Your Trusted Overhead Travelling Crane Manufacturer & Supplier

15 ton Overhead Cranes for Sale, Different Designs & Good Price

All You Want to Know About 15 Ton Bridge Crane

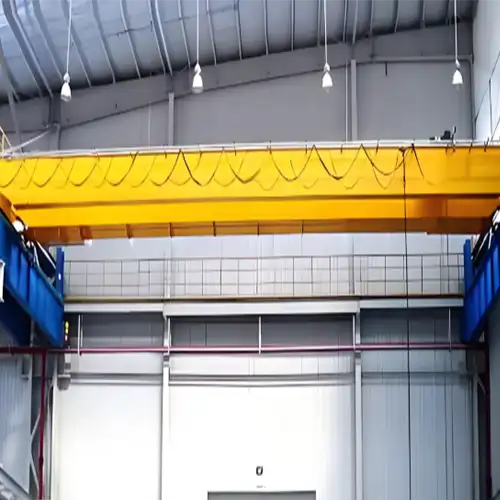

15 ton overhead crane for sale, good price. Main types of 15 ton bridge crane designs, specifications & uses & installation for you to get cost-effective 15 ton crane. A 15 ton overhead crane or bridge crane is used for light duty lifting. It has a light and compact design, high efficiency, and good performance. They are widely used for handlingmaterials in warehouses, workshops, garages, assembly plants, and other locations.

The bridge crane, as a material handling equipment, can be used for material lifting and transportation in a variety of industries. To ensure high-quality and safe work, our overheadcrane employs reliable motors and accessories. As a professional crane manufacturer in China with 30 years of experience we have designed types of overhead cranes with capacity from 1 ton to 550 ton. And the standard lifting capacity of overhead cranes are as following: 5 ton, 10 ton, 16 ton/3.2ton, 20 ton /5 ton, 32ton /5ton, 50 ton/10ton, 75ton/20ton, 100ton/20ton, 125ton/32ton, 150ton /30ton, 160ton/32ton, 200ton/50ton, 250ton/50ton, 300ton/75ton, 350ton/80ton, 400ton/80ton, 450ton /100ton, 500ton /100ton, 550ton /100T,etc.

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Main Types of Overhead Crane Types, Specifications & Features

Overhead Crane Overview

- Hot sale types: 1-5 ton, 10 ton, 20 ton, 25 ton, 32 ton, 50 ton, 74 ton,100 ton

- Top runing & under running, single girder & double girder, box girder & I beam

- Application: Efficienty transferring heavy loads in factory, warehouses,workshops, processing plants, shipyards, etc.

- 1-32 ton, Span : 7.5 -31.5 m

- Single Girder- Economical for ligher Applications

- Capacity: 1-32 ton, Span : 7.5 -31.5 m

- Double Girder- Box Girder Higher Capacity

- Capacity: 1-32 ton, Span : 7.5 -31.5 m

- Top Running -Maximize Lifting Height &Capacity

- Capacity: 1-32 ton, Span : 7.5 -31.5 m

- Under Running - No Need of Crane Columns

- Capacity: 500kg -550 ton, Span : 7.5 -31.5 m

- Wide Application, Various Configurations

- Capacity: 1 ton-75 ton, Span : 7.5 -31.5 m

- Explosion Proof, Enhanced Safety Crane

- Capacity: 1-20 ton, Span : 7.5 -34.5 m

- Bulk Material Handling, Types of Grab Buckets

- Capacity: 1-35 ton, Span : 7.5 -31.5 m

- Tailored Magnetic Chuck & Beam Spreader

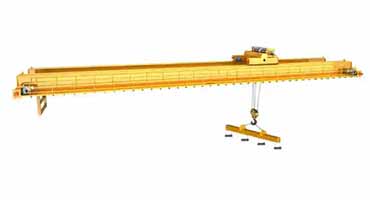

Hot Sale 15 ton overhead crane designs

The 15 ton overhead crane we provide can be single or double beam, depending on the customer's needs, and can be used for lifting or lowering. All of these types of overheadcranes 15 tons can be customized to meet specific needs.

Main girder design of overhead crane with 15 ton capacity

What exactly is a crane girder? A crane girder is a prefabricated metal beam that supports the crab or hoist head of a traveling overhead crane. These girders are typically "I" profile beams that can be reinforced at different points depending on the loads and crane configuration.

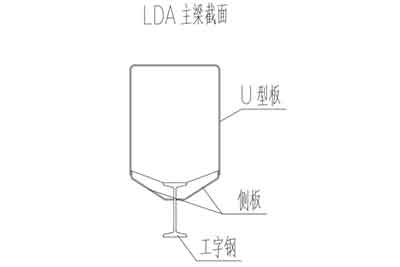

U shape girder with I beam - 15 ton overhead crane girder design option

This type of crane girder is frequently used in China, for single girder crane design, with the cd/md electric hoist suspended on the lower flange of crane girder. If you 15 ton overhead crane with this type of girder design is very economical and it is suitable for application with enough space.

- Economical overhead crane from China, with u shaped girder + I beam

- Single girder overhead crane with cd/md wire rope hoist

U shaped girder with i beam girder design drawing

ld single beam overhead crane girder production

single girder top running overhead crane girder cuting for easy transportation

Main girder after painting

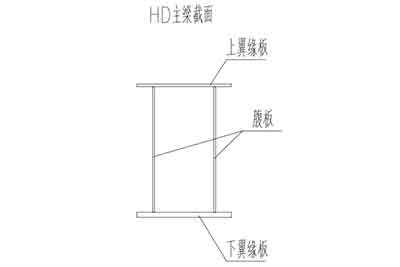

Box girder - overhead crane 15 design option

Box girder overhead crane is typical used box shaped or box constructed bridge girder, which are featured with low profile and reliable.

- Advanced overhead crane with European style, with box structured main girder

- Single girder overhead crane, equipped with low headroom wire rope hoist

Box girder overhead crane drawing - 15 ton overhead crane design option

Top runing single girder box girder crane under construction

box girder single beam top running crane girder finished

Double beam box girder overhead crane

End carriages or end trucks for single girder and double girder overhead cranes

Crane end carriages, also known as crane end trucks, are the driving components for overhead traveling cranes that move on rails and can be directly connected to crane bridge girders. To meet your requirements for top running crane end trucks and underhung crane end trucks, we have developed crane end carriages in a variety of designs with high flexibility and operating reliability.

Top running overhead crane main girder and end carriage connection

single girder top running overhead crane end carriage

Double beam overhead crane main girder and end carriage assembly

End carriage for double beam bridge crane with top running design

Connection Of Main Beam And End Beam

We can modify the overheadcrane's main beam and end beam connection mechanism to fit the various industrial installation requirements of our customers. We will use the HD single girder bridge crane as an example and briefly go over the installation process as well as the main beam and end beam's schematic diagram so that you can grasp it more easily.

connection of main girder and end carriages

connection of main girder and end carriages

- Method 1 is appropriate for factory building conditions with a high height from the track surface to the lowest point of the factory building, and can achieve a higher lifting height;

- Method 2 is appropriate for plant conditions with a relatively high height from the track surface to the lowest point of the plant, and can achieve a relatively higher lifting height. It can pass through the ribs at the root of the roof beam more easily.

- Method 3: appropriate for plant conditions with a low height from the track surface to the lowest point of the plant. However, as the main beam sinks, the lifting height will fall accordingly.

- Method 4: suitable for factory building conditions with a low height from the track surface to the factory building's lowest point. The main beam is tapped to the upper part to increase the lifting height.

- Method 5: appropriate for plant conditions with a low height from the track surface to the lowest point of the plant building and a lower overall roof beam. The lower part of the main girder is tapped, the upper part of the main girder is flush with the end girder, and the lifting height decreases as the main girder sinks.

Lifting system of 15 ton overhead hoists and hoist trolley

FEM standard low headroom hoist overhead crane 15 ton

Low profile hoist bridge crane 15 ton

Double girder chain hoist trolley crane

Double girder electric rope hoist trolley crane

Double girder european hoist trolley crane

15 ton open winch overhead bridge crane

15 Ton Overhead Crane Power Requirements

Crane electronic control equipment's transmission control scheme

The crane electronic control equipment should use a well-established and approved software for the transmission control scheme. The user and the manufacturer must come to a particular arrangement beforehand or ask for a supplementary plan if there are plans that do not adequately address actual demands and alternative plans suggested by the user are necessary.

Crane control options for 15 ton overhead cranes

By using a pendant control that hangs from the hoist or a separate festoon track, the hoist and crane operator can manage the crane and the load as it moves down the runway .

Remote control for overhead crane 15 ton

The transmitter and receiver are the two parts of the crane remote control, which make remote control of the overhead crane possible.

Crane cabin also called crane operator's cab is an important crane component of overhead travelling cranes and gantry cranes to secure crane operation in the various application even in the harsh applications.

Advanced VFD crane & hoist control,Advanced Crane & Hoist system to ensure greater speed adjustments precise load position, longer hoist life. Check now.

15 Ton Bridge Crane Dimensions

The 15 ton overhead crans provided can be designed with different designs and configurations.The low headroom design of the 15 ton bridge crane reduces the cost of erecting your workstation. This 15 ton heavy duty crane includes clever structural design elements and convenient installation features for your workstations. The working class range for the overhead crane 15 ton kit is from A4 to A8, depending on your personal preferences for the crane's operating environment. Click to check more on overhead crane specifications.

Overhead Bridge crane | Capacity | Span | Height | Coverage Area Type | Coverage Area | Motorization | ||||||

Single Girder Overhead Crane | 15 ton | 7.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Double Girder Electric Hoist Crane | 15 ton | 7.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Double Girder Overhead Crane with Open Winch | 15 ton | 7.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Ceiling-mounted Workstation Bridge Crane | 15 ton | 7.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Single Girder Low Headroom Overhead Crane | 15 ton | 7.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Single Girder FEM Stanndard Overhead Crane | 15 ton | 6m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Double Girder European Style Overhead Crane | 15 ton | 6m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Single Girder Explosion-proof Overhead Crane | 15 ton | 7.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Double Girder Explosion-proof Overhead Crane | 15 ton | 7.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Grab Overhead Crane | 15 ton | 10.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Electromagnetic Overhead Crane | 15 ton | 10.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Insulation Overhead Crane | 15 ton | 10.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Double Trolley Overhead Crane | 15 ton | 10.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Ladle Overhead Crane | 15 ton | 10.5m ~ 31.5m | customize | Square/Rectangle | 31.5m x Unlimited Length | Yes | ||||||

Applications of 15 ton overhead cranes

- The 15-ton overhead crane is suitable for working environments ranging from -25°C to +40°C, and the power supply is a three-phase alternating current 380V, 50HZ (can be customized according to the requirements of the use environment).

- Overhead cranes are widely used for material handling in the vast industrial sectors to improve efficiency and safety. The industrial overhead crane 15 ton can be used in the applications listed below:

- Foundries , Steel Mills ,Chemical Processing Industries ,Paper Mills ,Cement Plants ,Plastic Processing Industries ,Steel Godowns ,Machining Workshops ,Fabrication Workshops ,Assembly Workshops , etc.

- Overhead cranes are also commonly used when precise material handling such as, mold handling and installation and assembly of large parts and other loads are required, etc.

Delivery and Installation of overhead cranes

As for the package and delivery of 15 ton overhead crane, it can be classed into two parts, the main girder and parts. The color band cloth are used to pack the main beam and end beam, which is waterproof. For other small parts and electrical devices, the wooden box or cases are used to ensure safety and easy installation at working site. . Fast delivery is guaranteed under normal conditions , and our hoists and cranes always reach their destination on time.

If a crane's main girder is longer than 11 meters, we will cut it into 2-3 pieces to fit the container. In general, ourprofessional engineer provides the cut program, and we connect the cutting point with flange and high-strength bolts.

- Installation preparation: go through the construction approval procedures; prepare the installation plan; review installation personnel qualifications; technical disclosure; prepare installation machinery; site layout; review machine documents; inventory of parts.

- Acceptance of equipment and materials.

- Fundamental acceptance.

- Track installation and crane gear installation.

- The crane's operating mechanism and the main beam assembly.

- Bridge construction.

- Setup of the trolley and main beam electrical system.

- Setup of the driver's cab.

- Installation of electrical components.

- Installation of safety devices.

- The no-load test.

- Static load test 12.

- Acceptance and dynamic load testing.

Crane projects of 15 ton single girder overhead crane installed

As a bridge overhead crane manufacturer with more than 30 year experiences in bridge crane design and manufacture, we have provided standard overhead crane and customized industrial overhead bridge crane with capacity of 3 ton, 5 ton, 10 ton, 15 ton, 20 ton, 25 ton, 35 ton, 40 ton up to 100 ton and above for sale around word, such as, South Africa, Canada, Australia, Singapore, United States, United Kingdom, Philippines, India, Indonesia, Italy, Russia, Vietnam, Brazil,and other countries and area, etc. In the following, the 15 ton overhead crane projects are for your reference.

Basics of 15 ton grab overhead crane for sale Dominica

- Crane Type:15 ton overhead travelling cranes

- Date of Placing Oder:2018.05.22

- Date of Delivery :2018.6.17

- Way of Transportation: 40 GP,

- Way of Payment:100% LC

- Destination country: Dominica

- First Contact:2017.7.11

Basics of single girder eot crane for Sale Trinidad and Tobago

- Crane Type:Single Girder Overhead Crane

- Date of Placing Oder: 2017-2-28

- Date of Delivery : 2017-03-10

- Way of Transportation: 2*40 GP,By Sea

- Way of Payment: LC 100%

- Destination country: Trinidad and Tobago

- Destination port:CIF Point Lisas

- First Contact:2016.10

Basics of 40 ton / 15 ton double hoist overhead crane for sale Uzbekistan

- Crane Type:double hoist overhead crane

- Date of Placing Oder:2018.6.11

- Date of Delivery :2018.7.15

- Way of Transportation: Railway transportation, 40GP*2,

- Way of Payment:30% TT

- Destination country: Uzbekistan

- Destination port:CIP Tashkent

- First Contact:2015.6

Basics of 15 ton electric overhead crane for sale Pakistan

- Crane Type:Electric overhead travelling crane

- Date of Placing Oder:2018.5.29

- Date of Delivery :2018.6.29

- Way of Transportation:Truck transportation

- Way of Payment:T/T 50%

- Destination country: Pakistan

- Place of delivery: Kashgar,Xinjiang, China

- First Contact:2017.4

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Custom Overhead Crane Design & Manufacture for You

What are the benefits of selecting us as your overhead crane supplier? Our company is one of China's leading overhead crane manufacturers. When compared to other overhead crane suppliers, we have numerous advantages. Do you have any questions about our 15-ton overhead crane or us? Contact us to begin a long-term, win-win partnership.

- To begin with, our crane price is reasonable and competitive.

- We offer factory overhead crane prices because we have our own factories, and we also have very convenient transportation. As a result, we can guarantee a favorable and timely delivery.

- Third, we provide a complete bridgecrane service. We can provide a one-stop shop for clients all over the world.

How to get your customized 15 ton bridge crane?

Overhead cranes are typically customized pieces of liftingequipment. Typically, we will have extensive communication with customers to confirm certain details. Once you've determined what you require, we'll be able to provide custom overhead crane system. The following information are needed for crane price quotationduring the communication process:

- What is the size of your facility, workshop or warehouse or workstation?

- What is the overhead crane's span needed?

- What is your runway's length?

- Is it going to be installed or usedinside or outside?

- How many times will you lift per hour?

- What is the weight of the loads it will be used for handle usually?

If the 15 ton overhead crane or bridge crane is not the crane you need, we also provide 15 ton gantry crane and 15 ton jib cranes for your selection. Besides, the custom 15 ton crane are available, based on your lifting requirements and application conditions. Contact us now.

What is the 5 ton overhead crane price ?

The cost of a 15 ton bridge crane is affected by both internal and external factors. Overhead crane types and lifting capacities are the most influential factors.

- The price difference between single and double girder crane is significant. Because a single girder crane requires less material and takes less time to fabricate, its cost is lower than that of a double girder crane.Double girder bridge cranecan withstand greater work intensity.Contact ouroverhead crane specialist to confirm weather single girder or double girder is suitable for your application.

- Secondly, the crane price of large capacity crane is usually higher thanlower capacity crane. The light duty overhead crane is cheaper than heavy duty crane. The cost of a 15 ton bridge crane is lower than that of a 50-ton overhead crane.

- Furthermore, there are numerous other factors to consider, such as lifting height, span length, transportation cost, and so on. Please contact us with your specific needs, and we will provide you with a free quote. Contact us to get accurate 15 ton overhead crane price based on your particular crane design and configurations .

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Featured 15 ton Crane Design & Bridge Crane Projects

Coming soon!