Garage gantry crane & Garage overhead crane - Garage crane & Shop Crane

Garage cranes is a material handling crane which is used in your garages or shopes. As a crane manufactuerer and supplier, various types of garage cranes, shop cranes and warehouse cranes to meet your needs for material handling.

Elevating Efficiency: A Comprehensive Guide to Material Handling Overhead Garage Cranes

Garage Cranes is used to improve efficiency in Garages. One of the key aspects of efficiency lies in material handling – the ability to move, lift, and position objects quickly and safely. This is where overhead garage cranes come into play, offering a versatile and effective solution for a wide range of material handling tasks.

In garages of all types – from automotive repair shops to home workshops, industrial warehouses to aircraft hangars – efficient material handling is crucial. Whether it's lifting heavy components during maintenance procedures, organizing inventory for easy access, or optimizing space utilization, effective material handling can significantly impact productivity, safety, and overall workflow efficiency.

At the heart of efficient material handling in garages are overhead garage cranes. These cranes, also known as bridge cranes or overhead traveling cranes, are designed to move heavy loads horizontally and vertically within the garage space. They consist of a horizontal beam (bridge) that travels along elevated runways, supported by a framework mounted on the walls or ceiling of the garage.

Main Types of Garage Cranes

Based on crane design, the types of garage cranes can be grouped into garage gantry crane with capacity from 0.25 ton to 10 ton, garage jib cranes with capacity from 0.25 ton to 2 ton, and garage overhead cranes which also can be grouped into free standing overhead cranes and customized garage overhead cranes, etc.As per your specific garage or shop conditions, the garage cranes can be tailored to improve your material handling efficiency and safety.

Types of Overhead Garage Cranes Used

There are several types of overhead garage cranes commonly used, each with its own advantages and applications:

- Single Girder Overhead Garage Crane: This type of crane features a single bridge girder supported by end trucks on each side. It's suitable for light to moderate lifting tasks and is commonly found in smaller garages or workshops.

- Double Girder Overhead Garage Crane: Double girder cranes have two bridge girders supported by end trucks. They offer higher lifting capacities and are suitable for heavier loads, making them ideal for larger industrial garages and warehouses.

- Gantry Crane for Garage Use: Gantry cranes are similar to overhead cranes but are supported on legs that run on rails at ground level rather than being attached to the building structure. They provide versatility and mobility, making them suitable for outdoor or temporary garage setups.

- Jib Crane Applications in Garages: Jib cranes have a horizontal boom (jib) that is mounted to a vertical mast or wall-mounted bracket. They're used for localized lifting tasks within a limited area of the garage, such as loading/unloading materials or positioning tools and equipment.

- Portable Gantry Crane Solutions: Portable gantry cranes offer flexibility and ease of setup, making them suitable for various garage applications where mobility is required. They can be easily moved and positioned as needed, making them ideal for DIY enthusiasts or temporary garage setups.

Garage gantry crane

Garage portable gantry crane specifications: Capacity:0.25 ton -10ton, Span length: 2~16m,Lifting height : 2~12m, Working class : A2. Ask for garage crane price.

Garage overhead crane

Garage underslung overhead crane specifications: Capacity:0.5 ton to 10 ton, Span: 3m to 31.5m, Lifting Height: 6m to 18m,Working Class:A3 to A5. Ask for garage crane price.

Garage jib crane

Wall mounted jib crane specifications-Capacity: 0.25 ton-2 ton, Arm length: 2-6m, Lifting height: 2-6m, Rotating : 180, Working class: A3.Ask for garage crane price.

Garage overhead crane with free standing crane design

Garage overhead kbk crane specifications: Capacity: 125Kg-5000Kg,Lifting Height: 2.5m-12m,Maximum Span : 3-10m,Working Class: A3. Ask for garage crane price.

Advantages of garage cranes

- The garage crane will make you work easier, faster, better and safer.

- The garage crane with two parallel steel tracks makes a steel bridge work smoothly on your workshop.

- The garage crane can move your loads and objects left and right, or forward and right with easy operation.

- The garage crane can be used to handle various types of loads and objects with rare limitation.

- The garage bridge crane can be moved to anywhere at any time in the factory.

Benefits of Utilizing Overhead Garage Cranes

The benefits of utilizing overhead garage cranes are manifold: Increased Efficiency:

- Overhead cranes streamline material handling processes, reducing manual labor and minimizing downtime.

- Improved Safety: By lifting heavy loads off the ground and maneuvering them with precision, overhead cranes help mitigate the risk of accidents and injuries

- Space Optimization: Overhead cranes utilize vertical space effectively, allowing for better organization and storage of materials and equipment.

- Versatility: With various types and configurations available, overhead cranes can be tailored to suit specific garage requirements and applications.

Garage Gantry Crane

A garage gantry crane is a type of light duty or tiny gantry crane that is used for lifting. Because of its restricted loading capacity, it is not suitable for heavy-duty lifting. As a result, it's commonly used to lift and move small and medium-sized goods. This type of lifting equipment is a common garage option, but it may also be utilized to handle various items in a shop, warehouse, workstation, and other locations. The gantry crane in a garage is increasingly being used for many different sectors as well as for household use as a highly effective material handling solution.

As a leading gantry crane manufacturer in China, our company manufactures and customizes a variety of garage gantry cranes to meet the needs of our customers, including portable gantry cranes, steel gantry cranes for garages, and more. We'll create the greatest material handling solution for you, one that maximizes your benefits and meets your requirements. Please do not hesitate to contact us via the internet.

Gantry Crane for Garage Use

Typical Applicable Garages:

Boat or RV Garages

Agricultural Equipment Garages

Construction Equipment Storage

Main Functions or Typical Loads/Objects Handled:

Marine Engine and Hull Lifting

RV Chassis Maintenance and Repair

Tractor and Farm Machinery Handling

Construction Equipment Transport and Maintenance

Types of Garage Gantry Cranes

Garage gantry cranes come in a variety of shapes and sizes to accommodate diverse lifting requirements. It is more frequently equipped with wheels to allow for more flexibility in movement. We may also provide different forms of lifting equipment for garages, such as a garage bridge crane, depending on your needs and the structure of your building. Steel garage gantry cranes with fixed or adjustable height and span designs are available.

Garage gantry crane with singl girder crane design

Garage single girder gantry crane specifications: Capacity: 1ton-20ton, Span Length: 8~30m, Working Class: A3, A4. Ask for garage crane price.

Garage gantry crane with double girder crane design

Garage double girder gantry crane specifications: Capacity: 5 ton - 500 ton, Span Length: 12~35m, Working Class: A5, A6Ask for garage crane price.

Small garage gantry crane

Garage portable gantry crane specifications: Capacity:0.25 ton -10ton, Span length: 2~16m,Lifting height : 2~12m, Working class : A2.Ask for garage crane price.

Garage gantry crane with sem gantry design

Garage semi-gantry crane specifications: Capacity: 2 ton- 10 ton, Span Length: 8~20m, Working Class: A3, A4.Ask for garage crane price.

Features of a garage gantry crane

The garage gantry cranes are built in accordance with industry and international standards and principles. Here are some of the benefits of garage gantry cranes:

- The portable garage gantry crane is available in a variety of design options, including steel, varied sizes, and wheels, and can handle practically all lifting operations in the garage and other workplaces.

- The tiny portable gantry cranes we make are made using high-quality materials and components, as well as precise machining, to ensure that they are of the highest quality. The tiny garage crane is simple to assemble and disassemble, making it ideal for storage and transit. It may also be easily transported to various work spaces.

- The movement is safer and more stable because to the robust structure, I-beam, and spring support wheel designs. This gantry crane can help enhance garage output while also saving time and money.

Typical Applicable Garages:

- Boat or RV Garages: Gantry cranes find applications in boat or RV garages where there's a need to handle large and heavy components. These garages often house boats, yachts, or recreational vehicles (RVs) that require lifting for maintenance, repair, or storage. Gantry cranes offer the flexibility to lift marine engines, boat hulls, or RV chassis safely and efficiently within the garage space.

- Agricultural Equipment Garages: Gantry cranes are commonly used in agricultural equipment garages to handle heavy machinery such as tractors, combines, and implements. These garages require material handling solutions capable of lifting and maneuvering bulky agricultural equipment for maintenance, repair, or storage. Gantry cranes provide the necessary lifting capacity and mobility to support various agricultural equipment handling tasks.

- Construction Equipment Storage: Gantry cranes are employed in construction equipment storage facilities where heavy machinery and equipment need to be moved and maintained. These facilities house construction equipment such as excavators, loaders, and cranes, which require periodic maintenance and inspection. Gantry cranes facilitate the safe lifting and transportation of construction equipment, optimizing storage space and enhancing workflow efficiency.

Main Functions or Typical Loads/Objects Handled:

- Marine Engine and Hull Lifting: In boat or RV garages, gantry cranes are utilized for lifting and maneuvering marine engines and boat hulls during maintenance, repair, or winterization activities. These cranes provide the lifting capacity and precision required to handle large and heavy components safely, ensuring efficient servicing of boats, yachts, or RVs within the garage environment.

- RV Chassis Maintenance and Repair: Gantry cranes support RV chassis maintenance and repair tasks in garages dedicated to recreational vehicle storage and servicing. These cranes enable mechanics to lift and position RV chassis components for inspection, repair, or replacement, enhancing efficiency and safety in RV maintenance operations.

- Tractor and Farm Machinery Handling: In agricultural equipment garages, gantry cranes are used for lifting and handling heavy farm machinery such as tractors, combines, and plows. These cranes assist in tasks such as engine maintenance, component replacement, or equipment assembly, optimizing workflow efficiency and minimizing manual labor.

- Construction Equipment Transport and Maintenance: Gantry cranes facilitate the transportation and maintenance of construction equipment in storage facilities or workshops. These cranes can lift and move heavy machinery such as excavators, loaders, and cranes, supporting maintenance tasks such as engine repairs, hydraulic system servicing, or component replacement.

Gantry cranes serve as versatile material handling solutions in various garage environments, including boat or RV garages, agricultural equipment garages, and construction equipment storage facilities. Whether lifting marine engines, handling agricultural machinery, or transporting construction equipment, gantry cranes enhance efficiency and safety in garage operations.

Portable Gantry Crane Solutions

Typical Applicable Garages:

Home Garages

Construction Sites

Agricultural Facilities

Main Functions or Typical Loads/Objects Handled:

DIY Projects and Home Maintenance

Construction Materials Handling

Farm Machinery Maintenance

Temporary Lifting Needs in Various Environments

Typical Applicable Garages:

- Home Garages: Portable gantry cranes are well-suited for home garages, providing homeowners with a versatile lifting solution for various DIY projects and home maintenance tasks. These cranes can be easily transported and set up in residential garage spaces, offering convenient access to lifting capabilities for tasks such as engine swaps, vehicle repairs, or woodworking projects.

- Construction Sites: Construction sites often utilize portable gantry cranes to handle materials, equipment, and components in dynamic work environments. These cranes offer flexibility and mobility, allowing construction crews to move them to different locations as needed for lifting heavy construction materials, structural components, or machinery on-site.

- Agricultural Facilities: Agricultural facilities benefit from the portability and versatility of gantry cranes for various maintenance tasks and material handling operations. Whether servicing farm machinery, handling livestock equipment, or managing bulk materials, portable gantry cranes provide farmers and agricultural workers with a convenient lifting solution in barns, workshops, or outdoor spaces.

Main Functions or Typical Loads/Objects Handled:

- DIY Projects and Home Maintenance: Portable gantry cranes support DIY enthusiasts and homeowners in tackling various projects and home maintenance tasks. These cranes enable users to lift and maneuver heavy objects such as engines, tools, or building materials with ease, enhancing efficiency and safety in home garage environments.

- Construction Materials Handling: At construction sites, portable gantry cranes are utilized for lifting and transporting construction materials such as steel beams, concrete panels, or scaffolding components. These cranes offer the flexibility to move materials across the site, facilitating efficient construction workflows and minimizing manual handling risks.

- Farm Machinery Maintenance: In agricultural facilities, portable gantry cranes assist in maintenance and repair tasks for farm machinery and equipment. Whether servicing tractors, harvesters, or irrigation systems, these cranes provide farmers with the lifting capacity and mobility needed to perform maintenance tasks in barns, workshops, or outdoor areas.

- Temporary Lifting Needs in Various Environments: Portable gantry cranes serve as temporary lifting solutions in various environments where traditional overhead crane systems may not be practical or feasible. These cranes can be easily transported and set up in indoor or outdoor spaces, providing temporary lifting capabilities for specific projects or applications in construction, agriculture, manufacturing, or event management.

Portable gantry crane solutions offer flexibility, mobility, and convenience for lifting tasks in home garages, construction sites, agricultural facilities, and other environments. Whether handling DIY projects, construction materials, farm machinery, or temporary lifting needs, these cranes provide a versatile and efficient lifting solution for a wide range of applications.

Garage Jib Cranes

As a garage jib crane manufacturer and supplier, types of garage jib cranes are provided and turnkey garage jib crane projects services including garage jib crane design, garage jib crane production, to jib crane installation and maintenance for over the world.

Jib Crane Applications in Garages

Typical Applicable Garages:

Automotive Repair Garages

Home Workshops

Industrial Settings with Restricted Spaces

Main Functions or Typical Loads/Objects Handled:

Tool and Equipment Positioning

Loading/Unloading Materials

Handling Small to Medium-Sized Parts

Workstation Assistance for Assembly Tasks

Types of Garage Jib Cranes

Generally garage jib cranes can be grouped into fixed garage jib crane, including, floor mounted garage jib crane and wall mounted garage jib crane, wall travelling garage jib crane, and mobile garage jib crane, etc.

Garage jib crane with pillar jib design

Garage pillar jib crane specifications-Capacity:0.5 ton -10 ton, Arm length: 3-12m, Lifting height: 3-8m, Rotating : 180, 270, 360 ,Working class: Ask for garage crane price.

Garage jib crane with wall mounted crane design

Garage wall mounted jib crane specifications-Capacity: 0.25 ton-2 ton, Arm length: 2-6m, Lifting height: 2-6m, Rotating : 180, Working class: A3.Ask for garage crane price.

Garage jib crane with wall travelling crane design

Garage wall-travelling jib crane specifications-Capacity: 0.25 ton-10 ton, Span: 3-10m, Lifting height: 3-8m, Rotating : 180,Working class: A3. Ask for garage crane price.

Garage jib crane with portable crane design

Garage portable jib crane specifications- Capacity: 0.08 ton,1 ton, Lifting Height: 1.5- 3m, Turning Radius: 2m, 3m, Rotation Angle: 360°, Working class: A3.Ask for garage crane price.

Typical Applicable Garages:

- Automotive Repair Garages: Jib cranes are commonly utilized in automotive repair garages due to their versatility and ability to handle various lifting tasks efficiently. These cranes are often installed near work bays or service areas to provide easy access for mechanics working on vehicles. Automotive repair garages benefit from the compact design and maneuverability of jib cranes, allowing them to lift and position heavy components such as engines, transmissions, and suspension assemblies with precision.

- Home Workshops: Home workshops often incorporate jib cranes to assist DIY enthusiasts or hobbyists in their projects. Whether working on automotive repairs, woodworking, or home renovations, jib cranes provide homeowners with a convenient lifting solution for handling tools, equipment, and materials. In home workshops with limited space, jib cranes offer a compact and versatile alternative to larger overhead crane systems, allowing for efficient material handling without the need for extensive structural modifications.

- Industrial Settings with Restricted Spaces: Industrial settings with restricted spaces, such as manufacturing plants or warehouses, utilize jib cranes to maximize vertical lifting capacity in confined areas. These cranes are commonly installed in areas with limited overhead clearance or restricted access, where traditional overhead cranes may not be feasible. Jib cranes provide a flexible material handling solution for lifting and positioning loads in tight spaces, improving workflow efficiency and optimizing workspace utilization.

Main Functions or Typical Loads/Objects Handled:

- Tool and Equipment Positioning: Jib cranes are utilized to position tools and equipment within easy reach of workers in automotive repair garages, home workshops, and industrial settings. These cranes allow operators to lift and maneuver heavy tools, such as impact wrenches, grinders, and welders, to the desired location for use. By reducing the need for manual lifting and carrying, jib cranes enhance ergonomics and productivity in garage environments.

- Loading/Unloading Materials: In industrial settings, jib cranes assist in loading and unloading materials onto machinery, conveyors, or storage racks. These cranes are commonly used in manufacturing plants or warehouses to lift pallets, containers, or bulk materials for transportation or storage. Jib cranes provide a flexible and efficient material handling solution for moving heavy loads in confined spaces, improving logistics and streamlining operations.

- Handling Small to Medium-Sized Parts: Jib cranes are well-suited for handling small to medium-sized parts in automotive repair garages, home workshops, and industrial settings. These cranes enable operators to lift and position components such as engine blocks, transmissions, or machinery parts with precision and control. By providing a stable and reliable lifting solution, jib cranes enhance accuracy and efficiency in assembly, repair, and maintenance tasks.

- Workstation Assistance for Assembly Tasks: Jib cranes serve as workstation assistants in assembly tasks, supporting workers in positioning and assembling components. These cranes are commonly used in manufacturing plants or production lines to assist operators in assembling products or sub-assemblies. By providing ergonomic lifting capabilities and reducing manual handling, jib cranes improve efficiency and safety in assembly operations.

Jib cranes offer versatile material handling solutions for various garage environments, including automotive repair garages, home workshops, and industrial settings with restricted spaces. Whether positioning tools, loading materials, handling parts, or assisting in assembly tasks, jib cranes enhance productivity and efficiency while minimizing manual labor and improving workplace safety.

Garage Overhead Crane

In factories, warehouses, and storage yards, overhead cranes are widely used for loading, unloading, transporting, and lifting materials and items. Overhead garage cranes are classified into two types based on the crane girder: single girder and double girder. They are designed to satisfy a variety of industrial lifting work capacities, ranging from medium to heavy, and they are suitable for use in all stages of the manufacturing process.

Garage overhead crane with top running crane design

Garage single girder overhead crane specifications: Capacity:3.2 ton to 16 ton, Span: 7.5m to 28.5m,Lifting Height: 6m to 18m,Working Class:A5. Ask for garage crane price.

Garage overhead crane with suspension crane design

Garage underslung overhead crane specifications: Capacity:0.5 ton to 10 ton, Span: 3m to 31.5m, Lifting Height: 6m to 18m,Working Class:A3 to A5. Ask for garage crane price.

Garage overhead crane with free standing kbk crane

Garage kbk crane specifications: Capacity: 125 kg -5000 kg, Span Length: 3~15m, Working Class: A3. Ask for garage crane price.

Garage overhead crane with free standing monorail crane

Garage monorail crane specifications: Capacity: 50kg- 3.2 ton, Span Length: 0.7~12m, Working Class: A3, A4.Ask for garage crane price.

You will make your work easier, faster, better, and safer if you have a garage overhead crane. A steel bridge is easily installed on your workshop with the help of a garage overhead crane with two parallel steel tracks. The garage overhead crane can function more easily in any direction, whether left or right, forward or backward. Furthermore, there are no set limits for what you can lift or transport with a garage overhead crane. The garage overhead crane's main advantage is that it can move anywhere in the plant at any moment.

Single Girder Overhead Garage Crane

Typical Applicable Garages:

Automotive Repair Garages

Home Workshops

Small Industrial Workspaces

Main Functions or Typical Loads/Objects Handled:

Engine Swaps and Repairs

Lifting Vehicle Components (e.g., Transmissions, Suspensions)

General Maintenance Tasks

Small Machinery Handling

Typical Applicable Garages:

- Automotive Repair Garages: Single girder overhead garage cranes are commonly found in automotive repair garages due to their versatility and ability to handle various tasks efficiently. In these settings, the crane is utilized for tasks such as lifting and maneuvering engines, transmissions, and other heavy vehicle components during repairs and maintenance. The compact design of single girder cranes makes them suitable for navigating tight spaces commonly found in automotive repair garages. Additionally, their cost-effectiveness makes them an attractive option for smaller businesses or independent mechanics.

- Home Workshops: Home workshops often benefit from the addition of a single girder overhead garage crane, particularly for DIY enthusiasts or hobbyists working on automotive projects. These cranes provide homeowners with the ability to lift and position heavy components with ease, facilitating tasks such as engine swaps, vehicle restoration, and general maintenance. Single girder cranes are well-suited for home workshops due to their compact size and ease of installation, making them a practical solution for maximizing space and improving efficiency in DIY automotive projects.

- Small Industrial Workspaces: In small industrial workspaces where space is limited, single girder overhead garage cranes offer a versatile solution for material handling tasks. These cranes are commonly used for lifting and moving materials, parts, and equipment in manufacturing facilities, warehouses, and production lines. Their compact design allows them to be installed in areas with low headroom, making them ideal for optimizing vertical space in small industrial environments. Single girder cranes are also cost-effective options for small businesses looking to improve efficiency in material handling operations without compromising on performance or reliability.

Single girder overhead garage cranes are prized for their simplicity, cost-effectiveness, and versatility in various garage settings. Whether in automotive repair garages, home workshops, or small industrial workspaces, these cranes provide efficient material handling solutions, enhancing productivity and safety in garage environments of all sizes.

Main Functions or Typical Loads/Objects Handled:

- Engine Swaps and Repairs: Single girder overhead garage cranes excel in facilitating engine swaps and repairs in automotive repair garages and home workshops. These cranes provide the necessary lifting capacity and precision to safely remove and install vehicle engines. Whether it's lifting a compact car engine or a larger truck engine, the crane's robust construction and adjustable lifting height ensure efficient and controlled engine handling. This capability streamlines the engine replacement process, reducing downtime and labor costs associated with manual engine handling.

- Lifting Vehicle Components (e.g., Transmissions, Suspensions): Single girder overhead garage cranes are essential for lifting and maneuvering various vehicle components, including transmissions, suspensions, axles, and differentials. These components often require precise positioning during repairs and maintenance tasks. The crane's flexibility allows mechanics to lift and lower components safely, providing optimal access for inspection, repair, or replacement. By assisting with component handling, the crane enhances workflow efficiency and reduces the risk of damage to both the vehicle and personnel.

- General Maintenance Tasks: Beyond engine swaps and component repairs, single girder overhead garage cranes support a wide range of general maintenance tasks in automotive repair garages, home workshops, and small industrial workspaces. From lifting heavy tools and equipment to positioning workbenches or vehicle frames, the crane aids in various maintenance activities. Mechanics can easily lift and position objects such as tires, batteries, exhaust systems, and body panels, facilitating efficient servicing and enhancing workspace organization.

- Small Machinery Handling: In addition to automotive applications, single girder overhead garage cranes are suitable for handling small machinery and equipment in various industrial settings. Whether in manufacturing facilities or small workshops, these cranes assist in lifting and moving machinery such as benchtop drills, milling machines, lathes, and grinders. Their compact design and adjustable lifting capacities make them versatile tools for handling a wide range of machinery, improving workflow efficiency and ensuring safe material handling practices.

Overall, single girder overhead garage cranes play a crucial role in handling diverse loads and objects in automotive repair garages, home workshops, and small industrial workspaces. From engine swaps to general maintenance tasks and small machinery handling, these cranes offer efficient material handling solutions, enhancing productivity and safety in garage environments.

Double Girder Overhead Garage Crane

Typical Applicable Garages:

Commercial Truck Maintenance Garages

Large Industrial Facilities

Warehouses with Garage Spaces

Main Functions or Typical Loads/Objects Handled:

Heavy Vehicle Component Handling (e.g., Engines, Axles)

Palletized Goods Handling

Large Equipment and Machinery Maintenance

Bulk Material Handling

Typical Applicable Garages:

- Commercial Truck Maintenance Garages: Double girder overhead garage cranes are commonly used in commercial truck maintenance garages due to their robust construction and high lifting capacities. These cranes are well-suited for handling heavy vehicle components such as engines, axles, transmissions, and chassis assemblies. In commercial truck maintenance garages, where large trucks and fleets undergo extensive repairs and maintenance, double girder cranes provide the lifting power and precision required for handling bulky and cumbersome components.

- Large Industrial Facilities: Large industrial facilities with expansive workspaces and heavy-duty material handling requirements often utilize double girder overhead garage cranes. These cranes are ideal for handling oversized loads and equipment in industrial settings such as manufacturing plants, foundries, and steel mills. Their high lifting capacities and long spans make them suitable for lifting and transporting heavy machinery, structural components, and raw materials within the facility.

- Warehouses with Garage Spaces: Warehouses that incorporate garage spaces for vehicle maintenance or loading/unloading operations benefit from the versatility of double girder overhead garage cranes. These cranes support various material handling tasks, including lifting heavy palletized goods, equipment maintenance, and bulk material handling. In warehouse environments where space is limited and heavy loads need to be moved efficiently, double girder cranes provide a reliable solution for optimizing material flow and enhancing productivity.

Main Functions or Typical Loads/Objects Handled:

- Heavy Vehicle Component Handling (e.g., Engines, Axles): Double girder overhead garage cranes excel in handling heavy vehicle components commonly found in commercial truck maintenance garages. These cranes are capable of lifting and maneuvering engines, axles, transmissions, and other large truck components with ease and precision. Their high lifting capacities and wide spans provide ample clearance for working on large trucks and fleets, streamlining maintenance and repair operations.

- Palletized Goods Handling: In warehouses with garage spaces, double girder overhead garage cranes are utilized for lifting and transporting palletized goods. These cranes can handle heavy loads and large pallets with ease, facilitating efficient loading and unloading operations. Whether moving materials from storage racks to delivery trucks or positioning pallets for storage, double girder cranes provide the lifting power and stability required for palletized goods handling.

- Large Equipment and Machinery Maintenance: Double girder overhead garage cranes are essential for maintenance tasks involving large equipment and machinery in industrial facilities. These cranes provide the necessary lifting capacity and clearance to access and service heavy machinery such as industrial presses, forging equipment, and machining centers. By lifting and positioning equipment for inspection, repair, or replacement, double girder cranes support ongoing maintenance efforts, ensuring optimal equipment performance and longevity.

- Bulk Material Handling: In industrial environments where bulk materials need to be moved and processed, double girder overhead garage cranes play a vital role in bulk material handling operations. These cranes can lift and transport heavy materials such as steel coils, lumber stacks, and concrete precast elements with precision and efficiency. Their high lifting capacities and long spans make them well-suited for handling bulk materials in applications such as steel fabrication, construction, and manufacturing.

Double girder overhead garage cranes are versatile and powerful material handling solutions suitable for a wide range of applications in commercial truck maintenance garages, large industrial facilities, and warehouses with garage spaces. Whether handling heavy vehicle components, palletized goods, large equipment, or bulk materials, these cranes provide the lifting capacity, precision, and reliability required for efficient material handling operations.

Please do not hesitate to contact us if you require a garage overhead crane.

Comparative Analysis of Garage Crane Types and Their Suitability

In choosing the right overhead garage crane, it's crucial to conduct a comparative analysis to determine which type best suits the specific requirements of the garage. Factors such as space constraints, lifting capacity, mobility, and budgetary considerations should be taken into account. Understanding the typical applications and loads handled by each crane type helps garage owners and operators make informed decisions to optimize efficiency and safety in their material handling processes.

When selecting an overhead garage crane, conducting a comparative analysis is essential to ensure the chosen crane type aligns with the garage's specific requirements. Several factors, including space constraints, lifting capacity, mobility, and budgetary considerations, must be carefully evaluated. Below is a comparative analysis of common crane types used in garage environments, along with their suitability for various applications:

Single Girder Overhead Garage Crane:

Suitability: Ideal for garages with limited headroom or space constraints due to their compact design.

Lifting Capacity: Typically ranges from 0.5 tons to 20 tons, making them suitable for lifting medium-sized loads such as engines, transmissions, and machinery parts.

Mobility: Limited mobility within a defined track system, suitable for linear lifting applications.

Cost: Generally more cost-effective compared to double girder cranes, making them suitable for smaller budgets.

Double Girder Overhead Garage Crane:

Suitability: Well-suited for garages with high ceilings and heavy-duty lifting requirements.

Lifting Capacity: Offers higher lifting capacities ranging from 5 tons to 100 tons, making them suitable for lifting heavy vehicle components, machinery, and equipment.

Mobility: Provides enhanced stability and control, ideal for handling large and bulky loads with precision.

Cost: Typically higher initial investment compared to single girder cranes but offers greater lifting capacity and versatility for heavy-duty applications.

Gantry Crane for Garage Use:

Suitability: Versatile option suitable for garages requiring portability and flexibility in material handling.

Lifting Capacity: Variable lifting capacities ranging from light-duty (e.g., 0.5 tons) to heavy-duty (e.g., 10 tons), depending on the configuration and specifications.

Mobility: Offers mobility and flexibility to move the crane to different locations within the garage or to outdoor areas as needed.

Cost: Cost-effective solution compared to permanent overhead crane installations, especially for temporary or occasional lifting needs.

Jib Crane Applications in Garages:

Suitability: Ideal for garages with restricted space or specific workstation lifting requirements.

Lifting Capacity: Typically ranges from 0.25 tons to 5 tons, suitable for handling small to medium-sized loads in localized areas.

Mobility: Limited mobility within a fixed radius, making them suitable for lifting tasks within a specific workstation or work area.

Cost: Generally more affordable compared to overhead crane systems, providing a cost-effective solution for targeted lifting applications.

By comparing the features and suitability of different crane types, garage owners and operators can make informed decisions to optimize efficiency and safety in their material handling processes. Evaluating factors such as lifting capacity, mobility, and cost ensures the selected crane type aligns with the garage's specific requirements and budget constraints.

Garage Crane Hoists

As for different garage cranes, there are several garage crane hoists are available for your selection.

Manual garage crane hoist

Manual chain block & manual chain hoist for sale. Light,economical & handy manual hoists & hand hoists of 250kg, 1 ton, 1.5 ton , 2 ton , 3 ton , 4 ton , 5 ton , 6 ton,etc.Get garage crane hoist price.

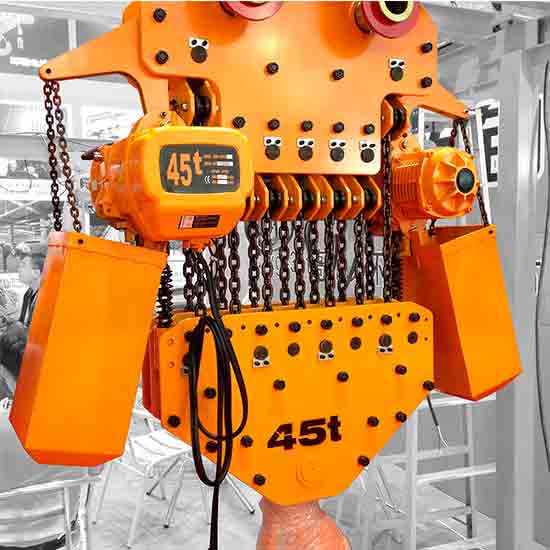

Electric garage crane hoist

DIN/FEM wire rope hoists - European standard low profile & low headroom hoists - Affordable crane hoists up 80 ton for types of overhead travelling cranes.Get garage crane hoist price.

Garage electric chain hoist

500kg-35 ton electric chain hoist with motorized trolley for overhead chain hoist crane, gantry chain hoist crane & jib chain hoist crane. Get garage crane hoist price.

Garage electric wire rope hoist

Chinese style electric crane hoist specifications: Capacity: 0.25 ton -80 ton. Get garage crane hoist price.

Overhead Garage Crane Applications in Different Garage Types

Automotive Repair Garage

Automotive repair garages are bustling hubs where vehicles undergo maintenance, repairs, and upgrades. Overhead garage cranes play a pivotal role in streamlining operations and enhancing productivity within these environments.

- Engine and Transmission Handling: Overhead garage cranes facilitate the safe and efficient removal and installation of vehicle engines and transmissions. These heavy components often require precise positioning and lifting, which is easily achieved with the help of a crane. Whether it's swapping out a faulty engine or replacing a transmission, the crane provides the necessary lifting power and stability to complete the task with ease.

- Chassis and Bodywork Lifting: When working on chassis repairs or bodywork modifications, overhead cranes offer invaluable assistance in lifting and maneuvering vehicle frames and body panels. Whether it's straightening a bent frame or replacing damaged body panels, the crane provides the necessary lifting capacity and precision to ensure accurate alignment and assembly.

- Parts Storage and Organization: In addition to lifting heavy components during repairs, overhead garage cranes are also utilized for parts storage and organization. By installing racks or shelves within the garage space, cranes can be used to lift and place parts onto storage shelves, maximizing floor space and keeping the workspace organized. This helps mechanics easily locate and access the necessary parts during repair jobs, reducing downtime and improving overall efficiency.

Overall, overhead garage cranes are indispensable tools in automotive repair garages, enhancing safety, efficiency, and organization in handling heavy vehicle components and parts. From engine swaps to chassis repairs, these cranes streamline operations and contribute to the smooth functioning of the garage environment.

Home Garage

Home garages serve as versatile spaces for a variety of activities, from DIY projects to vehicle maintenance and storage. Overhead garage cranes offer homeowners practical solutions for managing tasks efficiently within their garage environment.

- DIY Projects and Home Maintenance: Homeowners often utilize their garage spaces for DIY projects and general home maintenance tasks. Overhead garage cranes provide invaluable assistance in lifting heavy objects such as lumber, machinery, or appliances during construction or renovation projects. Whether it's installing overhead storage racks or lifting heavy tools and equipment, the crane offers convenience and efficiency for homeowners tackling DIY tasks.

- Vehicle Restoration and Customization: Enthusiasts passionate about vehicle restoration and customization frequently use their home garages as workshops. Overhead garage cranes play a crucial role in lifting and maneuvering vehicle components during restoration projects. From removing engines and transmissions to lifting car bodies for customization work, the crane provides the lifting capacity and precision required for intricate automotive tasks.

- Storage Optimization and Space Management: Home garages often face challenges with storage optimization and space management. Overhead garage cranes offer a solution by maximizing vertical space and enabling efficient storage of bulky items. By installing overhead storage platforms or using the crane to lift and position storage containers, homeowners can free up valuable floor space and keep their garage organized and clutter-free.

Overall, overhead garage cranes enhance the functionality of home garages, providing homeowners with the tools they need to tackle DIY projects, vehicle maintenance, and storage challenges effectively. From lifting heavy materials to optimizing storage space, these cranes contribute to a more efficient and organized garage environment.

Commercial Truck Maintenance Garage

Commercial truck maintenance garages are dedicated facilities where heavy-duty vehicles undergo maintenance, repairs, and inspections. These spaces require specialized equipment to handle the unique challenges associated with servicing large trucks and fleets. Overhead garage cranes play a crucial role in enhancing efficiency and safety within these environments.

- Heavy Truck Component Handling: One of the primary functions of overhead garage cranes in commercial truck maintenance garages is the handling of heavy truck components. Trucks are equipped with large and heavy parts such as engines, transmissions, axles, and suspension systems. Overhead cranes provide the lifting capacity and precision required to safely remove and install these components during repair and maintenance tasks. Whether it's lifting a diesel engine for overhaul or replacing a heavy-duty transmission, the crane streamlines the process and reduces manual labor, enhancing overall productivity.

- Fleet Maintenance Efficiency: Commercial truck maintenance garages often service entire fleets of vehicles, ranging from delivery trucks to tractor-trailers. Efficient fleet maintenance is essential to minimize downtime and keep vehicles operating at peak performance. Overhead garage cranes contribute to fleet maintenance efficiency by expediting repair processes and reducing turnaround times. With the ability to lift and maneuver heavy components with ease, cranes enable mechanics to work more quickly and effectively, ensuring that trucks are back on the road promptly.

- Safety Considerations for Large Vehicle Maintenance: Safety is paramount in commercial truck maintenance garages, where mechanics are tasked with working on large and heavy vehicles. Overhead garage cranes are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and injuries. Additionally, proper training and adherence to safety protocols are essential for crane operators and maintenance personnel. Safety considerations extend to the design and maintenance of the crane itself, ensuring that it remains in optimal working condition and poses minimal risk to personnel and equipment.

In summary, overhead garage cranes are indispensable tools in commercial truck maintenance garages, facilitating the handling of heavy truck components, improving fleet maintenance efficiency, and prioritizing safety in large vehicle maintenance operations. By streamlining processes and enhancing safety measures, cranes contribute to the smooth functioning of commercial truck maintenance facilities, ultimately benefiting fleet operators and drivers alike.

Boat or RV Garage

Boat and RV garages serve as dedicated spaces for the storage, maintenance, and upkeep of recreational vehicles such as boats and RVs. These specialized environments require equipment capable of handling the unique challenges associated with marine and recreational vehicle maintenance. Overhead garage cranes are invaluable tools in these garages, offering solutions for various tasks.

- Marine Engine and Hull Lifting: Boat garages often house watercraft of varying sizes, each equipped with heavy marine engines and hulls. Overhead garage cranes provide the lifting capacity and precision required to handle these components safely and efficiently. Whether it's removing an outboard motor for maintenance or lifting a boat hull for repairs, the crane simplifies the process and reduces the risk of damage to both the vessel and surrounding equipment.

- RV Chassis Maintenance: Recreational vehicles, or RVs, feature complex chassis systems that require regular maintenance and inspection to ensure safe and reliable operation. Overhead garage cranes enable mechanics to lift and support RV chassis components, such as suspensions, axles, and leveling systems, during repair and maintenance tasks. This facilitates access to hard-to-reach areas and allows for thorough inspection and servicing, ultimately prolonging the lifespan of the vehicle and ensuring a comfortable and safe travel experience for owners.

- Winterization and Seasonal Storage: Boat and RV owners often require assistance with winterization and seasonal storage of their vehicles to protect them from harsh weather conditions and prevent damage. Overhead garage cranes aid in lifting and positioning boats onto trailers or storage racks, as well as lifting RVs onto blocks or leveling systems for long-term storage. By utilizing the crane's lifting capabilities, garage owners can efficiently prepare vehicles for winter storage or retrieve them for seasonal use, ensuring they remain in optimal condition year-round.

In conclusion, overhead garage cranes are essential assets in boat and RV garages, facilitating marine engine and hull lifting, RV chassis maintenance, and seasonal storage operations. By providing the lifting capacity and precision required for these tasks, cranes contribute to the efficient and safe maintenance of boats and RVs, ultimately enhancing the ownership experience for enthusiasts and ensuring the longevity of their recreational vehicles.

Industrial Warehouse Garage

Industrial warehouse garages serve as integral components of logistics and supply chain operations, providing storage and maintenance facilities for goods and equipment. These spaces require efficient material handling solutions to optimize productivity and streamline operations. Overhead garage cranes fulfill various functions within industrial warehouse garages, enhancing efficiency and facilitating key tasks.

- Palletized Goods Handling: Palletized goods are a staple in warehouse environments, requiring efficient handling and storage solutions. Overhead garage cranes equipped with lifting attachments such as hooks, slings, or pallet lifters are used to move palletized goods within the warehouse space. By lifting and transporting pallets to and from storage racks, production lines, or loading docks, cranes facilitate smooth and efficient logistics operations, minimizing manual handling and reducing the risk of product damage.

- Equipment Maintenance and Repair: Industrial warehouse garages often house equipment and machinery essential for warehouse operations, such as forklifts, conveyors, and packaging machines. Overhead garage cranes play a crucial role in equipment maintenance and repair by providing the lifting capacity and mobility required to access and service machinery. Whether it's replacing worn-out components, conducting routine inspections, or performing repairs, cranes enable maintenance personnel to work safely and efficiently, minimizing downtime and optimizing equipment performance.

- Inventory Management Solutions: Effective inventory management is critical in warehouse operations to ensure accurate stock levels and timely order fulfillment. Overhead garage cranes contribute to inventory management solutions by facilitating the movement and organization of goods within the warehouse space. By lifting and positioning inventory onto storage racks, shelves, or pallets, cranes help maximize storage capacity and improve accessibility to goods. Additionally, cranes can be utilized for cycle counting, inventory audits, and stock replenishment activities, enhancing overall inventory accuracy and efficiency.

In summary, overhead garage cranes play a vital role in industrial warehouse garages, supporting palletized goods handling, equipment maintenance and repair, and inventory management solutions. By streamlining material handling processes and optimizing warehouse operations, cranes contribute to the efficiency and productivity of industrial facilities, ultimately driving business success and customer satisfaction.

Agricultural Equipment Garage

Agricultural equipment garages serve as essential facilities for maintaining and storing farm machinery and equipment used in agricultural operations. These spaces require robust material handling solutions to support the maintenance, handling, and storage of heavy-duty agricultural machinery. Overhead garage cranes fulfill various functions within agricultural equipment garages, contributing to efficiency and productivity in farm operations.

- Tractor and Farm Machinery Maintenance: Agricultural equipment garages are responsible for the maintenance and repair of tractors, tillers, harvesters, and other farm machinery. Overhead garage cranes provide the lifting capacity and maneuverability required to handle these heavy and cumbersome components safely. Whether it's lifting an engine for maintenance, replacing worn-out parts, or conducting routine inspections, cranes streamline the maintenance process, reducing downtime and ensuring that farm equipment remains in optimal working condition.

- Harvesting Equipment Handling: Harvesting equipment, such as combine harvesters, grain carts, and balers, plays a crucial role in agricultural operations during harvest seasons. Overhead garage cranes assist in the handling and positioning of harvesting equipment within the garage space. By lifting and maneuvering components such as headers, augers, and harvesting attachments, cranes facilitate maintenance, repair, and storage activities, ensuring that harvesting equipment is ready for use when needed.

- Weatherproofing and Outdoor Storage Solutions: Agricultural equipment garages often require outdoor storage solutions for farm machinery and equipment. Overhead garage cranes aid in weatherproofing and outdoor storage by lifting and positioning equipment onto trailers, storage racks, or outdoor platforms. By utilizing the crane's lifting capabilities, farmers can efficiently store equipment outdoors while protecting it from the elements. Additionally, cranes enable the repositioning and relocation of equipment as needed, maximizing space utilization and flexibility in outdoor storage areas.

In conclusion, overhead garage cranes play a vital role in agricultural equipment garages, supporting tractor and farm machinery maintenance, handling of harvesting equipment, and weatherproofing and outdoor storage solutions. By providing efficient material handling capabilities, cranes contribute to the smooth functioning of agricultural operations, ensuring that farm machinery remains in optimal condition and ready for use throughout the farming season.

Aircraft Hangar Garage

Aircraft hangar garages serve as specialized facilities for the maintenance, repair, and storage of aircraft. These spaces require precise material handling solutions to support the intricate maintenance tasks and comply with stringent aviation regulations. Overhead garage cranes play a critical role in aircraft hangar garages, facilitating aircraft component maintenance, hangar space optimization, and compliance with aviation standards.

- Aircraft Component Maintenance: Aircraft hangar garages are responsible for the maintenance and repair of various aircraft components, including engines, landing gear, wings, and control surfaces. Overhead garage cranes provide the lifting capacity and precision required to handle these sensitive and often heavy components safely. Whether it's lifting an engine for inspection, replacing landing gear components, or conducting structural repairs, cranes streamline the maintenance process, reducing turnaround times and ensuring that aircraft are maintained to the highest standards of safety and airworthiness.

- Hangar Space Optimization: Hangar space is a precious commodity in aircraft maintenance facilities, where aircraft storage and maintenance activities must be efficiently organized to maximize space utilization. Overhead garage cranes contribute to hangar space optimization by providing flexible material handling capabilities. By lifting and maneuvering aircraft components and equipment, cranes enable mechanics to utilize vertical space effectively, minimizing clutter and congestion on the hangar floor. This allows for smoother workflow and easier access to aircraft during maintenance operations.

- Compliance with Aviation Standards and Regulations: Compliance with aviation standards and regulations is paramount in aircraft maintenance facilities to ensure the safety and airworthiness of aircraft. Overhead garage cranes are designed and operated in accordance with aviation regulations and industry standards to meet the strict safety requirements of aircraft maintenance operations. Additionally, cranes are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and ensure compliance with aviation regulations.

In summary, overhead garage cranes are essential tools in aircraft hangar garages, supporting aircraft component maintenance, hangar space optimization, and compliance with aviation standards. By providing efficient material handling capabilities and ensuring adherence to safety and regulatory requirements, cranes contribute to the smooth and safe operation of aircraft maintenance facilities, ultimately ensuring the reliability and airworthiness of aircraft.

Construction Equipment Garage

Construction equipment garages serve as central hubs for storing, maintaining, and preparing heavy construction machinery and equipment for various construction projects. These facilities require efficient material handling solutions to streamline operations and ensure safety in dynamic construction environments. Overhead garage cranes play a crucial role in construction equipment garages, facilitating heavy construction machinery handling, site preparation, equipment transport, and implementing safety measures.

- Heavy Construction Machinery Handling: Construction equipment garages handle a wide range of heavy machinery, including excavators, bulldozers, cranes, and loaders. Overhead garage cranes provide the lifting capacity and precision required to handle these massive and often cumbersome machines safely. Whether it's lifting excavator buckets for maintenance, maneuvering crane counterweights, or positioning bulldozer blades, cranes streamline the handling process, reducing manual labor and minimizing the risk of accidents or damage to equipment.

- Site Preparation and Equipment Transport: Construction equipment garages are responsible for preparing construction sites and transporting machinery to and from project locations. Overhead garage cranes aid in site preparation and equipment transport by lifting and positioning construction materials, tools, and machinery onto trucks or trailers for transport. By utilizing the crane's lifting capabilities, construction crews can efficiently load and unload equipment, ensuring that machinery is deployed to the job site promptly and safely.

- Safety Measures for Construction Environments: Safety is paramount in construction environments, where workers are exposed to various hazards associated with heavy machinery and dynamic worksites. Overhead garage cranes are equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and injuries. Additionally, proper training and adherence to safety protocols are essential for crane operators and construction personnel. Safety considerations extend to the design and maintenance of the crane itself, ensuring that it meets the rigorous safety standards required for construction operations.

In summary, overhead garage cranes are indispensable tools in construction equipment garages, supporting heavy construction machinery handling, site preparation, equipment transport, and implementing safety measures in dynamic construction environments. By providing efficient material handling capabilities and ensuring adherence to safety protocols, cranes contribute to the smooth and safe operation of construction equipment facilities, ultimately enhancing productivity and ensuring the safety of construction crews.

Factors to Consider When Selecting an Overhead Garage Crane

Selecting the right overhead garage crane is crucial to ensure efficient material handling and safety within the garage environment. Several factors must be considered to choose a crane that meets the specific needs of the garage. Here are the key factors to consider:

Garage Size and Layout:

The size and layout of the garage are crucial factors to consider when selecting and installing an overhead crane. Here are some detailed considerations regarding garage size and layout:

Ceiling Height:

The available ceiling height directly impacts the type of overhead crane that can be installed. Higher ceilings allow for the installation of double girder cranes with larger lifting capacities, whereas lower ceilings may require single girder cranes or gantry cranes with lower profiles.

It's essential to consider not only the vertical clearance required for the crane but also additional space for lifting loads and trolley movement. Adequate clearance above the crane's highest lifting point ensures safe and efficient operation.

Floor Space:

The amount of floor space available in the garage influences the crane's footprint and configuration.

Double girder cranes typically require more floor space compared to single girder cranes due to their wider span and support structure.

Gantry cranes offer flexibility in terms of positioning and can be moved around the garage as needed. However, sufficient floor space is necessary for the crane's movement and operation.

Obstacles or Obstructions:

Identify any obstacles or obstructions within the garage layout that may interfere with crane installation or operation, such as support columns, ductwork, or lighting fixtures.

Considerations should also be made for doorways, windows, and other architectural features that could restrict crane movement or limit access to certain areas of the garage.

Accessibility:

Ensure that the overhead crane is positioned in a location that provides easy access to the areas where lifting tasks are performed most frequently.

Optimal placement of the crane maximizes efficiency in material handling operations and minimizes unnecessary movement of loads within the garage.

Future Expansion:

Anticipate future needs and potential changes in garage layout or operations when selecting an overhead crane.

Choose a crane system that allows for scalability and adaptability to accommodate future growth or modifications in the garage environment.

Safety Considerations:

Factor in safety considerations related to garage size and layout, such as clearances around moving parts, proximity to personnel work areas, and visibility of load paths.

Ensure that the chosen crane system complies with relevant safety standards and regulations to minimize the risk of accidents or injuries in the garage.

By carefully assessing the size and layout of the garage, garage owners and operators can determine the most suitable overhead crane system that fits seamlessly within the space while meeting their material handling requirements and safety considerations.

Weight Capacity and Load Specifications:

Assessing the weight capacity and load specifications is crucial for ensuring the effectiveness and safety of an overhead crane system within the garage environment. Here are further details on this aspect:

Determining Lifting Requirements:

Identify the heaviest loads that the overhead crane will need to lift regularly within the garage. This may include components such as vehicle engines, machinery parts, or construction materials.

Consider the maximum weight capacity required for lifting tasks, taking into account potential variations in load weights and configurations.

Considerations for Load Distribution:

Evaluate the distribution of weight across the loads to be lifted. Ensure that the crane's capacity exceeds the maximum load weight, accounting for factors such as load eccentricity and center of gravity.

Calculate the total load capacity based on the most demanding lifting scenarios to ensure safe operation under all conditions.

Lifting Height and Reach:

Determine the required lifting height and horizontal reach needed to access and maneuver loads within the garage space.

Choose a crane with a suitable lifting height and boom length to accommodate the vertical and horizontal movement of loads effectively.

Specialized Lifting Attachments or Accessories:

Consider any specialized lifting attachments or accessories required for specific lifting tasks within the garage. This may include lifting magnets, spreader bars, or custom lifting fixtures.

Ensure that the chosen crane system is compatible with the required attachments and accessories to support diverse material handling applications.

Safety Margin and Overload Protection:

Incorporate a safety margin into the crane's weight capacity calculations to provide a buffer for unexpected load variations or dynamic loading conditions.

Select a crane system equipped with overload protection features, such as load limit switches or overload detection devices, to prevent crane overload situations and ensure operator safety.

Compliance with Standards and Regulations:

Ensure that the selected overhead crane system complies with relevant industry standards and regulations governing load capacity, such as ANSI/ASME standards for overhead cranes.

Adhering to established standards helps maintain safe working practices and ensures the reliability and performance of the crane system over time.

By carefully assessing weight capacity and load specifications, garage owners and operators can select an overhead crane system that meets the lifting requirements of their specific applications while prioritizing safety and efficiency in material handling operations within the garage environment.

Space Constraints and Clearance Requirements:

When choosing an overhead crane for a garage, it's crucial to consider space constraints and clearance requirements to ensure safe and efficient operation. Here are additional details on this aspect:

Assessing Available Space:

Measure the available space within the garage, including the distance between support structures, walls, and other fixed objects.

Consider the overall layout of the garage and identify any potential obstacles or obstructions that may affect the crane's movement or operation.

Aisle Width and Turning Radius:

Determine the minimum aisle width required for the crane to maneuver safely within the garage space.

Take into account the crane's turning radius and ensure that there is sufficient clearance for the crane to rotate and change direction without colliding with walls or other structures.

Overhead Clearance:

Calculate the overhead clearance required for the crane's movement, taking into consideration the height of the crane itself, as well as the maximum lifting height required for lifting tasks.

Ensure that there is adequate clearance above the crane's path to prevent collisions with overhead obstructions such as lighting fixtures, ductwork, or ceiling beams.

Crane Configuration and Design:

Choose an overhead crane system with a compact design and flexible configuration options that can accommodate the space constraints within the garage.

Consider features such as telescoping booms, adjustable height settings, or foldable components that allow the crane to be tailored to the specific layout of the garage.

Maneuverability and Flexibility:

Select a crane system with sufficient maneuverability and flexibility to navigate through tight spaces and confined areas within the garage.

Opt for features such as dual-drive systems, variable speed controls, and precision steering mechanisms that enhance the crane's agility and responsiveness during operation.

Safety Considerations:

Prioritize safety by ensuring that the chosen crane system complies with relevant safety standards and regulations governing clearance requirements and safe operation.

Implement additional safety measures such as proximity sensors, collision avoidance systems, or audible alarms to alert operators to potential hazards in the crane's path.

By carefully assessing space constraints and clearance requirements, garage owners and operators can select an overhead crane system that fits seamlessly within the available space while ensuring safe and efficient material handling operations. Prioritizing maneuverability, flexibility, and safety features helps mitigate the risk of accidents or collisions in the garage environment.

Budgetary Considerations and Return on Investment:

When choosing an overhead garage crane, budgetary considerations play a pivotal role in the decision-making process. Here are further insights into this aspect:

Initial Investment Cost:

Evaluate the upfront cost of purchasing and installing the overhead crane system, including equipment, structural modifications, and installation fees.

Compare quotes from multiple crane suppliers to ensure competitive pricing and explore financing options or leasing arrangements to spread out the initial investment cost over time.

Ongoing Maintenance and Operating Expenses:

Estimate the ongoing maintenance and operating expenses associated with the overhead crane, including routine inspections, repairs, and energy consumption.

Consider factors such as crane lifespan, warranty coverage, and availability of spare parts when assessing long-term maintenance costs.

Expected Return on Investment (ROI):

Assess the potential return on investment (ROI) associated with implementing the overhead crane system in the garage.

Identify productivity improvements, efficiency gains, and cost savings that can be attributed to the crane's use, such as reduced labor costs, faster turnaround times, and minimized material handling errors.

Quantify the financial benefits of the crane system in terms of increased revenue, reduced downtime, and improved operational efficiency to justify the investment.

Balancing Upfront Costs with Long-Term Benefits:

Strike a balance between upfront costs and long-term benefits when evaluating the ROI of the overhead crane system.

Consider the total cost of ownership over the crane's lifespan, factoring in both direct and indirect costs associated with its acquisition and operation.

Look beyond immediate cost savings and focus on the overall value proposition offered by the crane system in terms of enhanced productivity, safety, and competitive advantage.

Exploring Cost-Effective Solutions:

Explore cost-effective alternatives or customization options that align with budgetary constraints while meeting essential requirements for material handling in the garage.

Consider modular crane systems, pre-engineered solutions, or refurbished equipment as viable options to reduce upfront costs without compromising performance or reliability.

Continuous Improvement and Optimization:

Continuously monitor and evaluate the performance of the overhead crane system to identify opportunities for optimization and cost savings.

Implement proactive maintenance strategies, operator training programs, and process improvements to maximize the ROI of the crane investment over time.

By carefully assessing budgetary considerations and ROI potential, garage owners and operators can make informed decisions when selecting an overhead crane system that delivers value, efficiency, and cost-effectiveness in their material handling operations. Balancing upfront costs with long-term benefits ensures a strategic investment that aligns with the garage's financial objectives and operational goals.

By carefully considering these factors when selecting an overhead garage crane, garage owners and operators can choose a crane that meets their specific requirements, optimizes material handling operations, and ensures a safe and productive working environment.

Installation, Operation, and Maintenance Guidelines

Efficient and safe operation of an overhead garage crane relies on proper installation, operation, and maintenance procedures. Following guidelines ensures optimal performance and longevity of the crane while prioritizing safety. Here are essential guidelines for crane installation, operation, and maintenance:

Proper Crane Installation Procedures:

Site Assessment: Conduct a thorough assessment of the garage space to determine suitable crane placement, taking into account factors such as structural integrity, ceiling height, and clearance requirements.

Structural Support: Ensure that the building structure can support the weight of the crane and the loads it will lift. Reinforce structural elements if necessary to meet load-bearing requirements.

Crane Assembly: Assemble the crane according to manufacturer guidelines, ensuring all components are securely fastened and aligned properly.

Electrical Wiring: Connect electrical wiring in accordance with local electrical codes and manufacturer specifications, ensuring proper grounding and voltage compatibility.

Testing and Certification: Perform comprehensive testing of the crane's functions and safety features before putting it into operation. Obtain necessary certifications and approvals from regulatory authorities.

Operator Training and Certification Requirements:

Operator Training: Provide comprehensive training for crane operators on proper operation, safety protocols, and emergency procedures. Training should cover crane controls, load handling techniques, and hazard awareness.

Certification: Ensure crane operators receive proper certification from accredited training programs or certification bodies. Certification demonstrates competency in crane operation and compliance with safety standards.

Routine Maintenance and Inspection Protocols:

Scheduled Inspections: Establish a routine inspection schedule for the crane, including daily, weekly, monthly, and annual inspections. Inspect critical components such as hoists, trolleys, brakes, and electrical systems for signs of wear or damage.

Lubrication: Regularly lubricate moving parts and components to prevent friction and ensure smooth operation. Use appropriate lubricants recommended by the crane manufacturer.

Safety Checks: Verify the functionality of safety features such as limit switches, overload protection devices, and emergency stop buttons during each inspection.

Documentation: Maintain detailed records of maintenance activities, inspections, and repairs for regulatory compliance and reference purposes.

Troubleshooting Common Issues and Solutions:

Electrical Malfunctions: Troubleshoot electrical issues such as power supply interruptions, faulty wiring, or control panel malfunctions by conducting voltage checks and continuity tests.

Mechanical Failures: Address mechanical failures such as worn-out bearings, damaged gears, or misaligned components promptly by replacing or repairing affected parts.

Operational Errors: Investigate operational errors or malfunctions caused by improper use or inadequate training. Provide additional training to operators and reinforce safety protocols to prevent recurrence.

Emergency Response: Develop protocols for responding to emergency situations such as equipment failures, load drops, or personnel injuries. Ensure all personnel are trained in emergency response procedures and have access to emergency communication and first aid resources.

By adhering to these installation, operation, and maintenance guidelines, garage owners and operators can ensure the safe and efficient operation of overhead garage cranes while minimizing downtime and maximizing productivity.

Overhead garage cranes have revolutionized material handling in various garage environments, offering numerous benefits and applications. From automotive repair garages to industrial warehouses, these cranes streamline operations, enhance efficiency, and prioritize safety. Key benefits include increased productivity, optimized space utilization, and reduced manual labor. Applications range from heavy machinery handling to palletized goods management, catering to diverse garage needs and requirements.

The future of garage material handling technology holds promising advancements aimed at further improving efficiency and safety. Automation and robotics are expected to play a significant role, with the integration of smart sensors, predictive maintenance systems, and advanced control algorithms. Collaborative robots (cobots) may become prevalent, assisting operators in handling tasks while ensuring human safety. Additionally, advancements in crane design and materials may lead to lighter, more agile cranes capable of handling heavier loads with greater precision.

In conclusion, overhead garage cranes represent an indispensable asset in enhancing garage efficiency and safety. By investing in the right crane solutions and adhering to proper installation, operation, and maintenance practices, garage owners and operators can optimize material handling operations, minimize downtime, and create safer working environments. As technology continues to evolve, the future holds exciting possibilities for further enhancing garage efficiency and safety through innovative crane solutions and advancements in material handling technology.

Incorporating overhead garage cranes into garage environments not only boosts productivity but also enhances safety standards, ultimately contributing to the overall success and sustainability of garage operations in various industries.

Get Your Garage Crane & Garage Hoist

For sale is a garage crane. Garage material handling cranes include garage bridge cranes, garage overhead cranes, garage gantry cranes, and garage jib cranes. Garage cranes of various types are available for purchase at a reasonable price. Now is the time to get your garage crane. Get more information on the garage crane by contacting us right now.