Gantry Cranes for Sale in Russia: Single Girder vs Double Girder

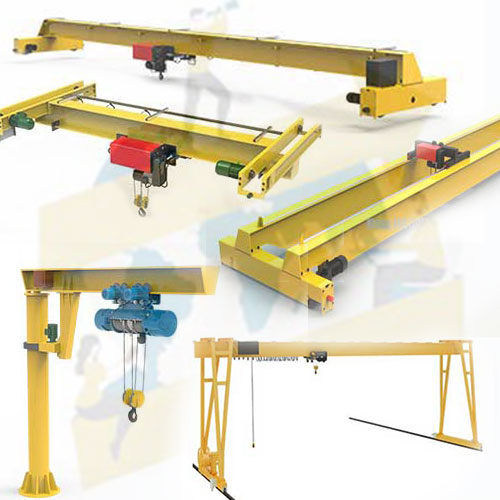

Gantry Cranes for Sale in Russia, Good Price. All Types of Single Girder Gantry Crane vs Double Girder Gantry Cranes to Get Your Cost-effective Solution.

Category: Russia

Your Trusted Gantry Crane Manufacturer & Supplier

Gantry Cranes for Sale in Russia: Single Girder vs Double Girder

All Types of Single Girder Gantry Crane vs Double Girder Gantry Cranes to Get Your Cost-effective Solution

Unraveling the Basics of Gantry Cranes

In the heart of Russia's bustling industrial landscape, gantry cranes emerge as silent yet powerful workhorses, seamlessly orchestrating the movement of materials with precision and efficiency. As we embark on this exploration of gantry cranes, it's essential to understand the fundamental principles that make them indispensable in various sectors.

Gantry cranes, characterized by their overhead structure and supporting legs, play a pivotal role in lifting and transporting heavy loads within industrial facilities. These mechanical marvels are not just machines; they are the backbone of Russia's material handling operations, offering a lifeline to industries ranging from manufacturing to logistics.

Lifting Progress: Gantry Cranes as Cornerstones in Russia's Industrial Evolution

To comprehend the present, we delve into the past, tracing the historical journey of gantry cranes in Russia's industrial evolution. From the earliest models that laid the foundation to the cutting-edge technologies of today, gantry cranes have been instrumental in shaping the nation's industrial prowess.

Gantry cranes have witnessed and adapted to the dynamic shifts in Russia's economic landscape. As the demand for efficient material handling grew, so did the capabilities of gantry cranes. Today, they stand as cornerstones, facilitating progress and efficiency in sectors that form the backbone of the nation's economy.

Join us on this journey as we unravel the intricacies of gantry cranes, exploring their diverse types, applications, and the profound impact they continue to have on Russia's industrial landscape. From the bustling ports to the heart of manufacturing, gantry cranes elevate industries to new heights of productivity and success.

Single Girder Gantry Cranes: Precision and Adaptability

Precision in Every Lift: Navigating the World of Single Girder Gantry Cranes in Russia

As we focus our lens on single girder gantry cranes, a world of precision and adaptability unfolds in Russia's industrial landscape. These sophisticated machines redefine the art of material handling, offering unparalleled accuracy and flexibility across diverse sectors.

Precision Redefined

Single girder gantry cranes are engineered to provide precision in every lift. Their design, featuring a single horizontal beam for support, allows for precise control and maneuverability. Whether it's lifting heavy machinery in a manufacturing facility or handling goods in a logistics center, single girder gantry cranes excel in delivering accuracy with each movement.

Adaptability at its Core

What sets single girder gantry cranes apart is their adaptability to various operational environments. Their lightweight design makes them agile and responsive, ideal for applications where space constraints or frequent repositioning are factors. In Russia, where industries often demand versatility in material handling, these cranes emerge as the go-to solution for dynamic and ever-changing operational needs.

Applications Across Industries

The applications of single girder gantry cranes span a spectrum of industries in Russia. In manufacturing, they play a pivotal role in lifting and positioning components with utmost accuracy, contributing to efficient production processes. In logistics and warehouses, their adaptability becomes crucial for swiftly moving goods, optimizing storage space, and enhancing overall operational efficiency.

Efficiency in Motion

Single girder gantry cranes are not just about precision; they are about keeping the wheels of industry in motion. The ability to handle moderate to heavy loads with finesse makes them indispensable in scenarios where efficiency is paramount. From automotive plants to steel and metallurgy facilities, these cranes become the backbone of operations, ensuring seamless workflow and elevated productivity.

Diverse Types of Single Girder Gantry Cranes Tailored for Russia's Industries

Diving deeper into the realm of single girder gantry cranes, we unveil a rich tapestry of diversity, showcasing how these cranes are meticulously tailored to meet the specific needs of various industries in Russia. From design variations to specialized configurations, the versatility of single girder gantry cranes is a testament to their adaptability across industrial landscapes.

The standard configuration of single girder gantry cranes provides a robust and cost-effective solution for lifting and transporting loads in a wide range of industries. With a single horizontal beam and sturdy construction, these cranes excel in day-to-day material handling tasks, making them a staple in manufacturing plants and warehouses across Russia.

In situations where only one side of the workspace needs a gantry crane, the semi-gantry crane configuration proves advantageous. By utilizing the existing structure of the facility as support on one side, these cranes provide a cost-effective solution while maintaining the efficiency and precision associated with single girder designs.

Portable Single Girder Gantry Cranes

Versatility reaches new heights with portable single girder gantry cranes. These mobile solutions are designed for on-the-go material handling, ideal for construction sites, maintenance operations, or any setting requiring frequent crane relocation. Their adaptability makes them indispensable in industries where flexibility is paramount.

Truss Girder Single Girder Gantry Cranes

The Truss girder gantry crane is widely used for high wind outdoor space. With high wind resistance, the truss single girder gantry crane can ensure your material handling safety and efficiency.

Specialized Single Girder Gantry Cranes

Tailored to meet the unique demands of specific industries, specialized single girder gantry cranes come with custom features and configurations. Whether it's a specific lifting capacity, a unique span requirement, or specialized features for a particular application, these cranes showcase the adaptability of single girder designs to address industry-specific challenges.

Economical Solution: Features and Benefits

Making Single Girder Gantry Cranes Ideal for Russian Applications

As we explore the realm of single girder gantry cranes, a key aspect that sets them apart is their economical nature. These cranes strike a balance between cost-effectiveness and high-performance, making them an ideal choice for various applications across the diverse industrial landscape of Russia.

Lightweight Design, Powerful Performance

One of the standout features of single girder gantry cranes is their lightweight design without compromising on performance. This characteristic makes them exceptionally agile and efficient, contributing to ease of installation, maintenance, and overall operational flexibility. In Russia, where adaptability is key, the lightweight nature of these cranes becomes a valuable asset.

Cost-Effective Solution

Economics play a crucial role in any industrial decision, and single girder gantry cranes excel in providing a cost-effective solution without compromising on lifting capacity or functionality. Their simplified design, utilizing a single beam for support, translates into reduced manufacturing and installation costs, offering a compelling choice for industries in Russia looking for efficiency within budget constraints.

Energy-Efficient Operation

In the pursuit of sustainability and cost savings, energy efficiency becomes a significant consideration. Single girder gantry cranes are designed with efficiency in mind, optimizing power consumption during operation. This not only contributes to a greener approach to industrial operations but also reduces long-term operational costs, aligning with the evolving priorities of industries in Russia.

Easy Installation and Maintenance

The simplicity in design and structure of single girder gantry cranes facilitates easy installation, minimizing downtime during setup. Additionally, their uncomplicated configuration simplifies maintenance tasks, reducing the need for intricate repairs and ensuring that these cranes can consistently deliver reliable performance over the long haul.

Versatility in Applications

The versatility of single girder gantry cranes makes them adaptable to a myriad of applications. From manufacturing facilities to logistics centers, their ability to handle various load sizes with precision positions them as reliable workhorses across diverse industries in Russia.

Join us in uncovering the economic prowess of single girder gantry cranes, where efficiency meets affordability. As we delve into their features and benefits, it becomes evident why these cranes are the go-to solution for industries in Russia seeking a reliable and cost-effective material handling solution.

Single Girder Gantry Cranes in Russia's Industrial Landscape

In the heart of Russia's manufacturing hubs, single girder gantry cranes emerge as catalysts for efficiency, precision, and overall manufacturing excellence. Their role in shaping the industrial landscape is profound, streamlining processes and ensuring that the wheels of production keep turning seamlessly.

Precision in Component Handling

Manufacturing demands precision, especially when handling components critical to the production process. Single girder gantry cranes excel in providing the accuracy required for lifting, positioning, and transporting components within a manufacturing facility. Whether it's the automotive sector, machinery production, or other manufacturing domains, these cranes become indispensable for maintaining precision in every step of the production line.

Flexible Production Layouts

One of the key advantages of single girder gantry cranes is their adaptability to various production layouts. In the ever-evolving landscape of manufacturing in Russia, where production facilities often undergo reconfiguration, these cranes offer flexibility. Their design allows them to navigate diverse layouts, ensuring that they can be seamlessly integrated into different manufacturing environments without significant modifications.

Efficient Material Flow

Efficient material flow is the lifeblood of manufacturing, and single girder gantry cranes play a pivotal role in optimizing this process. From raw material handling to finished product storage, these cranes facilitate a smooth and efficient material flow. Their ability to cover a wide working area ensures that no part of the manufacturing floor is left untouched, contributing to a streamlined and uninterrupted production cycle.

Handling Varied Load Sizes

Manufacturing operations often involve handling materials of different sizes and weights. Single girder gantry cranes, with their diverse load capacities and adaptable configurations, cater to the varied needs of manufacturers. Whether it's lifting heavy machinery components or transporting smaller parts, these cranes provide a solution that aligns with the specific requirements of different manufacturing processes.

Enhancing Workplace Safety

Safety is paramount in manufacturing, and single girder gantry cranes are designed with this priority in mind. Their precise control, stability, and adherence to safety standards contribute to creating a secure working environment. This focus on safety aligns with the stringent regulations and standards that govern industrial operations in Russia.

Safeguarding Efficiency in Single Girder Gantry Crane Operations in Russia

While single girder gantry cranes offer a plethora of benefits in Russia's industrial landscape, addressing common concerns is essential to safeguard efficiency and ensure smooth operations. Let's unveil and address these concerns, providing insights into how users can navigate potential challenges for optimal crane performance.

Safety Standards and Compliance

Ensuring adherence to safety standards and compliance is a primary concern for users of single girder gantry cranes. In Russia, where workplace safety regulations are stringent, it's crucial for crane operators and facility managers to stay abreast of the latest standards. Regular training programs, safety audits, and the implementation of modern safety features on the cranes themselves contribute to a safer working environment.

Maintenance and Service

Efficient maintenance and service schedules are vital for the uninterrupted operation of single girder gantry cranes. Users often express concerns about downtime due to maintenance activities. However, a well-planned maintenance strategy, including routine inspections, preventive maintenance, and swift resolution of any identified issues, minimizes downtime and contributes to the long-term reliability of the cranes.

Adaptability to Weather Conditions

Russia's diverse climate poses a unique challenge for crane operations. Extreme temperatures, precipitation, and other weather conditions can impact crane performance. Single girder gantry cranes, designed for adaptability, can navigate these challenges with proper precautions. Features like weather-resistant materials, anti-corrosion coatings, and advanced control systems contribute to their adaptability in varying weather conditions.

Operator Training and Skill Development

The efficiency of single girder gantry crane operations is closely linked to the skills and training of the operators. Concerns about operator competency and skill development can be addressed through comprehensive training programs. Ongoing skill development initiatives ensure that operators are well-equipped to handle the cranes with precision, promoting safe and efficient operations.

Load Capacity and Handling

Matching the load capacity of the crane to the specific requirements of the application is a concern often voiced by users. Properly assessing the load capacity needs and selecting the right crane configuration mitigates this concern. Single girder gantry cranes come in various capacities, and understanding the load dynamics ensures optimal performance and longevity.

By unveiling and addressing these top concerns, we aim to provide a roadmap for users of single girder gantry cranes in Russia. Proactive measures, adherence to standards, and a focus on operator training contribute to a seamless and efficient crane operation experience.

Navigating Single Girder Gantry Crane Operations:

Your Comprehensive Guide in Russia

Embark on a journey through the intricacies of single girder gantry crane operations in Russia with this comprehensive guide. Whether you're a prospective user, operator, or facility manager, this section provides practical insights into selecting, operating, and maintaining single girder gantry cranes for optimal efficiency and safety.

Selecting the Right Single Girder Gantry Crane

- Assessing Load Capacity Needs: Understand the specific load capacity requirements for your application to select a crane that aligns with your operational needs.

- Considering Workspace Constraints: Evaluate the available workspace and layout to choose a crane configuration that seamlessly integrates into your facility without hindering operations.

Operating with Precision

- Operator Training Programs: Invest in comprehensive training programs to enhance operator skills, ensuring precise and safe crane operations.

- Utilizing Advanced Control Features: Explore the advanced control features of single girder gantry cranes to optimize their performance during material handling tasks.

Ensuring Efficient Maintenance

- Implementing Routine Inspections: Regularly inspect all components of the crane, identifying and addressing potential issues before they escalate.

- Adhering to Manufacturer Guidelines: Follow the manufacturer's guidelines for maintenance and service to ensure the crane's longevity and reliable performance.

Adapting to Weather Challenges

- Weather-Resistant Features: Understand the weather conditions in your region and opt for single girder gantry cranes equipped with weather-resistant features.

- Implementing Precautionary Measures: Implement precautionary measures during adverse weather conditions to safeguard both the crane and the operational environment.

Double Girder Gantry Cranes Tailored for Russia's Industries

In the dynamic landscape of Russian industries, the spectrum of double girder gantry cranes goes beyond limits, offering a diverse range of configurations to meet the unique needs of each sector. Let's explore the various types of double girder gantry cranes, showcasing their versatility and adaptability across different industries in Russia.

Full Goliath Cranes, with their impressive structure spanning the entire working area, are a formidable choice for outdoor applications in Russia. From construction sites to storage yards, these cranes exhibit unparalleled strength and efficiency, handling heavy loads with ease.

Semi Goliath Cranes

Semi Goliath Cranes combine the strength of a full goliath crane with the flexibility of a gantry crane. With one end supported on the runway and the other on supporting columns, they are well-suited for applications where one side needs to travel on the ground while the other operates on elevated rails.

Single Leg Gantry Cranes

In scenarios where space is a constraint, Single Leg Gantry Cranes prove their worth. These cranes feature a single supporting leg, allowing them to operate efficiently in confined spaces without compromising on lifting capacity. Industries with limited space, such as certain manufacturing setups, find these cranes to be invaluable.

Double Leg Gantry Cranes

Double Leg Gantry Cranes offer enhanced stability and load-bearing capacity compared to their single leg counterparts. With two supporting legs, these cranes are ideal for heavy-duty applications in industries like steel manufacturing and shipbuilding, where robustness is paramount.

Portal Cranes, with their elevated structure and ability to traverse along a fixed path, are a common sight in various industrial settings. From manufacturing plants to logistics centers, these cranes provide a seamless solution for material handling across large work areas.

Exploring this spectrum of double girder gantry cranes reveals a versatile range tailored to the specific needs of Russia's industries. Whether it's the outdoor prowess of full goliath cranes or the space-saving design of single leg gantry cranes, each type brings unique advantages to enhance material handling efficiency across diverse applications.

Features and Benefits Making Double Girder Gantry Cranes Dominant in Russia

The dominance of double girder gantry cranes in Russia's heavy-duty applications stems from their exceptional features and benefits. Let's delve into the powerhouse attributes that make these cranes indispensable for industries requiring increased lifting capacity, stability, and reliability.

Increased Lifting Capacity

One of the standout features of double girder gantry cranes is their ability to handle heavier loads compared to their single girder counterparts. The dual girder configuration distributes the load more evenly, resulting in enhanced lifting capacity. This makes them the go-to choice for lifting and transporting substantial materials in steel, metallurgy, and heavy machinery industries in Russia.

Enhanced Stability and Rigidity

The dual girder design not only contributes to increased lifting capacity but also provides enhanced stability and rigidity. This added stability is crucial when dealing with large and heavy loads, ensuring precise and controlled movements. In sectors where precision is paramount, such as steel manufacturing, this feature becomes a game-changer.

Versatility in Handling Various Load Sizes

Double girder gantry cranes showcase versatility in handling a wide range of load sizes. From smaller components in manufacturing to bulk materials in construction, these cranes offer flexibility in accommodating diverse load requirements. This adaptability makes them a versatile solution across various Russian industries.

Long Span for Extensive Coverage

With a longer span compared to single girder cranes, double girder gantry cranes are well-suited for applications that require extensive coverage. This is particularly advantageous in industries where materials need to be moved across large work areas, such as construction projects or expansive manufacturing facilities.

Durability for Harsh Environments

Russian industrial environments can be demanding, requiring equipment that can withstand harsh conditions. Double girder gantry cranes are built with durability in mind, incorporating robust materials and protective features. This ensures a long service life, even in challenging operational settings and diverse climates.

Customization Options for Tailored Solutions

Double girder gantry cranes offer customization options to meet the specific needs of different industries. Whether it's adapting the crane for unique operational requirements or integrating advanced control features, customization ensures that the crane aligns seamlessly with the demands of each application.

In the realm of heavy-duty material handling, double girder gantry cranes stand as a powerhouse solution for Russia's industries. Their increased lifting capacity, stability, versatility, and durability make them a dominant force, driving efficiency and productivity across various sectors.

Double Girder Gantry Cranes Powering Russia's Heavy Industries

In the heart of Russia's heavy industries, where the demands are robust and the materials substantial, double girder gantry cranes emerge as the driving force behind efficiency and productivity. Let's explore how these cranes forge strength in sectors like steel and metallurgy, playing a pivotal role in shaping the landscape of heavy industries in Russia.

Steel Manufacturing: Precision in Every Lift

In the realm of steel manufacturing, precision is non-negotiable. Double girder gantry cranes bring unparalleled precision to the lifting and handling of raw materials, semi-finished products, and heavy components. Their stability and accuracy ensure that critical processes in steel production, such as material transfer and positioning, are executed with utmost reliability.

Metallurgical Giants: Handling Bulk Materials

Metallurgical plants dealing with bulk materials rely on the strength of double girder gantry cranes. From handling raw ores to transporting processed metals, these cranes excel in managing the weight and volume of materials integral to the metallurgical processes. Their increased lifting capacity and stability make them indispensable in the heavy and continuous operations of metallurgical giants in Russia.

Heavy Machinery Production: Seamless Material Handling

In the production of heavy machinery, where components can weigh several tons, seamless material handling is paramount. Double girder gantry cranes provide the strength and precision required to lift and move these hefty components, contributing to the streamlined assembly processes in the manufacturing of heavy machinery in Russia.

Shipbuilding: Maneuvering Bulky Ship Components

The shipbuilding industry demands the maneuvering of bulky and intricate components, and double girder gantry cranes rise to the challenge. Their robust design and precise control enable the efficient handling of ship sections, engines, and other heavy shipbuilding materials. These cranes play a crucial role in the construction of vessels, contributing to the maritime strength of Russia.

Foundries: Supporting Foundry Operations

Foundries involved in metal casting rely on the support of double girder gantry cranes for the transportation of molten metal, molds, and castings. The durability of these cranes, coupled with their ability to handle extreme temperatures and heavy loads, makes them essential in sustaining the operational flow within foundry environments.

In each heavy industry scenario, double girder gantry cranes prove their mettle by forging strength and efficiency. Whether in steel manufacturing, metallurgy, heavy machinery production, shipbuilding, or foundries, these cranes stand as stalwart allies, contributing to the foundational strength of Russia's heavy industries.

User Concerns in Focus:

Ensuring Seamless Double Girder Gantry Crane Operations in Russia

Operating heavy machinery, especially in demanding industrial environments, comes with its set of concerns. Let's delve into the specific concerns of users when it comes to double girder gantry cranes and how these concerns are addressed to ensure seamless operations within the unique context of the Russian industrial landscape.

Safety Standards and Compliance

Challenge: Users are often concerned about ensuring the highest safety standards and compliance with regulations, especially when dealing with heavy loads and complex industrial processes.

Solution: Double girder gantry cranes are designed and manufactured with a strong emphasis on safety. They adhere to international safety standards and are equipped with advanced safety features such as overload protection, emergency braking systems, and collision avoidance mechanisms. Regular inspections and compliance checks further ensure that these cranes meet and exceed the safety requirements set for industrial operations in Russia.

Maintenance and Service

Challenge: Downtime due to maintenance can be a concern for users, affecting operational efficiency and productivity.

Solution: Double girder gantry cranes are designed for ease of maintenance. Components are accessible for inspection and servicing, and maintenance schedules are structured to minimize downtime. Manufacturers and suppliers often provide comprehensive maintenance and service packages, including routine inspections, preventive maintenance, and prompt responses to any unexpected issues. This proactive approach ensures that the cranes operate smoothly and consistently, contributing to uninterrupted industrial processes.

Adaptability to Weather Conditions

Challenge: The diverse climate in Russia, ranging from extreme cold in the winter to warmer temperatures in the summer, poses challenges for equipment adaptability.

Solution: Double girder gantry cranes designed for the Russian market undergo rigorous testing to ensure adaptability to diverse weather conditions. Special considerations, such as cold-resistant components and corrosion-resistant materials, are integrated into the crane design. This adaptability ensures reliable performance even in challenging weather, making these cranes well-suited for the varying climate conditions across Russia.

By addressing these concerns head-on, the operation of double girder gantry cranes in Russia becomes not only seamless but also secure, efficient, and reliable. Manufacturers and suppliers play a crucial role in providing solutions that prioritize user concerns, making these cranes trusted assets in the industrial landscape of Russia.

Mastering Double Girder Gantry Crane Operations: Your In-Depth Guide in Russia

Unlock the keys to mastering the operation of double girder gantry cranes in the dynamic industrial landscape of Russia. This in-depth guide provides practical insights into optimizing performance, ensuring efficient maintenance, and prioritizing safety. Whether you are a current user or a potential purchaser, this guide is tailored to enhance your understanding and mastery of double girder gantry crane operations.

Optimizing Crane Performance

- Understanding Crane Capacities: Learn how to decipher the crane's capacities and tailor them to the specific requirements of your industrial operations.

- Advanced Control Features: Explore the capabilities of advanced control features and how they contribute to precision and efficiency in material handling.

- Efficient Load Handling Techniques: Master techniques for efficient load handling, ensuring maximum productivity and minimizing operational stress.

Efficient Maintenance Practices

- Routine Inspection Protocols: Establish a routine inspection schedule to identify potential issues early and ensure consistent crane performance.

- Preventive Maintenance Measures: Implement preventive maintenance measures to reduce the likelihood of unexpected breakdowns and extend the crane's service life.

- Troubleshooting Common Issues: Gain insights into troubleshooting common issues, empowering users to address minor concerns independently.

Prioritizing Safety in Operations

- Understanding Safety Features: Familiarize yourself with the safety features integrated into double girder gantry cranes and their role in preventing accidents.

- Operator Training and Certification: Emphasize the importance of operator training and certification to ensure competent and safe crane operation.

- Emergency Response Procedures: Establish clear emergency response procedures to address unforeseen situations and prioritize the well-being of personnel and equipment.

Double Girder Gantry Cranes: Heavy-Duty Excellence

Heavy-Duty Excellence: A Deep Dive into Double Girder Gantry Cranes in Russia

In the realm of heavy-duty material handling in Russia, double girder gantry cranes emerge as the epitome of strength and reliability. This section takes you on a deep dive into the robust design, advanced capabilities, and diverse applications of double girder gantry cranes, showcasing their heavy-duty excellence in the Russian industrial landscape.

Robust Design for Hefty Loads

Double girder gantry cranes are engineered with a robust design to handle hefty loads with ease. The dual girder configuration provides enhanced stability and strength, making these cranes ideal for lifting and transporting heavy machinery components, steel structures, and other substantial materials in Russia's heavy industries.

Versatility in Load Handling

The versatility of double girder gantry cranes shines in their ability to handle a wide range of load sizes and weights. From precise movements in manufacturing processes to the heavy lifting requirements of steel and metallurgical plants, these cranes offer versatility that aligns with the diverse needs of Russia's industrial sectors.

Spanning Large Work Areas

Double girder gantry cranes boast a large span, allowing them to cover extensive work areas. This capability is especially advantageous in industries where materials need to be moved across significant distances, such as in construction projects or expansive manufacturing facilities. The large span enhances the crane's reach and operational efficiency.

Precision in High-Tonnage Applications

When it comes to high-tonnage applications, precision becomes paramount. Double girder gantry cranes excel in providing precise control, ensuring that heavy loads are lifted, moved, and positioned with accuracy. This precision is essential in industries like steel manufacturing and heavy machinery production, where exact placement is crucial.

Durability for Demanding Environments

The demanding industrial environments in Russia require equipment that can withstand harsh conditions. Double girder gantry cranes are built for durability, incorporating features such as corrosion-resistant materials and protective coatings. This durability ensures a long service life, even in challenging operational settings.

Embark on this exploration of heavy-duty excellence with double girder gantry cranes in Russia. From their robust design and versatile load handling to the precision in high-tonnage applications, these cranes are engineered to meet the demanding needs of Russia's heavy industries.

Whether you are a seasoned operator or a prospective purchaser, this guide serves as your comprehensive resource for mastering double girder gantry crane operations in Russia. Elevate your knowledge, optimize your processes, and ensure the seamless integration of these heavy-duty cranes into your industrial operations.

Q&A Section: Addressing Your Concerns

Q How can I determine the right load capacity for my application?

A Assess the weight and dimensions of the heaviest load you'll be handling to match it with the crane's load capacity.

Q What training is required for crane operators in Russia?

A Crane operators should undergo comprehensive training on crane operation, safety protocols, and emergency procedures.

Q How often should maintenance activities be conducted?

A Regular maintenance, including inspections and preventive measures, should be conducted as per the manufacturer's recommendations.

Q Can single girder gantry cranes operate efficiently in extreme weather conditions?

A. Yes, with proper features and precautions, single girder gantry cranes can adapt to and operate efficiently in diverse weather conditions.

Navigate the world of single girder gantry crane operations in Russia with confidence using this comprehensive guide. From selection to daily operations and maintenance, this guide equips you with the knowledge to make informed decisions and ensure the optimal performance of your crane.

Single Girder vs. Double Girder Gantry Cranes

Box Girder Gantry Crane:

Single Girder Box Girder Gantry Crane:

Features:

- Single Girder Design: Simplicity and ease of use.

- Box Girder Structure: Provides stability and strength.

- Lightweight Design: Suitable for moderate lifting applications.

Benefits:

- Cost-Effective: Lower construction and installation costs compared to double girder cranes.

- Space Efficiency: Takes up less space, suitable for locations with space constraints.

- Versatility: Well-suited for various light to moderate lifting applications.

Applications:

- Warehousing: Efficient for lifting and moving goods in storage facilities.

- Manufacturing: Suitable for light to moderate lifting tasks in manufacturing settings.

- Maintenance Workshops: Ideal for tasks within workshops and small manufacturing facilities.

Double Girder Box Girder Gantry Crane:

Features:

- Dual Girder Design: Enhanced stability and increased load capacity.

- Box Girder Structure: Provides stability and strength for heavier loads.

- Increased Height: Suitable for lifting applications that require higher hook height.

Benefits:

- Increased Stability: Dual girder design enhances stability for heavier loads.

- Higher Load Capacity: Ideal for lifting heavier loads compared to single girder box girder cranes.

- Versatility: Suitable for various moderate to heavy lifting applications.

Applications:

- Heavy Manufacturing: Efficient for handling heavy materials in manufacturing settings.

- Construction Sites: Suitable for lifting tasks in construction with heavier loads.

- Ports and Shipping: Ideal for lifting and moving heavy cargo in port environments.

Similarities:

| Features | Single Girder Design | Double Girder Design |

|---|---|---|

| Girder Structure | Box-shaped for enhanced strength and stability | Box-shaped for enhanced strength and stability |

| Load Capacity | Suitable for moderate to heavy lifting | Suitable for heavy lifting |

| Applications | Industrial facilities, ports, construction sites | Industrial facilities, ports, construction sites |

| Stability | High stability | High stability |

| Cost | Higher construction and installation costs | Higher construction and installation costs |

Similarities:

- Box Girder Structure: Both single and double girder box girder gantry cranes share the characteristic of having a box girder structure, providing stability and strength.

- Versatility: Both types are versatile and suitable for various lifting applications, making them adaptable to different industrial settings.

- Applications: Both types find applications in warehousing, manufacturing, maintenance workshops, construction sites, and ports, showcasing adaptability in different industrial settings.

Truss Girder Gantry Crane:

Single Girder Truss Girder Gantry Crane:

Features:

- Truss Girder Structure: Lightweight and durable design.

- High Span Capability: Suitable for applications requiring long spans.

- Space Efficiency: Provides ample clearance while minimizing floor space impact.

Benefits:

- Long Span Capability: Ideal for lifting tasks with extended spans.

- Reduced Weight: Lightweight design allows for easy mobility.

- Cost-Effective: Offers cost savings in construction and installation.

Applications:

- Outdoor Construction Sites: Well-adapted for outdoor projects.

- Logistics and Warehousing: Efficient for material handling in warehouses.

- Infrastructure Projects: Lifting and placing components in large-scale construction.

Double Girder Truss Girder Gantry Crane:

Features:

- Truss Girder Structure: Lightweight yet robust design for heavy-duty tasks.

- Long Span Capability: Ideal for applications requiring extended spans.

- Enhanced Stability: Dual girder design provides increased stability.

Benefits:

- Long Span Capability: Suitable for tasks requiring extended spans.

- Reduced Weight: Lightweight design allows for better maneuverability.

- Cost-Effective: Offers cost savings in construction and installation.

Applications:

- Large Infrastructure Projects: Lifting and placing heavy components.

- Heavy Manufacturing: Handling large and bulky materials in industries.

- Ports and Shipping: Efficient for lifting heavy cargo in port environments.

Differences:

| Aspect | Single Girder Truss Girder Gantry Crane | Double Girder Truss Girder Gantry Crane |

|---|---|---|

| Girder Configuration | Single Girder | Double Girder |

| Load Capacity | Moderate | High |

| Span Capability | Moderate to Long | Long |

| Stability | Moderate | High |

| Weight | Lighter | Heavier |

| Construction and Installation Cost | Lower | Higher |

Similarities:

- Truss Girder Structure: Both single and double girder truss gantry cranes share the characteristic truss girder structure, providing strength and stability.

- Long Span Capability: Both types are suitable for applications requiring long spans, making them versatile for various industrial tasks.

- Cost-Effective: Single and double girder truss gantry cranes offer cost-effective solutions for specific lifting applications.

- Applications: Both types find applications in outdoor construction sites, logistics and warehousing, and infrastructure projects, showcasing adaptability in different industrial settings.

Semi Gantry Crane

Single Girder Semi Gantry Crane:

Features:

- Semi Gantry Configuration: Supported on one side by a runway system.

- Compact Design: Well-suited for locations with limited space.

- Easy Installation: Simplified installation process due to its partial gantry structure.

Benefits:

- Space Efficiency: Ideal for locations where a full gantry system may not be feasible.

- Cost-Effective: Lower construction and installation costs compared to full gantry cranes.

- Versatility: Suitable for various applications with moderate load capacities.

Applications:

- Outdoor Construction Sites: Maneuverable for lifting tasks in construction.

- Loading Docks: Efficient for loading and unloading goods from trucks.

- Maintenance Workshops: Versatile for tasks within workshops and manufacturing facilities.

Double Girder Semi Gantry Crane:

Features:

- Semi Gantry Configuration: Supported on one side by a runway system.

- Dual Girder Design: Enhanced stability and increased load capacity.

- Long Span Capability: Suitable for applications requiring extended spans.

Benefits:

- Increased Stability: Dual girder design provides enhanced stability.

- Higher Load Capacity: Ideal for lifting heavier loads compared to single girder semi gantry cranes.

- Versatility: Suitable for various applications with higher load capacities.

Applications:

- Heavy Manufacturing: Lifting and moving heavy materials in manufacturing settings.

- Ports and Shipping: Efficient for handling heavy cargo in port environments.

- Large Infrastructure Projects: Ideal for lifting heavy components in large-scale projects.

Differences:

| Aspect | Single Girder Semi Gantry Crane | Double Girder Semi Gantry Crane |

|---|---|---|

| Girder Configuration | Single Girder | Double Girder |

| Load Capacity | Moderate | High |

| Stability | Moderate | High |

| Construction and Installation Cost | Lower | Higher |

Similarities:

- Semi Gantry Configuration: Both single and double girder semi gantry cranes share the characteristic of being supported on one side by a runway system, providing flexibility in their application.

- Space Efficiency: Both types are designed to be space-efficient, making them suitable for locations with limited space availability.

- Applications: Both types find applications in outdoor construction sites, loading docks, maintenance workshops, ports, and large infrastructure projects, showcasing adaptability in different industrial settings.

Portable Gantry Crane:

Single Girder Portable Gantry Crane:

Features:

- Lightweight Structure: Designed for easy portability and maneuverability.

- Single Girder Design: Simplicity and ease of use.

- Quick Assembly: Can be assembled and disassembled rapidly.

Benefits:

- Portability: Easy to move to different locations within a facility.

- Cost-Effective: Lower construction and installation costs compared to heavier cranes.

- Versatility: Suitable for various light to moderate lifting applications.

Applications:

- Maintenance Workshops: Ideal for tasks within workshops and small manufacturing facilities.

- Warehousing: Efficient for lifting and moving goods in storage facilities.

- Construction Sites: Portable and adaptable for lifting tasks in construction.

Double Girder Portable Gantry Crane:

Features:

- Increased Stability: Dual girder design provides enhanced stability.

- Higher Load Capacity: Suitable for heavier lifting compared to single girder portable gantry cranes.

- Quick Assembly: Can be assembled and disassembled rapidly.

Benefits:

- Increased Stability: Dual girder design enhances stability for heavier loads.

- Higher Load Capacity: Ideal for lifting heavier loads compared to single girder portable gantry cranes.

- Versatility: Suitable for various light to moderate lifting applications.

Applications:

- Heavy Manufacturing: Efficient for handling heavy materials in manufacturing settings.

- Construction Sites: Portable and adaptable for lifting tasks in construction with heavier loads.

- Ports and Shipping: Suitable for lifting and moving heavy cargo in port environments.

Differences:

| Aspect | Single Girder Portable Gantry Crane | Double Girder Portable Gantry Crane |

|---|---|---|

| Girder Configuration | Single Girder | Double Girder |

| Load Capacity | Light to Moderate | Moderate to Heavy |

| Stability | Moderate | High |

| Construction and Installation Cost | Lower | Higher |

Similarities:

- Portability: Both single and double girder portable gantry cranes share the characteristic of being easily movable to different locations within a facility.

- Quick Assembly: Both types can be assembled and disassembled rapidly, providing flexibility in their use.

- Versatility: Both types are versatile and suitable for various light to moderate lifting applications, making them adaptable to different industrial settings.

Here's a table summarizing the differences and similarities between single girder and double girder gantry cranes for various designs:

| Design Type | Single Girder Gantry Crane | Double Girder Gantry Crane |

|---|---|---|

| Box Girder | Moderate to heavy lifting | Heavy lifting |

| Lower load capacity | Higher load capacity | |

| Lower construction and installation costs | Higher construction and installation costs | |

| Box-shaped girder structure | Box-shaped girder structure | |

| Truss Girder | Light to moderate lifting | Light to moderate lifting |

| Generally lower construction and installation costs | Generally lower construction and installation costs | |

| Truss-shaped girder structure | Truss-shaped girder structure | |

| Semi Gantry | Light to moderate lifting | Light to moderate lifting |

| Moderate stability | Moderate stability | |

| Combination of gantry and overhead crane features | Combination of gantry and overhead crane features | |

| Portable Gantry | Light to moderate lifting | Light to moderate lifting |

| Designed for easy movement within a facility | Designed for easy movement within a facility | |

| Quick assembly and disassembly | Quick assembly and disassembly |

This table provides a concise overview of the differences and similarities for each gantry crane design type with both single girder and double girder configurations.

Conclusion: Elevate with Confidence

Elevate with Confidence: Your Trusted Partners in Single and Double Girder Gantry Cranes for Russia's Success

In wrapping up this in-depth exploration of single girder and double girder gantry cranes tailored for Russia, it becomes evident that these sophisticated lifting solutions are far more than mechanical devices. They emerge as steadfast partners, ready to propel Russia's industries to unprecedented levels of efficiency and triumph.

Gantry cranes, whether equipped with a single girder for precision or a double girder for heavy-duty excellence, epitomize reliability in operations. As they dominate various sectors, from bustling ports to intricate manufacturing processes and ambitious construction projects, these cranes symbolize precision and power converging for optimal results.

Beyond their mechanical prowess, gantry cranes represent a commitment to progress, offering more than just lifting capabilities. They embody a promise of efficiency, safety, and adaptability, crucial elements in the dynamic industrial landscape of Russia.

So, as you embark on your industrial journey in Russia, envision gantry cranes not merely as machines but as stalwart allies. Elevate your operations with the confidence that comes from partnering with these reliable, powerful, and adaptable lifting solutions. May your endeavors reach new pinnacles of success, and remember, with gantry cranes, you're not just lifting loads – you're lifting the future of your industry.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch