Paper mill cranes, process overhead crane for paper mills

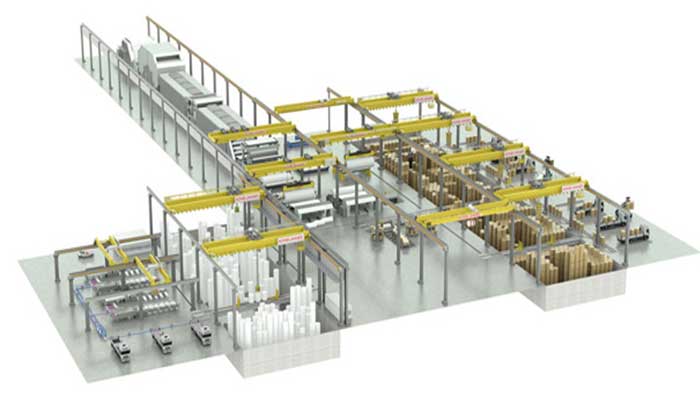

Processed overhead travelling cranes system minimizing your uptime

Paper mills process various types of usable papers, made from various types of organic fibers, such as wood pulp and cellulose plant fibers from plants such as bamboo or hemp. And in the recycled paper making mills, the new paper products are made from old processed newspapers, recycled rags, cloth or other materials. For the handling of tonnages of raw material and finished paper products , various types of paper mill cranes are required through the whole procedures from moving raw materials for processing to parent paper rolls stacking.

Overhead cranes for paper mills & paper rolling mills

Our processed overhead travelling cranes provide optimal industrial material handling solutions in the paper mills for every section of paper production process with high precision and safety which will keep returning of your investment by maximizing your uptime with remarkable endurance and low maintenance.

Overhead crane systems for paper processing & storage

With wide range of paper mill cranes and hoists , we are able to supply customized systematic overhead travelling crane solutions for the production of paper making:

- At the dry end of the paper making machine, the parent roll handling cranes are used for handling full reels safely and returning of empty reels effectively.

- At the wet end of the paper making machine, overhead paper mill cranes are used for the maintenance works, such as screens and felts replacement, etc.

- The paper roll handling cranes are also required to help the transportation and replacement of rollers and other components of the paper machine, and all the service and maintenance work in every sections of a paper manufacturing mill and plants

- The efficient production output of a paper mill requires the overhead travelling cranes reliable and versatile. Usually the full automatic or semi-automatic overhead cranes are used for paper roll stores which can pickup the the parent rolls gently and stack them vertically in the storage section.

Processed overhead travelling cranes for parent roll handling

Parent roll handling crane is a specially designed overhead travelling cranes for lifting and moving the finished products, the parent paper rolls, in the final workshops and move them to a specific location as required.

Double girder overhead travelling cranes with J hook roll lifters for paper roll handling

Main parameters of parent roll handling cranes

- Lifting capacity of paper roll handling cranes : 3.2t~50t

- Span of paper roll handling cranes : Customized

- Working Class of paper roll handling cranes : A6,A7,A8

- Parent roll lifter: J hook beam spreader

A wide range of paper mill cranes are available in the pulp and paper industry.Contact us to get your process crane for paper mill factory.

Features of overhead parent roll handling cranes

Intelligent control is adopted for the parent roll handling crane to meet busy productivity in the paper mill with high work efficiency and high lifting precision. With the encoder, sensor , and the programmable PLC , the industrial overhead crane crane system can meet your paper mill requirements which will largely improve your working efficiency and the safety during operation.

To combat the harsh application and ensure crane safety, anti-swing device is installed on the overhead crane systems to prevent the happening of accident together with the wireless communication module to ensure safety of the crane equipment under high speed working condition .

Paper mills maintenance & supportive material handling crane

Customized overhead cranes are vital material handling equipment in paper making industry. With rich experience on paper mill crane designing & manufacturing, we are able to offer turn-key overhead travelling crane solutions for material handling in your paper mills and paper making plant. The industrial overhead cranes can be used for material handling in the working area of paper making including raw material handling such as,woods depositing and transporting pulp processing line, parent paper roll and cardboard making line,and general material handling and machinery maintenance,etc.

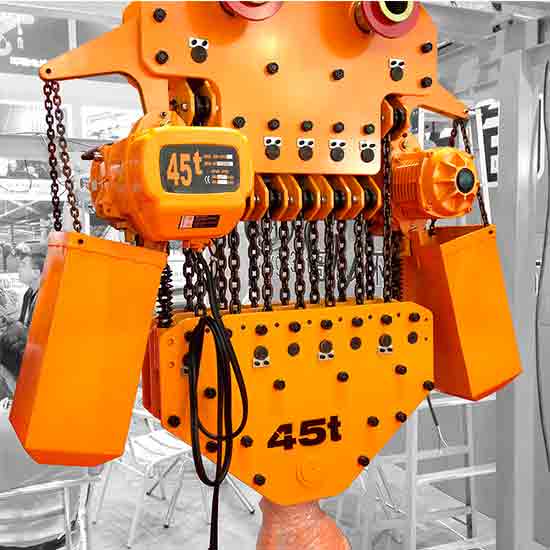

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

Safe & fast air operated hoists. Air hoist & pneumatic hoist is a compressed air powered hoist & air operated hoists, various hoist designs,wide specification, good price.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

As one of the best crane manufactuer and supplier in China, we offer crane sevices for turnkey crane projects ie.overhead, gantry & jib cranes and other travelling cranes from crane degin, manufactuering & installation, and crane parts supplying, etc.

Contact us to get tailored overhead crane design, free CAD overhead crane drawing, defined overhead crane specifications for your particular application with lower overhead crane costs & good overhead crane price. Send an overhead crane inquiry to your latest eot crane price now!

Overhead maintenance crane

- Lifting capacity of overhead maintenance crane: 3.2t~50t

- Span of overhead maintenance crane: Customized

Usually, the overhead maintenance crane systems can be used for the equipment maintenance including wet end crane for maintenance and empty roll change , coater crane , Deinking equipment maintenance crane , floor hoist and cranes, workshop crane, and workstation crane system, etc.

The wet end crane has multiple functions which can be used as maintenance crane for paper machine and also as a dry end crane back up.This paper mill cranes can be used to erect the paper machine, to help roll machine maintenance and to lift and transport machine parts. The particular designed overhead cranes can help to change the press or dryer section rolls of the paper machine quickly and accurately and also can ensure the safety of the heavy press rolls handling in warm, humid and aggressive application conditions of paper making workshops.

Single Girder Overhead Crane

- Lifting capacity of single girder overhead crane: 1~20t

- Span of single girder overhead crane: 7.5m~25.5m,

- Working class of single girder overhead crane: A5,A6

The single girder overhead crane is an ideal material handling solution for industrial applications for light material handling with capacity from 1 ton up to 20 tons. The single girder cranes are widely used and welcomed due to the features of light weight, small wheel pressure, multiple configurations with types of crane hoists, etc. The process crane can fit your application pleasantly, improve your efficiency,, make the best utilization of working space and save your investment on building construction, etc.

Pillar jib cranes with 180º 270º 360º rotation

- Lifting capacity of pillar jib crane: 0.5~10t

- Effective arm length of pillar jib crane: 5m~8m

- Rotary degree of pillar jib crane: 180º 270º 360º optional

Pillar jib cranes can help the overhead paper mill cranes for the supportive material handling works which can be designed with various configurations.

Paper roll lifter and tongs

For various heavy paper rolls handling at different industrial applications such as printing, types of paper roll lifters are developed such as, paper roll tongs, paper roll grippers or beam spreaders, etc. Processed roll lifters are available to fit your overhead travelling cranes and meet your specific application requirements to enable rapid and safe paper roll lifting and moving with a long working life.

Parent roll lifter - J hook beam spreader

The J hook beam roll lifter is an excellent ergonomic paper roll lifting devices. The hook of the beam roll lifter pick up rolls by taking a mandrel inserted into the roll. To meet different application requirements, the J hook beam roll lifter can be designed with the features of low Headroom,narrow side clearance and easy operation, etc.

The J hook beam roll lifter are usually used for handling the paper rolls which picks up the rolls by a mandrel inserted through the roll. The lifting eye is made from mild steel and upper inside edges are used to protect crane hook.

Features of the J hook beam roll lifter for handling parent rolls

- The J hook beam roll lifter is used to lift and move rolls by a mandrel or a shaft inserted through rolls easily and efficiently.

- For limited applications, the low headroom roll lifter designs are available with a pair of fixed or pivoting J-Hooks.

- 125% capacity proof tests for roll lifters are conducted before deliver and certificates are available if required

- Roll lifter options: Manual or motorized beam rotation, width adjustable spread, with high lifting capacity, Low headroom design Spreader beam design with top rigging, additional hooks,beam stand, hook linings etc.

Process one-stop paper mill cranes services

Cranes for paper mills or the paper mill cranes are important for paper making industry. Tailored overhead cranes systems for your specific applications will help you to improve working efficiency and ensure operation safety. Our industrial cranes are featured as high reliability, durability, low maintenance which can help to maximize your uptime!

Turn key serves for your paper mill material handling are available. We can provide you overhead cranes systems for paper making, storage, maintenance, and delivery, etc. Contact us to learn more about overhead crane, maintenance crane and types of paper mill cranes.