Storage Bridge Crane Overview and Indusrial Applications

Storage bridge cranes & custom industrial overhead cranes for light / heavy material handling in industrial use. Get your overhead storage crane design!

Category: Featured

Your Trusted Storage Bridge Crane Manufacturer & Supplier

Storage Bridge Cranes for Industrial Uses, Custom Industrial Crane

Storage bridge cranes & custom industrial overhead cranes for light / heavy material handling in industrial use. Get your overhead storage crane design!

Storage Bridge Cranes

Storage Bridge Cranes, the unsung heroes of material handling, play a pivotal role in streamlining industrial operations. But what exactly are these cranes, and why are they considered indispensable in the world of logistics and manufacturing?

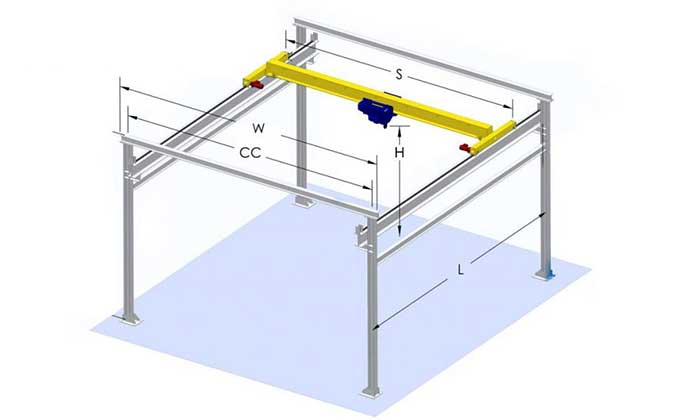

At its core, a Storage Bridge Crane is a type of overhead crane equipped with parallel runways, or bridges, where the hoist and trolley move. These cranes are designed for the efficient storage and retrieval of goods within a facility, offering a versatile solution for various industries.

Importance in Material Handling

The significance of Storage Bridge Cranes in material handling cannot be overstated. These cranes provide a dynamic and efficient means of lifting, moving, and organizing materials, contributing to the overall optimization of industrial processes. Whether it's in a bustling warehouse, a manufacturing plant, or an automotive facility, Storage Bridge Cranes play a crucial role in enhancing productivity and minimizing downtime.

Key Advantages and Features

What sets Storage Bridge Cranes apart from other material handling equipment? Let's delve into their key advantages and features:

- Versatility: Storage Bridge Cranes are known for their ability to cover large areas within a facility, providing a versatile solution for handling a wide range of materials.

- Optimized Workflow: By offering precise and controlled movement, these cranes optimize workflow in manufacturing and storage environments, reducing the time and effort required for material handling tasks.

- Customizable Capacities: From the nimble 1-ton crane to the robust 50-ton behemoth, Storage Bridge Cranes come in various capacities, allowing businesses to choose the right fit for their specific material handling needs.

- Space Efficiency: Utilizing overhead space, these cranes minimize floor obstruction, allowing for efficient use of space in warehouses and manufacturing plants.

- Enhanced Safety: Equipped with advanced safety features, Storage Bridge Cranes ensure the protection of both operators and valuable assets, adhering to industry regulations and standards.

In the upcoming parts of our comprehensive guide, we'll explore the diverse types and configurations of Storage Bridge Cranes, unveiling their applications in different industries, and providing insights into selecting the right capacity for your specific requirements. Join us on this journey as we unravel the power and potential of Storage Bridge Cranes in the world of material handling.

Types and Configurations of Storage Bridge Cranes

As we continue our exploration of Storage Bridge Cranes, it's crucial to understand the diverse types and configurations available. Each configuration offers unique features, making them suitable for specific applications. Let's dive into the world of bridge cranes and unravel the options at your disposal.

Single Girder Storage Bridge Cranes

Single Girder Bridge Cranes are characterized by having one main horizontal beam, or girder, that supports the hoist and trolley. These cranes are well-suited for lighter loads and applications with lower duty cycles.

Applications:

- Efficient handling of small to medium-sized loads.

- Ideal for small manufacturing plants and warehouses with limited space.

- Cost-effective solution for businesses with lighter material handling requirements.

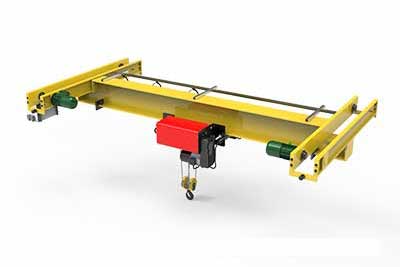

Double Girder Storage Bridge Cranes

Double Girder Bridge Cranes feature two parallel horizontal beams, providing increased stability and load-bearing capacity. They are designed for heavier loads and high-duty cycle applications.

Applications:

- Handling heavy materials in manufacturing plants.

- Suitable for industries with demanding material handling requirements.

- Efficient for lifting and moving large components and equipment.

Top Running vs. Under Running Cranes

Top Running Cranes run on elevated runway beams attached to the building structure, allowing for maximum hook height. These cranes are commonly used in larger facilities.

Applications:

- Ideal for facilities where maximizing hook height is crucial.

- Commonly used in warehouses and manufacturing plants.

Under Running Cranes operate on the bottom flange of runway beams, making them suitable for facilities with space constraints.

Applications:

- Suited for facilities with limited overhead space.

- Commonly used in workshops and smaller manufacturing setups.

Components and Features of Storage Bridge Cranes

To truly understand the capabilities of Storage Bridge Cranes, it's essential to explore the intricate details of their components and features. In this section, we'll delve into the key elements that make these cranes efficient and reliable in various industrial settings.

Hoists and Trolleys

Hoists: Overview of hoists as the lifting mechanism.

- Types of Hoists: Storage Bridge Cranes utilize various types of hoists, including electric chain hoists and wire rope hoists. Electric chain hoists are versatile, compact, and suitable for lighter loads. Wire rope hoists offer robust lifting capabilities and are ideal for heavier loads.

- Considerations for Selection: When selecting a hoist, considerations include load capacity, lifting height, and speed requirements. The type of material being handled, whether it's delicate components or heavy structures, influences the choice between electric chain hoists and wire rope hoists.

- Types of Trolleys: Trolleys can be manual or motorized. Manual trolleys are manually operated and suitable for lighter loads, while motorized trolleys enhance efficiency and are ideal for heavier loads and longer distances.

- Matching Trolley Type to Application: The choice between manual and motorized trolleys depends on the specific application's needs. For precise control and shorter distances, manual trolleys may suffice. However, motorized trolleys offer increased speed and ease of operation for larger facilities with more extensive material handling requirements.

Runway Systems

- Types of Runway Systems: Runway systems provide the support structure for the crane to traverse. They come in top-running and under-running configurations. Top-running systems are mounted on top of existing structures, while under-running systems are suspended from overhead supports.

- Design and Installation Considerations: Designing and installing runway systems involve considerations such as the facility layout, load capacity requirements, and the choice between top-running and under-running configurations based on available space and structural considerations.

- Runway Rail Selection: Discussion on the importance of choosing the right runway rail.

- Factors Influencing Rail Selection: Rail selection is crucial and depends on factors such as load capacity, track gauge, and material. Choosing the appropriate rail ensures smooth and precise movement of the crane along the runway.

Below-Hook Devices

Purpose and Types: Explanation of below-hook devices and their role in enhancing crane functionality.

