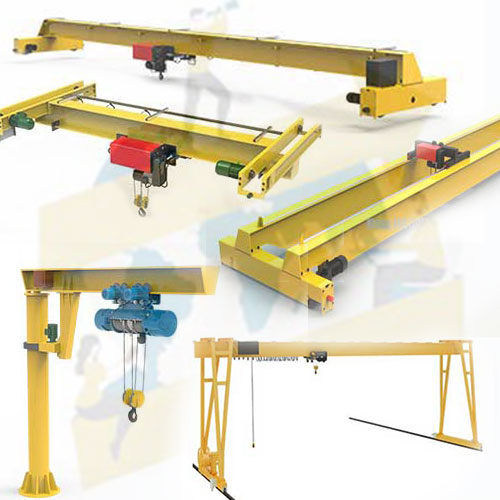

Electric Jib Cranes and Jib Hoists | 1 Ton, 2 Ton, 3Ton, 5 Ton 10 Ton

Electric jib cranes and jib hoists for sale Russia, good price. Customized wall jib crane, freestanding jib cranes, electric rope hoists & chain electric hoist.

Category: Russia

Your Trusted Electric Jib Cranes and Hoists Manufacturer & Supplier

Electric Jib Cranes and Jib Hoists | 1 Ton, 2 Ton, 3Ton, 5 Ton 10 Ton

Custom Wall Jib Crane, Freestanding Jib Cranes, Electric Rope Hoists & Chain Electric Hoists

Electric jib cranes and jib hoists for sale Russia, good price. Customized wall jib crane, freestanding jib cranes, electric rope hoists & chain electric hoist, hot sale 1 Ton, 2 Ton, 3Ton, 5 Ton 10 Ton, up to 16 ton.

Comprehensive Guide to Jib Cranes for Sale in Russia: Types, Applications, and Practical Insights

Jib Cranes, an integral part of material handling equipment, stand tall as versatile and ergonomic solutions designed to facilitate the movement of heavy loads within confined spaces. The jib cranes are characterized by their horizontal jib or boom supporting a moveable hoist fixed to a wall, floor, or pillar.

Their significance in industrial operations cannot be overstated. Jib Cranes offer a myriad of benefits, such as their ability to provide precise and controlled movement of heavy materials, aiding in streamlining production processes, and significantly reducing manual labor. They contribute to the optimization of workspace, allowing for efficient utilization of available areas, a crucial aspect in industries where space is a premium.

Within the Russian industrial sectors, Jib Cranes have emerged as indispensable tools, catering to the diverse needs of sectors ranging from manufacturing, construction, logistics, to shipping and more. Their adaptability, reliability, and ability to enhance operational efficiency have solidified their position as essential equipment across various industries within the region.

Types of Jib Cranes for Sale in Russia

Wall Jib Cranes

Features, Benefits, and Typical Applications

Wall-mounted Jib Cranes stand as stalwart solutions designed for efficiency and versatility. Their features, including a pivoting boom attached to a wall or pillar, make them indispensable in various industrial settings across Russia.

In the field of Russian industries, Wall-Mounted Jib Cranes find extensive application:

- Construction: These cranes play a pivotal role in construction sites, facilitating the movement of heavy materials with precision and safety. They streamline the construction process, ensuring efficient material handling at various stages of building projects.

- Manufacturing: Within manufacturing facilities, Wall-Mounted Jib Cranes assist in assembly lines, aiding in the lifting and movement of heavy components. Their adaptability enhances the workflow, contributing to increased productivity.

- Workshops: In smaller workspaces like workshops or maintenance areas, Wall-Mounted Jib Cranes offer a crucial advantage. Their ability to provide precise movement within limited spaces makes them invaluable for maneuvering heavy equipment or materials.

Industrial Applications in Russia

These cranes have found their niche in diverse industrial sectors across Russia. Their robust design and functionality cater to the specific needs of industries, ensuring seamless operations and enhanced productivity. The adaptability of Wall-Mounted Jib Cranes in addressing the challenges of material handling makes them a preferred choice in Russian industrial environments.

