Crane Projects & Cases

Single Girder & Double Girder Bridge | Top Running & Underhung Bridge

As a bridge crane manufacturer with more than 30 year experiences in bridge crane design and manufacture, we have provided standard bridge crane and customized industrial overhead bridge crane with capacity of 3 ton, 5 ton, 10 ton, 15 ton, 20 ton, 25 ton, 35 ton, 40 ton up to 100 ton and above for sale around word, such as, South Africa, Canada, Australia, Singapore, United States, United Kingdom, Philippines, India, Indonesia, Italy, Russia, Vietnam, Brazil,and other countries and area, etc.