Price Considerations When Buying Overhead Cranes in Russia

What factors influence the pricing of overhead cranes in the Russian market? How can buyers assess the cost-effectiveness of different crane options? Check!

Category: Russia

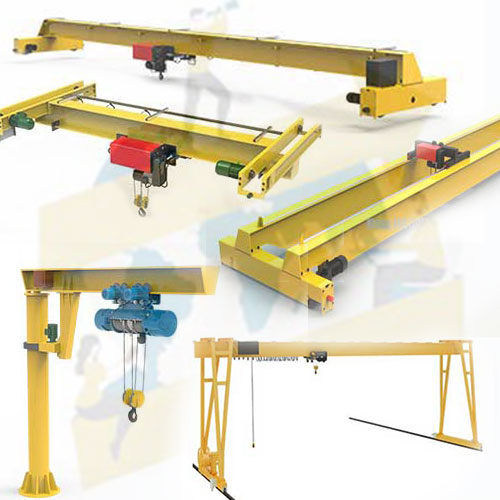

Your Trusted Overhead Crane Manufacturer & Supplier

Price Considerations When Buying Overhead Cranes in Russia

What factors influence the pricing of overhead cranes in the Russian market? How can buyers assess the cost-effectiveness of different crane options? Check!

Price Considerations When Buying Overhead Cranes in Russia

The acquisition of overhead cranes is a significant investment that goes beyond the mere transactional exchange of funds. It involves a strategic decision-making process with long-term implications for industrial operations. In the Russian market, where industries span from energy and manufacturing to aerospace and construction, the choice of overhead cranes is not only about finding a suitable lifting solution but also about navigating the intricate landscape of pricing considerations.

The significance of price considerations in the purchase of overhead cranes cannot be overstated. Price forms the financial cornerstone of any investment, and in the case of overhead cranes, it acts as a gateway to a multitude of factors that impact operational efficiency, safety, and overall productivity. Beyond being a numerical value on a quotation, the price of an overhead crane reflects the culmination of design intricacies, technological advancements, and adherence to industry standards.

Comprehensive Understanding of Factors:

To embark on this journey of crane acquisition, stakeholders must possess a comprehensive understanding of the myriad factors that influence crane pricing. It's not merely about comparing quotes but deciphering the nuances that differentiate one crane from another. This understanding involves delving into the realms of design complexity, lifting capacities, customization possibilities, material quality, technological integrations, and compliance with stringent standards.

An emphasis on a comprehensive understanding serves as a guiding principle. It urges buyers to look beyond the immediate and consider the long-term implications of their investment. A crane may seem like a standalone piece of equipment, but its role within an industrial ecosystem is intricate and interconnected. Therefore, a nuanced comprehension of the factors influencing pricing is akin to wielding a compass in an unfamiliar terrain, ensuring that each step is taken with foresight and awareness.

As industries in Russia evolve and adapt to changing demands, the overhead crane becomes more than a tool; it becomes a strategic asset. Thus, the introductory phase sets the stage for a journey where each element of price consideration is not seen in isolation but as part of a larger narrative – a narrative where the right crane choice contributes not only to the efficiency of lifting operations but also to the overall success and sustainability of the industrial landscape.

Factors Influencing Crane Pricing

Design and Engineering Complexity

The acquisition of overhead cranes in Russia involves a careful consideration of various factors, and chief among them is the intricate dance between design and engineering complexity. This factor is not only a crucial determinant of a crane's functionality but also a significant influencer of its pricing. Let's delve into the specific nuances of how the complexity of crane design and engineering directly impacts the financial investment required for such equipment.

Discussion on Complexity:

In the realm of overhead cranes, complexity in design and engineering refers to the level of sophistication and intricacy embedded within the structure and operational features of the crane. A crane designed for the diverse and demanding industrial landscape of Russia often necessitates a higher degree of engineering prowess and advanced design considerations. The more intricate the design, the more comprehensive the engineering solutions required to bring it to fruition.

Consider a scenario where a manufacturing facility in Russia requires an overhead crane tailored for precision lifting in a hazardous environment. This demands a complex design that incorporates advanced safety features, such as explosion-proof mechanisms and precise control systems. The engineering challenge extends beyond mere lifting capabilities to ensuring the crane operates seamlessly in the specific conditions of the industrial setting.

Examples of Intricate Designs:

- Explosion-Proof Overhead Cranes: In industries where explosive atmospheres are present, such as oil and gas or chemical manufacturing, overhead cranes with explosion-proof features are crucial. These intricate designs involve sealed components, specialized electrical systems, and robust engineering to prevent the risk of ignition.

- Automated Material Handling Systems: As industries in Russia embrace automation, overhead cranes integrated into automated material handling systems showcase intricate designs. These cranes may feature advanced sensors, automation controls, and smart technologies for seamless integration into the automated workflow.

- Cleanroom Crane Solutions: For industries like electronics or pharmaceuticals requiring cleanroom conditions, cranes with intricate designs are essential. These designs focus on minimizing particulate contamination, involving features such as specialized coatings, sealed components, and precise engineering to maintain cleanliness standards.

The impact of design and engineering complexity on crane pricing is inherent. The sophistication demanded by complex designs necessitates specialized expertise, advanced manufacturing processes, and the incorporation of high-quality materials. In the Russian market, where industries often have unique and challenging requirements, the investment in intricate design and engineering is reflected in the pricing of overhead cranes.

Buyers should be prepared to allocate a higher budget for cranes with complex designs tailored to meet specific industry demands. The financial investment is not merely for the physical crane but encompasses the research, engineering, and manufacturing efforts undertaken to ensure the crane aligns seamlessly with the industrial landscape of Russia. Therefore, recognizing and understanding the intricate nature of design and engineering complexity is pivotal for making informed decisions and securing overhead cranes that not only meet but exceed the expectations of the dynamic Russian industrial sector.

Lifting Capacity and Tonnage

In the dynamic and diverse industrial landscape of Russia, the lifting capacity and tonnage of overhead cranes stand as pivotal considerations in the procurement process. Understanding the correlation between lifting capacity and crane pricing is essential for industries seeking optimal performance in their material handling operations. Let's embark on an exploration of how the lifting capacity and tonnage directly influence the pricing of overhead cranes in the Russian market.

Exploration of Correlation:

The lifting capacity of an overhead crane, measured in tons, is a fundamental specification that dictates its ability to handle various loads within an industrial setting. In the exploration of the correlation between lifting capacity/tonnage and crane pricing, it's crucial to recognize that this relationship is not linear but holds significant implications for both the design and manufacturing of the crane.

As the lifting capacity of a crane increases, the engineering requirements become more demanding. Higher capacity cranes need robust structural components, enhanced safety features, and often involve specialized engineering to ensure stability and reliability during lifting operations. This escalation in engineering complexity contributes directly to the overall cost of the crane.

Analysis of Increased Costs:

The analysis of how higher capacity cranes typically come with increased costs unfolds in several dimensions:

- Structural Reinforcement: Cranes designed to lift heavier loads necessitate reinforced structures, including beams, girders, and support systems. The materials used for these structural elements, often high-strength alloys or specialized steel, incur higher material costs.

- Engineering Expertise: Designing a crane with increased lifting capacity requires advanced engineering expertise. The calculations, simulations, and testing processes to ensure the crane's safety and performance under heavy loads contribute to increased engineering costs.

- Safety Features: Higher capacity cranes must adhere to stringent safety standards. The incorporation of advanced safety features, such as overload protection systems and redundant mechanisms, adds to the overall cost.

- Customization for Specific Applications: In certain industries in Russia, unique lifting requirements demand customized solutions. Cranes designed for specialized applications, such as the handling of heavy machinery in metallurgical plants, require tailored engineering solutions, contributing to increased costs.

- Manufacturing Precision: The manufacturing processes for higher capacity cranes demand precision and quality control. The tolerances and specifications required for components subjected to heavy loads are more stringent, leading to increased manufacturing costs.

Understanding the nuanced relationship between lifting capacity and crane pricing is imperative for industries in Russia. While the initial investment for higher capacity cranes may be substantial, it reflects a commitment to operational efficiency, safety, and the ability to meet the demanding lifting requirements of diverse industrial sectors.

As industries continue to evolve and expand in Russia, the strategic selection of lifting capacity in overhead cranes becomes a key factor in enhancing overall productivity and ensuring a sound return on investment. Industries are encouraged to align their lifting capacity requirements with the specific demands of their operations, striking a balance between performance and cost-effectiveness.

Customization and Special Features

In the dynamic industrial landscape of Russia, where diverse sectors demand tailored solutions, the customization of overhead cranes and the incorporation of special features play a crucial role. This factor not only addresses the unique requirements of various industries but also significantly influences the pricing of overhead cranes. Let's delve into the intricacies of how customization and special features contribute to the overall pricing of overhead cranes in the Russian market.

Insight into Customization:

Customization in the realm of overhead cranes involves the adaptation of crane design, features, and functionalities to suit specific industrial applications. It's a process that goes beyond the standard configurations and requires a bespoke approach to meet the distinct challenges posed by different sectors in Russia. As industries evolve, the need for cranes that align seamlessly with their operational requirements becomes more pronounced.

The degree of customization directly impacts the overall cost of the crane. Tailoring a crane to meet specific lifting needs involves additional engineering efforts, specialized components, and sometimes the integration of advanced technologies. The flexibility offered by customization allows industries to optimize their material handling processes but comes with an associated investment.

Examples of Specialized Features:

- Automation and Smart Controls: Industries in Russia embracing Industry 4.0 principles may opt for overhead cranes with automation features and smart controls. These features allow for precise load control, automated material tracking, and integration into smart factory systems. The implementation of such advanced technologies adds to the overall cost.

- Adaptive Controls for Hazardous Environments: In sectors like oil and gas or chemical manufacturing, where hazardous environments are present, specialized features such as adaptive controls for explosion-proof cranes become crucial. The engineering and technology required for such features contribute to increased costs.

- High-Temperature Resistance: For applications in metallurgy or foundries where high temperatures are prevalent, cranes may require specialized coatings, heat-resistant materials, and cooling systems. The inclusion of these features, tailored for high-temperature environments, impacts the pricing.

- Load Monitoring Systems: Cranes equipped with load monitoring systems provide real-time data on the load being lifted. This feature is valuable in industries where precise load management is critical. The incorporation of load monitoring systems adds an extra layer of sophistication and cost.

- Environmental Resistance: Industries operating in challenging environments, such as those with high levels of dust or corrosive elements, may opt for cranes with enhanced environmental resistance features. These features involve additional protective coatings, sealed components, and corrosion-resistant materials, contributing to increased costs.

The impact of customization and special features on crane pricing is twofold. Firstly, the bespoke nature of customization involves additional engineering efforts, research and development, and often the creation of unique components, all of which contribute to increased production costs. Secondly, the incorporation of special features, whether for safety, automation, or environmental adaptation, involves the integration of advanced technologies and materials that come with their own associated costs.

While customization adds to the upfront investment, industries in Russia benefit from cranes that are finely tuned to their specific needs, resulting in enhanced operational efficiency and longevity. The strategic consideration of customization allows industries to invest in overhead cranes that not only meet but exceed the challenges posed by the diverse industrial landscape in Russia.

Materials Used in Construction

The construction of overhead cranes involves a careful selection of materials, a choice that extends beyond structural integrity to factors such as durability, resistance to environmental conditions, and overall performance. In the diverse industrial sectors of Russia, the materials chosen for crane construction play a significant role in determining their pricing. Let's conduct an examination of how the choice of materials influences crane pricing, with a particular focus on the cost implications of using high-quality and durable materials.

Examination of Material Impact:

The materials used in the construction of overhead cranes contribute to their overall performance, safety, and longevity. The choice of materials is a critical consideration, particularly in industries where cranes operate under challenging conditions, such as high temperatures, corrosive environments, or heavy dust exposure. The examination of how materials impact crane pricing involves understanding the interplay between material quality, manufacturing processes, and the specific requirements of different industrial applications.

Cost Implications of High-Quality Materials:

- High-Strength Alloys: The use of high-strength alloys, known for their superior tensile strength and durability, often comes with a higher price tag. Cranes constructed with high-strength alloys exhibit enhanced load-bearing capabilities and structural integrity, making them suitable for demanding lifting operations.

- Specialized Coatings: For cranes operating in environments with corrosive elements or extreme temperatures, the application of specialized coatings becomes essential. These coatings protect the crane's structural components from deterioration, but the materials and application processes contribute to increased costs.

- Advanced Composites: In certain applications, overhead cranes may incorporate advanced composite materials to achieve a balance between strength and weight. While these materials offer unique advantages, their use can impact pricing due to the specialized manufacturing techniques and materials involved.

- Corrosion-Resistant Metals: Cranes used in industries where corrosion is a significant concern, such as chemical processing or marine applications, may feature corrosion-resistant metals. The use of such metals, whether stainless steel or other alloys, adds to the overall cost but ensures longevity and reliability in corrosive environments.

- Heat-Resistant Materials: Industries with high-temperature operations, like metallurgy or foundries, may require cranes with components made from heat-resistant materials. These materials withstand elevated temperatures and contribute to the crane's ability to operate effectively in such environments.

Discussion on Durable Materials:

Durable materials are synonymous with reliability and extended service life. While the initial investment in cranes constructed with high-quality and durable materials may be higher, the long-term benefits often outweigh the upfront costs. The discussion on durable materials involves recognizing the following aspects:

- Longevity and Reduced Maintenance: Cranes constructed with durable materials tend to have a longer service life and require less frequent maintenance. This reduces the overall cost of ownership over the crane's lifecycle.

- Reliability in Challenging Environments: Industries operating in challenging environments, such as heavy manufacturing or outdoor applications, benefit from cranes that can withstand the rigors of the environment. Durable materials contribute to the crane's reliability in such conditions.

- Safety Assurance: High-quality materials contribute to the safety of overhead cranes. They ensure structural integrity, load-bearing capabilities, and resistance to wear and tear, providing assurance in terms of safe operations.

- Operational Efficiency: Cranes constructed with durable materials often exhibit better operational efficiency. They can handle heavier loads, withstand continuous use, and operate in diverse environmental conditions, contributing to enhanced overall efficiency.

In conclusion, the choice of materials in the construction of overhead cranes is a pivotal factor that influences their pricing and performance. While the use of high-quality and durable materials may incur higher upfront costs, the long-term benefits in terms of reliability, safety, and operational efficiency make it a strategic investment for industries in Russia seeking cranes that can thrive in their unique operational environments.

Manufacturing Standards and Certifications

In the intricate landscape of overhead crane procurement in Russia, adherence to manufacturing standards and certifications stands as a linchpin for ensuring quality, safety, and regulatory compliance. This factor not only shapes the performance and reliability of overhead cranes but also influences their pricing. Let's delve into an overview of how adherence to manufacturing standards and certifications can affect crane pricing, along with a discussion on the importance of meeting industry regulations.

Overview of Standards and Certifications:

Manufacturing standards and certifications serve as benchmarks that ensure overhead cranes meet predetermined criteria for design, construction, and performance. These standards can be international, national, or industry-specific, and adherence to them is indicative of a manufacturer's commitment to producing high-quality, safe, and reliable equipment. Certifications, such as CE (Conformité Européene), ISO (International Organization for Standardization), or industry-specific certifications like AIST (Association for Iron & Steel Technology) in the United States, are vital markers of compliance with established norms.

How Adherence Affects Pricing:

- Quality Assurance Processes: Manufacturers adhering to stringent standards invest in quality assurance processes throughout the manufacturing cycle. This involves meticulous inspection, testing, and documentation to ensure that every crane meets the specified standards. The cost of implementing these processes contributes to the overall pricing of the crane.

- Compliance with Safety Standards: Overhead cranes must adhere to safety standards to ensure the protection of workers, machinery, and the surrounding environment. Compliance with safety standards involves the incorporation of safety features, such as overload protection systems and emergency braking mechanisms, contributing to increased costs.

- Material and Component Specifications: Standards often dictate the specifications for materials and components used in crane construction. Using materials that meet or exceed these specifications ensures structural integrity and reliability but may involve higher material costs.

- Testing and Certification Fees: Manufacturers undergo testing and certification processes to validate compliance with standards. These processes, often conducted by third-party organizations, come with associated fees. These fees, coupled with the investment in meeting testing requirements, contribute to the overall pricing of the crane.

Discussion on Regulatory Compliance:

The discussion on the importance of meeting industry regulations encompasses several key aspects:

- Legal Compliance: Industries in Russia are subject to legal regulations and safety standards governing the use of industrial equipment. Adherence to these regulations is not just a matter of quality but a legal requirement. Non-compliance can result in legal consequences and operational disruptions.

- Operational Safety: Overhead cranes are integral to various industrial operations, and their safe and reliable performance is paramount. Regulatory compliance ensures that cranes are designed and manufactured to operate safely within specified parameters, minimizing the risk of accidents and ensuring worker safety.

- Industry Reputation: Manufacturers and suppliers that consistently adhere to manufacturing standards and certifications build a reputation for reliability and quality. Industries in Russia seeking overhead cranes are inclined to invest in equipment from reputable suppliers to ensure the longevity and performance of their operations.

- Global Market Access: Adherence to international standards and certifications facilitates global market access. Industries in Russia that aspire to expand their operations internationally or collaborate with global partners benefit from using equipment that meets recognized standards.

In conclusion, adherence to manufacturing standards and certifications is not merely a checkbox in the procurement process; it is a fundamental aspect that influences the pricing, performance, and regulatory compliance of overhead cranes. Industries in Russia are encouraged to prioritize suppliers and manufacturers that demonstrate a commitment to meeting and exceeding established standards, ensuring that the overhead cranes procured align seamlessly with industry regulations and the overarching goals of safety and operational excellence.

Technological Integration

In the dynamic landscape of industrial operations in Russia, the incorporation of advanced technologies into overhead cranes is not just a feature but a strategic necessity. While technological integration enhances the performance, safety, and efficiency of cranes, it also plays a crucial role in influencing their pricing. Let's conduct an analysis of how the incorporation of advanced technologies can impact crane pricing, accompanied by examples of technological features that may contribute to higher costs.

Analysis of Technological Impact:

Technological integration in overhead cranes represents a paradigm shift, transforming them from traditional lifting equipment to sophisticated tools optimized for the demands of modern industrial settings. The impact of technology on crane pricing is multifaceted, involving factors such as research and development, specialized components, and the implementation of cutting-edge features to meet the evolving needs of industries in Russia.

Examples of Technological Features:

- Automation and Smart Controls: The integration of automation and smart controls allows for precise and automated load handling. These features enable functionalities such as automated material tracking, precise positioning, and even the ability to integrate with other smart factory systems. The complex engineering and advanced control systems associated with automation contribute to increased costs.

- Load Monitoring Systems: Cranes equipped with load monitoring systems provide real-time data on the load being lifted. This technology ensures that the crane operates within specified load limits, enhancing safety and preventing overloads. The incorporation of load monitoring systems involves specialized sensors and control interfaces, contributing to higher costs.

- Anti-Sway Systems: Anti-sway systems use sophisticated algorithms to minimize load sway during lifting and positioning operations. This technology enhances precision and safety, particularly in applications where accurate load placement is critical. The implementation of anti-sway systems involves advanced sensors, control algorithms, and specialized engineering, impacting pricing.

- Remote Monitoring and Diagnostics: Overhead cranes equipped with remote monitoring and diagnostic capabilities allow for real-time tracking of performance metrics and the ability to diagnose issues remotely. This technology enhances maintenance efficiency but involves the integration of communication systems and sensor networks, contributing to higher costs.

- Energy-Efficient Drive Systems: Modern cranes often feature energy-efficient drive systems that optimize power consumption. These systems may involve variable frequency drives, regenerative braking, and other energy-saving technologies. While contributing to long-term operational cost savings, the initial investment in these advanced drive systems can be higher.

Strategic Considerations for Technological Integration:

- Operational Efficiency Gains: The incorporation of advanced technologies in overhead cranes can result in significant gains in operational efficiency. Industries in Russia must weigh the upfront investment against the long-term benefits of enhanced performance, reduced downtime, and improved overall efficiency.

- Industry-Specific Requirements: Different industrial sectors in Russia may have unique technological requirements. For example, industries with high precision and safety demands may prioritize cranes with advanced automation features, while others may focus on energy-efficient technologies. Understanding industry-specific needs is crucial for making informed decisions.

- Total Cost of Ownership: While the initial investment in technologically advanced cranes may be higher, industries should consider the total cost of ownership over the crane's lifecycle. Factors such as reduced maintenance, improved safety, and increased operational efficiency can contribute to long-term cost savings.

In conclusion, technological integration in overhead cranes is not just an added feature but a strategic investment that aligns with the evolving needs of industries in Russia. While it may impact the upfront pricing, the benefits in terms of performance, safety, and efficiency position technologically advanced cranes as valuable assets for industries seeking to thrive in the competitive and dynamic landscape of modern industrial operations.

Assessing Cost-Effectiveness

Total Cost of Ownership (TCO)

In the realm of overhead crane purchases, the concept of Total Cost of Ownership (TCO) stands as a critical metric that goes beyond the initial purchase price, providing a comprehensive understanding of the long-term costs associated with crane ownership. Let's delve into an explanation of the concept of TCO in the context of overhead crane purchases and provide guidance on evaluating long-term costs beyond the initial purchase price.

Explanation of TCO:

Total Cost of Ownership (TCO) is a holistic financial metric that considers all direct and indirect costs associated with owning and operating a piece of equipment throughout its entire lifecycle. In the context of overhead crane purchases, TCO encapsulates expenses beyond the initial acquisition, encompassing operational, maintenance, and potential downtime costs. It provides a more accurate representation of the economic impact of a crane over its lifespan.

Guidance on Evaluation:

- Initial Investment: While the initial purchase price is a significant component, it represents only a fraction of the TCO. Industries in Russia are advised to consider the initial investment as the starting point in their evaluation, recognizing that the true cost picture extends beyond this figure.

- Operational Costs: TCO includes the costs associated with the day-to-day operation of the overhead crane. This involves factors such as energy consumption, routine maintenance, and the efficiency of the crane in handling specific loads. Industries should assess the operational costs based on their specific usage patterns and industrial requirements.

- Maintenance and Repairs: A crucial aspect of TCO is the ongoing maintenance and repair costs throughout the crane's lifespan. Considerations should include the frequency of maintenance, the availability of spare parts, and the ease of conducting repairs. A well-maintained crane tends to have lower long-term costs.

- Downtime Costs: Unplanned downtime can have a significant financial impact. Industries should factor in the potential costs associated with crane downtime, such as lost production, delays in project timelines, and potential maintenance-related expenses. Choosing a reliable crane with a track record of minimal downtime contributes to cost-effectiveness.

- Upgrades and Adaptations: As industries evolve, the need for crane upgrades or adaptations may arise. TCO includes the costs associated with upgrading or adapting the crane to meet changing operational requirements. Evaluating the flexibility of a crane for future modifications is crucial for long-term cost-effectiveness.

- Energy Efficiency: Energy costs contribute to the operational expenses of overhead cranes. Consideration should be given to the energy efficiency of the crane, including features such as regenerative braking, energy-efficient drive systems, and automation that optimizes energy consumption.

- Longevity and Resale Value: The lifespan of the crane and its potential resale value at the end of its operational life are integral components of TCO. Investing in a crane with a longer lifespan and higher resale value can positively impact the overall cost-effectiveness.

- Safety and Compliance: Industries should factor in the costs associated with ensuring safety and compliance with industry regulations. A crane that meets or exceeds safety standards may incur lower long-term costs related to accidents, injuries, or regulatory fines.

In conclusion, assessing the Total Cost of Ownership (TCO) provides a comprehensive perspective for industries in Russia making overhead crane purchases. By considering all relevant costs throughout the crane's lifecycle, from acquisition to operation and potential modifications, industries can make informed decisions that align with their financial objectives and operational requirements.

Operational Efficiency and Productivity

In the dynamic industrial landscape of Russia, where efficiency and productivity are paramount, the operational efficiency of overhead cranes plays a pivotal role in determining overall cost-effectiveness. This section delves into a discussion on how crane efficiency and productivity contribute to cost-effectiveness, accompanied by examples of features that enhance operational efficiency.

Discussion on Efficiency and Productivity:

- Reduced Downtime: Operational efficiency is closely tied to minimizing downtime. Cranes equipped with advanced features, predictive maintenance capabilities, and reliable components contribute to reduced downtime, ensuring continuous operations and productivity.

- Optimized Load Handling: The efficiency of load handling operations is a critical factor. Cranes with features such as variable speed controls, precision positioning, and anti-sway systems enhance the accuracy and speed of load handling, leading to increased productivity.

- Automation and Smart Controls: The integration of automation and smart controls enhances operational efficiency by automating repetitive tasks, optimizing workflow, and reducing the need for manual intervention. Automated features contribute to consistent and efficient crane performance.

- Quick Start/Stop Functions: Cranes with quick start and stop functions enable swift response to operational commands. This feature is especially beneficial in applications where precision and rapid load handling are essential for maintaining overall productivity.

- Energy-Efficient Drive Systems: Energy-efficient drive systems contribute to cost-effectiveness by optimizing power consumption. Cranes with features such as regenerative braking and variable frequency drives not only reduce energy costs but also enhance overall operational efficiency.

Examples of Features Enhancing Operational Efficiency:

- Variable Frequency Drives (VFD): VFDs allow for precise control of motor speed, reducing energy consumption and providing smoother acceleration and deceleration. This feature enhances the operational efficiency of cranes, especially during variable load conditions.

- Automation for Repetitive Tasks: Cranes equipped with automation features for repetitive tasks, such as material handling within a specific pattern, contribute to increased productivity by minimizing the need for manual control and intervention.

- Anti-Sway Systems: Anti-sway systems use advanced algorithms to minimize load sway during lifting and positioning. This feature enhances operational efficiency by ensuring precise load placement, reducing the time required for corrections, and improving overall productivity.

- Remote Monitoring and Diagnostics: Remote monitoring and diagnostic capabilities enable real-time tracking of crane performance. This feature enhances efficiency by facilitating proactive maintenance, reducing the risk of unplanned downtime, and optimizing overall operational productivity.

- Load Monitoring Systems: Cranes with load monitoring systems provide real-time data on the load being lifted. This feature enhances operational efficiency by ensuring that the crane operates within specified load limits, contributing to safety and preventing overloads.

In conclusion, operational efficiency and productivity are integral components of overall cost-effectiveness when evaluating overhead cranes in Russia. Features that minimize downtime, optimize load handling, and incorporate advanced technologies contribute to enhanced operational efficiency, ensuring that industries can maximize their productivity while maintaining a focus on efficiency and profitability.

Maintenance and Repair Costs

In the realm of overhead crane ownership, understanding the relationship between crane design, materials, and maintenance costs is paramount for ensuring long-term cost-effectiveness. This section explores the intricacies of this relationship and provides guidance on assessing potential long-term maintenance expenses.

Exploration of Relationship:

- Crane Design and Components: The design of an overhead crane significantly influences its maintenance requirements. Cranes with simple, robust designs and easily accessible components tend to have lower maintenance costs. Complex designs or components requiring extensive disassembly for routine maintenance may contribute to higher expenses.

- Material Selection: The choice of materials in crane construction plays a crucial role in determining maintenance costs. High-quality, durable materials may incur a higher upfront cost but can lead to reduced maintenance needs over the crane's lifespan. Corrosion-resistant materials are essential for minimizing maintenance in challenging environments.

- Ease of Inspection and Access: Cranes designed for ease of inspection and maintenance access contribute to lower overall maintenance costs. Features such as accessible inspection points, well-labeled components, and simplified maintenance procedures facilitate efficient upkeep and reduce the time and resources required for maintenance activities.

Guidance on Assessing Maintenance Expenses:

- Consideration of Material Durability: When evaluating potential maintenance expenses, industries in Russia should consider the durability of materials used in crane construction. High-quality materials, especially those resistant to corrosion and wear, contribute to extended service life and reduced maintenance needs.

- Review of Component Lifespan: Components such as hoists, motors, and brakes have finite lifespans. Understanding the expected lifespan of critical components helps in planning for their eventual replacement and estimating long-term maintenance costs. Consider cranes with components known for reliability and longevity.

- Predictive Maintenance Technologies: Embracing predictive maintenance technologies can be a proactive strategy for minimizing unexpected breakdowns and controlling maintenance costs. Features such as real-time monitoring, condition-based maintenance, and predictive analytics enable early detection of potential issues, allowing for timely intervention.

- Manufacturer's Maintenance Recommendations: Manufacturers provide specific maintenance recommendations for their cranes. Following these guidelines is essential for optimal performance and longevity. Industries should assess whether a crane's maintenance requirements align with their operational capabilities and resources.

- Training and Expertise: The training of maintenance personnel and their expertise in handling specific crane models impact maintenance costs. Well-trained personnel can identify potential issues early, perform efficient maintenance tasks, and contribute to overall cost-effectiveness. Investing in training programs can yield long-term benefits.

- Historical Maintenance Records: Reviewing historical maintenance records, if available, provides insights into the past performance of a crane. Understanding the maintenance history helps anticipate potential future issues and estimate the ongoing maintenance costs.

- Availability of Spare Parts: The availability and cost of spare parts for a particular crane model should be considered. Cranes with readily available and competitively priced spare parts contribute to cost-effective maintenance. Additionally, assessing the ease of sourcing spare parts locally in Russia is crucial for minimizing downtime.

In conclusion, the relationship between crane design, materials, and maintenance costs is a critical consideration for industries in Russia seeking cost-effective overhead cranes. By carefully assessing the durability of materials, the lifespan of components, and the overall design features influencing maintenance, industries can make informed decisions that align with their long-term financial objectives and operational efficiency goals.

Energy Efficiency

In the contemporary industrial landscape of Russia, where sustainability and operational efficiency intersect, the role of energy-efficient features in determining the cost-effectiveness of overhead cranes cannot be overstated. This section provides insight into the significance of energy efficiency and highlights examples of energy-saving technologies that may impact operating costs.

Insight into Energy Efficiency:

- Operational Cost Reduction: Energy-efficient features in overhead cranes contribute to operational cost reduction by optimizing power consumption. Cranes that can perform the required tasks with minimal energy usage not only contribute to environmental sustainability but also enhance long-term cost-effectiveness.

- Environmental Impact: Beyond financial considerations, the energy efficiency of overhead cranes aligns with broader environmental goals. Reducing energy consumption not only lowers operational costs but also mitigates the ecological footprint, positioning industries in Russia as responsible stewards of environmental resources.

- Compliance with Standards: Many industrial sectors are subject to energy efficiency regulations. Choosing energy-efficient overhead cranes ensures compliance with these standards, avoiding potential penalties and contributing to a positive corporate image.

Examples of Energy-Saving Technologies:

- Variable Frequency Drives (VFD): VFDs enable precise control of motor speed, allowing the crane to adjust its energy consumption based on the load and operational requirements. This technology reduces overall energy usage and contributes to cost-effectiveness.

- Regenerative Braking Systems: Cranes equipped with regenerative braking systems convert excess energy generated during braking into usable electrical power. This energy is fed back into the power supply system, reducing the overall energy demand and lowering operational costs.

- Energy-Efficient Motors: The use of energy-efficient motors, such as those meeting high-efficiency standards like IE3 or IE4, contributes to reduced energy consumption. These motors are designed to operate with optimal efficiency, minimizing energy waste and lowering operational costs.

- Smart Automation for Power Management: Automation features that optimize power management, such as intelligent start-stop functions and load-dependent energy usage, contribute to energy efficiency. Cranes that can adapt their power consumption to the operational demands enhance overall cost-effectiveness.

- LED Lighting: While not directly related to crane operation, energy-efficient lighting on the crane contributes to reduced overall facility energy consumption. LED lights have lower energy requirements and longer lifespans, contributing to lower operational costs.

Strategic Considerations for Energy Efficiency:

- Total Cost of Ownership (TCO): Energy-efficient features may have an upfront cost but contribute to long-term savings. Industries in Russia should consider the Total Cost of Ownership (TCO) to evaluate the overall financial impact, including energy savings, over the crane's lifecycle.

- Operational Patterns: Understanding the specific operational patterns and energy requirements of the crane is crucial. Cranes that align with the operational demands of the industry while incorporating energy-efficient technologies offer a strategic advantage.

- Government Incentives: In some cases, governments provide incentives or subsidies for adopting energy-efficient technologies. Industries should explore available programs that may offset initial investment costs and enhance the financial attractiveness of energy-efficient cranes.

In conclusion, the incorporation of energy-efficient features in overhead cranes is a strategic investment that goes beyond immediate financial considerations. Industries in Russia, by prioritizing energy efficiency, not only contribute to sustainable practices but also enhance their long-term cost-effectiveness by minimizing operational costs and aligning with evolving environmental standards.

ROI Considerations

In the dynamic landscape of industrial investments, calculating the Return on Investment (ROI) is a fundamental aspect of assessing the cost-effectiveness of overhead cranes. This section provides an overview of how buyers can calculate the ROI for different crane options and offers guidance on factoring in productivity gains and cost savings over time.

Overview of ROI Calculation:

- Formula for ROI: The basic formula for calculating ROI is [(Net Gain from Investment / Cost of Investment) x 100]. Net Gain is calculated by subtracting the initial investment cost from the total benefits, including productivity gains and cost savings.

- Initial Investment: The initial investment includes the purchase price of the overhead crane, installation costs, and any additional expenses related to customization or site preparation. This figure serves as the starting point for ROI calculation.

Guidance on Factoring in Productivity Gains:

- Time Savings: Assess the extent to which the chosen overhead crane contributes to time savings in lifting, positioning, and material handling operations. Reduced cycle times and improved operational efficiency contribute to increased productivity.

- Operational Throughput: Consider the impact of the crane on overall operational throughput. Cranes that facilitate faster and more efficient material movement contribute to increased production capacities, resulting in enhanced productivity gains.

- Reduction in Downtime: Evaluate the crane's features that minimize downtime, such as predictive maintenance capabilities and reliability. A reduction in unplanned downtime directly translates into increased productivity and operational continuity.

- Labor Efficiency: Analyze how the chosen crane affects labor efficiency. Features such as automation, smart controls, and ease of operation contribute to labor savings and enhanced workforce productivity.

Guidance on Factoring in Cost Savings:

- Maintenance Cost Reduction: Consider the potential reduction in maintenance costs over time. Cranes with durable components, minimal maintenance requirements, and longer lifespans contribute to significant cost savings in terms of upkeep and repairs.

- Energy Efficiency: Evaluate the energy-efficient features of the crane and their impact on operational costs. Reduced energy consumption not only aligns with sustainability goals but also leads to direct cost savings over the crane's operational life.

- Reduction in Material Loss: Cranes with precise load handling capabilities contribute to a reduction in material loss or damage. Factoring in the avoided costs associated with material loss enhances the overall cost-effectiveness of the chosen crane.

- Safety Improvements: Consider how the crane's safety features contribute to cost savings. Enhanced safety reduces the risk of accidents, injuries, and associated expenses, including potential regulatory fines and increased insurance premiums.

Strategic Considerations for ROI:

- Long-Term Perspective: ROI calculations should consider the long-term perspective. While certain features may result in a higher upfront investment, their positive impact on productivity and cost savings over the crane's lifespan can significantly enhance the ROI.

- Industry-Specific Metrics: Different industrial sectors may prioritize specific metrics in their ROI calculations. Industries in Russia should align their ROI considerations with the key performance indicators (KPIs) relevant to their operational goals and sector-specific requirements.

- Flexibility and Adaptability: Assess the crane's flexibility and adaptability to evolving industry needs. A crane that can easily accommodate changes in operational requirements contributes to sustained productivity gains and cost savings over time.

In conclusion, calculating the Return on Investment (ROI) for overhead cranes in Russia involves a comprehensive evaluation of both productivity gains and cost savings. By adopting a strategic approach and factoring in the long-term perspective, industries can make informed decisions that align with their financial objectives and contribute to sustainable and cost-effective operations.

Conclusion

In the complex landscape of procuring overhead cranes in the Russian market, the factors influencing pricing are multifaceted and dynamic. This guide has aimed to shed light on crucial considerations, emphasizing the need for a comprehensive understanding of various elements that contribute to overhead crane costs. Let's recap the key factors influencing overhead crane pricing in the Russian market and encourage buyers to adopt a holistic approach in assessing cost-effectiveness and value tailored to their specific industrial applications.

- Design and Engineering Complexity: The intricacy of crane design and engineering influences pricing, with more complex designs potentially incurring higher costs.

- Lifting Capacity and Tonnage: The lifting capacity and tonnage of the crane directly impact pricing, with higher capacity cranes typically associated with increased costs.

- Customization and Special Features: The extent of customization and incorporation of special features contribute to overall pricing, allowing for tailored solutions but potentially raising upfront expenses.

- Materials Used in Construction: The choice of materials in crane construction influences pricing, with high-quality and durable materials potentially incurring higher initial costs.

- Manufacturing Standards and Certifications: Adherence to manufacturing standards and certifications can impact pricing, reflecting compliance with industry regulations.

- Technological Integration: The incorporation of advanced technologies may affect pricing, with features such as automation and smart controls contributing to higher upfront costs.

- Operational Efficiency and Productivity: Cranes with enhanced operational efficiency and productivity features may have higher initial costs but can lead to long-term cost-effectiveness.

- Maintenance and Repair Costs: The design, materials, and ease of maintenance influence ongoing maintenance costs, with considerations for long-term expenses.

- Energy Efficiency: Energy-efficient features contribute to overall cost-effectiveness, aligning with sustainability goals and potentially reducing operational costs.

- ROI Considerations: Calculating the Return on Investment (ROI) involves assessing productivity gains and cost savings over time, providing a comprehensive view of long-term cost-effectiveness.

Encouragement for Holistic Assessment:

Buyers in the Russian market are encouraged to adopt a holistic approach when assessing cost-effectiveness and value for their specific industrial applications. Considerations should extend beyond the initial purchase price and encompass the total cost of ownership, operational efficiency, long-term maintenance, and the strategic alignment of the crane with industry-specific requirements.

By taking a comprehensive view and understanding the interplay of various factors, buyers can make informed decisions that optimize cost-effectiveness while ensuring the chosen overhead crane meets the demands of their industrial operations.

In conclusion, the procurement of overhead cranes in Russia involves a nuanced evaluation process. By navigating the intricacies of pricing factors and considering the broader impact on operational efficiency and long-term costs, buyers can make strategic investments that contribute to the success and sustainability of their industrial endeavors.

Main Projects

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

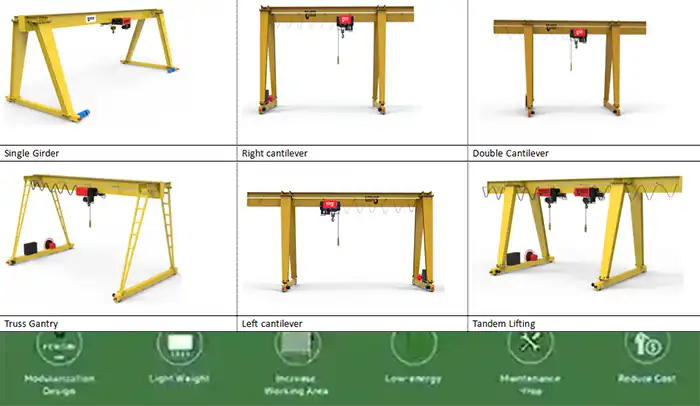

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch