Gantry Crane Uses: Types of Gantry Cranes Used in Industries

What are gantry crane uses? Gantry cranes, i.e, full gantry & semi gantry, portable gantry crane used in industries to improve safety & efficiency.

Category: Overhead Crane for Your Use

What are gantry cranes used for?

A gantry crane is a material handling crane that is mounted on a gantry structure or similar support frame, with the entire structure designed to straddle above a space carrying the load or object that needs to be moved. The gantry crane is one of the most common types of cranes , which can be grouped into single girder gantry crane & double girder gantry cranes and are widely used in the industrial sectors for a variety of material handling tasks. In addition, the size of gantry cranes can be scaled to almost any application, and the goliath crane's hoist can perform a variety of material handling tasks. We are experts in designing the best gantry hoist equipment so that your gantry crane can perform a variety of hoisting operations.

Moving loads

The largest gantry cranes now in use are those for transferring heavy loads, such as loading and unloading containers from boats on decks and in harbors. There are also some large gantry cranes or goliath crane capable of moving loads up to thousands of tons that are employed in the construction of vessels, cruise ships, and oil rigs. In fact, the world's largest cranes are gantry cranes, which have a simple yet effective crane design.

Weighing loads

With a modest modification to the gantry crane, it can be utilized to precisely weigh huge cargoes. You don't need an industrial scale or a loaded lorry to figure out how many tons of material or load you're hauling or moving. Your gantry crane will be able to weigh while moving material inside your production plant thanks to a high-precision scale for large loads. Efficiency is being pushed to its limits.

Rotating loads

It's a crucial operation to turn big loads without harming them or causing damage to commodities, persons, or infrastructure. It doesn't matter if it's a concrete structure, a boat's keel, or any other intermediate product that needs to be turned in order to perform other processes. A few tons of cargo falling to the floor due to a faulty load turning device will result in a significant financial and material loss, as well as possible damage to goods and infrastructure. We can customize your gantry crane to rotate any type of object, regardless of size, volume, or weight, with the right hoist and mechanism.

Where are the gantry cranes used ?

A gantry crane is a type of overhead crane that is supported by freestanding legs that travel on wheels or along a track or rail system. When there is no way to incorporate an overhead runway system, gantry cranes are frequently adopted.

They are usually utilized for outdoor applications or to supplement an existing overhead bridge crane system. A gantry crane, unlike a bridge crane, does not require permanent runway beams and support columns because it is not attached to the building's support structure. When compared to a similar specified bridge crane, this can result in considerable material cost savings and be a more cost-effective alternative.

Larger gantry systems may run on an embedded rail or track, usually in a straight line in a specialized work area. Smaller portable gantry systems can be moved about a facility on castors or wheels for maintenance or light fabrication operations.

What are gantry cranes ?

What are the main types of gantry cranes and their uses?

Gantry Cranes with a full gantry or semi-gantry design are widely employed in large fabrication applications or in outdoor yards such as rail yards, shipping and container yards, steel yards, and scrap yards.

They're also used in cement and precast applications for places where slab concrete is formed and dried. Their design enables them to be utilized outside while also allowing forklift trucks and other motorized traffic to work and pass beneath them.

Portable gantry cranes are typically used to lift and hold load or object in place while they are being worked on, produced, or assembled. Although the load isn't necessarily transported across the facility, the small gantry cranes can be relocated to operate on different parts or equipment.

In comparison to a jib crane or workstation crane, portable gantry systems can provide more flexibility. A jib crane is usually erected on a poured concrete base, and once it's in installed , it's ususlly for permanent . A small portable gantry crane can do the same job as a slewing jib crane, but it can be moved about your warehouse as your factory and business grows and you start optimizing and laying out the space of your warehouse or workstations. More on safe uses of gantry cranes

Gantry cranes for indoor shops

There are a full range of cranes for indoor material handling working environments such as shops, workstations, workshops, storage, warehouses, and facilties and buildings. Perhaps you're looking for a suspension crane, overhead crane, EOT crane, jib crane, light or heavy crane system, or even electric or chain hoists. And here we are. We have all types of the overhead material handling cranes you require. We actually provide more overhead material handling solutions rather than just products. For example, you can be concerned about the size of the structure or a specific spreader. We are confident in our ability to handle your material handling tasks with the best overhead material handling solutions and right gantry crane hoisting equipment.

