3 Ton Overhead Crane for Sale: Crane Designs & Crane Kits

3 ton overhead cranes for sale. Types of 3 ton overhead cranes, design options, & customizable crane kits for efficient, cost-effective material handling.

Category: Light Duty Crane 1, 2, 3 Ton

Your Trusted 3 Ton Overhead Crane Manufacturer & Supplier

3 Ton Overhead Crane & Economical 3 Ton Crane Kits For Sale Needs

All Types of 3 Ton Crane Design Options and Customized 3 Ton Crane Kits for Sale

3 Ton Overhead Cranes: Significance in Industrial Applications

3 Ton overhead cranes are essential tools in various industries, offering reliable solutions for lifting and moving materials with efficiency and precision. These cranes are often used in factories, warehouses, and construction sites, where heavy lifting is required but space is limited. They are designed to handle loads up to 3 tons, making them versatile enough for both light-duty and medium-duty applications.

With their robust design and advanced features, these cranes can handle a wide range of materials, from metal sheets and heavy equipment to smaller components like tools and machinery parts. In many cases, they help reduce labor costs, increase productivity, and improve safety by automating lifting tasks that would otherwise be done manually. The ability to lift heavy loads with ease makes the 3 Ton overhead crane a critical asset in both indoor and outdoor operations.

Importance of Selecting the Right Crane Type for Your Specific Needs

Choosing the right 3 Ton overhead crane is crucial to ensuring that your operations run smoothly and efficiently. The type of crane you select directly impacts how effectively you can move and position materials, the safety of your workers, and the overall cost of operation.

- Space Considerations: Different crane types fit better in different workspaces. For example, a top running crane may be ideal for high ceilings and larger areas, while an underhung crane is more suited for low ceilings and smaller spaces.

- Load Handling: Not all cranes are built to handle the same types of loads. Some cranes are designed for precise control, while others excel at lifting heavier or more irregular loads. It's important to match the crane type with the kinds of materials you'll be lifting most often.

- Installation Needs: Some cranes, like freestanding systems, don't require ceiling support and can be installed quickly, while others may require additional infrastructure, like beams or tracks. Choosing a crane type that matches your installation capabilities can save you time and money.

In summary, picking the right 3 Ton overhead crane for your needs isn't just about the lifting capacity. It's about optimizing your operations, reducing downtime, and ensuring that the crane can handle the tasks at hand safely and efficiently.

Your Trusted Overhead Crane Manufacturer & Supplier

Types of 3 Ton Overhead Bridge Cranes

Top Running 3 Ton Overhead Bridge Crane

Top Running Crane Systems

Top running cranes are mounted on tracks installed on the top of the building's supporting structure, such as beams or girders. The trolley travels along these overhead tracks, providing the crane with the ability to move across the length of the facility.

- The crane system utilizes the ceiling structure for support.

- Ideal for larger buildings with high ceilings.

- Offers flexibility in movement across expansive areas.

Benefits: Space Optimization, Ease of Movement, and Higher Lifting Heights

Top running cranes are highly beneficial for maximizing space and improving the efficiency of material handling. By utilizing the overhead space, they free up valuable floor area, which is essential for busy manufacturing environments.

- Maximizes vertical space for greater lifting heights.

- Smooth, easy movement allows for precise handling of loads.

- Helps optimize workflow by covering large areas without interfering with floor operations.

3 ton overhead crane single girder desgin for your reference

3 ton overhead cranes single girder , 2 units for tandem lifting

3 ton overhead crane double girder design for sale

Underhung 3 Ton Overhead Bridge Crane

Underhung Crane Systems

Underhung cranes are suspended from tracks that are mounted beneath the ceiling, rather than above it. This design allows for a more compact crane system, ideal for spaces with low ceilings or areas where overhead mounting is not possible.

- Mounted below the ceiling, saving vertical space.

- Lightweight design ideal for low-clearance environments.

- Easier to install in spaces where top running cranes wouldn't fit.

Benefits: Suitability for Smaller Spaces, Ease of Installation, and Cost-Effectiveness

Underhung cranes are ideal for smaller facilities with limited ceiling height. They are more cost-effective and simpler to install than top running cranes, making them a practical choice for businesses with budget or space constraints.

- Perfect for low ceiling heights and smaller spaces.

- Lower cost and faster installation process.

- Efficient for light-duty tasks in compact environments.

3 ton overhead crane with under running crane desgin with european style electric hoist

3 ton underhung bridge crane with electric travelling trolley electric chain hoist

3 ton underhung bridge crane with free standing supporting columns

Freestanding 3 Ton Overhead Bridge Crane

Key Features of Freestanding Systems

Freestanding cranes are not dependent on ceiling support. They are mounted on their own support columns, giving them the flexibility to be installed anywhere within the facility.

- Independent structure with columns supporting the crane.

- No need for ceiling or building support, allowing placement anywhere.

- Ideal for facilities with limited ceiling structures.

Benefits: Flexibility, No Need for Ceiling Support, and Easy Installation

Freestanding systems offer great flexibility in where they can be installed, especially in facilities where ceiling support is unavailable. These cranes are also easy to install, making them a popular choice for businesses that need to set up a crane system quickly.

- Can be installed in locations without ceiling support.

- Easy assembly and installation process.

- Flexible movement and adaptability for various tasks within the facility.

3 ton electric hoist overhead crane with free standing runnway structure

3 ton electric chain hoist overhead crane wtih customized runway, half freestanding and half ceiling mounted

outdoor overhead crane with free standing crane design

Single Girder vs. Double Girder Designs

Top Running 3 Ton Overhead Bridge Crane Single Girder Design

Advantages of Single Girder Systems for Light-Duty Operations

The single girder design uses one main beam to support the crane. It is a lighter and more cost-effective option, ideal for light-duty operations. The design is simpler and requires less material, making it perfect for smaller facilities or operations that don't need heavy lifting.

- Simpler design with one main support beam.

- Ideal for light-duty lifting tasks.

- Lower cost and lighter weight compared to double girder systems.

Crane Kits: Components and Assembly for Top Running Cranes

Top running single girder crane kits include the main girder, trolley, hoist, and end trucks. These kits are designed to be easy to assemble, providing a cost-effective solution for facilities needing a reliable crane system for lighter loads.

- Main components: girder, trolley, hoist, and end trucks.

- Easy assembly with pre-configured kits.

- Cost-effective and efficient for lighter applications.

Underhung 3 Ton Overhead Bridge Crane Single Girder Design

Key Features and Uses of Single Girder Underhung Cranes

Underhung single girder cranes are similar to their top-running counterparts but are mounted below the ceiling. This design is well-suited for environments where headroom is limited, or where the ceiling structure cannot support a top-running crane. It is perfect for light lifting tasks in smaller spaces.

- Mounted below the ceiling, saving vertical space.

- Suitable for low-clearance areas.

- Ideal for light-duty lifting in compact environments.

Overview of Crane Kits and Customization Options

The underhung single girder crane kits typically include the main girder, hoist, trolley, and mounting brackets. Customization options are available, allowing the system to be tailored to specific space or operational requirements. These kits offer flexibility and are easier to install in confined areas.

- Components: girder, hoist, trolley, and mounting brackets.

- Customizable options for space and lifting needs.

- Quick and easy to install in tight spaces.

Specialized 3 Ton Overhead Bridge Crane with Double Girder Design

Double Girder Design: Higher Lifting Capacities and Stability

A double girder crane features two main support beams, providing greater stability and strength for handling heavier loads. This design allows for higher lifting capacities and is ideal for more demanding operations. It is well-suited for environments where heavy lifting and higher safety margins are required.

- Two main beams for added strength and stability.

- Suitable for heavier lifting tasks.

- Higher lifting capacities compared to single girder cranes.

Applications for Heavier-Duty Tasks and Custom Design Options

Double girder cranes are typically used in industries that require the lifting of heavy loads, such as manufacturing plants, warehouses, or heavy equipment handling. Custom design options, including specialized hoists and safety features, can be added to meet the specific needs of each application.

- Ideal for heavy-duty tasks in industrial settings.

- Custom designs available for specialized applications.

- Added safety and control options to handle large loads.

Overhead Crane Kits and Components

Top Running Crane Kits with No Girder for 3 Ton Overhead Bridge Cranes

Components Included in a Top Running Crane Kit

Top running crane kits for 3 Ton overhead bridge cranes typically include all the necessary components for building a functional crane system. These kits feature the main girder, trolleys, hoists, end trucks, and electrification systems. The components are designed to fit together seamlessly, making assembly efficient and straightforward.

- Trolleys: Used to move the hoist across the girder.

- Hoists: The lifting mechanism for handling loads.

- End trucks: Allow the crane to move along the tracks.

- Electrification system: Powers the hoist and trolley.

Assembly and Installation Considerations

When assembling a top running crane kit, you'll need adequate space for installation, as the system requires mounting tracks or rails at the top of the structure. The installation process is relatively simple for those with experience but might require professional help depending on the complexity. Safety checks and alignment are essential to ensure smooth operation.

- Space requirements: Sufficient ceiling height to mount tracks.

- Installation complexity: Generally straightforward, but professional help may be needed for larger systems.

- Safety checks: Ensuring proper alignment and securing components is crucial.

Underhung Crane Kits for 3 Ton Overhead Bridge Cranes

Key Components of Underhung Crane Kits

Underhung crane kits are designed for installations where ceiling height is limited. The kit typically includes the main girder, hoist, trolleys, and mounting hardware. These components are mounted below the ceiling structure, making the system ideal for applications in spaces with lower headroom or where overhead support is insufficient.

- Hoists and trolleys: Mounted underneath the girder for movement.

- Mounting hardware: Securely attaches the system to the ceiling or structure.

Design Options for Ease of Installation and Adaptability

Underhung crane kits offer flexible design options for various applications. The system is designed to be adaptable, with options for different ceiling types and space configurations. Installation is generally easier than top running systems, but careful planning is required to ensure that the ceiling can support the crane's weight and movement.

- Flexible design options: Adaptable to different ceiling types and spaces.

- Easier installation: Less complex than top running cranes.

- Space-efficient: Ideal for lower headroom areas.

Freestanding Columns and Kits for 3 Ton Overhead Bridge Cranes

Importance of Freestanding Columns for Non-Ceiling Supported Installations

Freestanding columns are essential for installations where ceiling support is not available or practical. These columns act as independent support structures, allowing the crane to operate without relying on an overhead ceiling or beams. This is particularly useful in buildings with limited or no structural ceiling support.

- Independent support: Does not require ceiling or structural support.

- Ideal for custom installations: Used in spaces with no suitable ceiling structure.

- Flexibility: Can be installed anywhere in the facility.

Components for Freestanding 3 Ton Crane Setups

Freestanding crane kits include the column assemblies, girder systems, hoists, trolleys, and end trucks. The components are designed for easy integration into facilities that require a flexible and self-supporting system. These cranes can be configured for a variety of lifting tasks and are highly adaptable.

- Column assemblies: Provide vertical support for the crane.

- Girder systems and trolleys: Similar to traditional cranes but designed for freestanding configurations.

- End trucks and hoists: Allow for smooth movement and lifting operations.

Your Trusted Gantry Crane Manufacturer & Supplier

Types of 3 Ton Gantry Cranes for Sale: Steel Gantry Crane and Aluminum Gantry Cranes

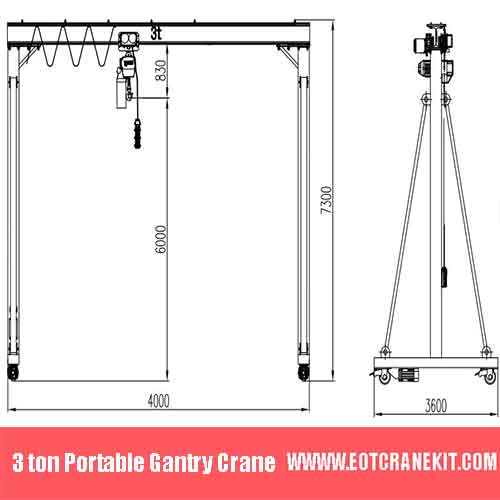

3 Ton Portable Gantry Crane Designs Options for Your Selection

Portable gantry cranes are versatile lifting systems that can be easily moved and set up in various locations within a facility. The 3 Ton portable gantry crane is ideal for applications that require flexibility and mobility, such as maintenance tasks or small-scale lifting projects.

Design Features:

- Adjustable height: Can be customized to meet the lifting requirements.

- Mobility: Equipped with wheels for easy movement around the facility.

- Durability: Built to withstand heavy-duty tasks with sturdy frames and hoisting systems.

Applications:

- Maintenance and repairs in tight spaces.

- Small industrial tasks in warehouses and workshops.

- Lifting and moving heavy machinery or equipment.

portable gantry crane 3 ton

freestanding a frame gantry crane 3 ton

3 ton adjustable gantry crane

3 Ton Aluminum Gantry Crane Options for Your Selection

Aluminum gantry cranes are lightweight alternatives to steel cranes. They provide the same functionality but are easier to transport and set up due to their reduced weight. These cranes are ideal for environments where portability and ease of use are important, while still maintaining the necessary lifting capacity.

Design Features:

- Lightweight construction: Easy to transport and maneuver.

- Adjustable height and span: Can be customized to fit your specific needs.

- Corrosion-resistant: Suitable for environments where rust could be a concern, such as coastal or wet areas.

Applications:

- Ideal for use in smaller workshops or areas with limited space.

- Suitable for industrial environments where weight is a key factor.

- Lifting and moving lighter loads in warehouses, laboratories, and workshops.

Aluminum gantry crane 3 ton

Span adjustable aluminum gantry crane 3 ton

Lightweighted aluminum portable gantry crane 3 ton

3 Ton Gantry Crane Design: Steel vs. Aluminum Gantry Crane

Choosing between steel and aluminum gantry cranes depends on your specific needs, including weight, durability, and the environment in which the crane will be used.

Steel Gantry Cranes:

- Strength and stability: Steel cranes are known for their strength and ability to handle heavier loads over longer spans.

- Durability: Suitable for harsh industrial environments, including outdoor and high-usage areas.

- Heavy-duty performance: Ideal for construction and heavy lifting tasks.

Aluminum Gantry Cranes:

- Lightweight and portable: Aluminum cranes are much lighter than steel cranes, making them easy to move and store.

- Corrosion-resistant: Perfect for environments with moisture, chemicals, or in coastal areas.

- Less robust than steel: Best suited for lighter duty applications and smaller spaces.

3 Ton Gantry Crane Kit

Gantry crane kits come with all the necessary components for assembling a fully functional crane system. These kits are designed for easy assembly and are ideal for businesses looking for cost-effective solutions without compromising on quality or performance.

Included Components:

- Main beams (either steel or aluminum).

- Adjustable legs for custom height settings.

- Hoist and trolley system for efficient load movement.

- Wheels for portability in portable models.

3 Ton Portable Gantry Crane Kit

Portable gantry crane kits provide the flexibility to set up and relocate the crane as needed. These kits include all the components necessary to assemble a mobile lifting solution that can be used in various locations.

Key Features:

- Adjustable height and span.

- Portability: Wheels or casters for easy movement.

- Easy assembly: Comes with clear instructions for simple setup.

3 Ton Aluminum Gantry Crane Kit

The aluminum gantry crane kit is perfect for applications requiring portability and ease of movement in environments where weight and corrosion resistance are important.

Key Features:

- Lightweight frame: Easier to move and transport than steel cranes.

- Corrosion-resistant parts: Suitable for wet or harsh environments.

- Adjustable design: Can be customized to suit different lifting needs.

These gantry crane kits are ideal for a variety of lifting tasks, from light industrial applications to more portable, flexible solutions for tight spaces or temporary setups.

Your Trusted Jib Crane Manufacturer & Supplier

Types of 3 Ton Jib Cranes for Sale: Wall Jib Cranes & Pillar Jib Cranes

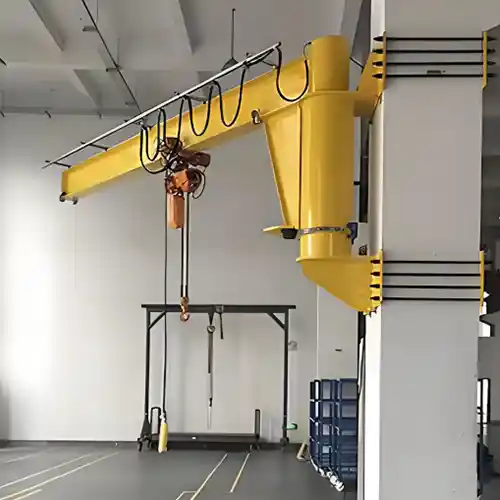

3 Ton Wall Jib Crane Designs Options for Your Selection

Wall jib cranes are mounted to the side of a building or structure, utilizing an existing wall to provide support. These cranes are ideal for tasks that require lifting in confined spaces or areas with limited floor space, offering excellent reach and maneuverability within a set radius.

Design Features:

- Wall-mounted support: Attached directly to a strong wall, which saves floor space.

- Rotating boom: Offers flexibility to move loads within the crane's working radius.

- Customizable arm length: Tailored to suit specific lifting tasks.

Applications:

- Suitable for light-duty lifting in warehouses or workshops with limited space.

- Ideal for indoor use in factories, assembly lines, or areas where a free-standing structure isn't feasible.

- Perfect for repetitive tasks in small, confined spaces like car repair shops or maintenance areas.

3 Ton Pillar Jib Cranes Options for Your Selection

Pillar jib cranes, also known as floor-mounted cranes, are independent structures mounted on a solid base. These cranes can rotate around their vertical axis, offering greater versatility compared to wall-mounted models. They are ideal for lifting heavier loads in a wider working area.

Design Features:

- Self-supporting structure: Requires no external walls, providing greater flexibility in crane placement.

- 360-degree rotation: Can move in any direction within its working radius.

- Heavy-duty construction: Built for more demanding lifting tasks with robust materials.

Applications:

- Often used in industrial environments such as factories, shipyards, or construction sites.

- Ideal for large warehouses where flexibility and load movement are important.

- Frequently used for handling heavy equipment or moving materials between different production areas.

3 Ton Jib Crane Design: Wall vs. Floor Jib Crane

When selecting between wall and floor jib cranes, understanding the unique benefits of each design will help you make the best choice for your operations.

Wall Jib Cranes:

- Space-saving: Wall-mounted design maximizes floor space and is ideal for confined areas.

- Installation: Easier to install since they leverage existing structures, reducing installation time and cost.

- Limitations: The load capacity and range are somewhat limited by the wall's strength and the crane's positioning.

Floor Jib Cranes:

- Greater flexibility: Can be placed anywhere on the floor, providing versatility in crane positioning.

- Higher load capacity: Generally able to handle heavier loads and more demanding tasks compared to wall-mounted models.

- Installation: Requires a solid foundation for the crane to be installed, making setup a bit more complex.

3 Ton Wall Jib Crane Kit

The 3 Ton wall jib crane kit provides everything you need to set up a wall-mounted crane system. This kit is ideal for smaller spaces where utilizing the building's structure is beneficial.

Key Features:

- Compact design: Saves floor space by using the existing wall for support.

- Easy installation: Mounts directly to a wall, making setup quick and efficient.

- Adjustable arm length: Customizable to suit specific lifting needs within the space.

3 Ton Floor Jib Crane Kit

The 3 Ton floor jib crane kit offers a self-supporting solution for areas that need a more versatile lifting option. These cranes provide the ability to rotate 360 degrees and are perfect for larger, more open spaces.

Key Features:

- Freestanding design: Can be placed anywhere on the floor without the need for wall support.

- Heavy-duty construction: Designed to handle more demanding tasks, making it suitable for industrial environments.

- 360-degree rotation: Provides flexibility to move loads in any direction.

Both wall and floor jib crane kits provide a complete and convenient solution for your lifting needs, allowing you to choose the option that best fits your space and load requirements.

Your Trusted Electric Hoist Manufacturer & Supplier

3 Ton Electric Hoists: Selection Options

Electric Chain Hoists for 3 Ton Cranes

Electric chain hoists are a popular choice for 3 Ton crane systems, especially in light to medium-duty applications where efficiency and ease of use are key.

Key Features and Benefits:

- Compact and Efficient: Electric chain hoists are smaller and lighter than wire rope hoists, making them ideal for confined spaces such as smaller workshops.

- Ease of Use: Designed with simple controls, these hoists are easy to operate, making them suitable for frequent lifting tasks in various environments.

- Cost-Effective: Generally more affordable, electric chain hoists offer a good balance between price and performance for 3 Ton lifting capacities.

- Low Maintenance: Fewer moving parts mean that electric chain hoists typically require less maintenance compared to wire rope hoists, reducing downtime and costs.

Applications:

- Light to Medium-Duty Lifting: Perfect for tasks like moving small to medium loads in manufacturing facilities, warehouses, and assembly lines.

- Workshops and Service Areas: Ideal for repair shops, small production areas, and maintenance tasks where quick and reliable lifting is required.

electric chain hoist

Low headrom electric chain hoist

European style electric chain hoist

Electric Wire Rope Hoists for 3 Ton Cranes

For operations that require higher lifting heights or more durable equipment, electric wire rope hoists are the ideal solution. They offer strength, resilience, and longer lifting distances.

Advantages:

- Higher Lifting Heights: Wire rope hoists are designed to lift heavy loads over greater vertical distances, making them a better fit for high-clearance applications.

- Durability and Strength: The steel wire rope provides exceptional strength and durability, ideal for heavy-duty tasks and demanding environments.

- Longer Lifespan: Due to their robust design, wire rope hoists generally offer a longer operational life, especially in harsh environments.

Ideal Applications:

- Heavy Lifting in Large Facilities: Suitable for environments like manufacturing plants, shipyards, and large warehouses where lifting heavy loads over long distances is required.

- Construction and Material Handling: Beneficial for lifting construction materials, large industrial components, and other heavy objects that require stability and durability.

Key Features to Look For:

- Anti-Wear Mechanisms: Features like automatic lubrication or wear-resistant ropes extend the durability of the hoist.

- Smooth Operation: Look for hoists with smooth start and stop functionality to minimize load slippage and prevent sudden jerks during operation.

3 ton electric wire rope hoist

3 ton wire rope electric hoist

Motor of 3 ton low headroom electric hoist

Hoist Motor Selection

Selecting the right motor for your 3 Ton hoist system is crucial for ensuring optimal performance, reliability, and safety.

Motor Specifications and Considerations:

- Power Requirements: The motor must meet the crane's weight capacity and lifting speed needs. Ensure that the motor can handle the 3 Ton load without risk of overloading.

- Duty Cycle: If the crane will be used frequently, opt for a motor designed for high-duty cycles to ensure consistent performance under demanding conditions.

- Environmental Considerations: If your crane will be used in wet, hazardous, or explosive environments, choose a motor with appropriate sealing or explosion-proof designs.

Motor Options:

- Standard Motors: These motors are typically sufficient for most operations and offer reliable performance in less demanding environments at a more affordable price.

- Variable Speed Motors: For tasks requiring precise control or variable lifting speeds, variable speed motors provide enhanced safety and better load handling by reducing sudden jerks during operation.

Choosing the right motor impacts not only the hoist's performance but also its safety and long-term maintenance. Be sure to match motor specifications with your operational needs for maximum efficiency.

Buying a 3 Ton Crane: Key Considerations

Evaluating Your Needs

When purchasing a 3 Ton crane, thorough evaluation of your specific operational needs will help ensure you select the right equipment for maximum efficiency and safety.

Crane Capacity and Span:

- Capacity: A 3 Ton crane should be able to lift loads up to 3 tons, but it's essential to verify that this is sufficient for your heaviest loads. Ensure that the crane's capacity matches both your current and future lifting requirements.

- Span: The span, or the distance the crane can cover, should fit the layout of your facility to ensure smooth and efficient material handling.

Headroom:

- Headroom refers to the vertical clearance available where the crane will be installed. Ensure there is enough headroom for the crane to operate without obstruction, particularly when lifting and moving loads.

Environmental Factors:

- Exposure to Harsh Conditions: Consider whether the crane will be exposed to factors like high humidity, chemicals, or extreme temperatures. Choose a crane built to withstand these environmental elements.

- Floor Conditions: Check whether the floor is smooth, level, or sloped, as this can affect installation and operation.

Types of Loads to Handle:

- Identify whether the crane will be lifting heavy equipment, raw materials, or smaller parts. The crane's design should be suitable for the types of loads you'll be handling, with considerations for load stability and secure lifting.

Price vs. Value

It's important to balance the price of the crane with the value it will provide over time.

Cost Considerations for Different Crane Types:

- Top Running Cranes: These tend to be more expensive but offer greater lifting heights, smoother operation, and the ability to handle heavier loads, making them a good investment for demanding tasks.

- Underhung or Gantry Cranes: More affordable options suitable for smaller operations or those with limited space.

- Jib Cranes: While generally economical, jib cranes may have limited reach or lifting height compared to overhead cranes.

Balancing Budget with Quality, Safety Features, and Durability:

- While staying within budget is important, don't sacrifice safety and quality for a lower initial cost. Opt for features like overload protection, corrosion-resistant materials, and variable-speed controls, which can provide better value in the long term by minimizing maintenance and improving operational safety.

Customizations and Specifications

Customizing your crane can enhance its performance, efficiency, and safety for specific applications.

Selecting the Right Features for Specialized Tasks:

- If your lifting tasks require specialized capabilities, consider customizations such as specialized hoisting systems or enhanced safety mechanisms like anti-collision features.

- Ensure the crane includes essential safety systems, such as overload limiters and emergency stop features, to prevent accidents and enhance operator control.

Crane Kits and Pre-assembled Options:

- Kits: Crane kits allow for greater customization during assembly, letting you select specific components and features to suit your needs.

- Pre-assembled Cranes: Pre-assembled cranes are often quicker to install and can save you time and installation costs, though they may offer less flexibility in terms of customization.

Selecting between a kit or pre-assembled crane depends on your timeline and whether you require specific customizations to meet operational needs.

FAQs on 3 Ton Crane and Hoist Purchases

What's the difference between a top running and underhung 3 Ton overhead crane?

- Top Running Cranes: These cranes run on rails positioned above the crane, utilizing the full height of the facility. They are ideal for larger facilities with sufficient ceiling space. They offer a higher lifting height and more space for load handling.

- Underhung Cranes: These cranes are mounted on tracks that are suspended from the ceiling, making them a better option for buildings with lower headroom. They tend to be more space-efficient and easier to install in smaller spaces.

How do I choose between a single girder and double girder crane for my application?

- Single Girder Cranes: These cranes are typically lighter, more cost-effective, and suitable for lighter duty tasks. They work best for applications where lifting capacity is not as high and operational efficiency is the focus.

- Double Girder Cranes: These cranes are stronger, providing more lifting capacity and greater stability. They are the preferred choice for heavier-duty tasks or operations that require higher lifting heights or heavier loads.

What factors influence the pricing of a 3 Ton crane or hoist?

- Type of Crane: Top running cranes generally cost more due to their design and ability to cover larger spans. Gantry cranes or jib cranes may be less expensive depending on the design.

- Components and Customizations: Features like electric hoists, specialized safety systems, and custom lifting options will affect the price. Additional accessories like remote control systems or variable speed controls also influence the final cost.

- Installation and Shipping Costs: Shipping fees, installation complexity, and lead times can all add to the overall cost.

Should I choose a gantry crane or an overhead crane for my facility?

- Gantry Cranes: Ideal for outdoor or open areas where you may not have the ceiling support for an overhead crane. They are more flexible as they don't require building modifications, but they typically cover a smaller range of heights and spans.

- Overhead Cranes: These are often better for indoor applications or for facilities with high ceilings. They provide more precise control and larger lifting heights but require installation of a track system and can be more expensive.

Can I buy a crane kit for customized installations?

Yes, crane kits are available and can be customized according to your needs. These kits typically include all necessary components for assembly, but you can add specific parts based on your application, such as custom lifting gear, controls, or hoists to meet your operational requirements.

What are the benefits of using a jib crane in tight spaces?

Jib cranes are compact and can be installed in tight spaces where a larger overhead or gantry crane may not fit. They are ideal for lifting small to medium-sized loads over short distances and offer great flexibility in confined areas. They also have a low cost of installation and maintenance compared to larger cranes.

How do I select the right electric hoist for my crane system?

- Capacity: The hoist should match the crane's capacity. For a 3 Ton crane, ensure the hoist is rated to handle at least that amount.

- Lifting Height: Choose a hoist that can provide the necessary lifting height for your application.

- Type of Load: Consider the type of load (e.g., equipment, materials) being lifted, as some hoists are better for certain materials or load types.

- Motor Specifications: Consider the motor power needed for your lifting requirements. You can choose between standard or variable speed motors based on the level of control required.

What are the maintenance considerations for 3 ton cranes and hoists?

- Regular Inspections: Ensure that all components, including hoists, rails, and lifting mechanisms, are checked regularly for wear and tear.

- Lubrication: Keep the moving parts well-lubricated to reduce friction and wear, especially for hoists and crane wheels.

- Load Testing: Periodically test the crane to ensure it can handle the rated load without issues.

- Safety Systems: Inspect safety features like overload limiters, emergency stop systems, and control systems to ensure they are functioning correctly.

- Cleaning: Keep the crane and hoist systems free from dirt and debris to maintain smooth operation and prevent corrosion.

Conclusion: Customized 3 Ton Crane and Kits for Your Needs, Send Us An Inquiry

How to Choose, Buy, and Install a 3 Ton Crane or Hoist

Choosing the right 3 Ton crane or hoist involves evaluating several important factors:

- Application Needs: Understand the type of load to be handled, the required lifting height, and the space available in your facility.

- Crane Design: Decide between top running, underhung, or gantry cranes based on your space and lifting requirements.

- Hoist Selection: Choose between electric chain or wire rope hoists, considering their durability, lifting height, and motor specifications.

- Customizations: Depending on the nature of your operations, you may want to customize features such as control systems, safety mechanisms, or load handling capacities.

- Assembly and Installation: Consider whether you want to assemble the crane yourself or opt for professional installation, ensuring the crane is set up correctly and efficiently.

Final Advice on Ensuring Safe, Efficient, and Cost-Effective Crane and Hoist Operation

- Safety First: Always prioritize safety features such as overload protection, limit switches, and emergency stop systems. Regular inspections and maintenance are essential for keeping your crane in top condition.

- Operational Efficiency: Choose the right hoist and crane design for your operations. A well-matched system will improve productivity and reduce downtime.

- Cost Considerations: While it's tempting to go for the cheapest option, consider the long-term value. Investing in higher-quality cranes with better safety and durability features can save you money on repairs and replacements in the future.

- Professional Guidance: If you are unsure about your choice, consult with experts who can help you select the best system for your needs. Proper planning and consultation can ensure you get the most cost-effective and suitable crane for your operations.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch