Full Gantry and Semi Gantry Cranes for Outdoor Storage in Russia

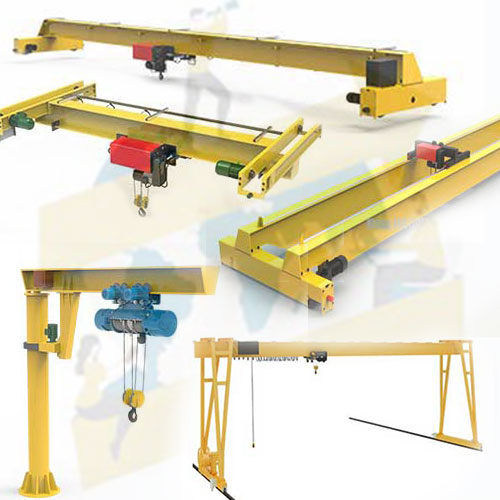

Full gantry crane 3 to 100 ton & semi gantry crane 1 to 30 ton for outdoor material handling i.e, storage yards, contributing to efficient logistics in Russia.

Category: Russia

Your Trusted Gantry Crane Manufacturer & Supplier

Full Gantry and Semi Gantry Cranes for Outdoor Storage in Russia

Full Gantry Crane 3 to 100 Ton & Semi Gantry Crane 1 to 30 Ton for Outdoor Material Handling

Full gantry crane 3 to 100 ton & semi gantry crane 1 to 30 ton for outdoor material handling i.e, storage yards, contributing to efficient logistics in Russia.

Full and Semi Gantry Cranes for Sale Optimizing Outdoor Storage in Russia

In the vast expanse of Russia's outdoor storage and logistics operations, the role of gantry cranes is pivotal, providing indispensable solutions for efficient material handling. Two distinct variants, full gantry cranes and semi gantry cranes, have emerged as stalwarts in optimizing outdoor storage yards. Each design brings its unique set of features and applications, catering to the diverse needs of industries ranging from manufacturing to construction.

Russia's vast landscape and diverse industries necessitate efficient outdoor storage solutions. Outdoor storage yards serve as crucial hubs for storing raw materials, finished products, and containers awaiting transportation. The strategic placement of outdoor storage facilities is integral to streamline supply chains and ensure seamless logistics operations.

Role of Full and Semi Gantry Cranes

As pivotal players in the material handling and logistics arena, full and semi gantry cranes play a transformative role in optimizing outdoor storage in Russia.These powerful machines are tailored to meet the unique demands of outdoor storage yards, contributing to enhanced efficiency, precision, and speed in logistics operations. This guide delves into the applications, benefits, and real-world examples of full and semi gantry cranes, shedding light on their instrumental role in shaping Russia's logistics landscape.

Full gantry cranes are robust and versatile, presenting a complete-span structure with substantial lifting capacity. Their design enables them to efficiently handle heavy loads in outdoor storage yards, offering a high level of automation and adaptability. With a focus on streamlined storage and retrieval processes, full gantry cranes become essential components in large outdoor facilities. Their adaptability to various environments makes them key contributors to the optimization of storage operations.

On the other hand, semi gantry cranes provide a balanced approach to outdoor storage scenarios. Supported by a runway system on one end and moving on wheels along the ground on the other, these cranes offer flexibility in material handling. Especially adept at navigating irregular terrains, semi gantry cranes are well-suited for outdoor storage yards with varying topographies. Their design allows for efficient load movement and precise positioning, making them valuable assets in the logistics chain.

Your Trusted Gantry Crane Manufacturer & Supplier

Full Gantry Cranes for Outdoor Storage

Full gantry cranes stand as robust solutions for outdoor storage, offering a high level of automation and efficiency. With their full-span structure and substantial lifting capacity, these cranes excel in handling heavy loads in outdoor storage yards. Their adaptability to diverse environments makes them indispensable for optimizing the storage and retrieval processes in large outdoor facilities.

Full gantry crane for outdoor use

Types of Full Gantry Cranes for Outdoor Use in Russia

- Single Girder Full Gantry Crane:This type of full gantry crane features a single main beam supported on both ends by rigid legs. Single girder gantry cranes are suitable for lighter to moderate lifting capacities and are often used in outdoor storage yards for versatile material handling.

- Double Girder Full Gantry Crane:Characterized by two main beams running parallel to each other, double girder full gantry cranes offer increased stability and higher lifting capacities. These cranes are well-suited for heavy-duty outdoor applications, such as handling large machinery or bulky materials.

- Rubber-Tired Gantry Crane (RTG):RTG cranes are equipped with rubber tires, providing excellent mobility on various surfaces. They are commonly used in outdoor storage yards, including shipping container terminals and intermodal facilities. RTG cranes can move quickly between storage stacks, optimizing container handling.

- Rail Mounted Gantry Crane (RMG):RMG cranes are designed to travel on fixed rails, offering precise and controlled movement. They are often used in outdoor storage yards with dedicated rail systems, providing efficient container stacking and retrieval. RMG cranes are suitable for high-density storage applications.

- Cantilever Gantry Crane:Cantilever gantry cranes have a projecting beam (cantilever) on one or both sides of the supporting legs. This design allows for increased lateral reach, making them suitable for outdoor storage yards where materials need to be accessed from various angles.

- Truss Gantry Crane:Truss gantry cranes use a truss structure for their horizontal beams, providing strength and stability. They are employed in outdoor storage applications where the crane needs to span longer distances while maintaining structural integrity.

Features of Full Gantry Cranes

Each type of full gantry crane serves specific purposes in outdoor storage yards, contributing to efficient logistics and material handling operations across diverse industries in Russia.

Full gantry cranes are robust material handling solutions designed specifically for outdoor storage applications. Here's a more detailed explanation of their key features and functionalities:

- Robust Design:Full gantry cranes are characterized by their sturdy and durable construction. The robust design ensures that these cranes can withstand the challenges posed by outdoor environments, including varying weather conditions and exposure to elements.

- High Level of Automation:Automation is a key feature of full gantry cranes. These cranes are equipped with advanced control systems that enable automated operation, reducing the need for manual intervention. Automation enhances efficiency, speeds up processes, and minimizes the risk of errors in outdoor storage yards.

- Full-Span Structure:The defining feature of full gantry cranes is their full-span structure. This means that the crane spans the entire width of the outdoor storage yard. This structural design provides extensive coverage, allowing the crane to reach and lift materials across the entire storage are

- Substantial Lifting Capacity:Full gantry cranes are designed to handle heavy loads with ease. Their substantial lifting capacity makes them suitable for lifting and transporting large and bulky materials commonly found in outdoor storage yards. This lifting prowess contributes to efficient and timely material handling operations.

- Adaptability to Diverse Environments:Outdoor storage yards often have varied terrains and conditions. Full gantry cranes are engineered for adaptability, capable of navigating different outdoor environments. This adaptability ensures that the crane can operate smoothly across a range of conditions, maintaining productivity in diverse settings.

- Optimization of Storage and Retrieval Processes:The primary purpose of full gantry cranes in outdoor storage is to optimize storage and retrieval processes. These cranes facilitate efficient organization and movement of materials within the storage yard. Their full-span reach enables them to access materials located anywhere in the yard, contributing to streamlined operations.

In summary, full gantry cranes combine robust construction, automation, extensive reach, and substantial lifting capacity to provide a comprehensive solution for outdoor storage needs. Their adaptability and efficiency make them essential for optimizing material handling processes in large outdoor facilities.

Your Trusted Overhead Gantry Crane Manufacturer & Supplier

Semi Gantry Cranes

Semi gantry cranes bring a balanced approach to outdoor storage scenarios. With one end supported by a runway system and the other end moving on wheels along the ground, they provide flexibility in material handling. Semi gantry cranes are adept at navigating irregular terrains, making them well-suited for outdoor storage yards with varying topographies. Their design allows for efficient load movement and precise positioning.

Double girder semi gantry crane

Box girder semi gantry cranes

Types of Semi Gantry Cranes for Outdoor Use in Russia

- Single Leg Semi Gantry Crane:A single leg semi gantry crane is supported by one rigid leg, while the other end moves along the ground on wheels. This design offers flexibility in material handling and makes it suitable for outdoor storage yards with varying topographies.

- Truss Design Semi Gantry Crane:Semi gantry cranes with a truss design use a triangular framework for their horizontal beams, providing strength and stability. The truss design is advantageous in outdoor storage applications where the crane needs to span longer distances while maintaining structural integrity.

Features of Semi Gantry Cranes

Semi gantry cranes offer a unique and balanced solution for outdoor storage applications, combining the advantages of both gantry and overhead crane designs. Here's a detailed explanation of the key features and benefits of semi gantry cranes:

- Balanced Design:Semi gantry cranes feature a balanced design where one end is supported by a runway system, typically installed on an existing structure, while the other end moves on wheels along the ground. This design provides a balanced and stable configuration, ensuring effective material handling with enhanced flexibility.

- Flexibility in Material Handling:The semi gantry crane's design allows for a high degree of flexibility in material handling. The supported end can travel along a fixed runway, providing precision and control, while the wheeled end allows for easy mobility and adaptability to different areas of the outdoor storage yard. This flexibility enhances the crane's versatility in handling various materials and navigating around obstacles.

- Navigating Irregular Terrains:Outdoor storage yards often have irregular terrains, and semi gantry cranes are well-suited to handle such conditions. The wheeled end of the crane can navigate uneven or rough surfaces, making it adaptable to varying topographies. This capability is crucial for efficient material handling in outdoor environments with diverse ground conditions.

- Efficient Load Movement:Semi gantry cranes are designed for efficient load movement. The supported end provides stability and precision, ensuring controlled lifting and lowering of materials. The wheeled end contributes to smooth horizontal movement, allowing for easy transportation of loads within the storage yard. This combination of stability and mobility optimizes the overall material handling process.

- Precise Positioning:Semi gantry cranes excel in precise positioning of loads. The supported end's fixed runway system enables accurate placement of materials, while the wheeled end facilitates precise movements along the ground. This precision is particularly important in outdoor storage scenarios where organized and strategic positioning of materials is crucial for efficient operations.

- Adaptability to Varying Topographies:One of the significant advantages of semi gantry cranes is their adaptability to varying topographies. The wheeled end can traverse different terrains, making these cranes suitable for outdoor storage yards with uneven surfaces. This adaptability ensures consistent performance across diverse environments.

In summary, semi gantry cranes offer a balanced and flexible solution for outdoor storage yards. Their unique design allows for efficient material handling, precise positioning, and adaptability to varying terrains, making them valuable assets in optimizing logistics and material flow in outdoor storage scenarios.

Specialized Variations

The dynamic requirements of outdoor storage yards often call for specialized adaptations of full and semi gantry cranes. This section explores variations equipped with features such as weather-resistant coatings, advanced control systems, and customized lifting attachments. These specialized cranes are designed to address specific challenges posed by outdoor storage environments, ensuring optimal performance and longevity.

Specialized Variations: Enhancing Outdoor Storage Efficiency

In the realm of outdoor storage, where diverse challenges abound, specialized variations of full and semi gantry cranes emerge as tailored solutions to address specific requirements. These variations go beyond the standard configurations, incorporating advanced features and adaptations to optimize efficiency in outdoor storage yards. Here's a detailed exploration of the specialized variations:

- Weather-Resistant Coatings:Outdoor storage yards are exposed to varying weather conditions, including rain, snow, and harsh sunlight. Specialized gantry cranes often come equipped with weather-resistant coatings, providing protection against corrosion and ensuring durability in challenging environmental conditions. These coatings extend the lifespan of the crane components, contributing to long-term reliability.

- Advanced Control Systems:To enhance precision and control in material handling, specialized gantry cranes feature advanced control systems. These systems may include automation, remote monitoring, and intelligent controls, allowing operators to manage crane operations with efficiency and accuracy. Advanced control features contribute to smoother workflows and optimized logistics in outdoor storage applications.

- Customized Lifting Attachments:The nature of materials stored outdoors can vary widely, from heavy machinery to delicate components. Specialized gantry cranes often incorporate customized lifting attachments designed to handle specific types of loads. Whether it's specialized hooks, magnets, or clamps, these attachments ensure secure and precise lifting, accommodating the unique characteristics of the materials being handled.

- Enhanced Mobility Features:In outdoor storage yards with expansive layouts, the mobility of gantry cranes becomes crucial. Specialized variations may include enhanced mobility features such as all-terrain wheels or track systems, allowing the crane to navigate uneven surfaces and varying terrains. Improved mobility ensures that the crane can reach and handle materials efficiently across the entire storage yard.

- Adjustable Height and Span:Outdoor storage scenarios often involve handling materials of different sizes and shapes. Specialized gantry cranes may feature adjustable height and span capabilities, allowing operators to customize the crane configuration based on the specific requirements of the materials being lifted. This adaptability enhances the versatility of the crane in accommodating diverse storage needs.

- Load Monitoring and Safety Systems:Safety is paramount in outdoor storage environments. Specialized gantry cranes may integrate advanced load monitoring and safety systems. These systems provide real-time data on load conditions, ensuring that the crane operates within safe parameters. Additionally, safety features such as collision avoidance systems contribute to accident prevention in dynamic outdoor storage settings.

- Environmentally Friendly Designs:As sustainability gains importance, some specialized gantry cranes are designed with environmentally friendly features. This may include energy-efficient components, eco-friendly materials, and reduced emissions. Such cranes align with the growing emphasis on sustainable practices in industrial operations.

In conclusion, specialized variations of full and semi gantry cranes play a pivotal role in addressing the unique challenges posed by outdoor storage environments. These adaptations, ranging from weather-resistant coatings to advanced control systems, ensure that gantry cranes not only meet but exceed the demands of outdoor storage yards, contributing to enhanced efficiency and optimized logistics.

Your Trusted Overhead Gantry Crane Manufacturer & Supplier

Applications in Outdoor Storage Yards

Container Handling

In the complex logistics of outdoor storage yards, the efficiency of container handling is paramount. Full gantry cranes, with their expansive span and high lifting capacity, are ideal for reaching and lifting containers from various positions. Their full automation capabilities contribute to swift and precise movements, ensuring seamless loading and unloading processes. Semi gantry cranes, with one end supported by a runway system and the other on wheels, offer flexibility in navigating through the outdoor storage yard, allowing for strategic positioning of containers even in challenging terrains.

These cranes play a crucial role in the intermodal transportation of goods, seamlessly transferring containers between trucks, trains, and storage areas. The ability to handle different container sizes and types makes them versatile solutions for the diverse needs of outdoor storage yards.

For container handling , which type of gantry crane are preferred , the full gantry crane or semi gantry cranes ?

The preference between full gantry cranes and semi gantry cranes for container handling depends on various factors, including the specific requirements of the operation and the characteristics of the outdoor storage yard. Here's a general comparison to help guide the choice:

Full Gantry Cranes for Container Handling:

Advantages:

- Well-suited for operations requiring a complete standalone structure.

- Provides a stable and robust platform for lifting and moving containers.

- Typically offers higher lifting capacities.

Considerations:

- Higher initial cost and more complex installation.

- Stationary nature may limit flexibility in handling containers in different areas of the yard.

Semi Gantry Cranes for Container Handling:

Advantages:

- Greater mobility along the ground on wheels, allowing flexibility in material handling.

- Well-adapted to outdoor storage yards with uneven terrains.

- Generally more cost-effective with straightforward installation.

Considerations:

- Lower lifting capacities compared to full gantry cranes.

- Limited in terms of span due to the supporting runway system.

Preference Recommendation:

- For large, flat, and even terrains with high lifting capacity requirements, a full gantry crane may be preferred.

- For outdoor storage yards with irregular terrains and a need for flexibility in material handling at a more cost-effective setup, a semi gantry crane could be a suitable choice.

The final decision should consider the specific needs, budget constraints, and operational characteristics of the container handling application.

In Russia, various types of gantry cranes are used for container handling in outdoor storage yards. Two prominent types include:

Rubber-Tired Gantry Cranes (RTGs):

Overview: RTGs are mobile gantry cranes equipped with rubber tires, allowing them to travel on paved surfaces. They are commonly used in container terminals and outdoor storage yards.

Features:

- Rubber tires provide mobility and flexibility in container handling operations.

- They can lift containers directly from trucks or stack containers in storage yards.

- RTGs are electrically powered, contributing to environmental sustainability.

Applications: RTGs are suitable for handling containers in terminals, depots, and outdoor storage areas, offering efficient and versatile solutions.

Rail-Mounted Gantry Cranes (RMGs):

Overview: RMGs are gantry cranes that travel along a rail system. They are typically used in container yards and intermodal facilities.

Features:

- RMGs are mounted on rails, providing precise and structured movement within the storage yard.

- They are known for their high stacking capabilities, allowing the vertical storage of containers.

- RMGs can handle multiple containers simultaneously, improving operational efficiency.

Applications: RMGs are well-suited for large container terminals and storage yards where a systematic and rail-guided approach to container handling is required.

These types of gantry cranes are chosen based on the specific needs and operational requirements of the outdoor storage facility. The selection depends on factors such as the layout of the storage yard, the volume of container traffic, and the need for flexibility in handling different container sizes and types.

Material Movement and Storage

Gantry cranes bring efficiency to the movement and storage of a wide range of materials in outdoor storage yards. From raw materials, such as steel and lumber, to finished products awaiting distribution, these cranes provide a reliable means of material handling.

For outdoor material handling and stroage, what are the difference and similarity of full gantry cranes and semi gantry cranes ?

Full gantry cranes, with their full-span structure, can cover large areas, optimizing the arrangement of materials for easy access and retrieval.Semi gantry cranes, with their unique design, are adept at navigating through uneven terrains, allowing for the strategic placement of materials in outdoor settings with varying topographies. Their precision in material movement contributes to organized storage and streamlined operations in outdoor storage yards.

Typical Application Conditions for Full Gantry Cranes:

- Large Outdoor Storage Yards:Full gantry cranes are preferred in vast outdoor storage yards where a complete standalone structure is feasible.

- High Lifting Capacity Requirements:Full gantry cranes excel in applications with heavy lifting requirements, making them suitable for handling large and dense objects.

- Flat and Even Terrains:The stationary nature of full gantry cranes is well-suited for flat and even terrains, ensuring stability during lifting and movement.

Complete Coverage of the Yard:

- In situations where the entire outdoor storage yard needs to be covered efficiently, full gantry cranes provide a stable and comprehensive solution.

- Typical Loads or Objects Preferably Handled by Full Gantry Cranes:

- Large containers, steel coils, machinery parts, heavy equipment, and other bulky or heavy objects where high lifting capacity and stability are crucial.

Typical Application Conditions for Semi Gantry Cranes:

- Uneven Terrains:Semi gantry cranes are preferred in outdoor storage yards with irregular or uneven terrains, where the supporting runway system aids in stability.

- Flexibility in Material Handling:Due to their design with one end supported and the other moving on wheels, semi gantry cranes offer flexibility in material handling, making them adaptable to different scenarios.

Cost-Effective Solutions:

- Semi gantry cranes are generally more cost-effective in terms of installation, making them suitable for applications with budget constraints.

Partial Coverage of the Yard:

- In situations where only certain areas of the outdoor storage yard need to be covered, semi gantry cranes provide a more mobile and economical solution.

- Typical Loads or Objects Preferably Handled by Semi Gantry Cranes:

- Containers, materials, or objects requiring flexibility in movement, and scenarios where a cost-effective and adaptable solution is preferred over high lifting capacity.

Differences and Similarities between Full and Semi Gantry Cranes for Outdoor Material Handling and Storage:

Support Structure:

- Full Gantry Crane:Structure: Full gantry cranes have a complete and standalone structure that spans the entire width of the outdoor storage yard.

- Semi Gantry Crane:Structure: Semi gantry cranes have one end supported by a fixed runway system, while the other end moves along the ground on wheels.

Mobility:

- Full Gantry Crane:Mobility: Full gantry cranes are typically stationary and do not move along the ground.

- Semi Gantry Crane:Mobility: Semi gantry cranes are mobile on the ground, allowing them to move along a rail or track system.

Terrain Adaptability:

- Full Gantry Crane:Terrain Limitation: Full gantry cranes are suitable for flat and even terrains due to their stationary nature.

- Semi Gantry Crane:Terrain Adaptability: Semi gantry cranes can adapt to uneven terrains as one end is supported while the other moves on wheels, providing flexibility.

Flexibility:

- Full Gantry Crane:Flexibility: Full gantry cranes may have limitations in terms of flexibility as they are stationary structures.

- Semi Gantry Crane:Flexibility: Semi gantry cranes offer greater flexibility in material handling due to their ability to move along the ground.

Cost and Installation:

Full Gantry Crane:

- Cost: Full gantry cranes may have a higher initial cost due to their complete structure.

- Installation: Installation of full gantry cranes can be more complex.

Semi Gantry Crane:

- Cost: Semi gantry cranes may be more cost-effective than full gantry cranes.

- Installation: Installation of semi gantry cranes is often more straightforward.

Material Handling Range:

- Full Gantry Crane:Handling Range: Full gantry cranes can cover a wider area in terms of material handling.

- Semi Gantry Crane:Handling Range: Semi gantry cranes are suitable for specific paths and areas due to their mobile nature.

Both types of gantry cranes ensure that materials are efficiently handled, reducing manual labor and minimizing the risk of damage during transportation and storage. Their role in enhancing material flow and organization makes them indispensable assets for the effective functioning of outdoor storage facilities.

While both full and semi gantry cranes contribute to outdoor material handling and storage, the choice between them depends on factors such as the terrain, required mobility, budget considerations, and the specific needs of the outdoor storage yard. Each type offers unique advantages, making them suitable for different applications and environments.

Speed and Precision

Operational speed and precision are paramount in the efficient functioning of outdoor storage logistics, and both full and semi gantry cranes are designed to excel in these aspects.

Full Gantry Cranes:

- Swift Movements: Full gantry cranes, with their full-span structure and powerful lifting capacity, facilitate swift movements across large outdoor storage yards. This agility is crucial for handling time-sensitive operations and optimizing logistics workflows.

- Precise Positioning: Equipped with advanced control systems, full gantry cranes ensure precise positioning of loads. This precision is particularly valuable when dealing with tightly packed storage areas or when specific placements are required.

Semi Gantry Cranes:

- Flexibility and Precision: Semi gantry cranes offer a balanced approach, providing flexibility in material handling along with precise positioning. Their ability to navigate irregular terrains allows for efficient load movement, contributing to the precision required in outdoor storage logistics.

- Adaptable Maneuverability: The design of semi gantry cranes focuses on enhancing maneuverability. This adaptability is beneficial when dealing with varying topographies, ensuring that materials can be moved with precision despite challenging outdoor conditions.

Minimizing Downtime

Reducing downtime is a critical factor in enhancing the overall efficiency of outdoor storage operations. Both types of gantry cranes come equipped with features to address this concern.

Full Gantry Cranes:

- Quick Load Handling: Full gantry cranes often feature mechanisms for quick load attachment and release. This accelerates the handling process, minimizing the time required for loading and unloading operations.

- Proactive Maintenance: Implementing proactive maintenance schedules and using easily replaceable components are common practices with full gantry cranes. This approach helps in reducing the risk of unexpected breakdowns, contributing to continuous operations.

Semi Gantry Cranes:

- Efficient Controls: Semi gantry cranes are designed with efficient controls that contribute to streamlined operations. The ease of control ensures that the crane functions smoothly, reducing the chances of operational interruptions.

- Adaptable Components: Similar to full gantry cranes, semi gantry cranes often incorporate easily replaceable components, simplifying maintenance tasks and minimizing the impact of potential downtime.

In summary, both full and semi gantry cranes are engineered to enhance speed, precision, and minimize downtime in outdoor storage logistics, making them valuable assets for efficient material handling in diverse environments.

Case Studies

Full Gantry Cranes:

Port Logistics Optimization: In the port of Novorossiysk, full gantry cranes have been instrumental in optimizing outdoor storage logistics. These cranes efficiently handle container movements, ensuring quick and precise placement in designated storage areas. This has significantly reduced turnaround times for vessels and enhanced overall port efficiency.

Steel Yard Efficiency: A steel manufacturing facility in Chelyabinsk utilizes full gantry cranes for handling and storing heavy steel coils in outdoor yards. The cranes' speed and precision have streamlined the material flow, contributing to a more organized and efficient steel storage process.

Semi Gantry Cranes:

Construction Materials Handling: In construction material yards in Moscow, semi gantry cranes have proven their adaptability to varying terrains. Their ability to navigate uneven surfaces has facilitated the efficient movement of construction materials, ensuring a steady supply to ongoing projects.

Lumber Yard Optimization: A lumber yard in Siberia employs semi gantry cranes for the storage and retrieval of lumber products. The cranes' flexibility in maneuvering around stacks of lumber has minimized handling time and reduced the risk of damage, leading to improved overall logistics efficiency.

Testimonials

Full Gantry Cranes:

Marina Petrova, Logistics Manager: "The deployment of full gantry cranes in our outdoor storage area has been a game-changer. The speed at which we can handle containers and materials has significantly improved, allowing us to meet tight schedules with ease."

Semi Gantry Cranes:

Dmitri Ivanov, Construction Site Supervisor: "Semi gantry cranes have proven invaluable in our construction material yard. Their ability to navigate through uneven terrain ensures that materials reach the right spot quickly, supporting our construction timelines."

These real-world examples and testimonials illustrate how both full and semi gantry cranes play a pivotal role in optimizing outdoor storage and logistics operations across various industries in Russia.The adaptability and efficiency of these cranes contribute to enhanced productivity and streamlined material handling processes.

Challenges and Solutions

Addressing Operational Challenges

Common Challenges in Outdoor Storage Operations:

- Variable Terrain: Outdoor storage yards often feature uneven terrain, presenting challenges for material handling equipment.

- Weather Conditions: Adverse weather conditions, such as rain or snow, can impact the efficiency and safety of outdoor operations.

- Diverse Loads: Handling diverse loads, including containers, construction materials, and heavy machinery, requires versatile solutions.

Solutions with Full and Semi Gantry Cranes:

- Adaptability to Terrain: Both full and semi gantry cranes are designed to navigate variable terrains. While full gantry cranes offer a full-span structure for stability, semi gantry cranes excel in flexibility, adapting to uneven surfaces.

- Weather-Resistant Features: Full gantry cranes can be equipped with weather-resistant coatings and protective measures, ensuring reliable operation in challenging weather conditions. Semi gantry cranes, with their ground-level mobility, offer easy maneuverability despite weather challenges.

- Versatility in Load Handling: Full and semi gantry cranes come with customizable lifting attachments, making them versatile for handling different types of loads. This adaptability ensures efficiency in handling diverse materials present in outdoor storage yards.

Maintenance Considerations

Key Aspects of Maintenance for Outdoor Storage Environments:

- Corrosion Protection: Outdoor exposure can lead to corrosion. Regular inspections and application of corrosion-resistant coatings are crucial for extending crane life.

- Weather Sealing: Ensuring effective weather sealing mechanisms helps prevent damage from exposure to rain, snow, or extreme temperatures.

- Control System Checks: Regular checks on control systems, including sensors and automation features, are essential for maintaining operational efficiency.

Maintenance Practices for Longevity:

- Scheduled Inspections: Implementing a routine inspection schedule to identify and address potential issues before they escalate.

- Proactive Repairs: Addressing minor repairs promptly to prevent them from developing into major breakdowns.

- Training Programs: Providing training to maintenance personnel for effective troubleshooting and timely intervention.

By addressing operational challenges and implementing robust maintenance practices, both full and semi gantry cranes can ensure reliable and efficient performance in outdoor storage environments. These measures contribute to the longevity of the equipment and sustained productivity in logistics operations.

Future Prospects

Technological Advancements

- Automation Integration: Future full and semi gantry cranes are likely to witness increased integration of automation technologies, enhancing operational efficiency and reducing the need for manual intervention.

- Advanced Control Systems: Anticipate the development of more advanced control systems, incorporating real-time data analytics and predictive maintenance features for proactive issue resolution.

- Improved Safety Features: Continuous advancements in safety technologies, such as collision avoidance systems and enhanced sensors, will be integrated into the design to ensure safer operations in outdoor storage environments.

- IoT Connectivity: Full and semi gantry cranes may become more connected through the Internet of Things (IoT), enabling seamless communication between different components and providing valuable data for performance optimization.

Anticipated Growth in Usage

- Increased Demand in E-commerce Logistics: With the growing prominence of e-commerce and online retail, the demand for efficient outdoor storage solutions, including full and semi gantry cranes, is expected to rise.

- Expansion in Construction and Infrastructure Projects: The construction sector's expansion and increasing infrastructure projects will drive the need for optimized outdoor storage, creating opportunities for the widespread use of gantry cranes.

- Integration in Smart Logistics Networks: Full and semi gantry cranes are likely to play a pivotal role in the development of smart logistics networks, contributing to the overall efficiency and sustainability of outdoor storage operations.

- Customization for Specific Industries: The adaptability of gantry cranes will lead to their increased adoption in specific industries like manufacturing, automotive, and energy, contributing to the diversification of their usage.

As technological advancements continue and industries evolve, the future holds promising growth and innovation for full and semi gantry cranes in optimizing outdoor storage and logistics operations in Russia.

Wrap it up

In the dynamic landscape of outdoor storage and logistics in Russia, full and semi gantry cranes stand as indispensable contributors, optimizing operations and enhancing efficiency. Their robust designs, diverse applications, and technological advancements have made them key players in the logistics chain, shaping the way materials are handled and stored in outdoor environments.

These cranes have proven instrumental in addressing the unique challenges posed by outdoor storage, offering solutions that elevate the speed, precision, and safety of logistics operations. Whether handling containers, moving heavy materials, or supporting construction projects, full and semi gantry cranes have left an indelible mark on the efficiency and effectiveness of outdoor storage yards.

Looking Ahead

As we look to the future, the role of full and semi gantry cranes is poised to expand even further. Anticipated technological advancements will usher in an era of smarter, more connected cranes, further enhancing their capabilities and contributing to the overall evolution of outdoor storage logistics. The continued growth of industries, particularly in e-commerce, construction, and smart logistics networks, is expected to fuel the demand for these cranes.

In conclusion, the journey of full and semi gantry cranes in Russia's outdoor storage and logistics sector is marked by innovation, efficiency, and a commitment to overcoming challenges. As they continue to evolve and adapt, these cranes will play a pivotal role in shaping the future of outdoor storage operations, setting new standards for logistics excellence in Russia. Click to learn more on Full Gantry Crane vs Semi Gantry Crane or leave us your inquiry downbelow.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch