6.3+6.3 Ton EOT Crane for Agricultural Equipment Plant Australia

Overhead travelling cranes for Australian agricultural equipment plant - 6.3 ton + 6.3 ton European overhead crane,not cheap price but cost-effective.

Why 6.3 ton +6.3 ton box girder overhead crane is selected but not 51% cheaper LD type 5 ton + 5ton single girder overhead crane by Australian agricultural plant?Custom designed overhead travelling crane solution will benefit you for the long run. Read on how the Australian client get their overhead travelling crane.

Who is the Australian Client?

The client is an agricultural equipment manufacturer based in Brisbane, Australia, that specializes in grain crop harvesting and distribution. On May 15, the client found us through a Google search and submitted us his requirements and specifications.

What does Australian client need?

An Australian agricultural equipment manufacturer has ordered a 5+ 5 ton single girder overhead crane. The Australian client intends to extend the shed and install two sets of overhead cranes in the new shed, and they initially contacted us with the following overhead crane inquiry:

"We would like to know your price and availability on crane with the following specs:

- 1 LD10 (5+5)t-20m – 4.035m A3 single girder overhead crane

- Lifting capacity: 10(5+5) tons Span: 20meters Lifting height: 4.035meters Lifting speed: 2.7m/min CT speed: 21m/min LT speed: 20m/min Power: 415v 60hz 3phase Motor protection grade: IP54 Control method: Wireless

- Working class: A3 Working temperature:-20~+40℃

- 2 Runway Beam (40 m*2) 396*199*7*11mm (40m*2)

- 3 CRANE RAIL SYSTEM (40 m*2) P38 TRACK (40m*2)

- 4 POWER SUPPLY SYSTEM (40m) BUSBAR SYSTEM (40m)

- CURRENT COLLECTOR 1 set

- 5 China Domestic transportation + China Qingdao port charge

- 6 FOB Qingdao port Price

- 7 Sea freight to Brisbane port (40'GP)

Kind Regards,

N***n D***y

Production Engineer"

Want to get an overhead crane price quote right immediately based on your exact overhead crane parameters? Take your time. We provide more than simply an overhead crane; we provide a custom-designed and comprehensive material handling solution for your workshop.

How to find out custom box girder crane solution

The Australian client intends to extend the shed and add two sets of overhead cranes in the new shed, with speedy turnaround being a major consideration. Dora, one of our top salespeople, did not rush to provide the price requested in the original inquiry after receiving it. She put in time and effort into conducting a background check and communicating with the client in order to gain a deeper understanding of the customer's company needs. Let's have a look at what Dora did:

1. Identify your requirements and application.

Dora called the agricultural equipment plant to speak with their engineer about the workshop application after examining the box girder overhead crane inquiry. The client provided a photo of the current shed, as well as machines and a shed extension design. The following are the photographs and drawings that were emailed to her:

Agricultural equipment workshop of Australian client

Workshop drawing of Australian agricultural equipment plant

Two sets of classic type 5 ton + 5 ton single girder overhead cranes (EOT cranes) traveling in the same span of the shed are the basic needs, and the box girder overhead travelling crane specifications are as follows.

2. European specifications 6.3 ton + 6.3 ton single girder EOT crane is recommended.

Based on the manufacturing line and company needs in the next 3-5 years, we recommend two sets of European-spec 6.3 ton + 6.3 ton single girder EOT cranes traveling in different spans. Because certain equipment are as long as 18 meters, each EOT box girder overhead travelling crane has two lifting points. When lifting long-sized equipment, two lifting points can work independently and concurrently, providing flexibility while also ensuring safety and stability. In terms of control, one remote may operate two lifting points, lifting them both separately and concurrently.

3.Technical details have been confirmed.

We looked into every element in order to remedy the material handling issue. We can assist you in determining the most appropriate crane option with our technical assistance.

The client encountered a selection problem with the overhead box girder overhead travelling crane rails during the communication. This is how we determine which overhead crane rail is best for him.

Thursday, 23 May 2019 12:25 PM

""""""""""""""

For the rails, do you prefer the type of square steel 50*30mm (picture below)?

If this type, as the rated capacity of the crane is bigger now, rails will be 60*40mm.

The rails need to be welded with bearing beams.

It's better that our factory does the welding, when you receive the rails, they are already connected with bearing beams.

Otherwise, you will need to arrange welders to do the extra welding after you receive them.

If the rails do not necessarily have to be square type, actually we recommend P type rails (take P30 as an example, picture below).

P30 can either be welded to bearing beams, or use bolted clamps and platens to connect.

According to our understanding of AU standard, bolted clamps and platens are better.

To compare these two rails, the advantage of square steel is it's cheaper (about 30% cheaper than P type).

Its disadvantage is wheels of end carriages will be easily wear off because of the square corners.

That's why square steel is now becoming less prevalent than P type when choosing rails.

When you look at P type rail, you can see the corners are round-shaped, and the round corners are to protect wheels when running.

In the long run, we recommend P type rails.

Please let me know which you prefer and I will include it in revised quotation. Thanks!

Regards,

Dora

""""""""""""""

Hi Dora,

We are happy to go with 2x 106m of the P30 type.

Any welding required, we will do here.

Kind Regards,

N***n D***y

Production Engineer

""""""""""""""

Throughout the process, all aspects are double-checked to ensure that the box girder overhead travelling crane solution is the best fit.

4. Final Solution: 6.3 ton + 6.3 ton overhead travelling crane

The final drawing with specifications was given to clients for final confirmation after all of the specifics of the box girder overhead travelling crane were finalized.

box girder overhead travelling crane desgin drawing for Australian client

TECHNICAL DATA

- Load capacity of overhead travelling crane: 6.3 ton+6.3 ton

- Span of overhead travelling crane:20m

- Lifting height of overhead travelling crane:5.5m

- Weight of girder of overhead travelling crane:4.92t

- Weight of overhead crane crab:0.6t+0.6t

- Weight of overhead crane end truck:1.05t

- Weight of elebox:.0.15t

- Weight of overhead travelling crane:7.32t

- The max wheel load of overhead travelling crane:89.4KN

- Main lifting speed of overhead travelling crane: 0.7~4.0m/minSTEPLESS

- Trolley travelling speed of overhead travelling crane:2.0~20m/minSTEPLESS

- Bridge travelling speed of overhead travelling crane: 2.0~20m/minSTEPLESS

- Lifting power of overhead travelling crane: 5.5kWx2

- Trolley motor power of overhead travelling crane: 0.55kWx2

- Bridge motor power of overhead travelling crane: .0.75kWx2

- Supply power of overhead travelling crane: 13.6kW

- Power supply of overhead travelling crane: 415V/3P/50Hz

- Rail type of overhead travelling crane: P30

- Crane group of overhead travelling crane: FEM2m(A5)

- Lifting group of overhead travelling crane: .FEM2m(M5)

- Trolley traversing group of overhead travelling crane: FEM2m(M5)

- Bridge travelling group of overhead travelling crane: FEM2m(M5)

- Control method of overhead travelling crane:..............Remote Control

- Crane use of overhead travelling crane: Indoors

- Application temperature of overhead travelling crane: .-10-40

The final quotation of the 6.3 + 6.3 ton box girder overhead travelling crane is 50.5 percent more than the original quotation, and the box girder overhead travelling crane is better suitable for the application and future demands of the client, winning the client's positive affirmation. What we are dedicated is to deliver the most suited crane solution for you and your future demands with professionalism.

What about crane fabrication and packaging?

After receiving a favorable response, the production of a box girder overhead travelling crane is on the horizon. The production images of the box girder overhead travelling cranes are emailed to the client during each step of the process to ensure that you are aware of all the intricacies of your crane.

With deep understanding of Australian crane standard (AS 1418.1) in the crane design and later in fabrication, painting, and seaworthy packaging, the 6.3 ton + 6.3 ton overhead travelling crane is totally meet the Australian standards and requirements.

We owe a debt of gratitude to our Melbourne-based partner, who greatly aided us in comprehending the Australian Crane and Hoist Standard. In the contact with the client, our partner also gave time and crane experience to help finalize the specifications.

Main girder of 6.3 + 6.3 ton overhead travelling crane

What is the result we delivered?

Professionalism and prompt execution ensure complete customer satisfaction. On May 29, the client placed an order and paid a deposit (two weeks after the inquiry date). We delivered on our promise of a quick turnaround time from fabrication to shipping. Our professionalism and swift execution have been praised by the client.

On June 25th, the fabrication and painting were completed (4 weeks after deposit)

On the night of July 16, Bulk Cargo was loaded into the ship.

6.3 ton + 6.3 ton overhead travelling crane delivery Australia

What does client say and what do we aimat?

6.3 ton+ 6.3 ton overhead travelling crane wins Australian client's 100% satisfaction.

"You have been very helpful and accommodating to our requirements, thank you.""I have business with several Chinese companies but you have been the best so far!"

For agricultural equipment handling, a custom designed 6.3+6.3 ton overhead travelling crane is for sale in Australia, with a crane price that is 50.5 percent higher than an LD type 5 ton + 5 ton single girder overhead crane. Why was a 6.3 + 6.3 ton overhead traveling crane chosen? The key to a long-term benefit for the client is custom design of the overhead travelling crane. As Dora indicated, our goal is to address the client's concerns and deliver the best lifting solution possible. It won't be easy, but we're on our way! Now is the time to contact us for your custom bridge crane solution.

Hoist & Cranes for General Use for Sale Australia

0.25 ton to 550 ton overhead cranes for wide industrial applications. Types of overhead cranes with different crane configuration, ie, Top running overhead cranes , Under hung or overhead cranes, and free standing overhead KBK cranes, with various crane bridge girder designs, including single girder, double girder ,box girder, Beam girder, monorails, etc., are manufactured and supplied for industrial material handling in various workshops and workstations, etc.

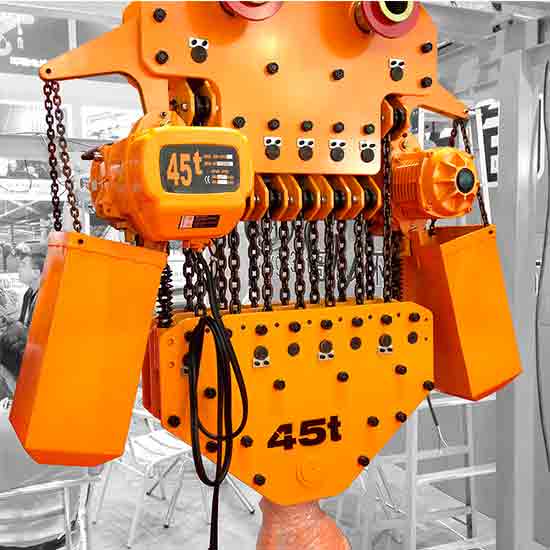

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

Safe & fast air operated hoists. Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs,wide specification, good price.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.