To ensure optimal performance and safety, addressing user concerns is paramount. Wall-Mounted Jib Crane manufacturers in Russia prioritize the implementation of safety features and adherence to quality standards. Moreover, providing user-friendly interfaces and operational training contributes significantly to addressing concerns related to crane usage.

Crane Hoist Types: Electric Chain Hoist, Wire Rope Hoist

Wall-Mounted Jib Cranes are complemented by various hoist types, each catering to specific load capacities and operational requirements. The Electric Chain Hoist and Wire Rope Hoist stand out as reliable choices, offering different advantages based on their unique mechanisms and load-bearing capacities.

Main Types of Wall Jib Cranes

Features:

- Fixed wall or column attachment.

- Up to 180-degree rotation.

- Compact design for confined spaces.

- Various load capacity options.

- Optimizes space, ideal for small areas.

- Precise load positioning.

- Reduces floor obstruction.

- Versatile for manufacturing and warehouses.

- Manufacturing workstations.

- Warehousing for loading/unloading.

- Maintenance tasks.

- Small-scale operations.

Features:

- Horizontal rail for movement.

- Combines rotation and travel.

- Extended coverage with rail.

- Accurate load positioning.

- Versatile for both horizontal and vertical movement.

- Covers a wider area efficiently.

- Enhances assembly line productivity.

- Ideal for precise loading/unloading.

- Optimizes space usage.

- Manufacturing and assembly lines.

- Warehousing for extended storage.

- Construction sites with complex layouts.

- Workshops for repairs and maintenance.

Fixed Wall Jib Crane:

Features:

- Fixed position on the wall or vertical surface.

- Fixed jib arm that can rotate horizontally.

- Typically available in various load capacity options.

- Suitable for precise load positioning within a limited area.

- Maximizes use of vertical space while minimizing floor obstruction.

- Provides precise load positioning without moving the entire crane.

- Cost-effective and straightforward design.

- Enhanced safety due to reduced risk of collisions in crowded work areas.

- Manufacturing: For moving and positioning materials in production cells.

- Workshops: For tasks such as engine or equipment maintenance.

- Loading docks: For loading and unloading of goods from trucks.

- Assembly lines: For precise part placement during assembly processes.

Articulating Wall Jib Crane:

Features:

- Multi-segmented jib arm with articulating joints.

- Offers greater flexibility and reach around obstacles.

- Available in various load capacity options.

- Capable of precise load positioning.

- Versatile and adaptable for accessing tight or hard-to-reach spaces.

- Reduces the need for extensive manual labor in complex work areas.

- Provides precise control over load placement.

- Suitable for handling irregularly shaped or oversized loads.

- Manufacturing: For reaching into workstations with obstacles.

- Warehouses: For retrieving items from high shelves or racks.

- Construction sites: For lifting materials in confined spaces.

- Assembly lines: For positioning components during assembly.

Telescoping Wall Jib Crane:

Features:

- Jib arm with telescoping sections that extend and retract.

- Variable reach capabilities.

- Available in various load capacity options.

- Precise load positioning.

- Adjustable reach for handling loads at varying distances.

- Efficient use of space, as it can reach both near and far areas.

- Reduces the need for multiple cranes with fixed jib arms.

- Ideal for tasks with changing load placement requirements.

- Warehouses: For accessing goods on different shelves or racks.

- Loading docks: For reaching into trucks with varying load positions.

- Assembly lines: For accommodating changing assembly processes.

- Manufacturing: For handling materials with variable placement needs.

Foundation-Mounted Wall Jib Crane:

Features:

- Designed to be attached to a foundation or floor.

- Offers similar functionality to wall-mounted cranes.

- Available in various load capacity options.

- Precise load positioning.

- Suitable for situations where wall mounting is not feasible.

- Provides stability and support for heavy loads.

- Maximizes vertical space utilization.

- Enhances safety in areas with floor space limitations.

- Heavy manufacturing: For lifting and positioning large machinery.

- Construction sites: For material handling in outdoor environments.

- Warehouses: For efficiently accessing goods in storage.

Features:

- Compact design for limited vertical clearance.

- Short jib arm suitable for low headroom environments.

- Horizontal rotation for precise load positioning.

- Maximizes vertical space in areas with low headroom.

- Efficient use of floor space while providing lifting capabilities.

- Enhanced safety by reducing overhead collision risks.

- Workshops, garages, and machine shops.

- Retail spaces and stock handling.

- Industrial maintenance areas.

- Assembly lines with limited vertical space.

Explosion-Proof Wall Jib Crane:

Features:

- Specially designed for hazardous environments.

- Sealed electrical components and protected electronics.

- Compliance with strict safety standards.

- Safe operation in explosive atmospheres.

- Reduced risk of sparks or heat causing explosions.

- Precision load handling and compliance assurance.

- Chemical plants and oil refineries.

- Pharmaceutical manufacturing.

- Grain handling facilities.

- Paint and coating operations.

Corrosion-Resistant Wall Jib Crane:

Features:

- Built with materials and coatings to resist corrosion.

- Designed to prevent rust formation.

- Sealed components for corrosion protection.

- Durability in harsh, corrosive environments.

- Extended lifespan, reducing maintenance costs.

- Reliable performance in corrosive conditions.

- Cost-efficiency over time.

- Ideal for marine, chemical, and wastewater industries.

Typical Applications:

- Marine and offshore environments.

- Chemical processing plants.

- Wastewater treatment facilities.

- Food processing and outdoor use.

Each type of wall jib crane has its own set of features that make it suitable for particular applications. Choosing the right type depends on factors such as available space, load capacity, reach requirements, and the need for precise load positioning. These cranes play a crucial role in improving material handling efficiency and safety across various industries.

Free-Standing Jib Cranes

Free-Standing Jib Cranes stand as versatile solutions catering to a wide array of industrial needs across various sectors in Russia. Their defining features, including a freestanding support structure and a pivoting boom, make them highly adaptable and functional.

These cranes find versatile usage across different Russian sectors:

- Warehousing: In storage facilities, Free-Standing Jib Cranes optimize load handling, efficiently organizing and moving goods within limited spaces. They enhance storage operations by facilitating quick and precise movement of materials.

- Logistics: Transportation hubs benefit from the efficiency of Free-Standing Jib Cranes during loading and unloading processes. Their agility and ability to reach different points within the area streamline logistics operations.

- Maintenance Areas: Supporting machinery repairs and installations, these cranes play a crucial role in maintenance workshops. Their flexibility and reach aid in lifting heavy machinery components, contributing to efficient repair and installation processes.

Specific Applications and Use Cases in Russia

Within the Russian industrial landscape, Free-Standing Jib Cranes have garnered a prominent place due to their multifaceted utility. Industries leverage their functionality for specific applications, where their adaptability and efficiency shine, ensuring smooth operations across varied settings.

Addressing user concerns is pivotal for ensuring seamless operations and safety. Manufacturers of Free-Standing Jib Cranes in Russia focus on providing comprehensive solutions to common concerns related to crane operations. Safety features, user training, and maintenance guidelines are emphasized to alleviate user apprehensions.

Crane Hoist Types: Manual Chain Hoist, Air Hoist

Free-Standing Jib Cranes, akin to other jib crane types, benefit from a variety of hoist options. The Manual Chain Hoist and Air Hoist are among the primary choices, offering distinct advantages based on load capacities, operational requirements, and ease of use within different industrial settings.

Light-Duty Freestanding Jib Crane

- Designed for relatively lighter loads.Commonly used in workshops, assembly lines, and maintenance tasks.Lifting capacity typically ranges from a few hundred pounds to a few tons.

Medium-Duty Freestanding Jib Crane 10 Ton

- Offers higher lifting capacity compared to light-duty cranes.Suitable for moderately heavy loads in manufacturing and industrial settings.Lifting capacity usually ranges from a few tons to around 10 tons.

Heavy-Duty Freestanding Jib Crane

- Engineered for lifting heavy loads.Used in heavy industrial applications, foundries, and shipyards.Lifting capacity can exceed 10 tons, depending on the design and application.

Standard Cantilever Freestanding Jib Crane:

- Design: This type of jib crane features a jib arm that extends directly from the column in a fixed horizontal orientation. The jib arm is rigidly connected to the column.

- Functionality: The crane can rotate around the column, providing a circular working area within its radius. The load can be lifted, moved horizontally, and positioned at various points within the coverage area.

- Applications: Standard cantilever jib cranes are commonly used in scenarios where loads need to be moved back and forth along a linear path. They are suitable for tasks like transferring materials from one location to another, feeding machines, and facilitating general material handling operations.

- Advantages: These cranes are simple in design and provide reliable lifting and positioning capabilities. They are effective for applications that require regular, repetitive movements within a defined radius.

Articulating Cantilever Freestanding Jib Crane:

- Design: An articulating cantilever jib crane, also known as a knuckle jib crane, has a jib arm with multiple pivot points, allowing for greater flexibility in movement.

- Functionality: The multiple pivot points enable the crane to articulate and extend its jib arm in various directions. This design allows the crane to reach around obstacles, access confined spaces, and perform intricate material handling tasks.

- Applications: Articulating cantilever jib cranes are well-suited for tasks that require precise positioning in tight or complex spaces. They are commonly used in assembly lines, machining operations, and areas with obstacles that traditional cranes might struggle to navigate.

- Advantages: The flexibility provided by the articulating design makes these cranes versatile and adaptable to a range of applications. They excel in scenarios where traditional straight-arm cranes would be limited by space constraints or obstacles.

In summary, the choice between a standard cantilever and an articulating cantilever Freestanding jib crane depends on the specific material handling needs of the application. If straightforward horizontal movements are sufficient, a standard cantilever crane might be suitable. However, if tasks require reaching around obstacles or into confined spaces, an articulating cantilever crane offers the necessary flexibility.

Foundation Jib Cranes:

Foundation jib cranes require a dedicated concrete foundation to be installed. The foundation serves as the base on which the crane's support structure, such as the column or mast, is securely anchored. This foundation provides stability and load distribution for the crane's operation. The installation of a foundation can involve digging, pouring concrete, and anchoring the crane's support structure using anchor bolts.

Advantages

- Provides a stable and secure base for the crane.Suitable for heavy-duty applications and larger cranes.Ensures proper load distribution and minimizes stress on the floor.Can accommodate cranes with higher load capacities.

Considerations

- Requires more planning and construction time due to foundation installation.May involve additional costs for concrete work and labor.Suitable for permanent installations where the crane's position won't need frequent changes.

Foundationless jib cranes

Foundationless jib crane that is designed for light loads handling and can be directly anchored to the cement floor using bolts. This type of crane is indeed a practical solution for smaller-scale lifting tasks. It's typically used in scenarios where heavy-duty lifting is not required, and the crane's installation needs to be straightforward and without the need for a separate foundation.

Advantages:

Foundationless jib cranes for light loads have some distinct advantages:

- Simplicity: These cranes are relatively easy to install due to the absence of a separate foundation. Bolting them directly to the cement floor reduces installation time and complexity.

- Cost-Effective: Foundationless jib cranes are often more budget-friendly than cranes that require a dedicated foundation. This makes them an attractive option for businesses with limited resources.

- Flexibility: Their lightweight and portable nature allows for easy relocation if needed. This flexibility can be beneficial in dynamic work environments.

- Quick Deployment: Since no concrete work is necessary, the crane can be put into operation shortly after installation, minimizing downtime.

- Light Loads: These cranes are designed for handling light loads, which is suitable for tasks involving smaller items that do not exceed the crane's weight capacity.

High-Level Features of Electric Jib Hoists and Cranes

Strengths of Jib Cranes for Varied Operations

Jib Cranes boast an array of strengths that make them indispensable in diverse operational environments. These strengths contribute to their effectiveness in handling heavy loads, optimizing workspace, and streamlining operations across multiple industries within Russia.

- Versatility: One of the primary strengths of Jib Cranes lies in their adaptability to multifaceted operations. They are capable of handling a wide range of loads, from lighter materials to substantial machinery components, with precision and ease.

- Maneuverability: The ability to pivot or articulate, characteristic of various types of Jib Cranes, ensures enhanced maneuverability. This attribute proves invaluable, particularly in confined spaces where precise movement is crucial.

- Space Optimization: Jib Cranes offer an advantage in space-constrained settings. Their design allows for efficient use of vertical space, freeing up floor areas for other essential activities, thus maximizing the utilization of available workspace.

Adaptability to Russian Industrial Settings

Within the dynamic industrial landscape of Russia, Jib Cranes have showcased remarkable adaptability. They seamlessly integrate into various sectors, addressing the specific demands and challenges posed by different industries in the region.

- Manufacturing Sector: In manufacturing plants, Jib Cranes contribute significantly to production efficiency by facilitating material handling, assembly, and machine loading processes.

- Construction Industry: Jib Cranes play a pivotal role in construction sites, aiding in the movement of heavy construction materials, reducing manual labor, and ensuring safety during building projects.

- Warehousing and Logistics: Within warehouses and logistics hubs, these cranes optimize space utilization and streamline the handling of goods, contributing to enhanced inventory management and distribution efficiency.

The adaptability of Jib Cranes to the unique requirements of each industry in Russia underscores their versatility and highlights their pivotal role in the optimization of industrial operations.

Operational Benefits of jib hoist and cranes in Russia

Increased Efficiency and Safety

Jib Cranes stand as stalwart allies in the pursuit of heightened efficiency and safety within Russian industrial settings. Their operational benefits directly contribute to the enhancement of these crucial aspects:

- Enhanced Efficiency: The incorporation of Jib Cranes in industrial workflows streamlines operations by expediting material handling processes. The precision and ease of movement they offer significantly reduce time spent on lifting and shifting heavy loads, thereby boosting overall operational efficiency.

- Safety First: Ensuring a safe working environment is paramount. Jib Cranes are equipped with safety features such as limit switches, overload protection, and emergency stop functionalities. These safety mechanisms mitigate the risks associated with material handling, reducing workplace accidents and ensuring the well-being of personnel.

Cost-Effectiveness in Russian Environments

In addition to efficiency and safety, Jib Cranes present a compelling case for cost-effectiveness in Russian industrial environments:

- Reduced Labor Costs: By mechanizing material handling tasks, Jib Cranes alleviate the need for extensive manual labor. This reduction in labor-intensive processes leads to optimized manpower utilization and potentially lowers labor costs for businesses.

- Maintenance and Longevity: While initial investments are crucial, Jib Cranes offer long-term cost savings. Their durable construction and minimal maintenance requirements contribute to a prolonged lifespan, reducing overall maintenance costs over time.

The combination of increased efficiency, heightened safety, and cost-effectiveness makes Jib Cranes indispensable assets in the Russian industrial landscape, aligning with the goals of optimizing operations while maintaining a focus on safety and financial prudence.

Typical Industrial Applications in Russia

Construction Sites

Construction sites in Russia witness the vital role played by Jib Cranes in ensuring seamless operations and efficient material handling:

Handling Construction Materials Efficiently and Precisely

Jib Cranes stand as indispensable assets in the realm of construction, primarily in handling materials with precision and efficiency. Whether it's transporting heavy construction materials to specific locations or aiding in the assembly of critical structural components, these cranes play a pivotal role.

Utilization in Building High-Rise Structures and Infrastructure Projects

The construction of high-rise structures and significant infrastructure projects demands precise handling of materials at varying elevations. Jib Cranes, especially Wall-Mounted and Free-Standing variants, are tailored to cater to these specific needs. They facilitate the movement of heavy loads to considerable heights, ensuring the smooth progression of such projects.

In addition to their efficiency in material handling, Jib Cranes contribute significantly to improving productivity while upholding safety standards at construction sites across Russia. Their ability to precisely position materials and aid in the installation of structural components makes them indispensable in the pursuit of completing projects on schedule and within stipulated safety parameters.

Manufacturing Facilities

Within the manufacturing sector in Russia, Jib Cranes play a crucial role in streamlining operations and enhancing productivity:

Aiding in Assembly Lines and Moving Heavy Components

Jib Cranes are integral to manufacturing processes, especially in assembly lines and production setups where heavy components need to be maneuvered efficiently. These cranes offer precision and reliability, aiding in the movement of heavy machinery parts or components along assembly lines. Their flexibility and reach make them invaluable for seamless production workflow.

Enhancing Production Workflow and Reducing Manual Labor

By mechanizing material handling tasks, Jib Cranes significantly reduce the reliance on manual labor in manufacturing facilities. The incorporation of these cranes not only enhances workflow efficiency but also reduces the physical strain on workers, fostering a safer and more productive work environment.

The adaptability of Jib Cranes to varying load capacities and their capability to provide controlled movement contribute to the optimization of manufacturing operations in Russia. Their ability to swiftly move heavy components without compromising on safety underscores their importance in ensuring a streamlined and efficient production process.

Warehouses and Logistics

In the field of warehouses and logistics, Jib Cranes play a pivotal role in optimizing operations and enhancing efficiency:

Optimizing Storage Space Utilization and Swift Cargo Handling

Within warehouses, space utilization is critical. Jib Cranes aid in optimizing storage space by facilitating the efficient movement of goods, particularly heavy items, to designated storage areas. Their ability to reach and maneuver within confined spaces enables the vertical stacking of goods, maximizing storage capacity.

Moreover, these cranes ensure swift cargo handling, expediting the loading and unloading of goods from storage shelves or transportation vehicles. The precision and ease of movement they offer significantly contribute to the seamless logistics operations within warehouses.

Streamlining Inventory Management and Distribution Processes

Efficient inventory management is fundamental to the logistics sector. Jib Cranes streamline these processes by enabling quick and controlled movement of goods. Whether it's sorting, organizing, or transferring inventory, these cranes enhance the speed and accuracy of these operations.

Additionally, in distribution centers, Jib Cranes aid in loading and unloading goods onto trucks or containers, ensuring a smooth flow of goods in and out of the facility. This capability significantly contributes to meeting delivery schedules and maintaining a streamlined supply chain.

The adaptability of Jib Cranes to the diverse demands of warehouse and logistics operations in Russia underscores their significance in optimizing storage, handling, and distribution processes.

Shipping and Dockyards

In the field of shipping and dockyards, Jib Cranes serve as indispensable tools for various essential tasks:

Supporting Loading/Unloading of Cargo onto Ships or Trucks

Jib Cranes are instrumental in the efficient and safe loading and unloading of cargo onto ships or trucks within dockyard facilities. Their ability to handle heavy loads with precision and reach varying heights or positions makes them invaluable assets in managing cargo operations.

These cranes aid in swiftly transferring cargo from storage areas to vessels or trucks, ensuring timely departures or deliveries. Their adaptability to different types of cargo and their robust design contribute to the smooth execution of such operations.

Facilitating Maintenance Work on Vessels and Port Equipment

Beyond cargo handling, Jib Cranes play a crucial role in facilitating maintenance activities within dockyards. They are utilized for lifting and positioning heavy components during maintenance or repair work on vessels, port equipment, or infrastructure. Their precision and maneuverability aid in ensuring efficient and safe maintenance operations.

The versatility of Jib Cranes in handling diverse cargo and supporting maintenance work within shipping and dockyard environments underscores their importance in ensuring operational efficiency and safety in Russia's maritime sector.

Addressing User Concerns with Jib Cranes in Russia

Safety Measures and Compliance

Ensuring safety is a paramount concern in the utilization of Jib Cranes. Manufacturers and operators address these concerns through adherence to safety standards and the implementation of various safety measures:

Compliance with Russian Safety Standards and Certifications

In Russia, Jib Crane manufacturers adhere to stringent safety standards set forth by regulatory bodies. These standards encompass design, manufacturing, installation, and operation guidelines to ensure the safety of personnel and equipment. Complying with these standards is imperative for manufacturers to attain certifications that validate the safety and reliability of their cranes.

Safety Features like Limit Switches, Overload Protection, etc.

Jib Cranes incorporate an array of safety features to mitigate potential risks associated with their operation. These features include:

Limit Switches: Preventing the crane from exceeding designated travel limits, ensuring safe operation within defined parameters.

Overload Protection: Safeguarding against excessive loads by automatically stopping the crane in case of overload, preventing potential accidents.

Emergency Stop Mechanisms: Allowing immediate cessation of crane operations in emergency situations, prioritizing personnel safety.

Furthermore, continuous monitoring, regular maintenance, and operator training play pivotal roles in ensuring the effectiveness of these safety features.

By prioritizing safety measures and compliance with established standards, Jib Crane manufacturers and operators in Russia aim to create a secure working environment, mitigating potential risks associated with crane operations.

Maintenance and Servicing

Ensuring proper maintenance and servicing of Jib Cranes is essential for their optimal performance and longevity. Manufacturers and service providers address user concerns by offering comprehensive maintenance guidelines and services:

Guidelines for Regular Maintenance to Ensure Optimal Performance

Jib Crane manufacturers provide detailed maintenance guidelines outlining routine checks and procedures. These guidelines encompass various aspects:

Scheduled Inspections: Regular inspections to assess mechanical components, electrical systems, and safety features.

Lubrication Procedures: Guidelines for lubricating moving parts to prevent wear and maintain smooth operation.

Component Replacement: Recommendations for timely replacement of parts subject to wear and tear.

Following these maintenance guidelines ensures the continuous and reliable operation of Jib Cranes, mitigating potential risks and ensuring their longevity.

Availability of Maintenance Services and Spare Parts

In Russia, manufacturers and authorized service providers offer maintenance services tailored to Jib Cranes. These services include:

Routine Maintenance: Scheduled visits by trained technicians for inspections, adjustments, and necessary repairs.

Emergency Repair Services: Prompt response and assistance in case of unexpected breakdowns or faults.

Spare Parts Availability: Ensuring a readily available supply of genuine spare parts for quick replacements or repairs.

The availability of comprehensive maintenance services, along with a ready stock of genuine spare parts, ensures minimal downtime and optimal performance of Jib Cranes in Russian industrial settings.

Customization Options

Tailoring Jib Cranes to suit specific industrial requirements is a key aspect addressed by manufacturers to meet diverse needs within the Russian market:

Tailoring Cranes to Suit Specific Industrial Requirements

Jib Crane manufacturers offer customization options to align with unique industrial demands. These include:

Load Capacity Adjustments: Tailoring cranes to handle specific load capacities required by different industries, whether lighter loads for intricate operations or heavier loads for robust applications.

Reach and Span Adjustments: Modifying the crane's reach or span to suit spatial constraints or specific operational requirements within industrial settings.

Mounting Configurations: Offering variations in mounting options (wall-mounted, free-standing, etc.) to accommodate different workspace layouts.

These customization options ensure that Jib Cranes are optimized to meet the precise needs of various industries in Russia, enhancing their efficiency and effectiveness in diverse operational environments.

Options for Additional Accessories and Control Mechanisms

Manufacturers provide a range of additional accessories and control mechanisms, enhancing the functionality and usability of Jib Cranes:

Remote Controls: Providing remote control options for crane operation, enhancing convenience and operator safety, especially in scenarios where precise control is required.

Specialized Attachments: Offering various attachments and specialized tools compatible with Jib Cranes to cater to specific tasks or industries, enhancing their versatility.

Automation Integration: Facilitating integration with automation systems to optimize crane operations, improve workflow, and reduce manual intervention.

FAQs on Jib Cranes for Sale in Russia

a. What Load Capacities Do Jib Cranes Offer?

Jib Cranes are available in a wide range of load capacities tailored to suit various industrial needs in Russia. These capacities typically vary from smaller models with lighter load capacities of a few hundred kilograms to larger, heavy-duty cranes capable of handling several tons of weight. Manufacturers offer diverse options to match specific load requirements across different industries.

b. How to Choose the Right Jib Crane for a Specific Application?

Selecting the appropriate Jib Crane involves considering various factors, including:

Load Capacity: Assess the weight and size of the loads the crane will handle.

Span and Reach: Determine the required coverage area and the crane's reach within the workspace.

Mounting Type: Choose between wall-mounted, free-standing, or articulating options based on spatial constraints and operational needs.

Safety Features: Ensure the crane is equipped with essential safety features matching the application's safety requirements.

Consulting with experts or manufacturers helps in selecting the most suitable Jib Crane for a specific industrial application in Russia.

c. Are There Additional Safety Features Available?

Yes, Jib Cranes often come with additional safety features beyond standard mechanisms like limit switches and overload protection. Some additional safety features include:

Emergency Stop Buttons: Immediate cessation of crane operations in emergency situations.

Anti-Collision Systems: Preventing collisions between cranes or with obstacles in the workspace.

Load Monitoring Systems: Monitoring and alerting operators of load capacities to avoid overloading.

Manufacturers offer a range of optional safety features to enhance the overall safety standards of Jib Cranes.

d. What Maintenance Is Required for Optimal Performance?

Regular maintenance is essential for ensuring optimal performance of Jib Cranes. This includes:

Scheduled Inspections: Regular checks of mechanical and electrical components.

Lubrication: Periodic lubrication of moving parts to prevent wear.

Component Replacement: Timely replacement of worn-out parts to maintain efficiency.

Following manufacturer-recommended maintenance schedules and guidelines is crucial for optimal crane performance and longevity.

e. What Are the Power Source Options for Crane Hoists?

Jib Crane hoists utilize various power sources, including:

Electric Power: Electric hoists powered by electricity are commonly used for their ease of operation and control.

Pneumatic Power: Air-powered hoists suitable for environments where electricity is not viable or in hazardous areas.

Manual Power: Manual hoists operated by hand for lighter loads and situations where power sources are limited.

The choice of power source depends on factors such as load capacity, operational requirements, and the specific industrial environment.

Contact Us to Get Your Custom Jib Hoist and Jib Crane in Russia

In conclusion, the diverse landscape of Jib Cranes available for sale in Russia caters to a multitude of industrial needs, offering a range of types, benefits, and applications:

From Wall-Mounted to Free-Standing and Articulating variants, Jib Cranes showcase versatility, aiding industries in construction, manufacturing, logistics, shipping, and more. Their adaptability, combined with features like precise handling, safety mechanisms, and load capacity options, make them invaluable assets across diverse industrial sectors in Russia.

For those seeking optimal solutions for material handling and operational efficiency, consider the myriad benefits Jib Cranes offer. These cranes not only enhance productivity and safety but also offer customizable options tailored to specific industrial requirements. Embrace the efficiency, safety, and adaptability that Jib Cranes bring to your operations in Russia.

Should you have any inquiries or wish to explore the possibilities of integrating Jib Cranes into your industrial setup, feel free to contact us at [Insert Contact Information]. Our team of experts is dedicated to providing tailored solutions and guidance to address your material handling needs in Russia.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch