Metal Processing

Various types of industrial cranes, including EAF charging crane, ladle crane, forging crane, finished product handling overhead travelling cranes other process cranes, are widely used for steel, iron, aluminum and copper processing industry for material handling in the process of raw materials handling, machining, fabricating, shaping and finished products handling, transportation and storage, etc.

Overview of Overhead Cranes in Steelmaking

Explore essential overhead crane types, capacities, and applications for efficient steelmaking and handling steel products in various settings.

Overhead cranes play a crucial role in the steelmaking industry, serving as the backbone of production and post-production processes. These powerful machines are essential for moving heavy loads across the factory floor, from raw materials to finished products. In steel production, overhead cranes handle everything from massive steel scrap to molten metal, making them indispensable in keeping operations smooth and efficient.

In the production stages, overhead cranes help in the charging of electric arc furnaces and handling of molten steel, significantly reducing manual labor and increasing safety. In post-production, they manage the movement of hot and cold rolled steel, ensuring products are processed quickly and accurately.

Benefits and Efficiencies Provided by Overhead Cranes

One of the biggest advantages of overhead cranes is their ability to streamline operations. They enhance safety by reducing the need for manual handling of heavy and dangerous materials. This automation not only minimizes the risk of injury but also increases efficiency, allowing for faster processing and movement of materials.

Another key benefit is their versatility. Overhead cranes can be equipped with various attachments like clamshell buckets, orange peel grab or magnetic grabs, making them suitable for different tasks, from scrap handling to precise casting operations. This adaptability means fewer types of equipment are needed, saving on costs and maintenance.

Practical tip: When choosing an overhead crane, consider the specific needs of your operation. Think about the types of loads you'll handle, the space available, and the required lifting capacity. Investing in a crane that matches these needs will pay off in efficiency and safety. Trust me, having the right equipment can make a world of difference in your operations.

In summary, overhead cranes are more than just big machines; they are vital tools that drive efficiency, safety, and productivity in steelmaking. With the right crane, you can tackle the toughest jobs with ease, ensuring a smoother, more reliable production process.

Overhead Crane Choices: Overhead Cranes for Steelworks, Fabrication & Storage

Industry Challenges

Industries that manufacture and process metal components and products rely on industrial overhead travelling cranes system for handling loads such as metal stock, coils, bars, work-in-process, and finished items, etc. Due to the specialized industrial application, the metal processing industrial cranes are facing the following challenges:

- For the crowded shops with narrow, confined spaces, the Industrial cranes should be with optimal design to make the best utilization of the value space.

- Various types of industrial cranes are used for moving and lifting materials and products to reduce the manpower and improve safety.

- The industrial overhead cranes are required to support full-capacity operations and are durable to withstand the busy production for a long time.

- Reasonable material handling crane costs make the best value of your investment on the industrial cranes.

Due to the hazards and dangerous environment of metal processing industry, the industrial material handling cranes needed should withstand the harsh conditions with high temperature, open flame, high dusty, corrosive gas and strong vibrations, etc.. to guarantee the safety and productivity.

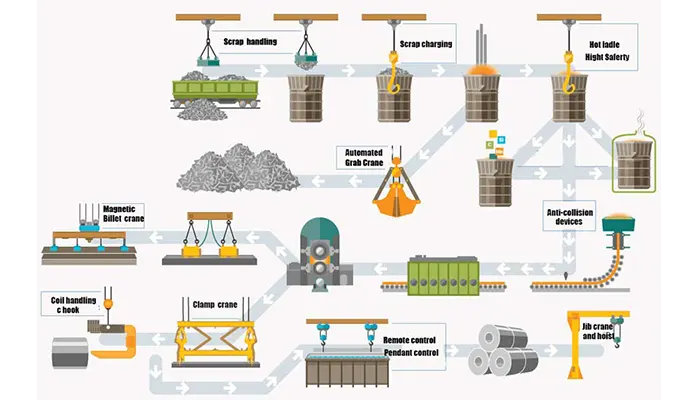

Material handling solutions for every stage of steel production

Types of industrial cranes solutions are used to in every process of metal processing to meet maximum safety and productivity levels, including:

- Scrapyard - Steel scrap handling begins at the scrapyard, where a scrap handling crane is adopted to transport the metal scraps to the smelting area. Usually, the Electric Overhead Travelling Bridge Cranes or Gantry cranes with a grab bucket or magnet are used to handle the tonnes of metal scraps in different shapes and sizes.

- Smelting – During the smelting of scrap metals, the processed overhead cranes are required to lift and transport the molten metals or ladles in the extreme environment. Safe handling of the extreme temperature ladle comes the first. The tundish and ladle cranes equipped with ladle hook and ladle bucket are installed for the safe handling of molten metal and ladle with enhanced safety.

- Rolling Mill – The hot and malleable slabs and billets from the smelters are transported to the rolling mill for casting and shaping.The overhead travelling cranes in the rolling mills are equipped with specialized below-the-hook devices such as detachable magnets and tongs for efficient handling of slabs and billets.

- Storage Area – Overhead bridge cranes are installed to move around in the warehouse for the handling of steel coils, etc. Forklifts are mainly For the stack steel products on the high storage racks, the forklifts are usually used for its high accessibility to reach anywhere around the racks where a crane is difficult.

Types of industry cranes for metal processing industry

Various types of industrial cranes for steel mill and steel plants, including EAF charging crane, ladle crane, forging crane, finished product handling overhead travelling cranes & scrap crane and other process cranes, are widely used for steel, iron, aluminum and copper processing industry for material handling in the process of raw materials handling, machining, fabricating, shaping and finished products handling, transportation and storage, etc.

Scrap handling cranes- custom overhead cranes for steel mills

In scrap yard, efficient scrap handling is important. The customized scrap handling cranes ,based on your application and production requirements, can efficiently transport the metal scrap to the trucks or designated places as required .To combat the harsh environment of high dusty and noisy, the enhanced safety devices and measures are used to ensure the safety of operation and your crane operator.

Scrap charging crane- tailored overhead cranes for steel mills

Charging cranes are heavy duty overhead travelling crane , also called scrap charging crane, furnace charging crane, converter charging crane. which are used to feed scrap into the furnace. The scrap charging cranes are a type of steel mill cranes as the ladle crane, teeming crane, casting crane, foundry crane,which can ensure safe and efficient operation in the extreme heat, dusty and harsh conditions of the steel making industry, with sharing features of high safety, reliability and stability, etc.

Molten metal & ladle casting crane- overhead crane designed for steel mills

The molten metal handling crane also named, ladle teeming crane, casting crane or foundry crane is a type of specialized industrial cranes, designed and manufactured for handling molten metal & ladle from a furnace to the casting areas. Safety and reliable is the prominent features of ladle handling, equipped with double braking system, safety controls and other various safety measures and div ices to meet the industrial requirements in efficiency and safety.

Billet handling cranes& Slab handling cranes -Processed overhead travelling cranes for steel mills

The slab and billet handling overhead travelling cranes are used for the handling of hot or normal temperature billets, blooms or slabs, etc.The process industrial overhead cranes with lifting clamps or magnets are required to lift and transport the hot heavy steel slabs from the casting area to a rolling mill or for taking the room temperature steel slabs to the designated storage places for stacking, loading and unloading operation with high safety, reliability and efficiency.

Forging cranes- heavy duty steel mill overhead cranes

The forging crane is a process industrial overhead cranes for types of forge pieces lifting, cushioning and overturning, etc. The forging cranes are very important material handling equipment in forging workshops. The rated lifting capacity of forging crane is the total weight of , the processed lifting devices , the up-ender, and the biggest work piece lifted.

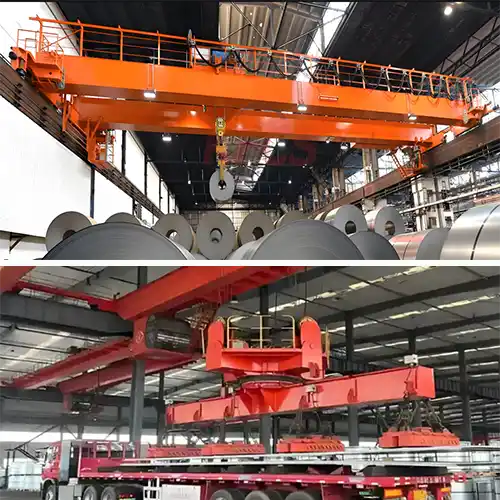

Coils, bars and plate handling cranes - steel mill downstream products handling overhead cranes

With different lifting devices, the industrial material handling cranes can handle the various types of steel products such as, the coils, bars, plates and other steel products from the rolling area to the next destination as required.

Overhead crane for generaul material handling in steel mills

The industrial overhead cranes are designed and manufactured based on the advanced crane technology with high quality and wide configurations and specifications which can lift and transport loads from 5 ton, 10 ton, 15 ton, 20 ton up to 500 tons .

Gantry crane for steel mill material handling

Industrial gantry cranes are widely used in steel mill for material handling , such as grab gantry crane for steel scap handling, finished steel production handling, such as steel plate, steel pipe, steel beams, steel bars, etc.

Overhead Crane Applications in Steelmaking Procedures

Steelmaking Process Overview

Steelmaking is a complex, multi-stage process that transforms raw materials into steel. It starts with melting scrap metal or iron ore in a furnace, then refining the molten metal to achieve the desired chemical composition and properties. The process includes charging the furnace, refining, casting, and finally rolling the steel into various shapes.

Overhead cranes are crucial at every stage of this process. They handle everything from moving raw materials to the furnace, managing molten metal, and even transporting finished steel products. By doing so, they ensure that operations are more efficient and safer. These cranes streamline production, reduce manual labor, and minimize the risk of accidents associated with handling heavy and dangerous materials.

Scrap Yard Handling

- Crane Type: Single Girder Overhead Cranes, Gantry Cranes

- Typical Capacity: 5 to 30 tons

- Typical Objects Handled: Steel scrap, metal bales

- Below Hook Devices: Clamshell buckets, magnetic grabs

In the scrap yard, overhead cranes are essential for handling large quantities of steel scrap. Single girder and gantry cranes are commonly used due to their robustness and ability to handle heavy loads efficiently.

Practical Tips for Selection:

- Opt for cranes built to withstand heavy usage and harsh conditions. Durability is key since these cranes often face intense wear and tear.

- Magnetic grabs and clamshell buckets are highly effective for sorting and moving scrap metal. They ensure a clean, efficient process by easily picking up and separating different types of scrap.

Electric Arc Furnace (EAF) Charging

- Crane Type: Double Girder Overhead Cranes

- Typical Capacity: 20 to 50 tons

- Typical Objects Handled: Scrap metal, additives

- Below Hook Devices: Heavy-duty buckets, charging baskets

Charging the Electric Arc Furnace involves moving scrap metal and additives into the furnace. Double girder overhead cranes are preferred for this job due to their high load capacity and stability.

Practical Tips for Selection:

- Choose cranes with a high load capacity and precise control mechanisms to handle the heavy and often irregular loads safely.

- Ensure the crane has heat-resistant features to manage the extreme temperatures involved in furnace charging.

Ladle Handling

- Crane Type: Heavy Duty Double Girder Overhead Cranes

- Typical Capacity: 30 to 100 tons

- Typical Objects Handled: Ladles with molten steel

- Below Hook Devices: Ladle hooks, specialized molten steel handling attachments

Handling ladles filled with molten steel requires heavy-duty cranes capable of withstanding high temperatures and handling substantial weights.

Practical Tips for Selection:

- Prioritize cranes with excellent heat resistance and safety features to handle molten steel securely.

- The crane's design should offer precise control to minimize the risk of spills and accidents during ladle movement.

Continuous Casting

- Crane Type: Semi-Gantry Cranes, Cantilever Cranes

- Typical Capacity: 20 to 50 tons

- Typical Objects Handled: Mold sections, steel billets

- Below Hook Devices: Mold handlers, billet clamps

During continuous casting, cranes manage the movement of mold sections and steel billets. Semi-gantry and cantilever cranes are well-suited for this task due to their ability to navigate complex casting setups.

Practical Tips for Selection:

- Opt for cranes with high precision and automation features to ensure efficient handling of molds and billets.

- Ensure that the crane is compatible with existing casting equipment to maintain a smooth and integrated operation.

With these insights, you can choose the right overhead cranes to optimize your steelmaking processes, ensuring efficiency, safety, and reliability at every stage.

Overhead Crane Applications in Post-Steel Product Production

Hot Rolling Mills

- Crane Type: Double Girder Overhead Cranes

- Typical Capacity: 20 to 80 tons

- Typical Objects Handled: Hot rolled coils, plates

- Below Hook Devices: Coil grabs, plate lifting devices

In hot rolling mills, overhead cranes are essential for handling heavy and fast-moving loads like hot rolled coils and plates. Double girder overhead cranes are ideal for this environment due to their high capacity and stability, which are necessary for managing the intense demands of hot rolling processes.

Practical Tips for Selection:

- Choose cranes with high-speed capabilities and excellent stability to keep up with the rapid movement and heavy loads typical in hot rolling mills.

- Make sure the cranes are equipped to handle the high temperatures of hot coils safely, with features like heat-resistant coatings and insulation.

Cold Rolling Mills

- Crane Type: Single Girder Overhead Cranes

- Typical Capacity: 10 to 50 tons

- Typical Objects Handled: Cold rolled coils, sheets

- Below Hook Devices: Coil lifters, sheet grabs

In cold rolling mills, precision and control are key. Single girder overhead cranes are often used because they offer the fine control needed for handling delicate cold-rolled materials such as coils and sheets.

Practical Tips for Selection:

- Opt for cranes that provide precise control and minimal vibration to avoid damaging sensitive cold-rolled products.

- Ensure the cranes have adjustable lifting mechanisms to accommodate various sheet sizes and ensure versatile handling in the mill.

Steel Storage and Warehousing

- Crane Type: Overhead Bridge Cranes, Storage Cranes

- Typical Capacity: 10 to 30 tons

- Typical Objects Handled: Steel coils, plates, sections

- Below Hook Devices: Magnetic lifts, coil spinners

For steel storage and warehousing, overhead bridge cranes and storage cranes are crucial for organizing and moving steel products efficiently. These cranes help maximize storage space and improve maneuverability within the warehouse.

Practical Tips for Selection:

- Choose cranes designed to maximize space and offer high maneuverability to ensure efficient warehouse operations.

- Ensure the cranes can handle a variety of steel products with ease, incorporating features like magnetic lifts and coil spinners to handle different types of loads.

Steel Fabrication Workshops

- Crane Type: Jib Cranes, Overhead Bridge Cranes

- Typical Capacity: 5 to 20 tons

- Typical Objects Handled: Fabricated steel parts, structural sections

- Below Hook Devices: Custom lifting fixtures, beam tongs

In steel fabrication workshops, the focus is on handling fabricated steel parts and structural sections with flexibility and precision. Jib cranes and overhead bridge cranes are commonly used due to their adaptability and ease of use in a workshop setting.

Practical Tips for Selection:

- Opt for cranes with customizable features to accommodate various fabrication tasks and different part sizes.

- Ensure the cranes offer flexibility and ease of use to handle diverse fabrication activities efficiently, enhancing productivity and reducing downtime.

By choosing the right type of overhead crane for each application, you can ensure smooth and efficient operations across different stages of steel product production and handling.

Typical Overhead Crane Designs for Different Workshops

Scrap Yard Cranes

- Design Features: In scrap yards, cranes must be built to withstand harsh conditions. Look for cranes with high durability, large hook heights, and robust construction. These features are essential for managing the frequent and heavy loads of scrap metal. Large hook heights are crucial for reaching high stacks of scrap and allowing for efficient loading and unloading. The cranes should also be designed to resist wear and tear from the abrasive nature of scrap materials.

- Typical Crane Type: Gantry Cranes, Single Girder Cranes. Gantry cranes are often preferred for their ability to operate on tracks and cover large areas, making them ideal for handling bulky scrap metal. Single girder cranes, while less robust than gantry cranes, are still suitable for lighter scrap handling and offer a cost-effective solution for less demanding applications.

EAF and Ladle Handling Cranes

- Design Features: Cranes used in Electric Arc Furnace (EAF) and ladle handling require heavy-duty construction to manage extremely heavy loads and withstand high temperatures. Heat-resistant components are necessary to handle the intense heat from molten metal. Precision controls are also vital to ensure safe and accurate handling of ladles and molten steel, minimizing the risk of spills and accidents.

- Typical Crane Type: Double Girder Cranes. Double girder cranes are preferred in these applications due to their high load capacity and robust design. They provide the strength and stability needed for lifting and transporting heavy ladles filled with molten steel. The double girder configuration also allows for more precise control and greater lifting heights.

Rolling Mill Cranes

- Design Features: Rolling mill cranes need to operate at high speeds while maintaining stability during load movements. They should be designed to handle the rapid pace of hot rolled coils and plates, which requires both speed and stability. Features such as high-speed operation and advanced stability systems are critical to ensure smooth and efficient processing in rolling mills.

- Typical Crane Type: Double Girder Cranes, Single Girder Cranes. Double girder cranes are often used in high-speed applications due to their greater strength and stability. Single girder cranes, while generally used for lighter loads, can also be suitable for rolling mills if the application is less demanding and cost considerations are a factor.

Warehousing Cranes

- Design Features: In warehousing, cranes are designed for efficiency in space management and load handling. Compact designs are preferred to maximize warehouse space, while high lifting speeds ensure quick movement of products. Efficient load handling capabilities are necessary for managing various types of steel products, including coils, plates, and sections.

- Typical Crane Type: Overhead Bridge Cranes, Storage Cranes. Overhead bridge cranes are commonly used in warehouses for their ability to cover large areas and handle different types of products. Storage cranes are designed specifically for efficient storage and retrieval of items, making them ideal for managing inventory and optimizing warehouse operations.

These designs ensure that cranes are tailored to the specific needs and challenges of each workshop environment, improving efficiency and safety in steelmaking and handling processes.

Tips for Selecting the Right Overhead Crane for Your Workshop

Determine the Specific Needs of Your Procedure

When selecting an overhead crane, the first step is to clearly define what you need. Start by assessing the types of loads and objects your crane will handle. Are you lifting heavy steel beams, delicate coils, or scrap metal? Each load type might require different features. Next, evaluate the required lifting capacity and crane reach. For instance, if you need to lift heavy loads high up or across long distances, ensure your crane can meet these demands. Knowing these specifics helps narrow down your options to those best suited for your workshop.

Consider Crane Type and Design

Choosing the right crane type is crucial. Single girder cranes are often cost-effective and suitable for lighter loads, while double girder cranes offer greater strength and are ideal for heavy-duty applications. Gantry cranes can cover large areas and are great for outdoor use or areas where overhead structures aren't feasible. Match the crane type to your specific application and the layout of your workshop. Ensure that the crane design aligns with your operational requirements and fits within your spatial constraints to avoid issues down the line.

Focus on Load Capacity and Hook Devices

It's essential to pick a crane with adequate capacity for your heaviest loads. A crane that's too small can be a safety hazard and lead to operational inefficiencies. Also, ensure that the crane's hook devices, like grabs, slings, or magnets, are tailored to the types of objects you handle. For example, magnetic grabs are ideal for scrap metal, while coil lifters are better suited for handling rolled steel. Matching these devices to your handling needs ensures smoother operations and minimizes the risk of damage to both the crane and your materials.

Under Hook Lifting Devices

For the various material handling in the metal processing plants,there are types of below-the-hook devices are adopted to ensure the handling safety and efficiency. We offer tailored industrial hoists, cranes and lifting devices for your unique applications to ensure your material handling safety and efficiency in the steel mills and metal processing plants.

Evaluate Safety and Maintenance Features

Safety should always be a top priority. Look for cranes equipped with features like overload protection and emergency stop mechanisms to prevent accidents and damage. Additionally, consider how easy it is to maintain the crane. Regular maintenance is key to extending the life of your equipment and ensuring reliable performance. Choose cranes that offer easy access for routine checks and repairs, reducing downtime and maintenance costs. This proactive approach can save you time and money in the long run and keep your operations running smoothly.

In the field of steelmaking and post-production, overhead cranes play a pivotal role in ensuring efficiency and safety across various stages. Throughout steelmaking, from scrap yard handling to ladle management and continuous casting, different crane types and capacities are employed to meet specific needs. Gantry cranes and single girder cranes are effective in handling scrap, while double girder cranes excel in the demanding environment of EAF and ladle handling. For rolling mills and warehousing, cranes must balance speed, stability, and space efficiency. Understanding the right crane type, capacity, and design features is crucial for optimizing performance and maintaining safety standards.

The overhead crane industry is set to embrace several exciting advancements. Emerging technologies such as IoT integration and advanced automation are revolutionizing crane operations, offering real-time data and predictive maintenance capabilities. Innovations in materials and design are enhancing crane durability and efficiency, while advancements in safety features continue to push the boundaries of what's possible. These trends promise to further streamline operations, improve safety, and increase the overall efficiency of steelmaking and handling processes. Staying updated with these innovations will help ensure that your equipment remains at the forefront of industry standards.

One-stop Industrial Crane Services for Metal Processing

Overhead lifting cranes are one of the necessary equipment for metal processing industry including iron & steel, aluminum, and other basic metals. As a professional and experienced industrial crane manufacturer and supplier, we can offer you turnkey project services for the entire material handling crane solution in your industrial applications.

With expertise in the the design and manufacture of industrial cranes , we have installed various overhead travelling cranes solutions for steel smelting area and foundries, rolling mills all over the world with high-capacity & high-performance to meet maximum safety and productivity. Our various types of industrial process cranes are designed and manufactured with wide crane designs and diverse below-the-hook devices to optimize the material handling flow from handling scrap, ladle, to metal products handling , storage, delivery and equipment maintenance, etc.