Full gantry cranes can be designed with single girder & double girder gantry design

Semi-gantry crane and single leg ganry crane with single beam & double beam gantry crane design

Steel portable gantry cranes with various design such as, fixed height gantry, height and span adjustable gantry crane

Aluminium gantry cranes with various height height design, height and span adjustable alum gantry

Garage gantry crane & Garage overhead crane

Design and process of garage cranes and shop cranes: 0.25 ton to 10 ton garage gantry cranes, garage overhead cranes with tailored design, 500kg to 2 ton garage jib crane. Get your garage gantry crane design right away!

In warehouses, there will be a requirement for handling heavy loads and objects all the time. This lifting process will be helped by warehouse gantry cranes. These warehouse cranes can be used in almost any type of warehouse.

Gantry cranes for outdoor use

Gantry cranes are suitable for a wide range of outdoor tasks. Outdoor gantry cranes are commonly employed at highway construction sites, railway construction construction sites, subway/metro construction sites, tunnel construction sites, shipbuilding yards, and even stone handling plants, and other places and working sites.

What will the gantry crane be used for? Metal scrap, stone, workpieces, tools, machines, precast beam, bridge, tank, sections, ship body, hull, tunnel machine, shield, slag, and other objects or items can all be handled by a gantry crane.

Shipbuilding gantry cranes are a type of gantry crane that is primarily utilized for the construction of berth assembled hulls. This gantry crane for shipbuilding has several functions, including up and down, lifting, and piecewise air turn. The hull turning and shutting procedure, for example, are two notable advantages. Shipyard gantry cranes, with their massive hoisting capacity and great efficiency, are dedicated to partial transport of large ships, butt joining, and overturning on dock or shipway.

Gantry crane used in construction

For construction industry, various tyeps of gantry cranes are widely to improve safety and construction efficienty. Construction gantry cranes can be utilized to lift the heavy materials which are frequently found in these locations

Subway Crane, Tunnel Gantry Crane & Metro Use Gantry Crane

Subway cranes, tunnel gantry cranes, and metro cranes are all examples of gantry cranes used in the construction industry. Gantry cranes with capacities of 20 ton, 30 ton, 40 ton, and 50 ton are used for subway, underground, and metro material handling.

Contact us to get your customized gantry crane used in industry of construction.

Self Lifting Gantry Cranes- Road& Bridge Constructions

MQ series gantry cranes are classified as unidirectional or bidirectional based on their structure and function. It installed a fixed lifting mechanism in the rigid gantry frame for the unidirectional gantry hoist. Because the gantry crane travels along the dam orbit and its service unit is a line, it can only lift a list of the gate. A bidirectional goliath gantry hoist installs trolley track perpendicular to the hoist's travel in the gantry frame. The trolley equipped with a lifting mechanism can travel along the track. As a result, a bidirectional gantry hoist can lift multi-column gate or trash rack lists between upstream and downstream.

Move Girder Cranes

Move girder cranes are specially designed for railway passenger dedicated line construction and used to produce a beam, carry beam, and launch beam; it can use two sets of 500t(450t) to lift beam and one set of 1000t(900t) to set up two lifting points for lifting beam in the railway passenger dedicated line construction.

To finish handling all beams in the preset field, move girder gantry cranes utilize tire line technology and can implement a variety of walk line models, including straight, oblique, and crosswise. Its benefits include great adaptability, high efficiency, a small occupied space, and the elimination of the requirement to lay rail. This type of goliath crane is used to lift, handle, and load the beam by most preset field in the construction of the high-speed railway in China.

Beam Lifting Gantry Cranes

Beam lifting goliath cranes are used to lift, handle, and load beams in the predefined field when the high-speed railway weight is less than 1000t. It can travel along the laid rail and its running mechanism can rotate 90 degrees to allow for straight travel as well as transverse travel to handle all beams in the preset field.

Bridge Erection Cranes

Bridge erection cranes are used to hoist concrete beams or bridges onto highway construction supports.

Straight line, curve line (R greater than 2000m), longitudinal slope less than or equal to twenty thousand of 20m, 24m, 32m, composite beam, and continuous steel structure may all be erected with this type of bridge beam erection crane.

The Erect Bridge Crane is mostly used on highways and railways. Bridge Beam Erection Cranes typically is used for hoisting and lifting concrete girders in general railway, highway , bridge construction and bridge building.

Gantry Crane for Shield Tunneling Machines

Shield gantry cranes are used in the construction process to lift the cutter and shield body of an underground excavation shield tunneling machine as well as the tunnel support segment. With its flexible operation, perfect safety instructions, and overload protection device system, the trolley of this gantry crane is a rotating disc that adapts to the demand of different digging directions.

Shield gantry cranes have the benefit of stable performance, high production efficiency, and multi-functions, which also can be used for maintenance. The upper slewing sling design are used to meet the needs of different digging directions. The gantry cranes are designed with flexible operation mode, with improved safety instructions and overload protection device, to ensure maximum safety of operating personnel and equipment.

Port and terminal container yards

Container handling is another important function of gantry cranes. Without a doubt, global trade is becoming increasingly important in people's daily lives. There are numerous ports and terminals that handle containers at all hours of the day and night. This is why container gantry cranes are required. There are various types of container gantry cranes. The most common are RMG, RTG, STS, portal cranes, and so on. A rail-mounted gantry crane, or RMG crane, for example, is used to handle large amounts of containers at port and container yards. Our container gantry crane is now intelligent enough to handle containers using fully automatic operation and rotatable spreaders.

Container gantry cranes are commonly used in container terminals and are classified as rail mounted gantry cranes or rubber tyred gantry cranes. Trailers unload containers from ships and transport them to the container yard or storage yard, where they are stocked by container gantry cranes or loaded directly, which speeds up the turnover of container gantry cranes or other material handling cranes.

Gantry crane for hydropower stations

The gantry crane at the hydro-power station is primarily utilized to lift, open, and close sluice gates, as well as perform installation work. Despite the fact that the gantry crane is not a typical overhead gantry crane, the material handling task it performs is extremely heavy, so it is critical to improve the work-level effectively.

Door Type Electric Gate Hoists

Electric gate hoist gantry cranes are primarily used for hydraulic equipment transport, installation, and maintenance of hydroelectric generating units such as floodgates, trash racks, and so on.

Electric gate hoist gantry cranes are also used in large-scale water supply and drainage, water conservation, and hydropower engineering. It is used to control the lift and fall of any large or medium-sized cast iron gate, steel gate, or trash rack in order to open and close it.

Gantry cranes for cement,concrete & precast yard

Industrial gantry cranes in cement, concrete & precast yard are frequently used for in & outdoor bulky & heavy material handling, i.e, precast concrete beam, plate,pole,etc.

Gantry crane used in industry of marble, granite & stone

The marble, granite and stone gantry cranes are used for marble, granite & stone lifting in quarry, pit & stone processing warehouse. Types of gantry crane & overhead cranes are avaiable for efficient blocks extraction to slabs delivery.

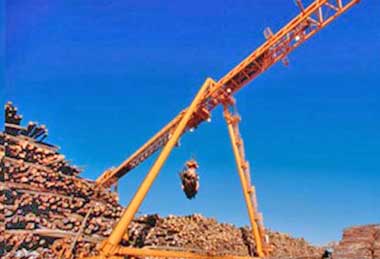

Woodyard gantry crane & log crane used in industry of forestry

For log and wood timber handling in wood yards and wood processing mills, a gantry crane with a customized process crane design is used. Gantry cranes for wood yard and log handling are available for purchase.

Grab bucket gantry crane for mining industry

Mining gantry cranes have a wide range of applications in power plants, ore, limestone, coke, coal, sand, slag, loose clay, and other granular material warehouses.

Mining gantry cranes can be used for material handling in mining and mineral processing, as well as material supply, to increase productivity and ensure safety in harsh environments with potentially hazardous gas, steam, and air.

Gantry crane with grab for waste handling & scrap handling

The waste handling gantry crane can meet lifting requirements in a variety of situations thanks to manual, semi-automatic, and fully automatic operation control options. With full automatic control, the waste is primarily used for nighttime operation and waste handling without deliveries on Sundays and holidays.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch