Top running crane vs. Underhung crane

Overhead travelling cranes come into various crane designs and configurations with diverse of crane specifications and parameters to meet different lifting requirements and industrial application conditions, and many of which function a specific purpose for a particular operation. Will your crane's end trucks /end carriage will move on top of the crane runway or on the bottom flange of the crane runway? Top running bridge crane & under hung bridge crane, which is right overhead travelling crane for you? Let's learn more about the advantages of a top running overhead crane system, and a underhung overhead crane system and how they distinguish from each other to help you find out the the right overhead travelling crane solution.

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Top Running Overhead Crane

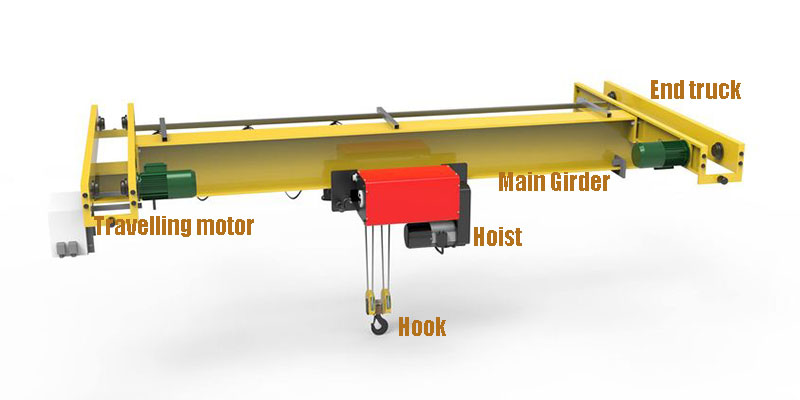

With top running crane design, the overhead travelling cranes run on a fixed rail or track system on the top of each runway beam. The top running cranes can be designed in a single girder overhead crane or double girder overhead crane configuration which are optimal for extremely heavy material handling.

Top running single girder overhead crane 3d model

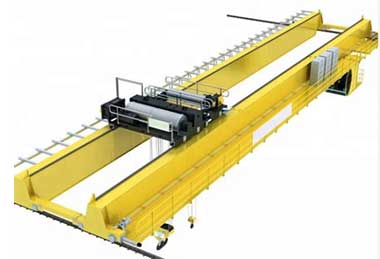

Top running double girder overhead crane with hoist trolley

Top running double girder overhead crane with open winch trolley

What is a top running overhead crane ?

A top running overhead crane move on the top of each runway beam with fixed crane rails which enables the end trucks or end carriages of overhead crane to carry the main bridge girder and lifting hoist along the top of the runway system.

The top running cranes can be designed in a single girder overhead crane or double girder overhead crane configuration. A single girder bridge utilizes an underhung trolley and hoist, while a double girder design most often utilizes a top running trolley and hoist.

Single girder top running overhead crane

A top running single girder crane is the most frequently used overhead bridge crane system for the top running crane configuration typically meets the needs of lifting requirements and facility space requirements for most customers.

Advantages of single girder top running overhead crane

- Typical lifting capacity of top running single girder crane : 0.5 ton to 20 tons

- Typical service duty of top running single girder crane: Light to medium duty

- Lifting system of top running single girder crane: motorized monorail hoists, wire rope hoists, chain hoists

- Common applications of single girder top running crane: Light manufacturing, fabrication and machine shops, light assembly line, warehousing facilities, maintenance and repair centers

- Compact structure, light deadweight, easy installation & maintenance

- Faster speed are possible for crane travelling and hoisting .

- Single girder design, less material , lower production cost , lower overall price

Types of single girder top running overhead cranes

Single girder top running overhead cranes can be grouped into different types to meet your needs and lifting requiremt. Top running overhead crane with process crane designs are available. Contact us to get free consulation on top running crae design and top running crane price.

Double girder top running overhead crane

A top running double girder bridge crane will provide the most overhead room, as well as the greatest hook height. An under running double girder overhead travelling cranes are mounted on a runway structure that has been integrated into the ceiling structure of the building which are an effective solutions for low headroom or tight headroom clearance applications.

Advantages of double girder top running overhead crane

- Typical load capacity of top running double girder crane: 20-500 tons

- Typical service duty of top running double girder crane: Medium to heavy duty

- Lifting system of top running double girder crane: wire rope hoist trolley, chain hoists trolley, open winch trolley

- Common applications of double girder top running crane: Steel and metal mills, coil handling, foundries, large fabrication and stamping facilities, paper mills, casting plants, large-scale tool and die facilities

- Best hook and lifting height, maximize overhead floor space, high travelling speed and hoisting speed

Types of double girder top running cranes

Double girder top running cranes are the first choice for heavy duty material handling in workshops which needs a very large range of crane spans, hook height and travelling speed range. Generally, the double girder top running cranes are available with multiple hoisting systems including Hoist trolley system & Open winch trolley system, depending on the wight of lifting loads and lifting requirements.

Besides, the top running double girder overhead cranes can be equipped with various below -the-hook devices and crane attachments for various industrial applications which including Ladle crane , Hook crane, Grab Crane,Electromagnetic Crane, Electromagnetic beam spreader, Tong crane / clamping crane/ gripper crane

Features & advantages of top running overhead cranes

High Capacity , heavy loads handling

Top running types of overhead cranes are supported by runway columns or by building structure which are designed for heavy duty material handling with no limiting capacity. The top running overhead travelling cranes can be designed for light loads handling with small capacity of 500kg and also can be designed for heavy loads handling with large tonnages up to 500 tons.

Larger lifting height, wider crane span

Overhead travelling cranes with top running crane designs can offer added lift height in workshops with limited headroom because the overhead cranes travel on rails on top of the runway beam. With double girder bridge design, the crane hoist and hoist trolley can run on the top of the two main girders with the lifting hook placing between the two crane beams which will can maximize the lifting height of the overhead travelling crane.

Usually, top running overhead cranes are larger than under running overhead cranes, because top running cranes can be designed and built with higher capacities and wider crane spans.

Easy installation & maintenance

Due to the top running cranes are supported on rails on top of the runway beams with no suspended load factor, the installation and necessary maintenance of the top running crane is much easier than that of the under hung bridge crane. During the working life of top running overhead cranes, the bridge track or rail system require more frequently inspection and maintenance for alignment or other tacking problems than an under running crane. However, the inspection and maintain services are fairly easy to conduct and take less downtime than an under running overhead crane.

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Under Running Overhead Crane

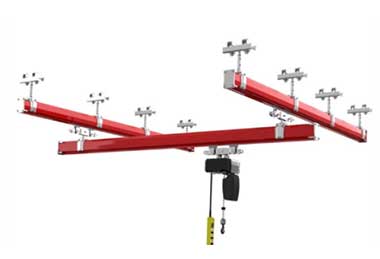

With underhung bridge cranes design, the end trucks / end carriages move on the bottom flange of the runway beam unlike the top running overhead travelling cranes. The underslung overhead cranes are usually supported and mounted to the ceiling structure or roof structure which are ideal solution for workshops or warehouses with low clearance or low headroom space.

What is an under running overhead crane?-An under running crane are also named underhung crane or underslung crane whose end carriages/ end trucks travelling on the bottom flange of the runway beam, which enables the crane bridge girder running under the crane runway, Under running overhead cranes can be designed into verious types such as single girder underhung crane& double girder underhung crane, monoral underrunning crane, kbk under running crane, etc.

Single girder under running crane

Double girder under running crane

KBK under running crane

Overview of Under Running Overhead Cranes:

- Typical lifting capacity of under running overhead crane :0.25 ton to 10-tons

- Typical service duty:Light to medium duty

- Lifting system of under running overhead crane : motorized monorail hoists, wire rope hoists, chain hoists

- Common applications of under running overhead crane : Assembly, fabrication shops, maintenance buildings, and manufacturing facilities

- Maximizes floor space if attached or supported by existing ceiling structures or roof structure

- Lower material costs if there is no requirement for runway support columns.

- Attached to ceiling structure, higher lifting height, suitable for low headroom application.

Types of underhung bridge cranes

Types of under running overhead cranes

Under running overhead crane also can be designed in to single girder crane and double girder crane designs, equpped with various types of crane hoists, hoist winch and hoist trolley, etc.

Under running overhead travelling cranes are most commonly designed in a single girder overhead crane configuration with monorail trolley hoists for lighter loads handling with small capacity of 10 tons or less.Underslung cranes are also can be designed with double girder overhead crane configuration for higher capacities and supportive column can be added if necessary.which would be very expensive.

An under running single girder overhead crane can adopt a suspension hoist and trolley which move across the bottom flange of the bridge beam. A double girder under running bridge crane can run the hoist trolley on the top or on the bottom of the bridge beams.

Freestanding underhung overhead crane

Under running cranes can be designed in a free-standing overhead crane configuration with the requirements of additional support or mounting columns if the existing support structure of the workshop can not support the weight of crane and loads .

Free sanding double girder kbk crane

Free standing single girder kbk crane

Rigid free standing suspension kbk crane

Advantages of under running overhead cranes

Ceiling mounted crane system, free your floor space

The ceiling mounted underhung types of cranes enable you to maximize the floor space in your workshops for production and storage to make the best utilization of your floor space..

Compact crane design, best workshop space utilization

With ceiling roof mounted design, the underhung bridge cranes provide excellent side approach and make the best use of the width and height of your workshops. The under running crane are the ideal solutions for workshops and warehouse with low headroom clearance and space where a top running overhead crane system is impractical. Hook height and lift height is less than top running overhead cranes because the main crane girder and monorail hoist are suspended right underneath the crane runways.

Complex installation and maintenance

The installation and maintenance of an under running overhead crane system is more complex and taking longer downtime because of the suspension crane design. Even though it takes long time to check the alignment or crane wheel, it is easier to maintain the alignment and there are fewer tracking problems because the movement of crane I-beam is limited, fastened and secured to building structure.

Top Running Overhead Crane 5 ton

Underhung overhead crane & Underhung bridge crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Comparison of Top Running Crane and Underhung Crane

Top running cranes and underhung cranes are two types of overhead crane systems that are used for lifting and moving heavy loads within a facility. Here's an overview of the main features, pros, and cons of each type:

Top Running Crane

A top running crane has a single girder mounted on top of runway beams, which allows the crane to travel along the length of the facility. Here are some of the main features, pros, and cons of a top running crane:

Features:

- Single girder configuration

- Mounted on top of runway beams

- Can have a lifting capacity of up to 150 tons or more

- Can be designed to operate at high speeds

Pros:

- Suitable for heavy loads

- Can span long distances

- Can be customized to meet specific requirements

- Can be designed for high-speed operation

Cons:

- Requires more space due to the height of the runway beams

- More expensive than underhung cranes due to the additional cost of the runway beams and supports

- Requires a more robust support structure due to its higher profile

- Main Types of Top Running Cranes and Their Features

- There are two main types of top running cranes:

Single Girder Top Running Crane:

This type of crane has a single girder mounted on top of runway beams. It is typically used for lighter loads and spans up to 100ft. Some of the main features of a single girder top running crane include:

- Lower cost than double girder top running crane

- Suitable for light loads

- Can be designed for high-speed operation

- Can be customized to meet specific requirements

Double Girder Top Running Crane:

This type of crane has two girders mounted on top of runway beams. It is typically used for heavier loads and spans up to 150ft or more. Some of the main features of a double girder top running crane include:

- Suitable for heavy loads

- Can span long distances

- Can be designed for high-speed operation

- Can be customized to meet specific requirements

Underhung Crane

An underhung crane has a single girder mounted below the runway beams, which allows the crane to travel along the length of the facility while taking up less space than a top running crane. Here are some of the main features, pros, and cons of an underhung crane:

Features:

- Single girder configuration

- Mounted below the runway beams

- Can have a lifting capacity of up to 10 tons or more

- Low profile design

Pros:

- Requires less space than a top running crane

- Lower cost than a top running crane due to the simpler support structure

- Suitable for lighter loads

Cons:

- Limited lifting capacity compared to top running cranes

- Limited span compared to top running cranes

- Limited customization options

In summary, both top running cranes and underhung cranes have their own unique features, pros, and cons. The choice between the two will depend on the specific requirements of the client, including lifting capacity, available space, and budget.

Main Types of Underhung Cranes and Their Features

There are two main types of underhung cranes:

Single Girder Underhung Crane:

- This type of crane has a single girder mounted below the runway beams. It is typically used for lighter loads and spans up to 50ft. Some of the main features of a single girder underhung crane include:

- Lower cost than double girder underhung crane

- Suitable for light loads

- Requires less space than a top running crane

- Can be customized to meet specific requirements

Double Girder Underhung Crane:

This type of crane has two girders mounted below the runway beams. It is typically used for heavier loads and spans up to 100ft or more. Some of the main features of a double girder underhung crane include:

- Suitable for heavy loads

- Can span long distances

- Requires less space than a top running crane

- Can be customized to meet specific requirements

Main Structure Difference of Top Running Crane and Underhung Cranes

The main structural difference between a top running crane and an underhung crane is the position of the crane's main girder in relation to the runway beams. In a top running crane, the main girder is mounted on top of the runway beams, while in an underhung crane, the main girder is mounted below the runway beams.

Difference in Main Girder, End Carriages, Electric Hoists, and Crane Runway Designs

In terms of the main girder, end carriages, and electric hoists, there may be some differences between top running and underhung cranes depending on the specific design and manufacturer. However, the main difference is in the position of these components in relation to the runway beams.

As for crane runway designs, there may be differences in the support structure required for top running and underhung cranes. Top running cranes require a more robust support structure due to the height of the runway beams, while underhung cranes require a simpler support structure due to their low profile design.

Here is a comparison of the specifications of top running cranes and underhung cranes in terms of main girder, end carriages, electric hoists, and crane runway designs:

Main Girder

- Top Running Crane: Single or double girder mounted on top of runway beams

- Underhung Crane: Single or double girder mounted below the runway beams

End Carriages

- Top Running Crane: Wheels mounted on top of runway beams

- Underhung Crane: Wheels mounted below the runway beams

Electric Hoists

- Top Running Crane: Electric hoist mounted on the main girder

- Underhung Crane: Electric hoist mounted on the trolley

Crane Runway Designs

- Top Running Crane: Requires a more robust support structure due to the height of the runway beams

- Underhung Crane: Requires a simpler support structure due to the low profile design

In summary, the main girder, end carriages, electric hoists, and crane runway designs differ between top running cranes and underhung cranes. The main girder and end carriages are mounted in different positions depending on the type of crane. The electric hoist is mounted in different locations depending on the type of crane. The crane runway designs also differ, with top running cranes requiring a more robust support structure due to the height of the runway beams, while underhung cranes require a simpler support structure due to their low profile design.

Difference in Mounting Types, Space Required, and Required Crane Supporting Structure

The mounting type, space required, and required crane supporting structure differ between top running cranes and underhung cranes.

Mounting Types

Top running cranes are mounted on top of runway beams, while underhung cranes are mounted below the runway beams. The mounting type affects the amount of space required for the crane system and the required supporting structure.

Difference in mounting types

The mounting types of top running and underhung cranes are different. Top running cranes are supported by the building structure or runway support columns and ride on rails on top of the runway beam. Underhung cranes use wheels that are supported by the bottom flange of the runway beam to move the bridge up and down the runway.

Required Crane Supporting Structure

Top running cranes require a more robust supporting structure than underhung cranes due to the height of the runway beams. The supporting structure for a top running crane must be strong enough to support the weight of the crane and the load being lifted. Underhung cranes require a simpler supporting structure due to their low profile design.

Space Required

Top running cranes require more space than underhung cranes due to the height of the runway beams needed to support the crane. Underhung cranes require less space due to their low profile design.

Difference in Crane Installation

The installation process for a top running crane and an underhung crane may differ due to the differences in the support structure required for each type. Top running cranes require a more robust support structure, which may require more time and effort to install. Underhung cranes require a simpler support structure, which may result in a quicker installation time.

Difference in Crane Runway Construction

The construction of the crane runway may differ depending on the type of crane being installed. Top running cranes require a higher runway beam due to their mounting position, while underhung cranes require a lower runway beam due to their low profile design. The runway beams for both types of cranes must be strong enough to support the weight of the crane and the load being lifted.

In summary, the mounting type, space required, and required crane supporting structure differ between top running cranes and underhung cranes. Top running cranes require more space and a more robust supporting structure due to the height of the runway beams needed to support the crane. Underhung cranes require less space and a simpler supporting structure due to their low profile design. The construction of the crane runway may also differ depending on the type of crane being installed.

Difference in Crane Maintenance

The maintenance requirements for a top running crane and an underhung crane may differ depending on the specific design and manufacturer. However, some general differences may include:

- Top running cranes may require more frequent maintenance due to their more robust support structure.

- Underhung cranes may require less frequent maintenance due to their simpler support structure.

Maintenance tasks for both types of cranes may include inspections, lubrication, and replacement of worn or damaged components.

In summary, the main structural difference between a top running crane and an underhung crane is the position of the main girder in relation to the runway beams. While there may be some differences in the main girder, end carriages, electric hoists, and crane runway designs depending on the specific design and manufacturer, the main difference is in the position of these components. Differences in installation and maintenance requirements may also exist depending on the specific design and manufacturer.

How to Select Between theTop Running Crane & Underhung Crane Systems

When selecting an overhead crane system, clients have the option to choose between a top running crane and an underhung crane. Here's an overview of the main differences between the two:

- Configuration: A top running crane has a single girder mounted on top of runway beams, while an underhung crane has a single girder mounted below the runway beams.

- Space Requirements: A top running crane requires more space than an underhung crane due to the height of the runway beams needed to support the crane. An underhung crane requires less space due to its low profile design.

- Lifting Capacity: Both top running and underhung cranes can have a similar lifting capacity, but top running cranes are typically used for heavier loads due to their more robust design.

- Cost: Top running cranes are generally more expensive than underhung cranes due to the additional cost of the runway beams and supports.

Top concerns for clients when selecting a crane system

When selecting an overhead crane system, clients may have several concerns, including:

- Lifting Capacity: The lifting capacity of the crane should be sufficient for the client's needs.

- Space Requirements: The available space in the facility may be a limiting factor when selecting a crane system.

- Safety: The safety features of the crane system should meet all relevant safety standards and regulations.

- Cost: The cost of the crane system should be within the client's budget.

- Maintenance: The maintenance requirements of the crane system should be considered to ensure that it can be properly maintained over its lifespan.

Frequently Asked Questions about Overhead Crane Systems

Q: What is the maximum lifting capacity of an overhead crane system?

A: The maximum lifting capacity of an overhead crane system can vary depending on the specific model and design. However, most overhead crane systems have a lifting capacity ranging from 1 ton to 400 tons or more.

Q: What is the difference between a top running crane and an underhung crane?

A: The main difference between a top running crane and an underhung crane is the way they are supported. A top running crane runs on rails that are mounted on top of the building structure, while an underhung crane is suspended from the building structure through an I-beam.

Q: How much space is required for an overhead crane system?

A: The amount of space required for an overhead crane system depends on the specific model and design. Generally, overhead crane systems require enough clearance height to accommodate the lifted load plus the height of the crane itself. The runway length should also be sufficient to provide adequate travel distance.

Q: What are the safety features of an overhead crane system?

A: Overhead crane systems are equipped with various safety features, including limit switches to prevent overtravel, overload protection, emergency stop buttons, warning lights, and audible alarms. Additionally, operators are required to undergo training and certification to ensure safe operation.

Q: What is the cost of an overhead crane system?

A: The cost of an overhead crane system can vary widely depending on the specific model and design, as well as installation and maintenance costs. Generally, overhead crane systems can range from a few thousand dollars to several hundred thousand dollars.

Q: How often does an overhead crane system need to be maintained?

A: Overhead crane systems require regular maintenance to ensure safe and efficient operation. Maintenance schedules can vary depending on usage and manufacturer recommendations, but generally, maintenance should be performed at least annually.

Q: What is the expected lifespan of an overhead crane system?

A: The expected lifespan of an overhead crane system can vary depending on usage and maintenance. However, with proper care and maintenance, many overhead crane systems can last 20 years or more.

Q: Can an overhead crane system be customized to meet specific requirements?

A: Yes, overhead crane systems can be customized to meet specific requirements. Manufacturers offer various options for customization, including lifting capacity, span length, runway length, and control options.

Which Type is Right for You, Top Running Crane or Underhung Crane ?

Top running overhead crane and underhung bridge crane, which type of crane is right for your application? Confront the various crane designs and optional crane configurations, careful and thoroughly consideration are required to select a top running crane or under running crane. The following factors can help you to select a top running or under running crane system for your application:

- Is the existing support structure capable of supporting the weight of crane and loads?

- Any additional support structure are required?

- Are there existing runways which can accommodate the crane?

- What is the capacity of the loads required to be lifted?

- What is the condition of the available overhead room ? High, unobstructed ceilings, or limited headroom?

- What is the lifting height required?

- How much of the bridge will the hoist trolley need?

- Does your loads need to be handled near the edges or walls of the building?

- How is the condition of floor space?

The above questions help you to understand your application conditions and help you to select from the top running and underhung overhead cranes. The top-running crane systems are widely adopted for handling heavy loads while under-hung bridge cranes are widely used for flexibility and functionality with an ergonomic design providing versatility and usability. Any problem or doubt on top running overhead crane and under hung bridge crane, please feel free to contact us. Free consultation and process crane design for your overhead travelling crane are available for all honest clients or customers. Send us your inquiry on overhead travelling crane today.