- Types of Below-Hook Devices: Below-hook devices include hooks, lifting beams, and custom attachments. These devices extend the capabilities of the crane, enabling it to handle various types of loads and configurations.

- Applications in Different Industries: Below-hook devices find applications in different industries. For example, specialized lifting beams may be used in the aerospace industry for lifting and moving aircraft components, showcasing the adaptability of these devices.

Customization for Specific Loads: Importance of customizing below-hook devices for handling unique loads.

Control Systems

Crane Control Mechanisms: Overview of control systems governing crane movement.

- Different Control Mechanisms: Crane control mechanisms include pendant controls, where operators control the crane using a handheld pendant, and radio remote controls, which provide flexibility by allowing operators to control the crane from a distance.

- Advantages and Considerations: Pendant controls offer direct line-of-sight operation, while radio remote controls provide greater flexibility and safety by allowing operators to position themselves optimally based on the load and facility layout.

- Automation trends involve integrating Industry 4.0 technologies for data-driven decision-making. This includes real-time monitoring, predictive maintenance, and connectivity to broader manufacturing systems.

Safety Features

- Load Limiters and Overload Protection: Importance of load limiters in preventing overloading.

- Overload Protection: Load limiters and overload protection mechanisms are essential for preventing overloading, ensuring that the crane operates within its specified capacity limits.

- Collision Avoidance Systems: Explanation of collision avoidance systems to prevent accidents.

- Collision Avoidance: Collision avoidance systems utilize technologies such as sensors and cameras to detect obstacles and prevent collisions. This enhances safety in busy industrial environments where multiple cranes or other equipment may be operating simultaneously.

- Emergency Stop and Fail-Safe Systems: Discussion on emergency stop features and fail-safe systems.

- Role in Halting Crane Operations: Emergency stop features and fail-safe systems play a crucial role in halting crane operations in emergency situations. This ensures the safety of both operators and equipment in critical applications.

- Integrated Control and Safety: In a modern manufacturing facility, an integrated control system with safety features ensures not only efficient material handling but also a safe working environment. For example, collision avoidance systems can prevent accidents, and emergency stop features provide a quick response in unforeseen circumstances.

In summary, the components and features of Storage Bridge Cranes, including hoists, trolleys, runway systems, below-hook devices, control systems, and safety features, collectively contribute to efficient, safe, and tailored material handling solutions across various industrial applications.

Safety Guidelines and Regulations for Storage Bridge Cranes

Safety is paramount when it comes to the operation of Storage Bridge Cranes. In this section, we will explore the regulatory landscape, safe operating procedures, training requirements, and real-world case studies that highlight the successful implementation of safety measures.

OSHA Regulations and Compliance

- Compliance Requirements: OSHA regulations establish compliance requirements for crane manufacturers, installers, and operators. Understanding and adhering to these regulations is essential for creating a safe working environment and preventing accidents.

- Importance of Adhering to Standards: OSHA sets standards for load capacity and overload protection to ensure the safe operation of Storage Bridge Cranes. Adhering to these standards is crucial for preventing accidents, protecting workers, and maintaining equipment integrity.

Safe Operating Procedures

- Importance of Inspections: Comprehensive pre-operational checks involve inspecting critical components such as hoists, trolleys, controls, and safety features. Regular inspections help identify potential issues before they escalate, contributing to the overall safety of crane operations.

- Best Practices for Securing Loads: Safe load handling protocols include proper techniques for lifting, moving, and lowering loads. Emphasizing best practices in load securing ensures that materials are handled safely, minimizing the risk of accidents during material handling operations.

- Training on Emergency Procedures: Training operators on effective emergency stop and shutdown procedures is essential. Operators should be equipped to take quick and decisive actions in emergency situations, contributing to the overall safety of crane operations.

- Significance of Operator Training: OSHA mandates specific requirements for operator certification and training. Ensuring that crane operators are well-trained is crucial for safe and efficient crane operations, reducing the risk of accidents and promoting a culture of safety.

- Benefits of Simulation: Incorporating crane simulator training provides operators with realistic and risk-free learning experiences. Simulators allow operators to practice handling various applications, enhancing their skills and readiness for real-world operations.

Applications of Storage Bridge Cranes

Now that we've gained insights into the types and configurations of Storage Bridge Cranes, it's time to explore their diverse applications across various industries. From warehouses to manufacturing plants, these cranes play a pivotal role in optimizing material handling processes.

Warehousing and Distribution Centers

Warehousing and distribution centers operate in a high-demand environment, requiring seamless coordination and rapid material handling. Storage Bridge Cranes are strategically employed to meet the dynamic needs of these facilities, contributing significantly to their overall efficiency.

In conclusion, the pallet handling capabilities of Storage Bridge Cranes bring a level of efficiency and precision to warehouse operations that is crucial in the modern logistics landscape. This process not only streamlines storage but also contributes to accurate inventory management and timely order fulfillment.Key Components and Mechanisms:

- Hoists: The hoist is a critical component responsible for lifting and lowering pallets. It ensures controlled and accurate movements during the handling process.

- Trolleys: Trolleys, which move horizontally along the crane's bridge, are equipped with the hoist. They enable the crane to transport pallets seamlessly to designated storage locations.

Applications and Benifits

In a typical application, the process of pallet handling involves several steps:

- Goods Arrival: Products arrive at the warehouse on pallets, either from manufacturing facilities or external suppliers. Palletized goods are a standard method for transporting and storing items in bulk.

- Storage Bridge Crane Activation: Upon arrival, the Storage Bridge Crane is activated to commence the pallet handling process. The crane's control system ensures a smooth start to operations.

- Pallet Identification: Modern Storage Bridge Cranes may be equipped with automated systems for pallet identification. This can include barcode scanning or RFID technology, allowing the crane to recognize and track each pallet.

- Lifting and Movement: The hoist engages with the pallet, securely lifting it off the ground. Trolleys move the hoisted pallet horizontally, allowing the crane to transport it to its designated storage location within the warehouse.

- Organized Storage: Once positioned over the designated storage area, the crane carefully lowers the pallet into place. This organized storage system optimizes the use of vertical space within the warehouse, maximizing storage capacity.

- Inventory Management: The entire process is often integrated with warehouse management systems (WMS). This integration ensures real-time tracking of inventory levels, providing accurate data on the location and quantity of stored pallets.

Benefits of Pallet Handling by Storage Bridge Cranes:

- Precision and Control: Storage Bridge Cranes offer precise control during the lifting and movement of pallets, minimizing the risk of damage to goods.

- Vertical Storage Optimization: By utilizing vertical space within the warehouse, Storage Bridge Cranes optimize storage capacity, allowing for increased inventory without expanding the facility's footprint.

- Speed and Efficiency: The automated nature of pallet handling by Storage Bridge Cranes contributes to swift and efficient material handling processes, reducing the time required for storage and retrieval.

- Reduced Manual Labor: Automation in pallet handling reduces the reliance on manual labor, minimizing the need for human intervention and lowering the risk of injuries.

Order Picking:

The swift transportation of goods to picking stations is a critical aspect of warehousing operations. Storage Bridge Cranes facilitate the rapid movement of pallets to designated picking stations, where workers can efficiently retrieve items to fulfill customer orders. This process minimizes the time required for order picking and enhances overall order fulfillment speed.

Order picking is a pivotal step in warehousing operations, and the efficiency of this process directly impacts overall order fulfillment speed. Storage Bridge Cranes play a crucial role in facilitating swift transportation of goods to designated picking stations, enhancing the efficiency of order picking tasks.

Key Components and Mechanisms:

- Trolleys and Hoists: Similar to the pallet handling process, trolleys equipped with hoists are fundamental components. These allow for the horizontal movement and precise positioning of pallets carrying goods to the picking stations.

- Control Systems: Advanced control systems govern the movement of the crane, ensuring accurate placement of pallets at picking stations and seamless coordination with order picking workflows.

Application:

The order picking process involving Storage Bridge Cranes typically unfolds as follows:

- Order Receipt: Customer orders are received, and the items to be picked are identified. These orders can vary in size, requiring a mix of different products stored within the warehouse.

- Crane Activation: The Storage Bridge Crane is activated to initiate the order picking process. The crane's control system takes into account the order details, including the specific items and their locations within the warehouse.

- Pallet Retrieval: The crane identifies and retrieves the pallet containing the items required for the order. This retrieval process is efficient and precise, minimizing delays in accessing the necessary goods.

- Transportation to Picking Station: The crane transports the pallet to the designated picking station. This can be a specific area equipped for manual picking by workers or an automated picking system, depending on the warehouse's setup.

- Picking by Workers: At the picking station, workers can efficiently retrieve the required items from the pallet. The organized arrangement facilitated by the crane ensures that items are easily accessible, reducing the time and effort needed for picking.

- Continuous Flow: As one order is being picked, the crane can simultaneously work on retrieving pallets for other orders. This continuous flow ensures that the order picking process remains efficient and aligned with the fast-paced nature of modern e-commerce and distribution.

- Return to Storage: Once the order picking is complete, the crane can return the pallet to its designated storage location, ready for the next order fulfillment cycle.

Benefits of Order Picking by Storage Bridge Cranes:

- Speed and Accuracy: The swift and automated movement of pallets to picking stations ensures quick access to goods, contributing to faster order fulfillment.

- Optimized Labor Utilization: Storage Bridge Cranes reduce the manual labor required for transporting goods to picking stations, allowing workers to focus on the actual picking process.

- Efficient Workflows: The seamless integration of cranes with order picking workflows ensures a continuous and efficient process, minimizing idle time and improving overall productivity.

- Reduced Error Rates: The precision of Storage Bridge Cranes in positioning pallets at picking stations reduces the risk of errors in the order picking process.

In summary, Storage Bridge Cranes enhance the order picking process by providing a streamlined and automated solution for transporting goods to picking stations. This efficiency is crucial in meeting the demands of fast-paced order fulfillment within warehousing operations.

Cross-Docking:

- Overview: Cross-docking involves the quick transfer of goods between incoming and outgoing shipments without prolonged storage.

- Application: Storage Bridge Cranes play a pivotal role in expediting the cross-docking process. They efficiently lift and move pallets from incoming shipments to outgoing shipments, reducing the need for extended storage periods. This streamlined approach enhances the overall agility of the distribution center.

Benefits of Storage Bridge Cranes in Warehousing:

- Time Efficiency: The precise and rapid movement of goods by Storage Bridge Cranes significantly reduces the time required for tasks such as pallet handling, order picking, and cross-docking.

- Optimized Storage: The ability to lift and organize palletized goods allows for optimized storage within the warehouse. Storage Bridge Cranes make use of vertical space, minimizing the footprint of stored goods on the warehouse floor.

- Reduced Labor Intensity: Automation through Storage Bridge Cranes reduces the manual labor required for material handling tasks. This not only improves efficiency but also minimizes the risk of human error.

- Flexibility in Operations: Storage Bridge Cranes offer flexibility in adapting to changing operational needs. They can efficiently handle various types of goods, making them versatile in accommodating diverse inventory requirements.

In summary, the application of Storage Bridge Cranes in warehousing and distribution centers transforms these facilities into hubs of efficiency. The ability to handle palletized goods, expedite order picking, and streamline cross-docking processes positions these cranes as indispensable assets in the fast-paced world of logistics.

Manufacturing Plants

In manufacturing plants, precision and efficiency are paramount. Storage Bridge Cranes contribute to for Raw material handling including Lifting and moving raw materials seamlessly for uninterrupted production, Transporting materials between different stages of the manufacturing process, and for handling the organized storage of finished products before they are shipped.

In the dynamic and precision-driven environment of manufacturing plants, the role of Storage Bridge Cranes is pivotal. These cranes contribute significantly to the seamless flow of materials throughout various stages of production, ensuring uninterrupted processes and organized storage.

Benefits in Manufacturing Plants:

- Uninterrupted Production: Storage Bridge Cranes contribute to the continuous flow of raw materials, preventing bottlenecks in production and ensuring that manufacturing processes remain uninterrupted.

- Efficient Workflows: The precise movement of materials, whether raw or in progress, between different manufacturing stages is achieved with efficiency, optimizing overall workflows.

- Optimized Space Utilization: Storage Bridge Cranes make use of vertical space, enabling the efficient storage of raw materials, work-in-progress items, and finished goods. This optimization is particularly valuable in manufacturing plants where space may be limited.

- Reduced Material Handling Time: By automating material handling processes, Storage Bridge Cranes significantly reduce the time required to transport materials within the manufacturing facility. This contributes to faster production cycles.

- Enhanced Safety: The precision and control offered by Storage Bridge Cranes contribute to a safer working environment in manufacturing plants. Automated movements reduce the risk of accidents associated with manual material handling.

- Organized Storage: Finished goods are systematically stored using Storage Bridge Cranes, ensuring that products are readily accessible for shipping. This organized approach contributes to efficient inventory management.

Integration with Manufacturing Processes:

- Automated Production Lines: Storage Bridge Cranes can be integrated into automated production lines, seamlessly transporting materials between robotic workstations or machining centers.

- Collaboration with Robotics: In manufacturing environments with robotics, Storage Bridge Cranes complement these systems, ensuring a smooth exchange of materials between robotic cells.

In summary, the application of Storage Bridge Cranes in manufacturing plants goes beyond material handling; it is a key element in achieving precision, efficiency, and safety in the production processes. Whether lifting raw materials, transporting work-in-progress items, or organizing finished goods, these cranes play a vital role in the success of manufacturing operations.

Raw Material Handling:

Raw material handling is a fundamental aspect of manufacturing operations, and Storage Bridge Cranes are designed to excel in this crucial function. The precision and efficiency with which these cranes handle raw materials lay the foundation for uninterrupted production processes.

Key Components and Mechanisms:

- Hoists and Trolleys: The hoists, equipped with lifting mechanisms, provide the vertical movement necessary for handling raw materials. Trolleys, moving horizontally along the crane's bridge, facilitate the precise positioning of materials.

- Control Systems: Advanced control systems govern the movements of the crane, ensuring accurate and controlled lifting and transport of raw materials.

Application:

The raw material handling process involving Storage Bridge Cranes typically unfolds as follows:

- Arrival of Raw Materials: The manufacturing process begins with the arrival of raw materials at the manufacturing plant. These materials can include metals, plastics, textiles, or any other components required for production.

- Storage Bridge Crane Activation: Upon arrival, Storage Bridge Cranes are activated to commence the raw material handling process. The control systems are engaged to ensure a precise and controlled start to operations.

- Material Identification and Retrieval: Modern Storage Bridge Cranes may be equipped with automated systems for material identification. This can include barcode scanning or RFID technology, allowing the crane to recognize and retrieve specific raw materials based on the manufacturing requirements.

- Lifting and Transport: The hoists of the crane engage with the raw materials, lifting them off the ground. Trolleys move horizontally, allowing the crane to transport the materials to the appropriate storage or processing areas within the manufacturing facility.

- Positioning for Processing: Depending on the manufacturing process, the crane precisely positions the raw materials at designated areas for further processing. This may involve placing materials near machining centers, production cells, or storage locations.

- Integration with Production Lines: Storage Bridge Cranes can be seamlessly integrated into automated production lines, ensuring a continuous flow of raw materials to support manufacturing processes.

- Real-time Monitoring: Advanced control systems enable real-time monitoring of the raw material handling process. This includes tracking the location of materials, ensuring accurate positioning, and making adjustments as needed.

Benefits in Raw Material Handling:

- Uninterrupted Production: Storage Bridge Cranes contribute to the continuous and uninterrupted flow of raw materials, preventing delays in production processes.

- Reduced Manual Labor: Automation in raw material handling reduces the reliance on manual labor, minimizing the physical strain on workers and enhancing overall efficiency.

- Optimized Space Utilization: By utilizing vertical space, Storage Bridge Cranes optimize the storage of raw materials, allowing for increased inventory without expanding the manufacturing facility's footprint.

- Enhanced Safety: The precision and control offered by Storage Bridge Cranes contribute to a safer working environment. Automated movements reduce the risk of accidents associated with manual material handling.

- Efficient Workflows: The automated handling of raw materials ensures efficient workflows, reducing the time required for material transport and positioning.

In summary, raw material handling by Storage Bridge Cranes is a cornerstone of manufacturing operations. The ability to lift, transport, and position raw materials with precision contributes to the overall efficiency, safety, and success of manufacturing processes within a plant.

Work-in-Progress (WIP):

Work-in-progress (WIP) refers to materials and components that are in various stages of the manufacturing process. Storage Bridge Cranes are instrumental in facilitating the seamless movement of these materials between different stages, ensuring efficient and continuous production workflows.

Key Components and Mechanisms:

- Trolleys and Hoists: The trolleys equipped with hoists enable the horizontal and vertical movement of materials, allowing for precise transportation of work-in-progress components.

- Control Systems: Advanced control systems govern the movements of the crane, ensuring accurate positioning and transport of WIP materials based on production requirements.

Application:

The work-in-progress handling process involving Storage Bridge Cranes typically unfolds as follows:

- Component Arrival and Processing: Components and materials arrive at the manufacturing plant and undergo various stages of processing. This can include machining, assembly, or any other manufacturing processes specific to the industry.

- Identification and Tracking: Storage Bridge Cranes may be equipped with systems for the identification and tracking of WIP materials. This ensures that each component is recognized, and its movement is accurately monitored within the manufacturing facility.

- Transportation Between Workstations: As components move through different stages of production, Storage Bridge Cranes facilitate their transportation between workstations or production cells. This can involve transferring materials from one area to another for specific processing steps.

- Integration with Automated Cells: In modern manufacturing environments with automated cells or robotic workstations, Storage Bridge Cranes seamlessly integrate into these systems. They transport WIP materials to and from automated cells, allowing for efficient collaboration between automated processes and human-operated workstations.

- Precise Positioning for Assembly: For products requiring assembly, Storage Bridge Cranes precisely position WIP materials at assembly stations. This ensures that workers have easy access to components, streamlining the assembly process.

- Real-time Monitoring: The control systems of Storage Bridge Cranes enable real-time monitoring of WIP materials. This includes tracking the location of components, ensuring they are in the correct processing stage, and making adjustments as needed.

Benefits in Handling Work-in-Progress:

- Efficient Workflow Coordination: Storage Bridge Cranes facilitate the efficient movement of materials between different stages, ensuring a coordinated workflow in the manufacturing plant.

- Optimized Production Processes: The precise handling of WIP materials contributes to optimized production processes. Components are transported to the right locations at the right times, reducing idle time and enhancing overall efficiency.

- Collaboration with Automation: Storage Bridge Cranes seamlessly collaborate with automated cells and robotic workstations, allowing for a harmonized flow of materials between automated and human-operated processes.

- Reduced Manual Handling: Automation in WIP handling reduces the manual labor required for transporting components between workstations, minimizing the risk of errors and injuries.

- Adaptability to Changing Workflows: The flexibility of Storage Bridge Cranes allows for easy adaptation to changing production workflows. This is particularly valuable in environments where manufacturing processes are dynamic.

In summary, the handling of work-in-progress materials by Storage Bridge Cranes is a key element in optimizing manufacturing processes. From precise positioning for assembly to efficient transportation between workstations, these cranes contribute to the overall agility and success of manufacturing operations within a plant.

Finished Goods Storage:

Finished Goods Storage:

After the completion of the manufacturing process, the efficient and organized storage of finished products is crucial before they are shipped to customers or distribution centers. Storage Bridge Cranes play a vital role in this stage, ensuring that finished goods are stored in designated areas within the facility.

Key Components and Mechanisms:

- Trolleys and Hoists: Similar to other material handling processes, trolleys equipped with hoists facilitate the vertical and horizontal movement of finished goods.

- Control Systems: Advanced control systems govern the movements of the crane, allowing for precise positioning and storage of finished products.

Application:

The finished goods storage process involving Storage Bridge Cranes typically unfolds as follows:

- Completion of Manufacturing: Once the manufacturing process is complete, finished products are ready for storage. This can include items such as consumer goods, electronics, or any other products produced by the manufacturing plant.

- Quality Checks and Inspections: Before storage, finished goods may undergo quality checks and inspections to ensure that they meet the required standards. This step ensures that only high-quality products are stored and later shipped to customers.

- Activation of Storage Bridge Crane: Storage Bridge Cranes are activated to begin the transportation of finished goods. The control systems are engaged to orchestrate the precise movement of the crane.

- Lifting and Transportation: The hoists of the crane engage with the finished goods, lifting them off the production floor. Trolleys move horizontally, allowing the crane to transport the finished products to designated storage areas.

- Positioning for Storage: The crane positions the finished goods at their designated storage locations. This can include shelves, racks, or other storage systems within the facility. The precise positioning ensures efficient use of storage space.

- Integration with Inventory Management: The entire process is often integrated with inventory management systems. This integration allows for real-time tracking of finished goods, ensuring accurate data on the location and quantity of stored products.

- Accessibility for Retrieval: Finished goods are stored in a manner that allows for easy retrieval when they are ready to be shipped. Storage Bridge Cranes contribute to the organization of stored products, minimizing the time required for retrieval.

Benefits in Finished Goods Storage:

- Optimized Storage Space: Storage Bridge Cranes make use of vertical space, optimizing the storage of finished goods within the facility. This vertical storage approach maximizes the available space.

- Efficient Retrieval Processes: The organized storage facilitated by Storage Bridge Cranes ensures that finished goods are easily accessible. This efficiency is crucial for timely retrieval when products are scheduled for shipment.

- Inventory Accuracy: Integration with inventory management systems ensures accurate tracking of finished goods. This contributes to maintaining precise inventory levels and facilitates effective order fulfillment.

- Reduced Manual Handling: The automated nature of finished goods storage by Storage Bridge Cranes minimizes the manual labor required for moving and positioning products within the facility.

- Flexibility for Varied Products: Storage Bridge Cranes offer flexibility in handling a variety of finished products, accommodating different sizes, shapes, and quantities.

In summary, the role of Storage Bridge Cranes in finished goods storage is pivotal in ensuring that products are stored efficiently, organized, and readily accessible. This contributes to streamlined inventory management and prepares finished goods for timely shipment to customers or distribution centers.

Automotive Industry

In the automotive industry, where precision and strength are paramount, Storage Bridge Cranes serve as indispensable assets. Their role extends to the efficient handling of various car components, including heavy elements like engines and chassis. Additionally, these cranes play a crucial role in the movement of tools and dies within the manufacturing processes.

Key Functions:

- Handling Car Components: Overview: Storage Bridge Cranes are essential for lifting and moving heavy car components, contributing to the precision required in automotive manufacturing.

- Application: In the automotive manufacturing process, large and heavy components such as engines and chassis need to be moved between different workstations. Storage Bridge Cranes efficiently lift and transport these components, ensuring a smooth and controlled workflow.

Tool and Die Handling:

- Overview: Tool and die handling is a critical aspect of automotive manufacturing, requiring precision in the movement of specialized equipment.

- Application: Storage Bridge Cranes are instrumental in the efficient movement of tools and dies within manufacturing processes. These tools are essential for shaping and forming various components of an automobile, and the cranes facilitate their seamless transportation between machining stations and storage areas.

Benefits in the Automotive Industry:

- Precision in Component Handling: Storage Bridge Cranes offer precise control during the lifting and movement of heavy car components. This precision is crucial in automotive manufacturing, where accuracy is paramount.

- Optimized Production Workflows: The efficient movement of car components between workstations is facilitated by Storage Bridge Cranes, optimizing production workflows in the automotive manufacturing process.

- Enhanced Safety: The strength and stability of Storage Bridge Cranes contribute to a safer working environment in the automotive industry. Heavy components can be moved with control and accuracy, minimizing the risk of accidents.

- Streamlined Tool and Die Handling: In tool and die handling, Storage Bridge Cranes contribute to the efficient and organized movement of these critical components. This ensures that tools are readily available when needed in manufacturing processes.

- Support for Varied Manufacturing Processes: The versatility of Storage Bridge Cranes allows them to adapt to the diverse manufacturing processes within the automotive industry. Whether handling large car components or transporting precision tools, these cranes meet the industry's varied needs.

- Integration with Automated Systems: In modern automotive manufacturing facilities with automated systems, Storage Bridge Cranes seamlessly integrate into these systems, supporting the collaboration between automated processes and manual operations.

Applications:

- Engine Assembly: Storage Bridge Cranes are utilized in the assembly of engines, lifting and positioning engine components at different stages of the assembly line.

- Chassis Handling: The movement of chassis components, which can be large and heavy, is efficiently managed by Storage Bridge Cranes in automotive manufacturing.

- Tool and Die Maintenance: In tool and die maintenance processes, these cranes assist in transporting and positioning specialized equipment for maintenance and replacement.

In summary, Storage Bridge Cranes play a pivotal role in meeting the demanding requirements of the automotive industry. Whether handling heavy car components or facilitating the movement of critical tools and dies, these cranes contribute to the precision, efficiency, and safety essential in automotive manufacturing processes.

Steel and Metal Industries

Within the robust steel and metal industries, Storage Bridge Cranes play a crucial role in addressing the unique challenges presented by heavy materials. Their applications shine particularly in handling steel coils and contributing to the assembly of large steel structures for industrial buildings.

Steel Coil Handling:

Steel coil handling is a critical aspect of the steel industry, especially in the production of rolled steel. Storage Bridge Cranes are specifically designed to efficiently lift and transport heavy steel coils, contributing to the seamless flow of materials in the manufacturing process.

Key Components and Mechanisms:

- High-Capacity Hoists: The hoists of Storage Bridge Cranes are equipped with high-capacity lifting mechanisms, allowing them to handle the considerable weight of steel coils.

- Trolleys and Bridge Movement: Trolleys, moving horizontally along the crane's bridge, facilitate the precise positioning of steel coils. The bridge movement enables the crane to cover a larger area, reaching storage locations and processing equipment.

- Advanced Control Systems: The crane's movements are governed by advanced control systems, ensuring accurate and controlled handling of steel coils throughout the production process.

Application:

The steel coil handling process involving Storage Bridge Cranes typically unfolds as follows:

- Coil Retrieval from Storage: The process begins with the retrieval of steel coils from storage areas within the facility. Storage Bridge Cranes are activated to lift the coils from designated storage locations.

- Transportation to Processing Equipment: Once lifted, the cranes transport the steel coils to processing equipment, such as rolling mills or other machinery involved in the production of rolled steel. The horizontal movement of the trolleys ensures precise positioning.

- Vertical and Horizontal Movements: Storage Bridge Cranes excel in both vertical and horizontal movements. This versatility allows them to lift steel coils off the ground, navigate through the facility horizontally, and position the coils at the required processing stations.

- Placement in Designated Locations: The cranes place the steel coils in designated locations within the production are This can include positioning coils on feeding lines for further processing or placing them in storage racks for temporary holding.

- Integration with Coil Processing Lines: Storage Bridge Cranes are often integrated into coil processing lines, where steel coils undergo unwinding, flattening, and other processing steps. The cranes ensure the smooth transition of coils between different stages of processing.

- Real-time Monitoring: The entire handling process is monitored in real-time using advanced control systems. This allows for accurate tracking of the location and status of steel coils, contributing to efficient production planning.

Benefits in Steel Coil Handling:

- Efficient Material Flow: Storage Bridge Cranes optimize the flow of steel coils within the production facility, ensuring a continuous and efficient manufacturing process.

- Reduced Manual Handling: The automation provided by these cranes minimizes the need for manual labor in the handling of heavy steel coils. This reduces the risk of injuries and enhances overall workplace safety.

- Quick and Precise Positioning: The ability to precisely position steel coils at various stages of the production process contributes to the overall speed and accuracy of steel manufacturing.

- Optimized Space Utilization: By utilizing both vertical and horizontal movements, Storage Bridge Cranes optimize the use of available space in the facility for storage and processing.

- Integration with Coil Processing Lines: The seamless integration of Storage Bridge Cranes into coil processing lines ensures a coordinated and synchronized flow of materials through different processing stages.

Steel Structure Manufacturing

In the realm of steel structure manufacturing, Storage Bridge Cranes play a pivotal role in assembling large components that form the framework of industrial buildings. These cranes are specifically designed to lift and position substantial steel beams, columns, and other structural elements with precision, contributing to the overall efficiency and quality of the manufacturing process.

Key Components and Mechanisms:

- Heavy-Duty Hoists: The hoists of Storage Bridge Cranes are equipped with heavy-duty lifting mechanisms, capable of handling the weight of large steel structural components.

- Bridge and Trolley Movement: The horizontal movement of the crane's bridge, combined with the trolley's horizontal and vertical movement, facilitates the precise positioning of steel elements during the assembly process.

- Control Systems: Advanced control systems govern the movements of the crane, ensuring accurate and controlled handling of large structural components.

Application:

The steel structure manufacturing process involving Storage Bridge Cranes typically unfolds as follows:

- Component Retrieval from Storage: Storage Bridge Cranes are employed to retrieve large steel structural components from storage areas within the facility. This includes beams, columns, and other elements required for the assembly.

- Transportation to Assembly Area: Once retrieved, the cranes transport the steel components to the assembly are This may involve navigating through the facility horizontally and vertically to reach the designated location.

- Lifting and Precise Positioning: Storage Bridge Cranes excel in lifting large steel structural elements and precisely positioning them for assembly. This is particularly important for aligning components accurately before welding or other joining processes.

- Integration with Welding Stations: The cranes are often integrated into the manufacturing process, allowing for seamless coordination with welding stations. The precise movement of the crane ensures that components are positioned optimally for welding.

- Assembling Steel Framework: Storage Bridge Cranes play a key role in the actual assembly of the steel framework for industrial buildings. This may involve lifting and positioning beams, columns, and other elements to form the structural skeleton of the building.

- Temporary Storage and Retrieval: In cases where components need to be temporarily stored during the assembly process, Storage Bridge Cranes facilitate their placement in designated storage areas. These components can be retrieved as needed for the ongoing construction.

- Real-time Monitoring: Advanced control systems enable real-time monitoring of the assembly process. This includes tracking the location and status of large steel structural components, ensuring efficient and controlled movements.

Benefits in Steel Structure Manufacturing:

- Precision in Assembly: Storage Bridge Cranes contribute to the precision required in assembling large steel structures, ensuring that components are accurately positioned for welding and construction.

- Optimized Workflow: The seamless integration of cranes into the assembly process optimizes the workflow, reducing delays and enhancing overall efficiency in steel structure manufacturing.

- Reduced Manual Labor: Automation in lifting and positioning large structural components reduces the reliance on manual labor, minimizing physical strain on workers and improving safety.

- Flexibility in Component Handling: Storage Bridge Cranes offer flexibility in handling various steel components, accommodating different sizes and shapes. This adaptability is valuable in the diverse landscape of industrial building construction.

- Enhanced Safety: The controlled and precise movements of Storage Bridge Cranes contribute to a safer working environment, minimizing the risk of accidents during the assembly of large steel structures.

Applications:

- Steel Frame Construction: Storage Bridge Cranes are commonly used in the construction of steel-framed industrial buildings, including warehouses, factories, and other large structures.

- Bridge Construction: In the construction of bridges, Storage Bridge Cranes assist in handling and assembling the structural elements that form the bridge framework.

- High-rise Building Construction: For steel-framed high-rise buildings, these cranes play a crucial role in lifting and positioning components during construction.

In summary, Storage Bridge Cranes are indispensable in the manufacturing of large steel structures for industrial buildings. Their ability to lift, position, and assemble substantial components contributes to the precision, efficiency, and safety required in the construction of robust steel frameworks.

Benefits in the Steel and Metal Industries:

- Heavy Load Handling: Storage Bridge Cranes are designed to handle heavy loads, making them well-suited for the weighty materials involved in the steel and metal industries.

- Efficient Coil Transportation: In the steel coil handling process, these cranes contribute to the efficient transportation of coils between storage, processing, and manufacturing areas. This efficiency is crucial for maintaining a continuous production flow.

- Accurate Steel Structure Assembly: The precision and control offered by Storage Bridge Cranes ensure the accurate assembly of large steel structures. This is essential for maintaining the structural integrity and quality of the final products.

- Optimized Workflows: By streamlining the movement of steel coils and components, Storage Bridge Cranes optimize workflows in steel and metal industries. This contributes to increased production efficiency.

- Space Utilization: The ability of Storage Bridge Cranes to move materials vertically and horizontally enables efficient space utilization, particularly in the storage of steel coils and the assembly of steel structures.

- Reduced Manual Labor: Automation in material handling by these cranes reduces the manual labor required for moving heavy steel coils and components. This not only enhances efficiency but also minimizes the risk of injuries.

Applications:

- Coil Processing Lines: Storage Bridge Cranes are commonly used in coil processing lines, where steel coils are unwound, flattened, and processed for further manufacturing.

- Steel Fabrication Shops: In steel fabrication shops, these cranes are employed for lifting and transporting various steel components, contributing to the assembly of structures.

- Metal Service Centers: Storage Bridge Cranes are utilized in metal service centers for the efficient movement of steel coils and metal sheets within the facility.

In summary, Storage Bridge Cranes are indispensable in the steel and metal industries, addressing the challenges posed by heavy materials. Whether handling steel coils in the production of rolled steel or contributing to the assembly of large steel structures, these cranes play a vital role in ensuring efficiency, precision, and safety in manufacturing processes.

Textile Industry

Textile plants leverage the advantages of Storage Bridge Cranes in two key areas: roll handling and the storage of finished textile products.

Roll Handling:

Roll handling is a crucial operation in textile plants, involving the lifting and transportation of rolls of fabric or other materials used in textile production. Storage Bridge Cranes are specifically designed to streamline this process, ensuring the efficient movement of rolls within the facility.

Key Components and Mechanisms:

- Specialized Roll Handling Attachments: Storage Bridge Cranes may be equipped with specialized attachments designed for lifting and handling rolls of fabric or other textile materials.

- Trolley and Bridge Movement: The horizontal movement of the crane's bridge, combined with the trolley's horizontal and vertical movement, facilitates the precise positioning and transportation of rolls within the facility.

- Control Systems: Advanced control systems govern the movements of the crane, allowing for accurate and controlled handling of textile rolls.

Application:

The roll handling process involving Storage Bridge Cranes in textile plants typically unfolds as follows:

- Roll Retrieval from Production Areas: Storage Bridge Cranes are employed to retrieve rolls of fabric or other textile materials from production areas. This includes lifting rolls from processing machines or storage racks.

- Transportation to Processing Stations: Once lifted, the cranes transport the rolls to various processing stations within the facility. This may involve navigating through the facility horizontally and vertically to reach the designated locations.

- Precise Positioning for Processing: Storage Bridge Cranes excel in precise positioning, ensuring that rolls are accurately placed at processing stations. This is crucial for continuous and efficient textile manufacturing.

- Integration with Textile Machinery: The cranes are often integrated into the textile production process, allowing for seamless coordination with machinery. This ensures that rolls are fed into processing equipment with precision.

- Roll Transfer Between Workstations: In facilities with multiple workstations, Storage Bridge Cranes facilitate the efficient transfer of rolls between different processing stages. This contributes to an optimized workflow in textile manufacturing.

Benefits in Roll Handling:

- Efficient Material Flow: Storage Bridge Cranes optimize the flow of textile rolls within the production facility, ensuring a continuous and efficient manufacturing process.

- Reduced Manual Handling: Automation in roll handling by these cranes minimizes the need for manual labor, reducing the risk of injuries and improving workplace safety.

- Quick and Precise Positioning: The ability to precisely position rolls at various stages of the production process contributes to the overall speed and accuracy of textile manufacturing.

- Optimized Space Utilization: By utilizing both vertical and horizontal movements, Storage Bridge Cranes optimize the use of available space in the facility for roll storage and processing.

Storage of Textile Products:

Efficient storage of finished textile products, such as carpets or fabric bolts, is essential in textile plants. Storage Bridge Cranes play a crucial role in this application by facilitating the organized storage and retrieval of these products.

Application:

The storage process involving Storage Bridge Cranes for textile products typically unfolds as follows:

- Retrieval of Finished Textile Products: Storage Bridge Cranes are employed to retrieve finished textile products, which may include carpets, fabric bolts, or other goods, from production areas or storage racks.

- Transportation to Designated Storage Areas: Once retrieved, the cranes transport the textile products to designated storage areas within the facility. This may involve lifting products vertically and moving horizontally to reach the desired storage location.

- Precise Placement in Storage: Storage Bridge Cranes excel in the precise placement of textile products in storage. This ensures that products are organized, easily accessible, and occupy optimal storage space.

- Integration with Inventory Systems: The entire storage process is often integrated with inventory management systems. This integration allows for real-time tracking of textile products, ensuring accurate data on the location and quantity of stored items.

- Efficient Retrieval for Shipping: When textile products are ready for shipment, Storage Bridge Cranes facilitate their efficient retrieval from storage. This includes lifting and transporting products to shipping areas for timely dispatch.

Benefits in Storage of Textile Products:

- Optimized Storage Space: Storage Bridge Cranes make use of vertical space, optimizing the storage of finished textile products within the facility. This vertical storage approach maximizes the available space.

- Efficient Retrieval Processes: The organized storage facilitated by Storage Bridge Cranes ensures that finished textile products are easily accessible. This efficiency is crucial for timely retrieval when products are scheduled for shipment.

- Inventory Accuracy: Integration with inventory management systems ensures accurate tracking of textile products. This contributes to maintaining precise inventory levels and facilitates effective order fulfillment.

- Reduced Manual Handling: The automated nature of textile product storage by Storage Bridge Cranes minimizes the manual labor required for moving and positioning products within the facility.

- Adaptability to Changing Storage Needs: The flexibility of Storage Bridge Cranes allows for easy adaptation to changing storage needs. This is particularly valuable in environments where textile product storage requirements may vary.

Applications: Carpet Manufacturing: Storage Bridge Cranes are commonly used in carpet manufacturing facilities for the efficient handling and storage of carpet rolls.

- Fabric Bolt Storage: In textile plants producing fabric bolts, these cranes contribute to the organized storage and retrieval of fabric products.

- Integrated Logistics: Storage Bridge Cranes are integrated into the overall logistics and material handling systems of textile plants, ensuring a seamless flow from production to storage and shipping.

In summary, Storage Bridge Cranes are indispensable in the textile industry, supporting both the handling of rolls during production and the efficient storage of finished textile products. Their versatility and automation contribute to optimized workflows, reduced manual labor, and enhanced efficiency in textile manufacturing processes.

Pharmaceutical Precision:

In pharmaceutical settings, precision is paramount. Storage Bridge Cranes play a vital role in the controlled handling of materials, ensuring a high level of accuracy and adherence to stringent quality standards.

Key Components and Mechanisms: Cleanroom Design: Storage Bridge Cranes designed for pharmaceutical applications often adhere to cleanroom standards, minimizing the risk of contamination in sensitive environments.

- Specialized Attachments: Cranes may be equipped with specialized attachments to handle pharmaceutical materials with precision and care.

- Advanced Control Systems: The control systems governing crane movements are designed to provide precise and controlled handling, crucial for pharmaceutical processes.

Application:

The pharmaceutical precision process involving Storage Bridge Cranes typically unfolds as follows:

- Handling of Raw Materials: Storage Bridge Cranes are utilized for the controlled lifting and movement of raw materials used in pharmaceutical manufacturing. This includes the precise transfer of ingredients to processing stations.

- Integration with Manufacturing Equipment: The cranes seamlessly integrate with pharmaceutical manufacturing equipment, ensuring that materials are accurately fed into machinery for formulation processes.

- Batch Processing: Storage Bridge Cranes contribute to batch processing by precisely handling and transporting materials between different stages of pharmaceutical production. This ensures consistency and quality in the final products.

- Packaging and Distribution: In the final stages, the cranes assist in the controlled handling of packaged pharmaceutical products, facilitating their organized storage and retrieval for distribution.

Benefits in Pharmaceutical Precision:

- Adherence to Cleanroom Standards: Storage Bridge Cranes designed for pharmaceutical precision adhere to cleanroom standards, minimizing the risk of contamination in sensitive pharmaceutical environments.

- Controlled Handling of Sensitive Materials: The advanced control systems of the cranes ensure controlled and precise handling of sensitive pharmaceutical materials, reducing the risk of damage or product variability.

- Integration with Automated Processes: Seamless integration with pharmaceutical manufacturing equipment allows for the automation of material handling processes, contributing to the overall efficiency of pharmaceutical production.

- Consistent Batch Processing: Storage Bridge Cranes contribute to the consistent handling of materials during batch processing, ensuring that pharmaceutical formulations meet strict quality standards.

Bulk Material Handling:

In various industrial environments, the efficient handling of bulk materials is essential for streamlined operations. Storage Bridge Cranes are well-suited for lifting and moving bulk materials with precision and speed.

Key Components and Mechanisms:

- High-Capacity Hoists: The cranes are equipped with high-capacity hoists capable of lifting heavy bulk materials.

- Versatile Attachments: Specialized attachments may be employed for handling different types of bulk materials, ensuring versatility in applications.

- Adaptable Runway Systems: The cranes operate on adaptable runway systems, allowing them to cover large areas and efficiently reach different locations for material handling.

Application:

The bulk material handling process involving Storage Bridge Cranes typically unfolds as follows:

- Loading and Unloading: Storage Bridge Cranes are utilized for loading and unloading bulk materials from storage areas or transportation vehicles.

- Precise Placement in Processing Areas: The cranes facilitate the precise placement of bulk materials in designated processing areas, ensuring efficient material flow within the industrial facility.

- Integration with Conveyor Systems: In facilities with conveyor systems, Storage Bridge Cranes play a role in seamlessly transferring bulk materials from one processing stage to another.

- Stockpile Management: The cranes contribute to the organized management of bulk material stockpiles, allowing for easy retrieval when needed for production.

- Transportation to Storage Silos: Bulk materials are efficiently transported to storage silos or designated storage locations within the facility. The cranes' adaptability allows them to reach different storage areas.

Benefits in Bulk Material Handling:

- High-Capacity Lifting: Storage Bridge Cranes, with their high-capacity hoists, are capable of lifting and transporting substantial quantities of bulk materials, optimizing material handling efficiency.

- Versatility in Material Types: Specialized attachments and adaptable designs allow the cranes to handle various types of bulk materials, providing versatility in industrial applications.

- Optimized Material Flow: The precise placement of bulk materials by Storage Bridge Cranes contributes to optimized material flow within the industrial facility, reducing bottlenecks and enhancing efficiency.

- Reduction in Manual Labor: Automation in bulk material handling minimizes the reliance on manual labor, reducing the physical strain on workers and improving overall workplace safety.

- Applications: Mining Operations: Storage Bridge Cranes are employed in mining operations for the efficient handling of extracted bulk materials, such as ores and minerals.

- Aggregate Industries: In industries dealing with aggregates, such as sand and gravel, these cranes assist in the organized handling and transportation of bulk materials.

- Chemical Processing Plants: Storage Bridge Cranes play a role in chemical processing plants, facilitating the precise movement of bulk materials for various chemical processes.

In summary, Storage Bridge Cranes find diverse applications in pharmaceutical precision and bulk material handling across various industrial sectors. Their adaptability, precision, and efficiency contribute to streamlined processes and improved material handling in these industries.

Selecting the Right Capacity for Your Needs

Choosing the right capacity for a Storage Bridge Crane is a critical decision that directly impacts its performance and efficiency. In this section, we'll explore the key considerations for determining the optimal load capacity and delve into practical examples through enlightening case studies.

Choosing the Right Configuration for Specific Applications

Considerations:

- Load Capacity: Match the crane's capacity to the weight of the materials being handled.

- Span: Consider the distance the crane needs to cover within the facility.

- Duty Cycle: Assess the frequency and intensity of material handling tasks to determine the appropriate crane type.

Considerations for Load Capacity

- Weight of Materials: Evaluate the average weight of the materials you handle regularly.

- Flexibility Planning: Consider potential variations in material weights. While the average weight provides a baseline, planning for flexibility ensures that the crane can adapt to occasional or unexpected heavier loads without compromising safety or efficiency.

- Higher Frequency Consideration: Facilities with high-frequency material handling, such as continuous production lines or distribution centers, may benefit from a crane with a higher load capacity. This prevents excessive wear and tear on the crane, ensuring it can handle the demands of frequent lifting and movement.

- Capacity Alignment with Growth: Anticipate changes in production volume or facility expansion. Ensuring that the crane's capacity aligns with future material handling needs prevents the need for premature replacements or upgrades, saving costs in the long run.

Matching Crane Capacity to Material Handling Requirements

Light Loads (1-3 Tons):

Ideal for small components, tools, and light manufacturing processes.

Cranes with a capacity for light loads are suitable for industries where precision and careful handling of smaller components are crucial.

- Applications: Ideal for handling small parts in electronics manufacturing, tool and die shops, and assembly lines where components are lightweight.

- Benefits: Provides precise control for delicate tasks and is energy-efficient for lower capacity requirements.

Medium Loads (5-15 Tons):

Versatile capacity for a range of applications in manufacturing, warehousing, and automotive industries.

Medium load capacity cranes strike a balance between strength and precision, making them versatile for various applications.

- Applications: Well-suited for manufacturing plants handling medium-sized components, warehousing operations with diverse loads, and automotive industry applications.

- Benefits: Offers flexibility for a broad range of material handling tasks, providing strength for heavier loads while maintaining precision.

Heavy Loads (20-50 Tons):

Tailored for heavy-duty applications in steel, aerospace, and large-scale manufacturing.

Cranes with heavy load capacities are designed for robust lifting capabilities, catering to industries with oversized and heavy materials.

- Applications: Essential in steel and metal industries for handling large coils or structures, aerospace industry for lifting heavy components, and large-scale manufacturing operations.

- Benefits: Provides the strength and stability required for heavy-duty applications, ensuring the safe and efficient handling of substantial materials.

- Real-world Application: Aerospace Manufacturing: In the aerospace industry, where components can be large and heavy, Storage Bridge Cranes with heavy load capacities are crucial. They facilitate the precise handling of aircraft parts, engines, and other substantial materials, ensuring safety and efficiency in the manufacturing process.

In summary, considering load capacity in relation to the weight of materials, material handling frequency, and anticipating future growth is essential. Matching the crane capacity to material handling requirements ensures optimal performance, efficiency, and safety in diverse industrial applications.

Benefits of Capacity Selection in Case Studies:

- Right-Sized Capacity: Each case study demonstrates the selection of a Storage Bridge Crane with a capacity that is well-suited to the specific needs of the facility. This ensures that the crane is neither underutilized nor strained by excessive loads.

- Optimized Operations: The chosen capacities contribute to the optimization of operations in each application. Whether it's precision in a small workshop, efficiency on an automotive assembly line, stability in a steel fabrication plant, or compliance in pharmaceutical manufacturing, the selected crane capacities align with the unique demands of each environment.

- Safety and Compliance: The capacity selection reflects a commitment to safety and compliance with industry standards. Whether handling precision components or heavy steel structures, the chosen crane capacities prioritize safety, preventing overloading and ensuring stable material handling.

- Efficiency in Material Flow: The right-sized crane capacities contribute to the overall efficiency of material flow in each case study. This includes streamlined production processes, efficient handling of diverse loads, and adherence to specific industry requirements.

- Manufacturing Diversity: The case studies showcase the versatility of Storage Bridge Cranes in diverse manufacturing environments. From precision component production to heavy steel fabrication, the capacity selection reflects the adaptability of these cranes to meet the unique needs of different industries.

In summary, the case studies exemplify the importance of selecting the right capacity for Storage Bridge Cranes based on the specific requirements of each application. Whether it's for precision in small workshops, efficiency in automotive assembly lines, stability in steel fabrication plants, or compliance in pharmaceutical manufacturing, the chosen capacities contribute to optimized and safe material handling operations.

These case studies illustrate the diverse applications and considerations involved in selecting the right capacity for Storage Bridge Cranes. The key lies in aligning the crane's capabilities with the specific needs of your industry and operational requirements.

In the upcoming sections, we'll delve into the components and features of Storage Bridge Cranes, shedding light on the technology and safety measures that enhance their performance and reliability. Stay with us as we uncover the intricacies of these powerful material handling solutions.

Case Studies on Safety Implementations

Automotive Manufacturing Facility:

- Implementation of strict safety protocols in an automotive assembly plant.

- The implementation of strict safety protocols in an automotive assembly plant resulted in a significant reduction in accidents. Operators demonstrated heightened awareness and adherence to safety procedures, contributing to an improved safety record.

Warehouse Operations Excellence:

- Safety-focused practices in a busy warehouse environment.

- Emphasizing safety-focused practices in a busy warehouse environment led to reduced incidents, increased efficiency, and the development of a positive safety culture among warehouse staff.

In summary, strict adherence to OSHA regulations, comprehensive safe operating procedures, ongoing training for operators, and the implementation of safety-focused practices in various industries contribute to creating a secure and productive environment when utilizing Storage Bridge Cranes.

Conclusion

As we reach the conclusion of our comprehensive guide on Storage Bridge Cranes, let's summarize the key takeaways and extend encouragement for further exploration and implementation in the dynamic world of material handling.

- Versatility and Efficiency: Storage Bridge Cranes offer versatile solutions for efficient material handling in various industries, from automotive and aerospace to warehousing and manufacturing.

- Types and Configurations: Understanding the types and configurations, including single girder, double girder, top running, and under running cranes, allows businesses to choose the most suitable option for their specific needs.

- Applications Across Industries: Storage Bridge Cranes find applications in diverse sectors, such as automotive, aerospace, steel, and textiles, showcasing their adaptability to different material handling requirements.

- Selecting the Right Capacity: Careful consideration of load capacity is crucial, with different crane capacities serving specific applications ranging from light loads to heavy-duty operations.

- Components and Features: Exploring the components and features, including hoists, trolleys, runway systems, below-hook devices, control systems, and safety features, sheds light on the technology driving these cranes.

- Installation and Maintenance Best Practices: Planning and designing crane installations, meticulous installation processes, routine maintenance, and effective troubleshooting contribute to the seamless operation of Storage Bridge Cranes.

- Safety Guidelines and Regulations: Adhering to OSHA regulations, implementing safe operating procedures, providing thorough training for operators, and learning from case studies ensure a safety-first approach.

- Cost Considerations and ROI: Understanding the initial costs, long-term benefits, calculating ROI, and exploring financing options are essential aspects of making informed decisions regarding Storage Bridge Crane investments.

Incorporating Storage Bridge Cranes into your material handling strategy can lead to increased productivity, improved safety, and a positive impact on your bottom line. As you embark on this journey, we wish you success and innovation in optimizing your material handling operations. Thank you for accompanying us through this in-depth exploration of the power and potential of Storage Bridge Cranes.

In summary, the efficient handling of steel coils by Storage Bridge Cranes is crucial for the success of the steel industry, particularly in the production of rolled steel. These cranes contribute to the optimization of material flow, reduced manual labor, and the overall efficiency of the steel manufacturing process.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch