Overhead Crane Sourcing : Made in Russia vs. Imported Cranes

What are the pros and cons of sourcing overhead cranes from local Russian manufacturers compared to importing cranes? Check & get most cost-effective solution for you.

Category: Russia

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Crane Sourcing : Made in Russia vs. Imported Cranes

Compare Advantages, Quality Considerations & Pricing Factors

What are the pros and cons of sourcing overhead cranes from local Russian manufacturers compared to importing cranes? Check & get most cost-effective solution for you.

Overhead Crane Sourcing Alternatives: Made in Russia vs. Imported Cranes

The decision to source overhead cranes, a pivotal component in various industrial operations, involves a careful consideration of multiple factors. Among the key considerations is whether to opt for cranes made in Russia or to explore the alternatives provided by imported cranes. This decision holds substantial implications for businesses, impacting aspects such as cost-effectiveness, quality standards, and the overall efficiency of industrial operations.

In this exploration of overhead crane sourcing alternatives, we will delve into the pros and cons of choosing between locally manufactured cranes in Russia and imported counterparts. This analysis aims to provide businesses with valuable insights to guide them in making informed decisions that align with their unique operational requirements and strategic objectives. We will scrutinize factors ranging from cost benefits and quality considerations to the diverse options offered by each sourcing alternative.

Join us on this journey as we navigate the landscape of overhead crane procurement, unraveling the complexities that businesses face when deciding between cranes made in Russia and those brought in from international markets.

Pros and Cons of Sourcing Overhead Cranes Locally (Made in Russia)

Benifits

- Cost Benefits - Choosing locally manufactured overhead cranes in Russia offers a range of cost benefits, primarily due to the elimination of extensive logistics and import-related expenses. The potential cost savings are significant, making it an attractive option for businesses looking to optimize their budget allocations. Reduced transportation costs and the absence of import fees contribute to the overall affordability of locally sourced cranes.

- Local Expertise - Access to local expertise is a distinctive advantage when opting for cranes made in Russia. Local manufacturers bring an in-depth understanding of the specific needs and nuances of the domestic market. This familiarity ensures that the procured cranes are tailored to meet industry-specific requirements and comply with local regulatory frameworks. The proximity to the market allows for a more responsive approach to customization, enhancing the adaptability of the cranes to the unique challenges posed by the Russian industrial landscape.

- Supporting Local Economy - Opting for locally sourced cranes contributes significantly to the growth of the local economy. By choosing products manufactured within the country, businesses actively participate in fostering economic development, job creation, and overall sustainability. Supporting local industries helps build a robust economic ecosystem, ensuring the vitality and resilience of the manufacturing sector.

In addition to these advantages, businesses need to carefully consider the potential challenges associated with sourcing overhead cranes locally in Russia, which will be explored in the following section.

Challenges

- Limited Variety -One significant challenge linked to sourcing overhead cranes locally in Russia revolves around the potential limitation in the variety of types and designs offered by local manufacturers. While domestic suppliers may excel in producing standard crane configurations, businesses seeking highly specialized or niche crane designs might encounter constraints. This limitation could result in a lack of flexibility in meeting diverse industrial demands, particularly when specific or unconventional crane configurations are required. In such cases, businesses may find a broader range of options through international suppliers that cater to a more extensive array of crane designs and functionalities.

Technology Innovation

Choosing locally manufactured cranes may pose challenges in accessing cutting-edge technologies. Local manufacturers, while proficient in meeting standard industry requirements, may face limitations in rapidly adopting the latest technological innovations. This could impact the technological sophistication of the procured cranes compared to their globally sourced counterparts. Businesses seeking state-of-the-art features, advanced automation, or specific technological integrations may find that international suppliers are more adept at incorporating the latest innovations into their crane designs. This challenge highlights the importance of considering the technological requirements of specific industrial applications when deciding on the sourcing strategy for overhead cranes in Russia.

Pros and Cons of Importing Overhead Cranes

Advantages

- Diverse Options - One of the prominent advantages of importing overhead cranes lies in the access to a diverse range of options. International markets offer a plethora of crane types, designs, and technological features, providing businesses with the flexibility to choose cranes that precisely meet their unique industrial requirements. The expansive variety ensures that businesses can find the most suitable crane configurations, even for highly specialized applications.

- Quality Standards - Importing overhead cranes introduces the potential advantage of adherence to international quality standards and certifications. Many renowned manufacturers from around the world comply with stringent quality control measures, ensuring that their products meet or exceed industry-specific standards. This commitment to quality provides businesses with the assurance that the imported cranes undergo rigorous testing and inspections, contributing to their reliability and longevity.

- Advanced Technologies - Choosing imported cranes offers businesses access to the latest technological innovations. International manufacturers often integrate cutting-edge technologies into their crane designs, providing advanced features such as automation, smart controls, and safety enhancements. This technological sophistication can significantly enhance the operational efficiency and safety of the overhead cranes, making them more adaptable to modern industrial demands.

In the subsequent sections, we will delve into the challenges associated with importing overhead cranes, offering a comprehensive view for businesses to make informed decisions based on their specific needs.

Challenges

- Import Costs - One of the primary challenges associated with importing overhead cranes is the presence of additional expenses related to the import process. Import costs encompass a range of expenditures, including shipping fees, customs duties, and taxes. These financial considerations can add a substantial amount to the overall procurement expenses, potentially impacting the cost-effectiveness of choosing imported cranes. Businesses need to carefully evaluate and budget for these additional costs to ensure a transparent and financially viable procurement process.

- Communication Barriers - Importing overhead cranes may introduce potential challenges in communication, particularly when dealing with international suppliers. Language differences, time zone variations, and cultural nuances can contribute to miscommunication or difficulties in understanding specific crane specifications. Effective communication is crucial for ensuring that the procured cranes meet the exact requirements of the business. Employing clear communication channels, possibly with the assistance of interpreters or translators, becomes essential to overcome these potential challenges.

- Service and Maintenance - Logistics challenges related to post-sale service and maintenance represent another consideration when opting for imported cranes. The physical distance between the business and the crane manufacturer may pose obstacles in providing timely and efficient service support. Ensuring a robust service and maintenance plan becomes imperative to address any operational issues promptly. Businesses must assess the capabilities of the international supplier to provide effective support and consider local service partners to mitigate potential challenges.

In the following chapter, we will conduct a comparative analysis, weighing the pros and cons of sourcing overhead cranes locally in Russia against the option of importing cranes from international markets. This analysis aims to guide businesses in making strategic decisions aligned with their operational needs and overarching objectives.

Quality Considerations

When it comes to sourcing overhead cranes, ensuring the highest quality is paramount for the seamless and safe operation of industrial processes. In this chapter, we will delve into the quality considerations associated with both locally manufactured cranes in Russia and imported alternatives.

Local Quality Standards

Exploring the quality standards adhered to by local manufacturers:

Local manufacturers in Russia adhere to a set of quality standards that align with national regulations. These standards are crafted to ensure that the produced overhead cranes meet the fundamental safety and performance requirements necessary for deployment in the domestic market. Exploring these local quality standards provides businesses with insights into the baseline expectations for the cranes, encompassing factors such as design, material quality, and safety features.

International Certifications

Assessing the certifications and quality control of imported cranes:

Imported cranes often come with international certifications and adhere to globally recognized quality control measures. Manufacturers from countries with robust industrial standards ensure that their cranes meet or exceed these standards. Certifications such as ISO, CE, or other industry-specific credentials serve as indicators of a crane's adherence to rigorous quality benchmarks. Assessing these certifications provides businesses with confidence in the quality and reliability of the imported cranes.

Industry-Specific Requirements

Considering how well each option meets industry-specific quality demands:

Different industries may have specific quality requirements based on the nature of their operations. Evaluating how well each sourcing option aligns with these industry-specific demands is crucial. Local manufacturers may have a nuanced understanding of domestic industry needs, ensuring that their cranes are tailored to meet these specific requirements. On the other hand, imported cranes with international certifications may bring a broader perspective and adherence to global best practices, potentially offering advantages in certain industries.

Pricing Factors

In the realm of overhead crane sourcing, a meticulous understanding of pricing factors is paramount for making judicious decisions. This chapter delves into the intricacies of pricing, offering a detailed analysis of the cost considerations associated with both locally manufactured cranes in Russia and their imported counterparts.

Cost Breakdown for Local Cranes

Analyzing the Factors Contributing to the Cost of Locally Manufactured Cranes:

When opting for locally manufactured cranes in Russia, a nuanced analysis of the cost breakdown becomes imperative. This involves a detailed examination of various contributing factors, such as raw materials, labor, manufacturing processes, and overheads. Unraveling the local cost structure provides businesses with insights into the components influencing the overall cost of domestically produced cranes.

Total Cost of Ownership for Imports

Evaluating the Total Cost of Ownership, Considering Import-Related Expenses:

The decision to import overhead cranes introduces a unique set of expenses that significantly contribute to the total cost of ownership. Beyond the initial purchase price, businesses need to consider additional factors, including shipping costs, customs duties, taxes, and any other logistics expenses. A comprehensive evaluation of the total cost of ownership provides a holistic perspective, allowing businesses to make informed decisions based on a thorough understanding of the financial implications associated with choosing imported cranes.

Case Studies and Success Stories

Real-life case studies serve as invaluable resources for businesses contemplating overhead crane sourcing strategies. This chapter presents a collection of case studies featuring businesses in Russia that have made decisions to either procure locally manufactured cranes or import cranes from other countries. The goal is to provide readers with tangible examples, shedding light on the experiences, challenges, and outcomes of these businesses.

Local Crane Procurement

Background

A manufacturing company in Russia decided to opt for locally manufactured cranes to align with their commitment to supporting the domestic economy and leveraging local expertise.

Challenges Faced

- Limited variety in crane types and designs.

- Potential delays in delivery due to fluctuations in local demand.

Outcomes

- Cost savings attributed to reduced transportation and import fees.

- Seamless integration with local industry standards and regulations.

- Contributed to the growth of the local economy.

Imported Crane Solution

Background

An aerospace company in Russia chose to import cranes to access advanced technological features and a diverse range of crane types.

Challenges Faced

- Higher initial investment due to import-related expenses.

- Communication challenges during the procurement process.

Outcomes

- Access to cutting-edge technologies not readily available locally.

- Enhanced operational efficiency and adaptability.

- Expanded options for meeting specific industry demands.

Hybrid Approach

Background

A construction company in Russia adopted a hybrid approach, sourcing certain crane components locally while importing specialized parts.

Challenges Faced

- Coordination challenges in aligning locally sourced and imported components.

- Ensuring compliance with both local and international standards.

Outcomes

- Customization options while benefiting from local cost advantages.

- Overcame challenges through strategic planning and collaboration.

These case studies provide a glimpse into the diverse experiences of businesses in Russia, showcasing how their decisions regarding crane sourcing strategies impacted their operations. The nuanced nature of each case study illustrates that there is no one-size-fits-all solution, emphasizing the importance of considering unique industry needs and organizational goals when making such strategic decisions.

In the subsequent sections, we will distill insights from these case studies, offering readers a deeper understanding of the practical implications associated with choosing between locally manufactured and imported cranes.

Making an Informed Decision

In the process of selecting the optimal sourcing strategy for overhead cranes, businesses face a complex decision-making landscape. This chapter aims to provide a comprehensive decision-making framework, equipping businesses with the guidance needed to navigate the intricacies of choosing between locally manufactured cranes in Russia and their imported counterparts.

Key Considerations in Decision-Making

Industry Needs

Understanding the specific needs of the industry is a foundational consideration. Local manufacturers in Russia may have a nuanced understanding of domestic industry requirements, offering cranes tailored to meet these specific demands. On the other hand, imported cranes with international certifications may bring a broader perspective, potentially offering advantages in certain industries. Evaluating how well each sourcing option aligns with the unique needs of the industry is pivotal.

Budget Constraints

An assessment of budget constraints is crucial for aligning the procurement strategy with financial goals. Local cranes may offer potential cost savings due to reduced transportation and import fees, making them more budget-friendly in certain scenarios. Conversely, imported cranes come with additional expenses related to shipping, customs duties, and taxes. A thorough analysis of the budget constraints enables businesses to make decisions that balance financial considerations with long-term value.

Long-Term Considerations

Considering the long-term implications of the decision is paramount. The total cost of ownership for imported cranes, factoring in import-related expenses, provides insight into the financial commitment over the crane's lifespan. Local cranes, with potential advantages in terms of local expertise and cost benefits, also require an evaluation of their long-term reliability and adaptability to evolving industry needs. Balancing short-term cost considerations with the potential long-term benefits is essential for a well-informed decision.

Decision-Making Framework

Step 1: Industry Analysis

- Evaluate the specific requirements and standards of the industry in which the overhead crane will operate.

- Consider whether locally manufactured cranes or imported cranes are better suited to meet these industry-specific demands.

Step 2: Budget Assessment

- Analyze budget constraints and determine the financial feasibility of each sourcing option.

- Consider the initial purchase price, as well as additional expenses associated with each option.

Step 3: Long-Term Viability

- Assess the long-term viability of each sourcing option in terms of reliability, adaptability, and potential for future industry changes.

- Consider the total cost of ownership and factor in maintenance and service requirements.

Step 4: Comparative Analysis

- Conduct a comparative analysis, weighing the advantages and challenges of both locally manufactured and imported cranes.

- Prioritize factors based on their significance to the specific needs and goals of the business.

Step 5: Informed Decision

- Synthesize the insights gained from the analysis to make an informed decision that aligns with the industry needs, budget constraints, and long-term considerations.

In the concluding sections, we will summarize the decision-making framework and offer additional insights to support businesses in making a strategic and well-informed choice for their overhead crane sourcing strategy.

Conclusion

In this comprehensive exploration of overhead crane sourcing alternatives, we delved into the intricate decision-making processes involved in choosing between locally manufactured cranes in Russia and their imported counterparts. As we conclude, let's recap the key points discussed and offer some parting insights for businesses navigating this crucial decision.

Recap of Key Points

Pros and Cons of Local Sourcing

Advantages:

- Potential cost savings due to reduced transportation and import fees.

- Access to local expertise and understanding of specific industry needs.

- Contribution to the growth of the local economy.

Challenges:

- Limited variety in crane types and designs.

- Potential limitations in adopting cutting-edge technologies.

Pros and Cons of Importing Cranes

Advantages:

- Access to a diverse range of crane types, designs, and technological features.

- Potential adherence to international quality standards and certifications.

- Availability of the latest technological innovations.

Challenges:

- Additional expenses related to shipping, customs duties, and taxes.

- Potential challenges in communication and understanding specifications.

Decision-Making Framework

- Analyzing industry needs, budget constraints, and long-term viability is crucial.

- A comparative analysis of advantages and challenges helps in making informed decisions.

- A step-by-step decision-making framework assists businesses in aligning their choices with their operational needs and industry requirements.

Pricing Factors

- A detailed breakdown of costs for locally manufactured and imported cranes provides insights.

- Evaluating the total cost of ownership for imports includes import-related expenses.

As businesses navigate the complexities of overhead crane sourcing, it is crucial to recognize that there is no one-size-fits-all solution. Each decision comes with its unique set of advantages and challenges, and the best choice depends on the specific needs, budget constraints, and long-term goals of the business.

We encourage businesses to approach the decision-making process with a holistic understanding of their industry, operational requirements, and financial considerations. By carefully weighing the pros and cons, businesses can make strategic decisions that not only meet their immediate needs but also contribute to their long-term success.

In the realm of overhead crane sourcing, informed decisions are the key to unlocking operational efficiency, ensuring safety, and maximizing the value derived from these essential industrial assets.

Main Projects

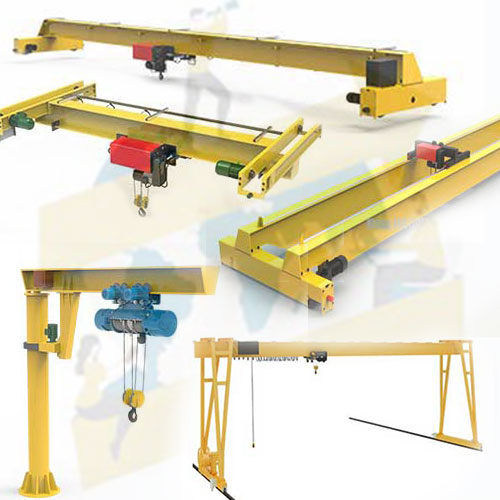

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch