European double girder FEM/ DIN standard wire rope hoist crane

Advanced double girder overhead crane based on European DIN/FEM Standard with 5 ton-80 ton electric wire rope hoist trolley for hoisting industrial materials - European advanced wire rope hoist cranes!

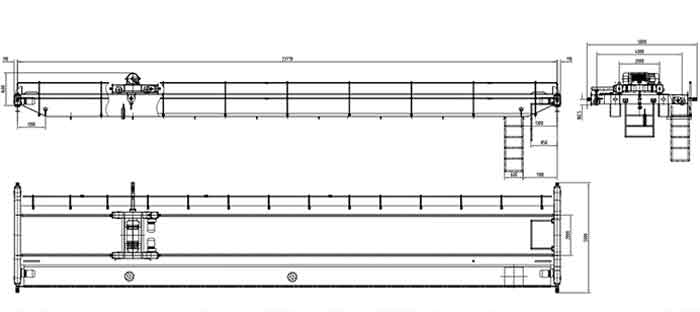

| Crane Type | Double girder hoist crane European style |

| Crane Capacity | 5-80 ton |

| Crane Span | 10.5-31.5m |

| Working Class: | A5 |

Category: Overhead Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

European Double Girder FEM/ DIN Standard Wire Rope Hoist Crane

5 Ton -80 Ton Double Girder Overhead Cranes

NLH type of overhead wire rope hoist trolley crane is an double girder overhead crane designed and processed in accordance with the European FEM / Din standards, equipped with FEM / DIN electric wire rope hoist trolley as the hoisting mechanism, widely used for general material handling in various industrial applications. Comparing with the Chinese conventional double girder bridge cranes , the European overhead cranes has the features of compact structure, low headroom and delicate appearance. With advanced technology and design concept, the NLH type of European standard overhead wire rope hoist crane is the advanced crane solution for various material handling occasion with high-level efficiency and reliability.

Main Parameters of DIN/ FEM Overhead Wire Rope Hoist Crane

The European standard wire rope hoist cranes is an advanced double girder overhead crane, designed on the base of European DIN/FEM Standard, with 5 ton-80 ton FEM electric wire rope hoist trolley for industrial materials hoisting. The European advanced wire rope hoist cranes, your desired wire rope hoist crane solution! Main parameters of DIN/ FEM wire rope hoist trolley double girder overhead crane are for your reference. Customized double girder wire rope hoist crane with your specific parameters are available. Please feel free to contact us by leaving a message below.

Double Girder Wire Rope Hoist Trolley Overhead Crane

- Overhead crane type: NLH European double girder crane with wire rope hoist trolley

- Load capacity of wire rope hoist crane : 5-80t

- Span of wire rope hoist crane : 10.5-31.5m

- Lifting height of wire rope hoist crane : 6-18m

- Work duty of wire rope hoist crane : A5

- Lifting speed: 0.4-5m/min

- Trolley running speed: 2-20m/min

- Crane running speed: 3-30m/min

Structure & Components of European Style Low Headroom Overhead Crane Double Girder

The NLH double girder wire rope hoist trolley overhead crane has all the advantages of the HD single girder wire rope hoist overhead crane. However, the double girder hoist trolley crane has the hoist trolley running over and between the two main beam girders, which makes the double girder hoist crane has a greater lifting capacity and higher hoisting height with more stability than that of a single girder rope hoist overhead crane.

The whole technical level of NLH European overhead crane reaches to the advanced leading level in international and domestic crane market. The professional designed crane structure of European overhead crane is optimized with strength, rigidity and stability, which is designed by taking into consideration of the convenience and possibilities of working environment, production, inspection, transportation, installation and maintenance.

There are a few main components constituting European overhead crane, including main beam girders, end beam/ end carriage, wire rope hoist trolley, crane running mechanism, electrical device and crane control system, etc. More crane parts and components.

Optimized european style girder design

Delicate cutting with high precision ,

Automatic welding, non-destructive testing, Epoxy zinc-rich pain, with 10+ years life

Intelligent wire rope hoists - Electric wire wire rope hoist crane parts

Smart driving, higher Efficiency

Step-less control trolley

Rotation lifting limit switch, 4 steps adjustable is possible.

Intelligent control - double girder rope hoist parts

Intelligent safety system

Ethernet/4G remote access

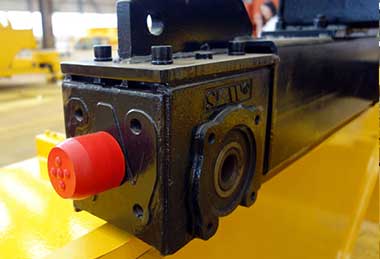

Moudular end carriage- overhead travelling wire rope hoist crane

Light weight, small size

Module joint designing

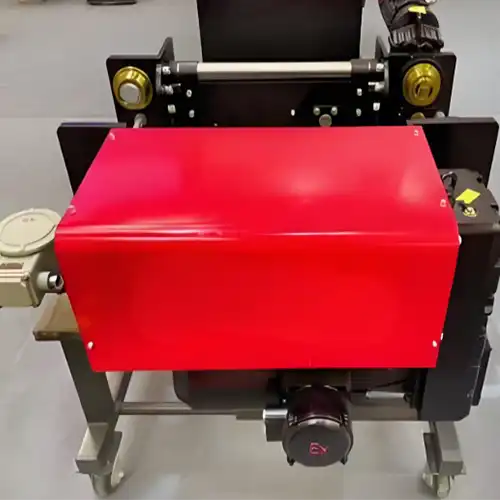

Hoist motor -electric wire rope hoist crane parts

Double speed or variable frequency, Protection class IP 55, Silent design , semi-grease lubrication, good sealing, no oil

Crane trolley wheel & buffer brake

Crane wheel is customized for you, reliable and long lasting, Crane buffer to ensure safety and preventing collision

Drum and wire rope - Double girder rope hoist crane parts

Large rope drum diameter,

Compact hoist dimensions,

minimized hook approaches .

Festoon cable - power supply system of double beam electric hoist crane

Flat cable with good elasticity,

Easy use air socket plug-in connection,, Maintenance-free, long life

European Standard Wire Rope Hoist Trolley

The ND type of electric wire rope hoist trolley installed on the NLH European overhead crane is also designed based on the FEM / DIN standard.The standard traveling speed of crane is 3-30m/min, standard traveling speed of trolley is 2-20m/min. As for lifting speed, frequency control makes it has optional speed besides the standard speed to meet customers different requirement.

European Electric Wire Rope Hoist

- Lifting Capacity: 1ton, 1 ton 2.5 ton, 3.2 ton, 6.3 ton, 8 ton, 10 ton, 12.5 ton up to 80 ton

- Lifting Height: 6m to 12m

- Lifting Speed: 0.66/4—1.6/10m/min

- Working Class: M5, M6

- Ambient Temperature: -20℃ to 40℃

European electric hoist and custom FEM wire rope hoist are available.

- Capacity of European crane winch :10 ton - 500 ton

- Lifting height of European crane winch: As your request

- Working Duty of European crane winch :M5

- Crane traveling of European crane winch:3-30 m/min

- Process crane winch are available for your particular industrial needs and applications.

Key Features, Advantages, and Design Variations

With advanced crane design and European technology imported, the FEM/ DIN standard double girder bridge crane is born with the the features and advantages as following:

- Compact & light weight structure. 0ptimized structure design of European overhead crane is compact and light weighted with stability.

- Save cost on workshop construction. The compact structure and small wheel load pressure can reduce investment on the construction of steel structure workshop and lower cost on lighting and heating.

- Strong and safe electric hoist cranes. The strong steel structure of the European overhead crane and Advanced FME hoists offers safe and efficient lift with capacity up to 80 tons.

- Ensure safety in various application. With featured parts and components or devices, such as explosion proof hoist or flame proof motor and electric components, the European overhead cranes can be used in hazardous environments ensure safer operation and personnel.

- More productivity with less down time. Easy use operation makes the operation of overhead crane simple and fast with more accuracy and safety, with will increase your productivity.

- Easy maintenance, less trouble. Easy access design and service-friendly technology makes maintenance easy and reduce your downtime and ensure your continuations working.

- Customized configuration, Optimal solution for you. Customized configurations for the European standard wire rope hoist cranes are available for your special requirements.

Customized Design Options for Specific Applications

European-style overhead cranes offer a high degree of customization to meet the unique needs of various industries. Whether it's selecting the right hoisting system, adjusting hook configurations, or choosing lifting capacities, these cranes can be tailored for a wide range of applications.

- Hoisting Systems: European cranes can be equipped with different hoisting systems, such as wire rope hoists or chain hoists, depending on the weight and type of load being handled. This flexibility allows for precise control over lifting operations, which is critical when lifting items of various shapes, sizes, or weights.

- Hook Configurations: Depending on the application, cranes can be configured with single or double hooks, or even with specialized auxiliary hooks for complex lifts. The use of dual hooks or split load systems helps distribute weight more evenly, which is particularly useful for lifting long, heavy, or awkwardly shaped materials.

- Lifting Capacities: European-style cranes can be designed to handle a broad spectrum of lifting capacities, ranging from light-duty to heavy-duty applications. Whether it's moving small components in a light industrial setting or handling massive machinery in a steel mill or shipyard, the crane's design can be optimized for the required capacity, ensuring efficiency and safety.

These customization options make European-style overhead cranes an ideal choice for industries such as automotive manufacturing, steel production, aerospace, and more, where specific lifting needs must be met with precision.

High Precision and Smooth Operation for Complex Loads

One of the defining characteristics of European-style overhead cranes is their precision and smooth operation, which are critical when lifting complex or delicate loads. High-precision hoists, often equipped with advanced control systems, allow operators to handle sensitive materials or components with minimal movement and vibration.

- Delicate Equipment Handling: For industries like aerospace or electronics manufacturing, where precision is paramount, these cranes allow for the safe and smooth handling of delicate parts, such as aircraft components or high-tech machinery, without risking damage during lifting.

- Machinery and Heavy Equipment: In applications that require lifting large or cumbersome machinery, the ability to precisely control lifting speeds and positions ensures that equipment is moved safely, avoiding the risk of tipping or shifting during transit.

- Complex Loads: European cranes, with their advanced control systems, are designed to lift complex loads, whether it's irregularly shaped materials or extremely heavy items. The ability to control the motion of the crane precisely reduces the risk of accidents and improves the overall efficiency of operations.

The combination of high-precision lifting and smooth operation ensures that European-style overhead cranes are not only suitable for standard lifting tasks but are also capable of handling more intricate, specialized lifting requirements.

Energy-Efficient Operation

Energy efficiency is a key benefit of European-style overhead cranes. These cranes are designed with the latest energy-saving technologies to reduce operational costs and environmental impact.

- Optimized Power Consumption: European cranes use advanced motors and drives that adjust the speed and power required for lifting tasks. By using energy only when necessary, the crane minimizes energy wastage during idle times and lifts, lowering electricity consumption and improving overall efficiency.

- Regenerative Braking Systems: Some European crane models are equipped with regenerative braking systems that recapture energy during braking and feed it back into the system, further reducing energy use. This feature helps to lower the total cost of ownership and contributes to more sustainable operations.

- Reduced Wear and Tear: The smooth and precise operation of European cranes also leads to reduced wear and tear on components, extending the crane's service life and reducing the need for maintenance, which can be both costly and resource-intensive.

For industries looking to reduce energy costs and minimize their environmental footprint, European-style overhead cranes offer a practical solution with long-term benefits for both the bottom line and sustainability efforts.

Safety Features and Compliance with EU Standards

European-style overhead cranes are built with safety as a top priority, ensuring that they meet or exceed the highest international standards. These cranes are designed with a variety of safety features that help prevent accidents and ensure safe operation in challenging environments.

- Compliance with EN 15011: European cranes comply with EN 15011, the European standard for overhead cranes, which outlines safety requirements for design, manufacturing, and testing. This standard ensures that cranes are built with proper safety mechanisms, such as load limiters, emergency stop buttons, and overload protection systems.

- Advanced Safety Features: Many European-style cranes are equipped with advanced safety features, such as anti-sway systems, which prevent load instability, and automatic overload protection, which helps prevent accidents when lifting heavy loads. Other features may include sensors to detect faults or abnormalities, ensuring that the crane operates within its designed limits.

- Operator Safety: Cranes are designed with ergonomic considerations for the operator, including easy-to-use controls and clear visibility, which enhance operational safety. Many European-style cranes also offer remote control options, allowing operators to control the crane from a safe distance, reducing the risk of accidents in hazardous environments.

- Environmental and Hazardous Site Safety: For industries such as oil and gas, mining, or shipbuilding, European cranes are available with explosion-proof or anti-corrosion designs, further enhancing safety in hazardous environments. These specialized designs ensure that cranes can operate safely in areas where hazardous materials or extreme conditions may exist.

By meeting stringent safety regulations and incorporating advanced safety features, European-style overhead cranes provide peace of mind for operators and facility managers, ensuring that lifting operations are both safe and efficient.

European-style overhead cranes are a versatile and reliable choice for various industries, offering numerous advantages, including customized design options, high-precision lifting, energy efficiency, and comprehensive safety features. Whether used for heavy-duty lifting in construction or handling delicate components in precision industries, these cranes are built to meet the diverse needs of modern manufacturing and industrial operations. Their compliance with international safety standards, combined with their advanced technological features, ensures that European-style cranes deliver optimal performance and reliability in a wide range of applications.

Hot Sale European Crane Desigens for Different Applications

Overhead Cranes with Euro Style Wire Rope Electric Hoist, Main Hook & Auxiliary Hook, Double Hoists

Overhead cranes equipped with Euro style wire rope electric hoists are an ideal solution for industries requiring high-performance lifting systems. Designed to handle a variety of loads, these cranes offer versatility with both a main hook and an auxiliary hook, making them suitable for applications ranging from general material handling to heavy-duty lifting tasks.

The Euro style wire rope electric hoist is engineered for smooth and efficient operation. With high lifting capacities, it ensures that heavy loads are lifted with precision, while the robust design and advanced features extend the hoist's lifespan and reduce maintenance needs. This type of hoist is known for its smooth motion and minimal wear and tear, making it highly reliable in demanding industrial environments.

The inclusion of both a main hook and an auxiliary hook allows for simultaneous or independent lifting, providing greater flexibility in operations. This setup is especially useful for lifting large or awkwardly shaped loads, as the auxiliary hook can be used to balance or stabilize the load while the main hook handles the primary lifting.

Double trolley hoists are often integrated into these overhead cranes to further increase lifting capabilities. The addition of a second hoist allows for higher capacity lifting, improving the crane's efficiency in heavy-duty applications, such as construction, manufacturing, and warehouses. The dual hoist setup also ensures redundancy, minimizing downtime in case of failure, and providing an added layer of safety.

Overall, overhead cranes with Euro style wire rope electric hoists, complete with main and auxiliary hooks, offer a versatile, efficient, and durable solution for a wide range of lifting applications.

Keywords: #OverheadCranes, #EuroStyleHoist, #WireRopeElectricHoist, #MainHook, #AuxiliaryHook, #DoubleHoists, #HeavyDutyLifting, #MaterialHandling, #IndustrialCranes, #HighCapacityLifting, #CraneSystem, #WarehouseCrane, #ConstructionCranes, #DualHoist

Double Girder Overhead Crane with Euro Style Low Headroom Wire Rope Electric Hoists

Double Girder Overhead Cranes with Euro Style Low Headroom Wire Rope Electric Hoists are designed to maximize lifting capacity while minimizing space requirements. Featuring a low headroom design, these cranes offer efficient operation in facilities with limited vertical clearance. The Euro-style wire rope electric hoists provide smooth and reliable lifting, ensuring precise load control. Ideal for heavy-duty industrial applications, these cranes are equipped with advanced safety features, ensuring high performance and durability. The combination of double girder structure and low headroom hoist makes this crane perfect for maximizing available space without compromising on lifting power and safety.

Key Design Features and Benefits

- Precision Lifting for Heavy Loads:The Euro style wire rope electric hoist is engineered for precise control when lifting heavy loads, making it ideal for tasks that require accuracy, such as handling large machinery or equipment in manufacturing plants. The hoist uses a smooth and controlled motion, reducing the risk of load swing or instability, which is crucial when working with bulky or heavy materials. Its advanced design ensures that even the heaviest items are lifted with stability and precision, reducing the likelihood of accidents or equipment damage.

- Superior Durability and Longevity:Euro style wire rope electric hoists are built to withstand the demands of tough industrial environments. They are constructed with high-quality materials and components designed to resist wear, corrosion, and fatigue under heavy use. This robust engineering helps ensure that the hoist performs reliably over long periods, even in challenging conditions such as high temperatures, heavy-duty lifting, or environments with corrosive elements. As a result, these hoists have a longer service life compared to other types, reducing the need for frequent replacements and repairs.

- Energy Efficiency and Cost Savings:One of the key advantages of the Euro style wire rope electric hoist is its energy-efficient operation. The hoist is designed to optimize power consumption, ensuring that it provides the necessary lifting capacity without excessive energy use. The advanced motor control systems and optimized hoisting mechanisms allow for smoother acceleration and deceleration, reducing energy wastage during operation. Over time, this energy-efficient design can result in significant cost savings, especially in facilities where cranes are used frequently or for extended periods.

- Low Maintenance Needs: The design of the Euro style wire rope electric hoist minimizes wear and tear, contributing to lower maintenance costs and longer operational intervals. The smooth operation of the hoist, coupled with high-quality components, reduces the friction and strain on moving parts, which in turn extends the time between maintenance checks. Additionally, the use of advanced materials and protective coatings helps prevent corrosion and damage from environmental factors, further reducing the frequency of repairs. This reliability and reduced maintenance need contribute to lower overall operational costs, making the hoist a cost-effective solution for long-term use.

Overall, the Euro style wire rope electric hoist in a double girder overhead crane configuration offers a combination of precision, durability, energy efficiency, and low maintenance, making it an ideal choice for heavy-duty lifting applications in industrial settings. Its design ensures that it can handle a variety of lifting tasks while keeping operational costs manageable and minimizing downtime.

European Style Overhead Cranes Double Girder with Main Hook & Auxiliary Hook

European Style Overhead Cranes with a double girder design are engineered for heavy-duty lifting and precise load handling. Equipped with both a main hook and an auxiliary hook, these cranes offer versatile lifting capabilities for a wide range of industrial applications. The main hook handles the primary load, while the auxiliary hook is used for lighter or secondary lifts, increasing operational efficiency. Designed with advanced safety features and high-quality components, these cranes ensure smooth operation, high reliability, and excellent durability in various environments, including manufacturing, warehouses, and steel mills. Their compact design also maximizes headroom and space utilization.

Main Hook: The Primary Lifting Solution

The main hook is the primary lifting mechanism on a double girder European style overhead crane. It is designed to handle the majority of lifting tasks, particularly when dealing with larger, heavier loads. The main hook is typically used for the bulk of the lifting operations, from transporting heavy machinery and equipment to moving large components within a production facility. Its strength and capacity allow it to carry out a wide range of tasks without compromising performance, making it the most commonly used lifting tool on the crane.

Auxiliary Hook: Versatility in Lifting

The auxiliary hook provides additional versatility to the lifting system, particularly when dealing with complex or irregular loads. Often smaller than the main hook, it is used for supplementary tasks, such as stabilizing or balancing heavy loads during lifting operations. The auxiliary hook can be used independently or in tandem with the main hook to lift oversized or awkwardly shaped items that require extra support. This dual-hook configuration makes the crane more flexible, allowing operators to safely handle a broader variety of loads without needing additional lifting equipment.

Benefits of Dual Hook Lifting

The ability to use both the main hook and the auxiliary hook offers several advantages, especially in operations that involve heavy or irregularly shaped loads:

- Stabilizing and Balancing Loads: The dual hook system allows the operator to stabilize a load by using the auxiliary hook to provide balance. This is especially useful when lifting long, heavy beams or large machinery, where maintaining load stability is crucial.

- Improved Load Handling: By utilizing both hooks, the crane can lift items in a more controlled manner, reducing the risk of load sway or damage. This is particularly important when handling fragile or expensive components that require precise positioning.

- Flexibility in Operations: Using the two hooks in tandem or independently provides greater flexibility. For example, when lifting large loads that require different lifting points, both hooks can be used to spread the weight, improving efficiency and safety.

Typical Applications

European style overhead cranes equipped with both main and auxiliary hooks are ideal for industries where heavy and irregular loads are common. Some typical applications include:

- Automotive Manufacturing: Handling large engine blocks, vehicle chassis, or other heavy automotive parts. The dual hook system is useful for positioning and stabilizing these components during assembly.

- Aerospace Manufacturing: Lifting and positioning large aircraft components, such as wings or fuselage sections, where precision and stability are required.

- Steel and Heavy Manufacturing: Moving large steel beams, metal plates, and other heavy materials. The additional support of the auxiliary hook makes it easier to manage these items without the need for additional lifting equipment.

- Warehouses and Distribution Centers: Lifting oversized or irregularly shaped packages and materials, improving operational flexibility and reducing the need for multiple lifting devices.

Increased Operational Efficiency

The dual hook lifting system increases operational efficiency in several ways:

- Reduced Equipment Requirements: With the ability to use both hooks for various lifting tasks, there's less need for additional lifting tools or cranes. This streamlines operations, saves on equipment costs, and simplifies crane management.

- Faster Load Handling: The main and auxiliary hooks can be used to lift, balance, and position loads more quickly, reducing cycle times and improving overall productivity. For example, lifting large or heavy components becomes faster and safer with the use of both hooks, allowing for quicker turnaround times in production or assembly lines.

- Reduced Downtime: Since the dual hook system offers more flexibility, there's less need for additional rigging or lifting equipment. This helps minimize downtime associated with equipment setup and adjustments, ensuring that cranes are ready for continuous operation.

In conclusion, European style overhead cranes with main and auxiliary hooks offer enhanced lifting flexibility, stability, and efficiency. This dual-hook configuration is ideal for handling heavy, irregular, or oversized loads, making it an excellent choice for industries like automotive manufacturing, aerospace, and steel production, where high lifting capacity and precise load control are essential for operational success.

What is a Double Hoist System?A double hoist system refers to the integration of two separate hoists operating on the same crane structure to lift exceptionally heavy or oversized loads. In this system, both hoists are typically mounted on the same trolley or two independent trolleys running along the crane's beams. The hoists can work together to lift the load or operate independently for more flexibility in handling different types of materials. The dual hoist configuration is especially useful in applications that require a higher lifting capacity than a single hoist can provide, allowing the crane to handle greater loads safely and efficiently.

Key Advantages of Double Hoists

- Higher Lifting Capacities:One of the primary advantages of a double hoist system is the increased lifting capacity. By using two hoists, the crane can lift significantly heavier loads, which is essential for industries like construction, shipbuilding, and steel manufacturing, where exceptionally large or heavy materials need to be moved. The additional hoist allows the crane to distribute the load more evenly, ensuring that the lifting capacity is not exceeded and reducing the stress on individual hoists. This design is ideal for tasks that require lifting equipment capable of handling weights that single-hoist cranes cannot manage efficiently.

- Redundancy and Reliability:The dual hoist configuration also provides increased redundancy, enhancing the overall reliability of the crane system. In the event that one hoist fails or requires maintenance, the other hoist can continue to operate, minimizing downtime and maintaining operational continuity. This redundancy is particularly valuable in industries where downtime can be costly and safety is a top priority. With both hoists working independently, the system ensures that one hoist can serve as a backup if needed, without compromising the lifting operation.

- Safety and Stability:Safety is a crucial factor when lifting large, heavy loads, and the use of double hoists significantly improves the stability of the crane during operation. The load is better balanced and evenly distributed between the two hoists, which reduces the likelihood of load sway or tipping, especially when lifting heavy or awkwardly shaped items. This balanced lifting approach also minimizes the risk of crane overload, which can occur if the load is unevenly distributed. With both hoists working together, the lifting process becomes more stable, reducing the potential for accidents or damage to both the crane and the load.

Common Applications of Double Hoist Cranes

Double hoist cranes are ideal for industries and applications that require high lifting capacities and reliability under demanding conditions. Some common applications include:

- Construction: Lifting large construction materials, such as steel beams, precast concrete elements, and heavy machinery. Double hoists provide the additional capacity needed to move oversized or heavy building components.

- Steel Manufacturing: Handling large steel plates, coils, and billets. These materials are often extremely heavy, and double hoists ensure that they are lifted safely and efficiently without exceeding the crane's capacity.

- Shipbuilding: Lifting large sections of ships or heavy machinery used in ship production. The stability and lifting power provided by double hoists are crucial for handling large, heavy components that must be moved with precision.

- Large-Scale Material Handling: Moving oversized or irregularly shaped materials in industrial warehouses, storage yards, or distribution centers. Double hoists allow these materials to be handled safely and efficiently, ensuring that weight is evenly distributed and minimizing the risk of crane overload.

European style top running double girder overhead cranes equipped with double hoists offer a reliable and efficient solution for lifting heavy, oversized loads across industries such as construction, shipbuilding, and steel manufacturing. The combination of increased lifting capacity, redundancy for reliability, and enhanced safety features makes this crane configuration an essential tool for demanding applications. With the ability to handle larger loads and maintain operational continuity, double hoist systems provide significant benefits in terms of productivity, cost-effectiveness, and safety in heavy-duty industrial environments.

Reliable Wire Rope Hoist Crane Solution for Your Workshop, Crane Projects for Your Reference

The European overhead cranes is the ideal solution for the workshops where a tough and reliable material handling overhead cranes needed. Whatever your field is, metallurgical, chemicals, stone pit, wood, oil refining, or general manufacturing, the European wire rope hoist trolley can be your selection. Specialized FEM/ DIN wire rope hoist overhead cranes can fit your various industrial requirement and needs with amazing satisfaction.

10 Ton Electric Travelling Double Girder Overhead Crane , Electric Wire Rope Hoist Crane

10 ton overhead crane for sale Bangladesh. Double girder overhead crane with European style double rail electric wire rope hoist. Check electric hoist eot crane video

20 Ton/ 5 Ton Double Girder Overhead Crane, European Style Wire Rope Hoist Crane for Sale Saudi Arabia

20 ton/ 5 ton overhead crane for sale Saudi Arabia,double girder overhead crane, with open winch hoist, with 20 ton & 5 ton hooks.Learn how to buy from China to Saudi Arabia.

25 Ton Overhead Crane & Bridge Crane for Machinery Manufacturing

25 ton overhead crane for sale, Double girder overhead crane 25 ton designed for conveyor manufacturing workshop. Check 25 ton bridge crane & feedback.

25 ton overhead crane for sale, Double girder overhead crane 25 ton designed for conveyor manufacturing workshop. Check 25 ton bridge crane & feedback.

25 Ton Overhead Crane, Double Girder Crane Design for Conveyor Manufacture Factory Australia

25 ton double girder overhead crane for sale Australia for conveyor equipment manufacturing factory. 25 ton overhead crane for sale Australia, good crane price and meet all your needs and related Australian regulations.

Mold Handling 40 Ton Bridge Crane in Automobile Parts Factory USA

Overhead bridge crane 40 tons for sale America for mold handling in automobile parts processing factory, 2 sets. Custom mold handling crane for sale.

Applications of European Style Overhead Cranes in Various Industries

European-style overhead cranes are essential in a variety of industries due to their precision, flexibility, and high-performance design. Equipped with advanced hoisting systems, such as the Euro style wire rope electric hoist, and customizable hook configurations, these cranes provide the versatility and power required for heavy-duty applications. Below, we explore how European-style cranes are used across different industries to meet specific operational needs.

10 Ton Double Girder Overhead Crane Project

In the following, the European style double girder overhead crane with 10 ton capacity is designed for a client from Pakistan. The testing video of the 10 ton electric overhead crane are presented for your reference. Contact us to get your customized double girder bridge crane with advanced crane design and European style.

Heavy Manufacturing & Steel Industry

In the heavy manufacturing and steel industry, overhead cranes are critical for handling large, heavy components and materials, often in high-temperature environments.

- Handling Heavy Loads: Steel mills and manufacturing plants require cranes capable of lifting heavy steel billets, slabs, coils, and other large components. European-style cranes, particularly double girder cranes with dual hoists, are well-suited for these tasks due to their high lifting capacities and ability to manage oversized loads safely and efficiently.

- High-Temperature Operations: Steel production processes, such as casting or hot rolling, involve extreme temperatures. Cranes in these environments must be designed with materials that can withstand heat and wear, and European-style cranes offer hoists and structures engineered for these demanding conditions.

- Precision and Efficiency: The precision of European-style overhead cranes is critical when moving and positioning heavy steel components, ensuring minimal margin for error during lifting operations. These cranes also maximize efficiency by allowing for fast, continuous movement of large loads, which is essential in high-volume manufacturing environments.

Aerospace & Automotive Manufacturing

European-style overhead cranes are especially beneficial in aerospace and automotive manufacturing, where precise lifting and handling of complex components are necessary.

- Handling Complex and Heavy Components: In aerospace, cranes are used to lift and move large, delicate parts, such as aircraft wings, fuselages, and engines. Automotive manufacturers use cranes to handle heavy engine blocks, transmission systems, and structural parts. With dual hoists and custom hook configurations, European cranes provide flexibility to lift various shapes and sizes of components safely.

- Dual Hoist Systems for Greater Flexibility: In aerospace and automotive production lines, dual hoists allow for synchronized or independent lifting of large components, improving operational flexibility. The ability to balance loads with auxiliary hooks helps prevent damage to delicate parts while ensuring that larger, heavier components are moved efficiently.

- Precision Lifting for Delicate Parts: The smooth and precise operation of European-style cranes makes them ideal for lifting delicate aerospace components, ensuring that no undue stress is placed on parts during transport, assembly, or maintenance.

Construction & Shipbuilding

Overhead cranes with double hoists are indispensable in the construction and shipbuilding industries, where they are used to move massive materials and prefabricated structures.

- Lifting Prefabricated Components: In construction, cranes are used to move large, prefabricated sections of buildings, such as steel beams, concrete panels, and structural columns. European cranes with dual hoists can lift these heavy, often awkwardly shaped components with precision, reducing the risk of damage and ensuring smooth installation.

- Shipbuilding and Heavy Loads: Shipyards use overhead cranes to lift and position large sections of ships, heavy machinery, and equipment. The size and weight of shipbuilding components make double hoist cranes essential for ensuring safe, efficient lifting and transport of materials, particularly in high-risk environments where stability and safety are crucial.

- Versatility in Construction: These cranes are not only used for heavy lifting but also for tasks such as hoisting scaffolding, construction materials, and even large machinery. The versatility of European cranes allows them to handle a variety of loads in construction sites and shipyards, improving productivity and reducing manual labor.

Warehouses & Distribution Centers

In warehouses and distribution centers, European-style overhead cranes equipped with dual hoists and Euro-style hoists are vital for optimizing material handling and maximizing space utilization.

- Efficient Material Handling: European cranes are designed to lift and move large quantities of goods within storage areas or warehouses. Their ability to handle both small and large loads efficiently makes them ideal for environments that require quick, high-volume handling of goods, such as consumer goods, electronics, or bulk materials.

- Maximizing Space Utilization: These cranes are often used in high-ceiling warehouses where space is limited. The overhead design allows for the use of vertical space, making it possible to store materials higher up and improve the overall storage capacity. The precision of the crane's hoisting system also ensures that loads are lifted and placed exactly where needed without causing damage to products or storage areas.

- Dual Hoist Efficiency: With dual hoists, European cranes can simultaneously handle multiple loads or manage different lifting requirements in the same space, increasing overall operational efficiency. Whether it's moving heavy pallets of goods or handling bulk materials, these cranes optimize workflows in distribution centers.

Ports and Shipping

In ports and shipping terminals, European-style overhead cranes with double hoists play a critical role in the handling of containers, bulk materials, and large marine equipment.

- Moving Large Shipping Containers: Ports use large overhead cranes with double hoists to handle the lifting and transportation of shipping containers. The ability to move containers quickly and efficiently is essential in busy ports where time is a critical factor. The dual hoist system ensures that containers are handled with greater stability and speed, reducing the potential for delays.

- Bulk Materials and Equipment Handling: Besides containers, overhead cranes in ports are also used for lifting bulk materials, such as coal, grain, or heavy equipment used in shipping operations. Double hoists are particularly useful for lifting heavy equipment or handling large, irregularly shaped materials, ensuring that cargo is moved safely and efficiently.

- Increased Port Efficiency: The use of overhead cranes with dual hoists in ports allows for simultaneous lifting of multiple containers or materials, improving the flow of goods through the port and reducing waiting times for ships and cargo. This level of efficiency is crucial for keeping operations on schedule in high-traffic shipping environments.

European-style overhead cranes, with their versatility, precision, and high lifting capacities, are an integral part of operations in numerous industries. From heavy manufacturing and aerospace to construction, shipbuilding, and ports, these cranes provide reliable and efficient solutions for lifting complex and heavy loads. Their customizable design options, dual hoist systems, and compliance with international safety standards ensure they meet the diverse needs of modern industrial applications. Whether improving operational efficiency, maximizing space, or ensuring the safe handling of materials, European-style cranes continue to play a key role in driving productivity and safety across various sectors. If you have any need or interest in the European style electric hoist overhead crane double girder desing, please leave us a message down below to check what we can do to save your crane cost on the European style low headroom hoist overhead crane.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch