MAGNETIC OVERHEAD CRANE & MAGNETIC GANTRY CRANE

Steel Plates, Beams,Profile, Pipe,Coil,Wire & Scrap

Reduce Costs and Increase Safety with Magnet Crane

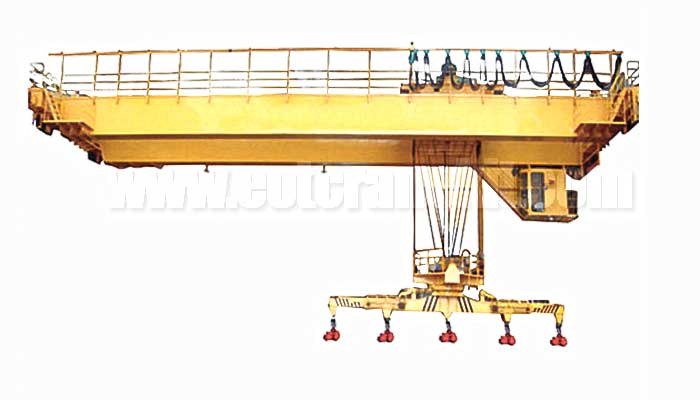

What is overhead magnetic crane? MAGNET CRANE referred to as electromagnetic cranes, these overhead cranes and gantry cranes are used to handle and move metals like steel and iron. Magnet material handling cranes can be found mostly in recycling plants, scrap yards, junkyards steel service center, or any other places or workpaces for steel and iron handling, etc.

How magnetic crane works? They work by creating a magnetic field with an electric current that flows through windings around the magnet. The electric current turns on and off the magnet as needed. The electrical current flows through an electromagnet, which is made up of an iron core with a wire wrapped around it. These magnetic overhead cranes have a straightforward task: they transport metals from one location to another. The magnet attracts metals, moves them to their proper location, and then the magnet is cut off, releasing the metals. Because of the constant current that runs through these magnet cranes, as well as the fact that it is frequently turned on and off and subjected to hard usage, a dependable power and automation cable is required.

Benefits of magnet cranes

- Ensure a safer lifting operation by providing a safe distance between crane operator and the overhead crane and gantry crane.

- Allow remote crane operation, from a safe distance with full range of vision for the overhead crane operator (subject to control system applied)

- Increases reliability and reduces wear and tear in service compared to slings and chains.

- Increases productivity and reduces labor as no slings are required.

- Multiple "fan off" sheets that allow sheet-to-sheet stacking without stacking.

- Ensure the load is safe and secure with an optional battery backup security system.

- Development of flexible and adaptable solutions for a variety of loads.

- Integration of a lifting beam of any capacity or length or with optional telescopic function.

- Add fixed hooks on the lifting beams to allow for regular upgrades from the lifting beam.

Types of magnetic cranes based on lifting crane structures

Magnetic overhead crane for a rectangular working area

A rectangle overhead bridge crane is a type of industrial crane used to transport metal and steel loads vertically and horizontally inside a rectangular space. It is made up of one or two horizontal girders or beams that are supported on the crane runway or runway columns.Rectangular overhead bridge cranes are especially effective for transporting massive objects over a specific area or along a production line. The rectangular magnetic bridge crane design allows it to cover a broader operating area than other types of cranes. They are usually equipped with magnetic chuck and beam spreader for handling metals objects or steel productions of various types, sizes or weights,etc.

Magnetic goliath gantry cranes

Magnetic gantry cranes is just like that of the rectangular overhead bridge cranes, which offering a rectangular covering area for heavy and large loads handling,but, instead of mounted on the top runway or columns, goliath gantry crane is designed with free standing supporting legs, which running on the ground beams or tracks. The magnetic gantry cranes can be designed with freestanding full goliath gantry cranes & Semi gantry cranes for indoor and outdoor applications and uses. The electromagnetic goliath gantry cranes are usullay used for outdoor applications for all types of steel objects handling of various sizes and weights, etc.

Magnetic Jib Crane with 360 degree rotary crane design covering a circular working area

A circular overhead crane typically referred to the rotary jib crane which is installed on floor mounted column or H structure, providing a full 360-degree range of motion, allowing the operator to put heavy loads effortlessly wherever in the circular working area in your workshops or workstations. The rotary jib crane can be equipped with magnets or vacuum lifter for loads handling with capacity from 500kg to 16 ton. There are various types of rotary jib cranes are available based on different jib crane designs, configuration, and lifting application and requirements.

Types of magnetic cranes based on the lifting magnet designs

- Electromagnetic Crane - The most popular kind of magnetic overhead crane is this one. It makes use of an electromagnet that is connected to the crane's hoist and, when activated, produces a powerful magnetic field. The magnetic field has sufficient strength to lift and move large objects. The bridge crane operator may simply regulate the raising and releasing of the weight because the magnetism can be turned on and off using a simple switch.

- Electro-Permanent Magnetic Crane - The electro permanent magnetic overhead crane employs a hybrid of electromagnetic and permanent magnet technologies. When the electromagnets are turned on, a strong magnetic field is created that attracts ferrous elements. Once the materials have been lifted, the permanent magnets take over and secure the load. This sort of industrial overhead crane is frequently used in hazardous areas where power outages could be fatal.

- Permanent Magnetic Cranes - The permanent magnetic cranes are lifting crane equipment, equipped with permanent magent for metal or steel objects handling. The permanent lifting magnet has two magnetic sources, one in the main body and one in the rotor. The lifting magnet projects magnetic flux to a ferromagnetic load underneath its poles when the two magnetic sources are pointing in the same magnetic direction. In contrast, when the two magnetic sources are pointing in the opposite magnetic direction, they absorb each other's energy and the lifting magnet is unable to release any magnetic flux. The load, meanwhile, is not attracted to the lifting magnet. You can adjust the magnetic direction of the magnetic source in the rotor and subsequently attract and release the load by moving the lifting magnet's handle.

- Battery-Powered Magnetic Crane - A battery powered magnetic crane is a hoisting device that uses rechargeable batteries magnetic to operate. Its goal is to provide a safe and effective method of transporting products in locations where energy is not always available. One of the primary benefits of battery-powered magnetic cranes is their adaptability. It can be used in practically any situation because it does not require an external power source. Furthermore, they are significantly quieter than traditional cranes, making them perfect for use in noisy environments. In terms of upkeep, battery-powered cranes require less than their electric-powered equivalents. This is because they have fewer moving components and do not require lubrication on a regular basis. They also offer a longer service life and a reduced total cost of ownership.

Types of magnetic cranes based on lifting loads

An electromagnetic crane is a term used to describe an overhead crane, equipped with lifting electromagnet or magnetic beam spreader for metal objects handling.What is an electromagnetic overhead crane used for?

- Because magnetic cranes are extremely powerful and versatile, and the custom engineered magnetic overhead crane and magnetic gantry crane can be used for a variety of industries such as metal fabrication, shipbuilding, steel mill, automotive, medical industry, mechanical engineering, transport company, material store, foundries, coil and pipe distributors, junkyards, shipyards, loading docks, warehouses, and other users of applicable steel products frequently utilize lifting electromagnets for cranes.

- The magnet cranes can be used in various handling situations, providing increased safety and efficiency when handling:Plates,Beams,Laser/Plasma/Flame cut profiles,Scrap materials,Rebar,Bar stock,Coiled strip product,Castings,Forgings,etc.

- The electromagnet on a lifting crane equipment can readily collect and carry tens of tons of heavy iron, iron wire, nails, steel scrap, and other types of steel items that cannot be packed or boxed.

Magnetic overhead cranes are used in many different industries, including the following sectors :

- Steel Industry - Magnetic overhead cranes are used by steel mills to quickly and effectively move heavy, big and large steel plates or coils from one location to another. Magnetic overhead cranes are ideal for the steel sector for a number of reasons, including the fact that the magnetic force enables the bridge crane to lift and move steel safely without harming it. In steel factories, circular EOT cranes are frequently employed.

- Recycling Industry - The industrial overhead cranes can be used in these sites to collect and move scrap metal, including old automobiles, appliances, and machinery. Large amounts of metal may be collected and transported quickly and efficiently thanks to the crane's magnets. In recycling facilities and scrapyards, rectangular bridge cranes are frequently employed.

- Port Terminals - In port terminals, magnetic bridge cranes can be used to load and unload cargo from ships. The crane's magnetic technology offers a strong lifting force that makes it simple to lift and move heavy objects like containers and bulk goods. Magnetic overhead bridge cranes are frequently mounted on tracks in port terminals, allowing them to travel along the length of the dock and access various parts of the ship. Using a remote control or a cabin on the industrial overhead crane, the crane operator may manage the crane's movement as required.

A wide range of magnet cranes, customized to suit client application, with a range of magnets to lift flats, radius sections, beam sections or hollow materials. Feel free to contact us by leave a message below or by WhatsApp: + 86 151 3871 1597.

Magnetic gantry crane for outdoor scrap lifting - outdoor gantry cranes

Magnetic overhead crane for steel wire handling

Magnetic beam overhead eot crane for steel plate handling

Magnetic overhead travelling crane for steel billet handling

Double girder overhead crane for steel squre pipe handling

Round magnetic overhead crane for steel ball handling

Underwater magnetic for steel scrap handling

Double girder bridge crane for steel coil handling

Magnetic overhead crane for hot temperature round steel handling

These large magnetic cranes are used to lift up and transport metals such as metallic and iron, that's in most cases found in recycling yards , waste distribution plants and junk yards. The electromagnetic cranes works by the usage of a magnetic field this is created by an electric current that can be turned on and off on every occasion when necessary. EOTCRANEKIT also designs and manufactures Telescopic Magnet Lifting Beams, offering adjustable carry centers for longer beams, plates or sections.

MAGNETIC OVERHEAD CRANE & MAGNETIC GANTRY CRANE

Customized magnetic lifter and magnetic cranes design for you

Custom magnetic overhead cranes, gantry cranes & jib cranes

The electromagnetic chuck is a type of electromagnets that uses the object to be attracted as its armature. It is a device that absorbs magnetically conductive substances by using the physical quantities of electricity and magnetism, and it is an indispensable lifting tool in metallurgy, mining, machinery, and other industries. The magnetic overhead crane and gantry crane will be outfitted with different magnets depending on the application and load handling.

The sealed coil of EOTCRANEKIT magnets is enclosed in cast iron to provide endurance and reliability in the harsh outdoor situations and temperature extremes that many of our clients confronted.

Round type lifting magnet

Oval lifting electromagnet

Rectangular lifting electromagnet

Magnetic beam speader

On selecting the right magnetic crane, the following factors are important for your selection:

Selection notes on crane magnet:

- When the temperature of the load to be sucked and transported is lower than 150 °C, the normal temperature type crane magnet is selected; if the temperature exceeds 150 °C to 600 °C, the high temperature type crane magnet is selected; if the temperature exceeds 600 °C, the ultra-high temperature type magnet is selected.

- For longer beams, plates or sections, the telescopic Magnet Lifting Beams with adjustable lift centers are usually adopted. For steel scrape, and small steel loads handling, the magnet chuck are a good option.

- When the power-on duration exceeds 60%, use the high-frequency type.

- When sucking and hoisting loads in water, use the submersible type crane magnets.

- Ambient temperature: normal temperature type -25℃-40℃, high temperature type above 40℃. The altitude does not exceed 4000m.

- Generally, it is necessary to ask the customer if he wants to maintain the magnetism in a power outage, and the magnetization time is 10~30min.

Parameter needed for lifting magnetic quotation

- The specific size of the material to be sucked (length, width, height or diameter and thickness)

- Number of loads to be lifted at one time (number of roots, number of sheets, number of bundles)

- Material temperature (conducting coil aluminum wire are for general use or copper wire are available on requested)

- Power failure retention time (default 10 minutes, the longer the time, the higher the price).

Depending on the weight of the load and the thickness of the material, EOTCRANEKIT magnets can be used to pick up a single item or multiple items. Magnets can also be used to rotate products from a horizontal to a vertical axis, allowing for easier stacking and loading without the need for chains.

EOTCRANEKIT's custom configuration service allows our customers to tailor their magnet lifting beam to their individual needs. The remote control's ergonomic design provides for comfortable and precise operation of the magnet system, as well as the ability to fan through the steel by manually increasing the magnet's intensity.

How to select right magnet for your material handling overhead crane?

Factors to consider when selecting a magnetic overhead cranes

- Weight capacity: The lifting capacity of the magnetic cranes should includes the self-weight of magnets and magnetic beam spreader and the maximum weight of the objects required to be handling . And also, the crane capacity should be be designed based on your needs of today and tomorrow. Learn more to check how to calculate the weight of overhead cranes or contact us by WhatsApp: + 86 151 3871 1597.

- Type of load: Take into account the kind of load that will be lifted because it will affect main specification and configuration design of overhead cranes, and also the selection of magnet required. For instance, if you're dealing scrap metal, a circular electromagnet crane are suggested, and also you can select the workshop overhead cranes for indoor use and freestanding gantry cranes for outdoor uses based your specific lifting requirements and application condition accordingly.

- Span and lift height: The crane's Span and Lift Height should also be considered. The span is the distance between the runway beams, and the lift height is the maximum height that the crane can hoist the load. Make sure the magnetic crane you choose has the height and span capabilities needed for your application.

- Power supply: Decide whether compressed air or electricity will be used to power the crane. Air-powered cranes are more suited for hazardous settings, but electric cranes are often more prevalent and simpler to maintain. As for electric overhead cranes, the specific power supply should be confirmed, such as, 380V50HZ3PH, or others, etc.

- Maintenance requirements: Take into account the crane's ease of maintenance as well as any ongoing costs for things like inspections and repairs.

- Crane safety: Make sure the crane has the necessary safety measures, such as overload protection, emergency stop buttons, and warning systems.

For different loads , the lifting required information is different. The main information required for electro permanent magnetic and magnetic overhead cranes and gantry cranes quote are presented in the following table. As for specific magnet price and electro-permanent magnetic crane price, please feel free to contact us. WhatsApp : + 86 151 3871 1597.

Parameter Needed to Quote Magnetic Bridge Crane

- Crane specifications:Crane capacity:___ Ton, Crane span ___ m, Crane lifting height ___ m, Runway length___ m

- Operating environment:Temperature: ___ ℃ Humidity : ___ %, Operating Place___ : A. Indoor B. Outdoor

- Control method:Crane control : ___ A. Panel control, B. PLC Control C. Remote Control D. Wire control, E. Cab Control

- Input voltage:Crane voltage:___ 380V50HZ3PH or others ___V__HZ __PH?

- Material detail:Steel material type:___ ,Steel temperature ℃:___,Material Size: ___,Lifting Material Weight ___ kg, Stacking/bundle height___ mm,

Parameter Needed to Quote Magnetic Lifter

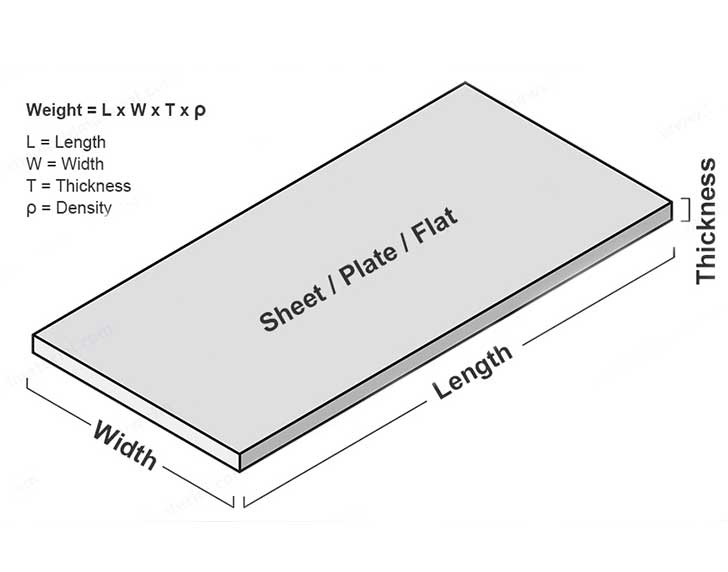

Steel Plate /Steel Slab

Rectangle shape:

- Length___ mm , Width___ mm , Thickness___ mm,

- Each time Lifting___ piece,

- A . Horizontal lifting B. Side lifting

Abnormal shape:

- Length___ mm, Width___ mm , Thickness___ mm,

- Shape size ( suggest provide drawing )

- Each time lifting___ pieces,

- A. Horizontal lifting B. Side lifting

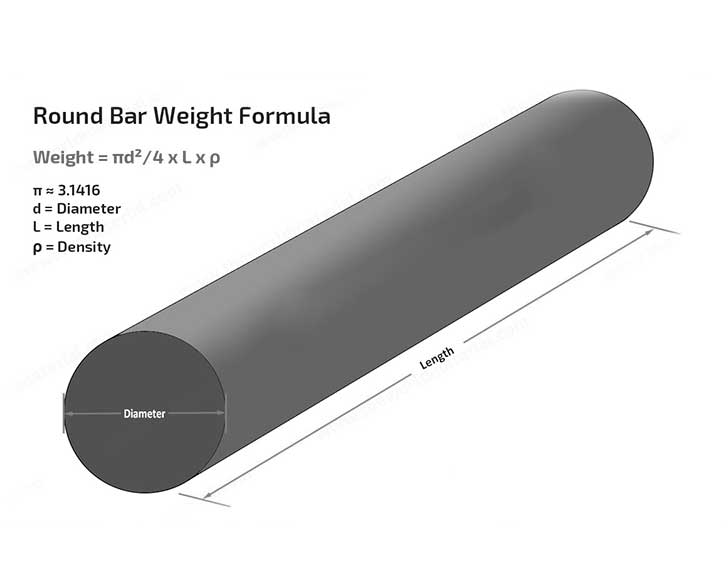

Steel Pipe /Steel Bar

Single piece

- Length___ mm, Diameter φ___ mm, Wall thickness___ mm

- Each time Lifting___ piece

- A. Horizontal lifting B. Side lifting

A bundle

- Single piece length___ mm, Bundle length___ mm, Bundle diameter φ___ mm,

- Bundle gap ___ mm,

- Each time Lifting ___ bundles

- Tie material , Width ___ mm , Thickness___ mm .

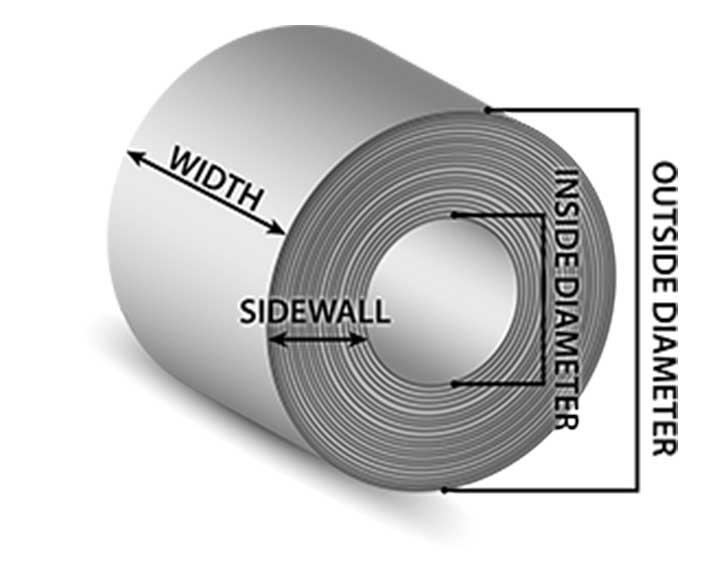

Steel Roll coil

- Types of steel roll : A Steel Coill, B Steel Wire Rob Coil ,

- Steel roll size; ID φ___ mm, OD φ___ mm, Width___ mm, Thickness___ mm

- Tightness : A. Loose Roll, B. Tight Roll,

- Steel roll position: ___A: Horizontal placed coil, B: Vertical placed coil

- Each time Lifting___ bundles

- Tie material , Width___ mm, Thickness___ mm .

Reduce Costs and Increase Safety with Magnet Crane

Magnetic Overhead Cranes & Magnetic Gantry Cranes Safety

Magnetic Crane Safety Instructions, Operation & Maintenance

It is important to learn the basic lifting magnet safety instructions (guidelines and factors) before using, and it is vital to always bear in mind the operation rules to enusre magetnic crane operation safety. Check the tips on lifting magentc safety instruction and operation from magnetic overhead crane manufacturer. If you want to know more, please feel free to contact us by leave a message below or WhatsApp: + 86 151 38 71 1597.

Lifting Magnetic Overhead Crane Safety Guidelines

- The lifting magnet and the load's surface must both be clean.

- No hooking of two lifting magnets without the use of a properly built spreader beam.

- The operator ought to keep the burden from being carried over people.

- The load must be evenly distributed in order to function properly.

- No person shall be permitted to stand on a hoisted workpiece.

- Avoid putting the magnet in shear.

- Prevent the load or magnet from making touch with any obstacles.

- Avoid lifting that is unevenly distributed.

Lifting Magnet Safety Factors

Unless otherwise stated, labeled lifting magnet capacities represent ultimate lift force - the lifting capability of the magnet on varied loads UNDER IDEAL CONDITIONS.

It would be difficult to anticipate all possible operating situations from one installation to the next and rate the magnet for each and every one of them. Instead, the magnet operator must do so by applying a safety factor to the magnet's ultimate lift strength, making sure that the safety factor used is as accurate as possible. The following are some of the operating conditions that influence the relevant safety factor:

Load surface conditions, Magnet surface conditions, Load flatness and rigidity, Load centering on the magnet, workiong environment and application conditions, Voltage variations (in the case of electromagnets), When any of these parameters is less than perfect, the operator must account for the associated negative consequences on the ultimate lift strength of the magnets.

During the operation of magnet crane, the operator is solely responsible for safety. Accidents can happen at any time when a heavy work load is being lifted, hung, and moved by lift magnets, especially when not following stringent operation guidelines or operating devices that have not been tested before use.

Lifting magnet safety operation rules

Any dropping of a large workload might cause property damage, bodily harm, or even death. When using a lifting magnet, the following safety operation guidelines must be remembered and followed.

- Never allow anyone who is not authorized to use the lifting magnets.

- Never use the lifting magnet without first checking it.

- Always remember that any lifting must have a 3:1 safety factor.

- Stay away from the work load at all times.

- Before lifting a work load, notify all staff on the job site.

- There is no vibration or impact on the lifting magnet during transit.

- Never move the lifting magnet and load over or near people.

- Personnel should not approach, stand, or pass under the magnet.

- Always maintain vigilance until the load has been landed.

- Never use the lifting magnet in temperatures above 80°C.

- Make the load surface clean. Remove any dust, burrs, superfluous paints, and chips.

- During lifting, the load must remain level.

- To lift a large plate, suspend two or more lifting magnets on a spreader bar.

- Always lift, move, and lay down the lifting magnet and load gently and evenly, with no rapid acceleration or deceleration.

Lifting magnet overhead crane safety is and should always be the operator's and magnetic lifter manufacturer's top focus.Magnetic crane systems, including tailored crane design, magnetic lifters on spreader bars or beams, are an excellent choice for high lifting and safe holding capacity. Customized overhead magnetic crane solutions are offered to make it simple to handle heavy ferromagnetic workpieces up to 40 tons safely and without deformations.

Safe operation procedures

A magnetic crane is a more frequently for safe and efficient metal or steel objects or loads with the features of easy and convenient operations, which are widely used in various industrial sectors and operations.

Material handling is a risky operation that requires functioning in a complex environment with challenging technology.

- We must prepare and train people in accordance with the features of construction programs.

- To prevent the entry of extraneous personnel, we should set up an alert location and a prominent warning sign; hazardous areas should be set up for supervision staff.

- Material handling must be done by professionals and technicians, and workers must get particular operating qualification certifications before they can work.

- Workers should select a safe working environment. People are not permitted to stand or pass through hazardous areas.

- Material handling requires a designated leader, and everyone else in the team must follow their instructions. Lifting orders cannot be used for other jobs. You should make sure the lifting driver hears the command signal clearly and accurately.

- Lifted objects must be tied according to the exact same rules as those used by cranes to link the right objects.

- The location where the components will be stored must be solid and flat. The members must be stable, piled, and leveled using square wooden pads. Their height should not exceed 1.6 meters. In order to strengthen their stability, the components should also be set up with the appropriate supports in addition to the bedding. To prevent objects falling and crushing humans, it is banned to let outsiders pass through the stacked features.

Inspection & maintenance for magnetic lifting crane safety

It is important to adhere to the manufacturer's recommendations for routinely maintaining and inspecting magnetic equipment. Schedules for inspection and maintenance should, when necessary, include:

- Power wires to the magnet should be examined for damage and supported properly.

- Check the suspension points on the magnet assembly for damage, and make sure the retention nuts are kept tight.

- Check the magnet face for any damage that could impair performance.

- Check the coil resistance value and the insulation resistance of the magnet to make sure that "inter-turn" defects have not formed while it is in use.

- Check the mechanical strength, insulation, and electrical conductivity of electrical plug and socket connectors.

- Lifting accessories, such as chains, links, and other items connected to the magnet, should be thoroughly inspected at regular intervals.

- Make sure the backup batteries are in good shape and that the battery-powered alarm functions when the power is out.

- Check for damage, the legibility of the control labels, and the proper operation of the controls, including any audible and visible warning systems, on control boxes and pendants.

- Magnetic adhesion is periodically checked by sandwiching a non-metallic "test piece" between the magnet and the substance. With the test piece placed, it ought to still be possible to pick up the load.

Reduce Costs and Increase Safety with Magnet Crane

Videos of Magnetic Overhead Cranes & Magnetic Gantry Cranes for

Handling Steel Plates, Beams,Profile, Pipe,Coil,Wire & Scrap

Scrap handling overhead crane with oral magnetic crane

Magnetic Gantry Crane with Magnetic Beam Spreader for Steel Plate Hoisting- Steel Plate Crane. If you want to check more video , please check our magnetic overhed crane list

Reduce Costs and Increase Safety with Magnet Crane