Types of Industry Cranes for Different Industrial Applications

Industrial cranes are machines that are utilized in the manufacturing and repair of machines. These are material-moving machines that use levers and pulleys to operate an arm, a long truss that lifts and lowers loads that can't be done by hand or tiny gear. Different types of Industrial Cranes are utilized on a daily basis in a wide range of industries; they are mostly used in large construction projects.

In simple terms, an Industrial Crane is a device or technology that carries and adjusts heavy loads, bridging gaps if they occur anywhere in the process, component, or structure. Cranes come in a variety of shapes and sizes, and they are employed for a variety of tasks.

Different types of Industrial Cranes

Cranes are built for a variety of jobs and functions. Aerial Cranes, Bridge Cranes, Crawler Cranes, Gantry Cranes, Jib Cranes, Railroad Cranes, Rough Terrain Cranes, Ship Deck Cranes, Tower Cranes, Truck Mounted Cranes, Workstation Cranes, Overhead Cranes, and many others are just a few examples. Industrial Cranes of this type are utilized all over the world. Sampson Moore of England invented and built the world's first electric overhead crane in 1876, which was used to hoist cannons at the Royal Arsenal in London. The first crane manufacturing firm, Ludwig Stuckenholz Company, was founded in Germany in 1830. Industrial cranes are used to raise and hoist big instruments and equipment that are impossible to lift manually.

Here are seven different types of industrial cranes that are employed in various vocations, projects, and settings.

Overhead Cranes

Overhead cranes, sometimes known as Bridge Cranes, are a type of crane commonly used in industrial settings. It consists of two parallel runways connected by a moving bridge. Also moving along the bridge is a lifting component. Because these are made in a variety of designs depending on the use, there are some general safety guidelines for overhead cranes that must be observed. Overhead cranes come in a variety of sizes and are commonly employed in situations where efficiency or downtime are crucial.Many enterprises employ an EOT (Electric Overhead Travelling) Crane, which is an electric crane controlled by a control pendant, radio/IR, remote pendant, or from an operator cabin. These cranes are commonly employed in factories to transport huge goods.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

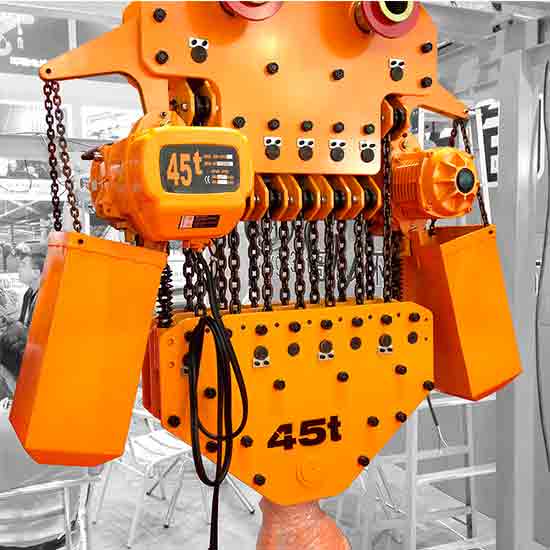

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

Truck Mounted Cranes

One of the numerous types of industrial cranes is truck mounted cranes. These are put to a truck with rubber tires and offer outstanding mobility. The pieces (outriggers) are used to stabilize the crane when it is transporting loads of goods. They can be extended vertically or horizontally. It aids in the accessibility of isolated places and is commonly employed in construction projects.

Tower Cranes

Tower cranes are the most well-known and recognized cranes, and they are commonly utilized in metropolitan construction projects. Their tall lattice booms stretch high into the skylines, and they are exceedingly tall. Hundreds of feet tall, tower cranes have long spinning lattice booms positioned at the top. They're also utilized to create skyscrapers and high-rise buildings, where they may transport materials from the ground to the tower.

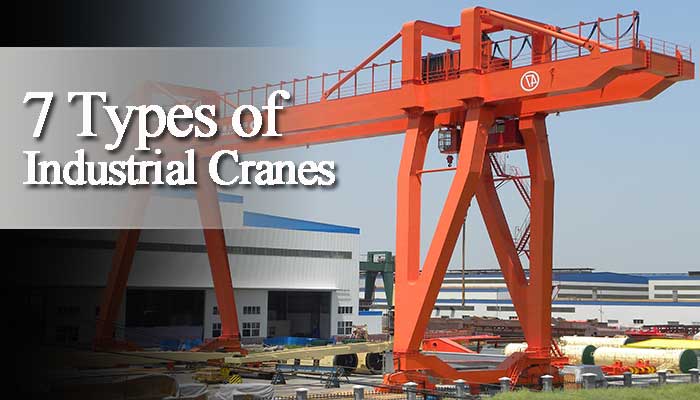

Gantry Crane

The Gantry Crane is one of the world's largest cranes, capable of lifting more than 20000 tons. This crane bridge is attached to the crane's tall wheeled legs at each end, making the entire construction mobile. They are used to load and unload containers as well as assemble massive ship components in harbors and shipyards. Smaller gantry cranes are commonly employed in industrial warehouses.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Jib Cranes

Jib Cranes are commonly employed in industrial fabrication, manufacturing, and maintenance applications where raw materials or other components must move in a circular or semi-circular coverage area. It is made up of a hoist and a single boom, which is usually an I-beam or square steel tubing.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

Rough Terrain Crane

Rough Terrain Crane is a crane with a single engine, which means the undercarriage and crane are powered by the same engine. Rough Terrain Crane is designed to be used off-road and is positioned on an undercarriage with four rubber tires. Its outriggers are extended vertically and horizontally to stabilize the crane.

Loader Crane

A loader crane is a hydraulically driven crane with an articulated arm that attaches to the trailer and is used to load equipment onto it. Because it can be folded into many sets or portions, the Loader Crane is suitable for usage in compact places. Because of their ability to fold, loader cranes can be taken or transported rapidly.

Advantages of Industrial Cranes

1.Each type of Industrial Crane has its own set of characteristics, such as load capacity, size, lifting heights, and weight.2.The mobility of heavy equipment is aided by the use of an industrial crane.

3.An industrial crane aids in the transportation of large components from one location to another.

4.Bridges the gap between rural places and easily accessible facilities that are unavailable.

5.It contributes to the industrialization and modernization of our country.

6.It relieves us of the discomfort and stress associated with manual labor involving the carrying of big loads.

7.It ensures the viability of industries, factories, manufacturing, and building.

8.Industrial Crane is safe and effective in all types of operations due to its structural stability.

Conclusion

During a project, civil engineers employ a variety of cranes. Industrial cranes transport huge loads and equipment to various locations; they may transfer large pipelines from one location to another; and we've all seen one type or another. These are advantageous during the construction of buildings, bridges, and overpasses. These are a valuable resource for the industry. It turns a difficult task into a simple one. It saves both time and labor costs. For each sort of project, there is a distinct type of industrial crane, thus each major feature should be understood.