Crane Design: Comparing Overhead Crane Designs in China & Russia

Custom overhead crane design for your needs. What are distinguishing features & design preferences in overhead cranes manufactured in China & Russia?

Category: Russia

Your Trusted Overhead Crane Manufacturer & Supplier

Comparing Overhead Crane Designs in China and Russia

Custom Overhead Crane & Cost-effective Lifting Solution for Your Indusrial Needs

Custom overhead crane design for your needs. What are distinguishing features & design preferences in overhead cranes manufactured in China & Russia?

The evolution of industrial machinery is a testament to the intricate fusion of engineering prowess and cultural influences, creating tools that are not just functional but often reflective of a nation's values. As we explore the realm of overhead crane designs, the distinct approaches taken by two major industrial players, China and Russia, come into sharp focus. This article aims to underscore the significance of comprehending and contrasting the design philosophies of overhead cranes in these nations. The emphasis lies not only on acknowledging the nuances in design but, crucially, understanding how these design disparities reverberate through the performance and adaptability of overhead cranes in diverse applications.

- Importance of Understanding Designs -The design of an overhead crane is not merely a cosmetic consideration; it is a reflection of the engineering principles, cultural ethos, and technological advancements of the manufacturing nation. Each curve, component, and feature embedded in the design serves a purpose beyond aesthetics, influencing how the crane performs under various conditions and in different industrial settings.

- Impact on Crane Performance -The engineering decisions made during the design phase have a profound impact on the operational efficiency and reliability of overhead cranes. Whether it's the choice of materials for construction, the level of technological integration, or the emphasis on customization, each element plays a role in determining how well a crane performs its designated tasks. Understanding these design intricacies is pivotal for industries seeking cranes that align seamlessly with their operational requirements.

- Suitability for Diverse Applications -No two industries are identical, and neither should be their overhead cranes. The design disparities between Chinese and Russian cranes directly influence their suitability for various applications. Some industries may benefit from the adaptability and precision of Chinese crane designs, while others may find the robustness and durability of Russian designs more fitting. Recognizing these differences is akin to selecting a tailored tool for a specific job — a decision that impacts productivity, safety, and overall operational success.

In essence, the introduction serves as a clarion call to delve beyond the surface of overhead crane designs in China and Russia. It invites readers to appreciate that these designs are not arbitrary; they are the result of a careful interplay of cultural, technological, and industrial factors. As we navigate through the distinguishing features of Chinese and Russian crane designs, the overarching goal is to empower industries with the knowledge needed to make informed decisions, ensuring that the selected overhead crane is not just a piece of machinery but a strategic asset tailored to their unique operational landscape.

Distinguishing Features of Chinese Overhead Crane Designs

Design Philosophy and Aesthetics

Chinese overhead crane designs are characterized by a harmonious blend of functionality and aesthetics, a reflection of the nation's rich cultural heritage and its commitment to technological innovation. These cranes go beyond mere industrial equipment; they embody a design philosophy that seamlessly integrates form and function.

- Aesthetic Preferences:Chinese crane designs often exhibit a sleek and modern aesthetic. Clean lines, balanced proportions, and attention to detail are common features. The aesthetics of these cranes are not just about visual appeal but are intricately tied to the overall user experience and the integration of cutting-edge technologies.

- Cultural Influences:The design philosophy of Chinese overhead cranes is deeply influenced by traditional Chinese culture, where balance, harmony, and precision are highly valued. This cultural underpinning is evident in the graceful curves and symmetrical designs that often characterize Chinese cranes.

- Engineering Principles:Beyond aesthetics, Chinese crane designs reflect advanced engineering principles. The emphasis on precision, efficiency, and adaptability is evident in the integration of state-of-the-art technologies and materials. These cranes are engineered to not only meet functional requirements but to do so with a touch of elegance.

- Discussion on Cultural Influences and Engineering Principles:The marriage of cultural influences and engineering principles in Chinese crane designs is a key differentiator. The aesthetics are not merely superficial; they are a tangible expression of the nation's commitment to craftsmanship and innovation. The incorporation of cultural elements ensures that these cranes are not just efficient tools but also carry a cultural narrative that resonates both domestically and internationally.

In essence, the design philosophy and aesthetics of Chinese overhead cranes create a distinctive identity that sets them apart on the global stage. They embody a fusion of tradition and modernity, making them not just industrial workhorses but pieces of engineering artistry. Understanding these distinguishing features is essential for industries seeking cranes that not only excel in performance but also align with their broader cultural and aesthetic sensibilities.

Let's create tables to showcase the similarities and differences between overhead crane designs in China and Russia.

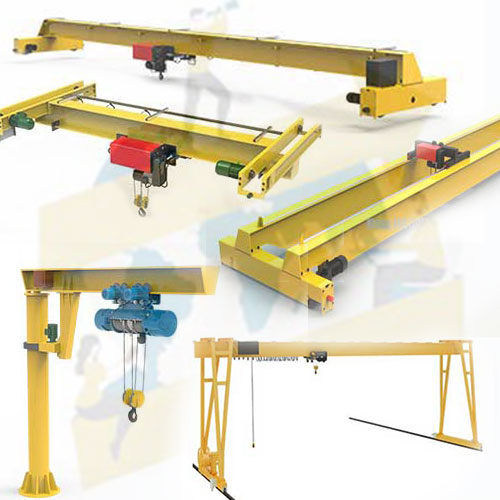

Main Types of Chinese Overhead Crane Designs

Single girder overhead crane

Single girder overhead crane specifications: Capacity:3.2 ton to 16 ton, Span: 7.5m to 28.5m,Lifting Height: 6m to 18m,Working Class:A5. Ask for single girder overhead crane price.

Double girder overhead crane

Double girder overhead crane specifications: Capacity:5 ton to 100ton,Span: 10.5m to 31.5m,Lifting Height: 6m to 18m,Working Class:A5- A7. Ask for double girder overhead crane price.

Suspension crane

Underslung overhead crane specifications: Capacity:0.5 ton to 10 ton, Span: 3m to 31.5m, Lifting Height: 6m to 18m,Working Class:A3 to A5. Ask for underrunning crane price & suspension crane price.

KBK crane

Overhead kbk crane specifications: Capacity: 125Kg-5000Kg,Lifting Height: 2.5m-12m,Maximum Span : 3-10m,Working Class: A3. Ask for kbk crane price & kbk light crane price.

Industrial crane

Customized industrial cranes for various industries such as, steel mill, oil & gas, automobile, machinery assembly, mining, general processing, etc.. Ask for industrial overhead crane price.

Process crane

For your specific applications, the process cranes are provided to meet your specific conditions and lifting requirements to save your crane costs.. Ask for process crane price.

Main Types of Chinese Gantry Crane Designs

Single girder gantry crane

Single girder gantry crane specifications: Capacity: 1ton-20ton, Span Length: 8~30m, Working Class: A3, A4. Ask for single girder gantry crane price.

L leg single girder gantry crane

L types gantry crane specifications: Capacity 5ton -32ton, Span Length: 18~35m, Working Class: A5, A6.Ask for l leg single beam gantry crane price.

Truss girder gantry crane

Truss gantry crane specifications: Capacity: 1 ton -50 ton, Span Length: 12~35m, Working Class: A5, A6. Ask for truss gantry crane price.

Double girder gantry crane

Double girder gantry crane specifications: Capacity: 5 ton - 500 ton, Span Length: 12~35m, Working Class: A5, A6.Ask for double girder gantry crane price.

Semi gantry crane

Semi-gantry crane specifications: Capacity: 2 ton- 10 ton, Span Length: 8~20m, Working Class: A3, A4.Ask for semi-gantry crane price.

Portable gantry crane

Portable gantry crane specifications: Capacity:0.25 ton -10ton, Span length: 2~16m,Lifting height : 2~12m, Working class : A2.Ask for small gantry crane price.

Main Types of Chinese Jib Crane Designs

Pillar jib crane

Pillar jib crane specifications-Capacity:0.5 ton -10 ton, Arm length: 3-12m, Lifting height: 3-8m, Rotating : 180, 270, 360 ,Working class: A3.Ask for free standing jib crane price.

Wall mounted jib crane

Wall mounted jib crane specifications-Capacity: 0.25 ton-2 ton, Arm length: 2-6m, Lifting height: 2-6m, Rotating : 180, Working class: A3.Ask for wall mounted jib crane price.

Wall travelling jib crane

Wall-travelling jib crane specifications-Capacity: 0.25 ton-10 ton, Span: 3-10m, Lifting height: 3-8m, Rotating : 180,Working class: A3. Ask for wall travelling jib crane price.

Slewing jib crane

Slewing jib cranes -floor & wall jib cranes- flexible swing or slewing jib arm & rotary crane design, 180, 270 &360 degree rotating jib crane for sale. Ask for slewing jib crane price.

Portable jib crane

Portable jib crane specifications- Capacity: 0.08 ton,1 ton, Lifting Height: 1.5- 3m, Turning Radius: 2m, 3m, Rotation Angle: 360°, Working class: A3.Ask for portable jib crane price.

Process jib crane

Process jib cranes for your specific application to lower your jib crane cost. Contact us to get your customized process jib crane design and your jib crane rate and crane price.

Similarities in Overhead Crane Designs

| Feature | Chinese Overhead Cranes | Russian Overhead Cranes |

|---|---|---|

| Durability | Robust construction for longevity | Emphasis on durability in challenging environments |

| Adaptability | Customization options for diverse applications | Adaptable to extreme weather and specific industrial conditions |

| Safety Standards | Adherence to national safety regulations | Adherence to and often exceeding national safety standards |

| Operational Efficiency | Integration of advanced control systems for precision | Straightforward control interfaces emphasizing simplicity |

| Technological Features | Incorporation of cutting-edge technologies | More conservative approach to technology integration |

| Material Selection | Use of lightweight materials for energy efficiency | Emphasis on robust construction with heavier materials |

Differences in Overhead Crane Designs

| Feature | Chinese Overhead Cranes | Russian Overhead Cranes |

|---|---|---|

| Customization Complexity | High degree of customization may lead to more complex maintenance | Standardized customization simplifying maintenance procedures |

| Maintenance Requirements | May require specialized maintenance expertise | Maintenance may be handled by technicians with broader expertise |

| Design Philosophy | Technological innovation and adaptability | Robust simplicity and adaptability to challenging environments |

| Control Systems | Advanced systems, including radio remote controls | Straightforward control interfaces with simplicity emphasis |

| Suitability for Industries | Manufacturing, automotive, logistics, and warehousing | Heavy-duty applications in manufacturing, automotive, and mining |

These tables provide a concise overview of the similarities and differences in overhead crane designs between China and Russia. They highlight key features, allowing for a quick comparison and understanding of the distinctive characteristics of cranes from each region.

Exploration of Technological Integration

Chinese overhead crane designs stand at the forefront of technological innovation, showcasing a high level of integration of cutting-edge features. These cranes are not just mechanical marvels; they are technologically advanced tools designed to enhance operational efficiency and safety.

Key Technological Features:

- Automation and Smart Controls:Chinese cranes often feature advanced automation systems that enable precise control and movement. Smart controls, coupled with sensors and feedback mechanisms, contribute to seamless and efficient crane operations.

- Real-time Monitoring Capabilities:The integration of real-time monitoring capabilities is a hallmark of Chinese crane designs. Operators can remotely monitor crucial parameters, ensuring optimal performance and facilitating prompt response to any operational challenges.

- IoT Connectivity:Many Chinese overhead cranes are equipped with Internet of Things (IoT) connectivity, enabling data exchange between devices. This connectivity enhances overall crane performance, allows for predictive maintenance, and contributes to a more connected industrial ecosystem.

- 4. Safety Systems:Technological integration extends to comprehensive safety systems. Chinese cranes often incorporate features such as collision avoidance systems, overload protection, and emergency braking, ensuring a secure working environment.

Highlighting Key Technological Features:

Chinese crane designs are characterized by the integration of advanced technologies that redefine the capabilities of traditional overhead cranes. The infusion of automation, real-time monitoring, IoT connectivity, and robust safety systems positions these cranes as not just tools for lifting and moving loads but as intelligent and adaptive solutions for modern industrial needs.

The emphasis on technological integration reflects China's commitment to Industry 4.0 principles, where the convergence of digital technologies with industrial processes is paramount. This forward-looking approach ensures that Chinese overhead cranes are not only efficient in their primary functions but also contribute to the broader goals of increased productivity, sustainability, and operational intelligence.

Understanding the depth of technological integration in Chinese overhead crane designs is essential for industries seeking to embrace the benefits of advanced industrial technologies. It positions these cranes as strategic assets in the digital transformation journey of industries, offering a glimpse into the future of smart and connected manufacturing environments.

Customization Options:

- Insight into Customization:One of the defining characteristics of Chinese overhead crane designs lies in the degree of customization offered by manufacturers. Chinese cranes are not standardized, one-size-fits-all solutions; instead, they are versatile tools that can be tailored to meet the unique requirements of diverse industries and applications.

- Degree of Customization:Chinese manufacturers recognize the varied needs of industries, and as a result, they provide a high degree of customization for their overhead cranes. This extends beyond mere aesthetics to encompass functional aspects, ensuring that the crane is precisely configured to optimize performance in specific operational environments.

Examples of Customizable Features:

- Lifting Capacity:Chinese cranes can be customized to accommodate a wide range of lifting capacities. Whether the requirement is for light-duty or heavy-duty lifting, manufacturers offer solutions tailored to the specific tonnage needs of the industry.

- Span and Height:The span and lifting height of Chinese overhead cranes are adjustable to suit the spatial constraints of different facilities. This customization ensures that the crane seamlessly integrates into the existing layout of the industrial space.

- Control Systems:Manufacturers offer flexibility in the type of control systems employed. From traditional pendant controls to more advanced radio remote controls and even automation features, Chinese cranes can be adapted to match the operator's preferences and the operational demands of the industry.

Adaptations Based on Industry Requirements

Chinese overhead cranes are adapted to suit the specific requirements of various industries. For example:

- In the automotive industry, cranes may feature specialized lifting attachments for handling vehicle components.

- In the steel industry, cranes can be designed with heat-resistant materials to withstand the harsh conditions of metallurgical processes.

Discussion on Customization Options:

The level of customization offered by Chinese manufacturers empowers industries to procure overhead cranes that align precisely with their operational needs. This adaptability is not a mere convenience but a strategic advantage. It ensures that the crane is not just a piece of equipment but a tailored solution designed to enhance productivity, efficiency, and safety in a specific industrial context.

The ability to customize lifting capacity, span, height, control systems, and other features reflects a commitment to meeting the diverse demands of modern industries. Understanding these customization options is crucial for industries seeking overhead cranes that seamlessly integrate into their workflows, providing a competitive edge in an ever-evolving industrial landscape.

Material Selection and Construction:

Examination of Materials:

The durability and performance of Chinese overhead cranes are significantly influenced by the materials selected for their construction. Chinese manufacturers carefully choose materials that not only meet engineering standards but also align with the nation's commitment to producing robust and reliable industrial machinery.

Materials Commonly Used:

- High-Strength Steel:Chinese overhead cranes often feature components constructed from high-strength steel. This material provides the necessary structural integrity while minimizing the weight of the crane, contributing to efficient and economical operation.

- Durable Alloy Components:Alloy components are frequently employed in critical areas of the crane, enhancing resistance to wear, corrosion, and fatigue. These alloys contribute to the overall longevity of the crane, especially in demanding industrial environments.

- Heat-Resistant Materials:In industries with elevated temperatures, such as metallurgy, Chinese cranes may incorporate heat-resistant materials. This ensures that the crane can withstand the challenging conditions associated with processes like molten metal handling.

Impact on Durability and Performance:

The material choices made in the construction of Chinese overhead cranes directly impact their durability, performance, and overall design. High-strength steel enhances load-bearing capacity without compromising structural integrity, while durable alloys contribute to longevity and reliability, even under strenuous operating conditions.

Discussion on Material Impact:

Chinese crane manufacturers prioritize the use of materials that not only meet international standards but also align with the nation's emphasis on quality and longevity. The careful selection of materials ensures that Chinese overhead cranes can withstand the rigors of industrial use, providing a reliable and durable solution for diverse applications.

Understanding the materials used in Chinese crane construction is essential for industries seeking equipment with a prolonged lifespan, reduced maintenance requirements, and optimal performance. The commitment to quality materials underscores China's position as a global leader in industrial machinery, where each component of the crane is chosen with precision to ensure its resilience and efficiency in the face of challenging operational environments.

Distinguishing Features of Russian Overhead Crane Designs

Cultural and Engineering Influences:

Russian overhead crane designs are a synthesis of cultural heritage and engineering ingenuity. Influenced by a rich history, diverse geography, and the demands of heavy industries, these cranes reflect a unique combination of cultural and engineering factors that set them apart in the global industrial landscape.

Cultural Influences:

- Practicality and Robustness:Russian crane designs often prioritize practicality and robustness, mirroring the nation's historical emphasis on durable and functional solutions. This cultural inclination is deeply rooted in a climate that demands resilience and efficiency in industrial operations.

- Aesthetic Simplicity:While functionality is paramount, Russian cranes exhibit a certain aesthetic simplicity. The designs are straightforward, focusing on essential features without unnecessary embellishments. This reflects a cultural ethos that values practicality over ornate aesthetics.

Engineering Influences:

- Adaptability to Challenging Environments:The diverse geography of Russia, including extreme climates and challenging terrains, influences crane designs. Russian cranes are engineered to adapt to these challenging environments, showcasing features that enhance performance in adverse conditions.

- Heavy-Duty Construction:The demands of heavy industries, such as metallurgy and mining, have a profound impact on Russian crane designs. Heavy-duty construction using robust materials is a common engineering choice to ensure the cranes withstand the rigors of demanding industrial processes.

Discussion on Design Preferences:

The cultural and engineering influences on Russian overhead crane designs create a distinctive set of design preferences. Practicality, durability, and adaptability to challenging environments are key considerations that permeate these designs. While aesthetics are generally straightforward, there is an inherent beauty in the simplicity of a design that prioritizes functionality.

Understanding the cultural and engineering influences on Russian crane designs provides insights into the nation's approach to industrial machinery. The emphasis on practical solutions and robust construction aligns with the historical and geographical context, making Russian cranes well-suited for industries that require resilience and efficiency in the face of diverse challenges.

Emphasis on Robustness and Durability:

Exploration of Robust Construction:

Russian overhead crane designs are characterized by a steadfast emphasis on robust construction, a feature deeply ingrained in the nation's industrial ethos. The need for durability and longevity in the face of challenging operational conditions is a driving force behind the design choices made by Russian manufacturers.

Examples of Design Features:

- Heavy-Gauge Steel Construction:Russian cranes often feature a robust framework constructed from heavy-gauge steel. This design choice ensures the structural integrity of the crane, providing a solid foundation for lifting heavy loads and enduring the stresses of industrial operations.

- Reinforced Components:Critical components of Russian overhead cranes, such as the bridge, trolley, and hoist, are reinforced to withstand heavy-duty usage. Reinforcement enhances load-bearing capacity and contributes to the overall durability of the crane.

- Corrosion-Resistant Coatings:Given Russia's diverse climate, including exposure to harsh winters, Russian cranes often incorporate corrosion-resistant coatings. These coatings protect the crane from environmental elements, extending its lifespan and reducing maintenance requirements.

- 4. Simple and Sturdy Design:The design philosophy of Russian cranes leans towards simplicity and sturdiness. This straightforward approach minimizes the number of intricate components, reducing the likelihood of mechanical failures and facilitating easier maintenance.

Enhancing Longevity and Reliability:

The emphasis on robustness and durability in Russian crane designs is not merely a design preference; it is a strategic choice to enhance the longevity and reliability of the equipment. These cranes are engineered to withstand the demands of heavy industries, where prolonged operational life is a critical factor.

Discussion on Design Emphasis:

The focus on robust construction and durability in Russian overhead crane designs reflects a commitment to providing industrial solutions that endure the test of time. The simplicity of design, coupled with the use of high-quality materials, creates cranes that excel in reliability, making them well-suited for industries where uninterrupted operation is paramount.

Understanding the emphasis on robustness and durability is essential for industries seeking overhead cranes that can withstand the challenges of heavy-duty applications. Russian cranes embody a design philosophy that prioritizes resilience, making them a reliable choice for industries demanding enduring performance in the face of demanding operational conditions.

Adaptability to Challenging Environments:

Russian overhead crane designs excel in adaptability to challenging environments, a characteristic born out of the nation's diverse climate and industrial landscape. These cranes are engineered to operate seamlessly in extreme weather conditions and specific industrial settings, showcasing features that ensure optimal performance.

Examples of Environmental Adaptations:

Cold-Weather Design

Given Russia's cold climate, Russian cranes often incorporate features to operate efficiently in sub-zero temperatures. These adaptations may include:

- Cold-resistant lubricants to maintain smooth operation in low temperatures.

- Insulated electrical components to prevent malfunctions caused by frost.

Weatherproofing:

Russian cranes are designed with weatherproofing measures to resist the impact of rain, snow, and other environmental elements. This includes sealed electrical components, corrosion-resistant materials, and protective coatings to safeguard against weather-induced wear.

Dust and Debris Resistance:

In industrial settings where dust and debris are prevalent, Russian cranes may feature designs that prevent the ingress of particles. Sealed components and strategic engineering minimize the risk of malfunctions caused by the accumulation of dust.

Adaptations for Specific Industries:

Russian crane designs are often tailored to the unique challenges of specific industries. For instance:

- In metallurgical settings, cranes may be equipped with heat-resistant components to withstand high temperatures.

- In mining operations, adaptations may include reinforced structures to handle heavy loads and harsh working conditions.

Ensuring Optimal Performance:

The adaptability of Russian crane designs to challenging environments is a testament to their versatility and reliability. These cranes are not only engineered for optimal performance in ideal conditions but are also equipped to thrive in the harshest industrial and climatic settings.

Discussion on Environmental Adaptations:

The ability of Russian cranes to adapt to challenging environments underscores their suitability for a wide range of industries. From extreme cold to industrial settings with specific environmental challenges, these cranes are designed to excel, ensuring uninterrupted performance even in the most demanding conditions.

Understanding the environmental adaptations of Russian overhead crane designs is crucial for industries operating in diverse climates or facing unique challenges. Russian cranes embody a design philosophy that prioritizes adaptability, making them a resilient choice for applications where environmental conditions are a critical factor in crane performance.

Safety and Compliance Standards:

Examination of Safety Standards:

Russian overhead crane designs place a paramount emphasis on safety, integrating robust safety standards and compliance considerations into their engineering. The commitment to ensuring a secure working environment is reflected in the design choices made by Russian manufacturers.

Discussion on Safety Standards:

Adherence to National Regulations:

Russian crane designs align with and often exceed national safety regulations. Manufacturers ensure that the cranes meet or surpass the safety standards set by regulatory authorities, providing a level of assurance to industries and operators.

Incorporation of Redundant Safety Systems:

Russian cranes are equipped with redundant safety systems to mitigate the risk of accidents. These systems may include:

- Emergency braking mechanisms to halt crane movement in critical situations.

- Overload protection features to prevent the crane from lifting loads beyond its specified capacity.

Operator Safety Considerations:

The design of Russian cranes incorporates features that prioritize operator safety. This includes ergonomic control interfaces, clear visibility, and safety barriers or enclosures to protect operators from potential hazards.

Impact on Overall Design and Performance:

The integration of safety standards and compliance considerations has a profound impact on the overall design and performance of Russian overhead cranes. These design features not only enhance the safety of crane operations but also contribute to the longevity and reliability of the equipment.

Discussion on Design Impact:

The emphasis on safety standards in Russian crane designs signifies a commitment to creating a secure working environment. By prioritizing compliance with national regulations and incorporating redundant safety features, these cranes contribute to accident prevention and the protection of both operators and assets.

Understanding the safety and compliance standards embedded in Russian overhead crane designs is crucial for industries prioritizing workplace safety. Russian cranes stand as reliable and secure solutions, where adherence to stringent safety measures is not just a design requirement but a fundamental aspect of the engineering philosophy.

Impact on Crane Performance and Suitability

Operational Efficiency -Analysis of Design Influence on Efficiency:

The design disparities between Chinese and Russian overhead cranes play a pivotal role in determining their operational efficiency. Each design philosophy brings forth unique features that either contribute to or detract from the overall performance of the crane.

Examples of Features Affecting Efficiency:

Control Systems:

- China:Chinese cranes often incorporate advanced control systems, such as radio remote controls and automation features. These systems enhance operator precision and streamline operations, contributing to overall efficiency.

- Russia:Russian cranes typically prioritize straightforward control interfaces, emphasizing simplicity. While this approach minimizes complexity, it may impact the speed and precision achievable in certain operations.

Customization Options:

- China:Chinese cranes offer a high degree of customization, allowing industries to tailor the crane's specifications to their exact needs. This adaptability enhances efficiency by providing a crane precisely suited to the demands of specific applications.

- Russia:Russian cranes, while adaptable, may have a more standardized approach to customization. This could impact efficiency in industries requiring highly specialized equipment.

Technological Integration:

- China:Chinese cranes often feature cutting-edge technologies, contributing to enhanced efficiency. Automation, sensor integration, and real-time monitoring systems are examples of technology-driven features.

- Russia:Russian cranes may prioritize a more conservative approach to technology integration. While robust and reliable, the absence of certain advanced features could affect efficiency in industries where automation is critical.

Material Selection:

- China:Chinese cranes may utilize lightweight yet durable materials, optimizing energy efficiency and reducing operational costs. This contributes to efficient handling of loads and economical long-term operation.

- Russia:Russian cranes, with their emphasis on robustness, may use heavier materials for added durability. While this enhances longevity, it might impact energy efficiency, especially in industries sensitive to power consumption.

Impact on Operational Efficiency:

The influence of design differences on operational efficiency is multi-faceted. Chinese cranes, with their technological prowess and customizable features, excel in industries where precision and adaptability are paramount. On the other hand, Russian cranes, emphasizing simplicity and robustness, offer reliability in demanding conditions but may be perceived as less adaptable in certain applications.

Understanding how design influences operational efficiency is crucial for industries seeking overhead cranes that align seamlessly with their specific operational requirements. Whether prioritizing advanced technology, customization options, or straightforward reliability, the choice between Chinese and Russian crane designs will hinge on the unique demands of each industrial setting.

Suitability for Industrial Applications:

Exploration of Design Preferences:

The distinct design preferences in Chinese and Russian overhead cranes significantly influence their suitability for various industrial applications. Examining how these designs align with specific industrial needs provides valuable insights into the strengths of each.

Case Studies on Industrial Applications:

Manufacturing and Automotive Industries:

- China:Chinese overhead cranes, known for their technological integration and customization options, find suitability in manufacturing and automotive sectors. The adaptability of Chinese cranes allows manufacturers to optimize production processes, enhancing efficiency and precision.

- Russia:Russian cranes, emphasizing robustness and simplicity, are well-suited for heavy-duty applications in manufacturing and automotive industries. Their durability ensures reliable performance in challenging environments.

Mining and Metallurgy:

- China:Chinese cranes, with their lightweight materials and advanced control systems, are suitable for certain mining applications where precise handling of loads is crucial. Automation features enhance safety and efficiency.

- Russia:Russian cranes, designed for heavy-duty construction, excel in the harsh conditions of mining and metallurgical operations. Their adaptability to extreme environments ensures longevity in challenging settings.

Construction and Infrastructure Projects:

- China:Chinese cranes, with their customizable features, cater to the diverse needs of construction projects. The ability to tailor specifications allows for efficient handling of various loads in construction and infrastructure development.

- Russia:Russian cranes, with an emphasis on durability, are suitable for construction applications where reliability is paramount. Their robust construction ensures uninterrupted operation in construction projects.

Logistics and Warehousing:

- China:Chinese cranes, with advanced automation and material selection for energy efficiency, are suitable for logistics and warehousing. The adaptability of these cranes supports streamlined material handling processes.

- Russia:Russian cranes, focusing on simplicity and durability, find applications in logistics and warehousing where reliability in handling heavy loads is essential. Their straightforward design facilitates ease of use.

Discussion on Suitability:

The suitability of Chinese and Russian overhead cranes for industrial applications is intricately tied to their design philosophies. Chinese cranes shine in industries demanding adaptability and precision, while Russian cranes excel in heavy-duty applications where reliability and durability are paramount.

Understanding the alignment of design preferences with specific industrial applications is crucial for industries seeking the most suitable overhead crane solutions. Case studies provide tangible examples of how each design meets the unique demands of diverse sectors, allowing businesses to make informed decisions based on their specific operational requirements.

Heavy-Duty Applications - Overhead Crane Designs

| Feature | Chinese Overhead Cranes | Russian Overhead Cranes |

|---|---|---|

| Design Emphasis | Emphasis on durability for handling heavy loads and sustained use | Prioritization of robust construction to endure heavy-duty tasks |

| Material Selection | Use of high-strength materials to optimize load-bearing capacity | Heavy-duty construction with durable materials for longevity |

| Customization Options | High degree of customization for tailored heavy-duty solutions | Adaptability with more standardized customization for robustness |

| Technological Features | Integration of automation for precise control and load handling | Conservative approach, focusing on reliability in heavy-duty tasks |

| Safety Standards | Adherence to stringent safety standards for heavy-load scenarios | Incorporation of redundant safety systems for enhanced protection |

| Operational Efficiency | Utilization of advanced control systems for efficient heavy lifting | Prioritization of straightforward control interfaces for reliability |

| Adaptability to Conditions | Adaptability to diverse heavy-duty industrial conditions | Adaptability to challenging environments and extreme weather |

- Both Chinese and Russian overhead cranes share a fundamental emphasis on durability, robust construction, and the use of high-quality materials to handle heavy loads and endure sustained use.

- Both designs prioritize safety standards, ensuring compliance with regulations and incorporating features for enhanced protection during heavy-duty tasks.

- Chinese cranes often feature a high degree of customization, allowing for tailored solutions to specific heavy-duty applications, while Russian cranes lean towards a more standardized approach in customization.

- Chinese cranes may integrate advanced control systems and automation for precise heavy lifting, while Russian cranes prioritize a straightforward control interface for reliability in heavy-duty tasks.

Maintenance Considerations:

Discussion on Maintenance Impact:

Maintenance is a critical aspect of ensuring the long-term performance and reliability of overhead cranes. The design features of Chinese and Russian cranes play a significant role in determining the ease of maintenance and the associated requirements for sustaining optimal performance over time.

Evaluation of Maintenance Requirements:

Chinese Overhead Cranes:

Design Features Impacting Maintenance:

- Advanced Control Systems: While providing operational advantages, intricate control systems in Chinese cranes may require specialized maintenance expertise.

- Customization Complexity: The high degree of customization may necessitate more detailed maintenance procedures, especially when dealing with unique specifications.

Maintenance Implications:

- Skilled Personnel: Maintenance may require technicians with expertise in advanced control systems and customized configurations.

- Regular Inspections: Customized features may need regular inspections to ensure continued performance, potentially increasing maintenance frequency.

Russian Overhead Cranes:

Design Features Impacting Maintenance:

- Robust Construction: The simplicity and robustness of Russian crane designs contribute to easier maintenance, with fewer intricate components.

- Standardized Customization: While adaptable, the more standardized approach to customization may simplify maintenance procedures.

Maintenance Implications:

- Durability: Robust construction minimizes wear and tear, potentially reducing the frequency of maintenance interventions.

- Broad Expertise: Maintenance of Russian cranes may be handled by technicians with broader expertise due to the straightforward design.

Discussion on Maintenance Impact:

The impact of design features on maintenance considerations varies between Chinese and Russian overhead cranes. Chinese cranes, with their advanced features and high customization potential, may demand specialized maintenance efforts. On the other hand, Russian cranes, designed for robust simplicity, may offer a more straightforward maintenance experience.

Understanding the implications of maintenance requirements is vital for industries planning for the long-term operation of their overhead cranes. It allows businesses to anticipate and manage maintenance costs, ensuring that the chosen crane design aligns with their maintenance capabilities and objectives.

Sourceing From Locally vs Imported Cranes

Let's compare the two options—buying overhead cranes locally in Russia and importing overhead cranes from outside Russia—by outlining the key considerations in bullet points and using tables.

Below is a table summarizing the pros and cons of sourcing overhead cranes locally (Made in Russia):

| Advantages of Local Sourcing (Made in Russia) | Challenges of Local Sourcing (Made in Russia) |

|---|---|

| Cost Benefits: Potential cost savings due to reduced transportation and import fees. | Limited Variety: Restriction to the types and designs offered by local manufacturers. |

| Local Expertise: Access to local expertise, understanding specific industry needs and regulations. | Technology Innovation: Possible limitations in access to cutting-edge technologies compared to global alternatives. |

| Supporting Local Economy: Contributing to the local economy and fostering business within the country. |

This table provides a concise overview of the advantages and challenges associated with locally sourcing overhead cranes in Russia.

Here is a table summarizing the pros and cons of importing overhead cranes:

| Advantages of Importing Overhead Cranes | Challenges of Importing Overhead Cranes |

|---|---|

| Diverse Options: Access to a wide range of crane types, designs, and technological features. | Import Costs: Additional expenses related to shipping, customs duties, and taxes. |

| Quality Standards: Potential adherence to international quality standards and certifications. | Communication Barriers: Potential challenges in communication and understanding specifications. |

| Advanced Technologies: Availability of the latest technological innovations. | Service and Maintenance: Logistics challenges for post-sale service and maintenance. |

Buying Overhead Cranes Locally in Russia

Advantages:

- Cost Benefits:Potential cost savings due to reduced transportation and import fees.

- Local Expertise: Access to local expertise, understanding specific industry needs and regulations.

- Supporting Local Economy: Contributes to the growth of the local economy by supporting businesses within the country.

Challenges:

- Limited Variety: Restriction to the types and designs offered by local manufacturers.

- Technology Innovation: Possible limitations in access to cutting-edge technologies compared to global alternatives.

Importing Overhead Cranes from Outside Russia

Advantages:

- Diverse Options: Access to a wide range of crane types, designs, and technological features.

- Quality Standards: Potential adherence to international quality standards and certifications.

- Advanced Technologies: Availability of the latest technological innovations.

Challenges:

- Import Costs: Additional expenses related to shipping, customs duties, and taxes.

- Communication Barriers: Potential challenges in communication and understanding specifications.

- Service and Maintenance: Logistics challenges for post-sale service and maintenance.

This comparison provides a clear overview of the advantages and challenges associated with both buying overhead cranes locally in Russia and importing them from outside Russia. Businesses can use this information to make informed decisions based on their specific needs and priorities.

Conclusion

The comparison of overhead crane designs in China and Russia reveals distinctive features rooted in cultural, engineering, and industrial influences. Chinese cranes, known for their technological prowess and high customization, contrast with Russian cranes, which prioritize robust simplicity and adaptability to challenging environments.

Understanding these design differences is paramount for industries seeking overhead cranes that align seamlessly with their operational needs. The selection of the right crane design can significantly impact efficiency, reliability, and long-term performance.

For buyers in search of the optimal overhead crane solution, the key lies in aligning design features with specific operational needs and industry requirements. Considerations should extend beyond immediate capabilities to encompass long-term maintenance, adaptability, and overall cost-effectiveness.

The diversity in overhead crane designs reflects the rich tapestry of industrial approaches in both China and Russia. While each design philosophy brings its own strengths, the ultimate choice depends on the nuanced demands of individual industries. Whether prioritizing technological innovation, adaptability to challenging environments, or robust simplicity, the chosen crane design should align harmoniously with the unique requirements of each application.

In conclusion, the comparison of overhead crane designs in China and Russia offers valuable insights for industries navigating the selection process. By carefully weighing the distinguishing features and considering the specific needs of their operations, buyers can make informed decisions that pave the way for enhanced efficiency, safety, and productivity in their industrial endeavors.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch